Flexco Y-Type User manual

Y-Type™Heavy-Duty

Secondary Belt Cleaner

Installation, Operation

and Maintenance Manual

www.flexco.com

Y-Type™with Purple

Polyurethane Blade

Y-Type™with White (Food

Grade) Polyurethane Blade

Y-Type™with Tungsten

Carbide Blade

2Y-Type™Standard-Duty Secondary Belt Cleaner

Y-Type™Secondary Belt Cleaner

Serial Number: _____________________________________________________________

Purchase Date:______________________________________________________________

Purchased From: ____________________________________________________________

Installation Date: ____________________________________________________________

Serial number information can be found on the Serial Number Label

included in the Information Packet found in the cleaner carton.

This information will be helpful for any future inquiries or questions

about belt cleaner replacement parts,specifications or troubleshooting.

1

Table of Contents

Section 1 – Important Information ........................................................................................................................2

1.1 General Introduction ................................................................................................................................................ 2

1.2 User Benefits .............................................................................................................................................................. 2

1.3 Service Option ........................................................................................................................................................... 2

Section 2 – Safety Considerations and Precautions ...............................................................................................3

2.1 Stationary Conveyors................................................................................................................................................ 3

2.2 Operating Conveyors ................................................................................................................................................ 3

Section 3 – Pre-Installation Checks and Options...................................................................................................4

3.1 Checklist ..................................................................................................................................................................... 4

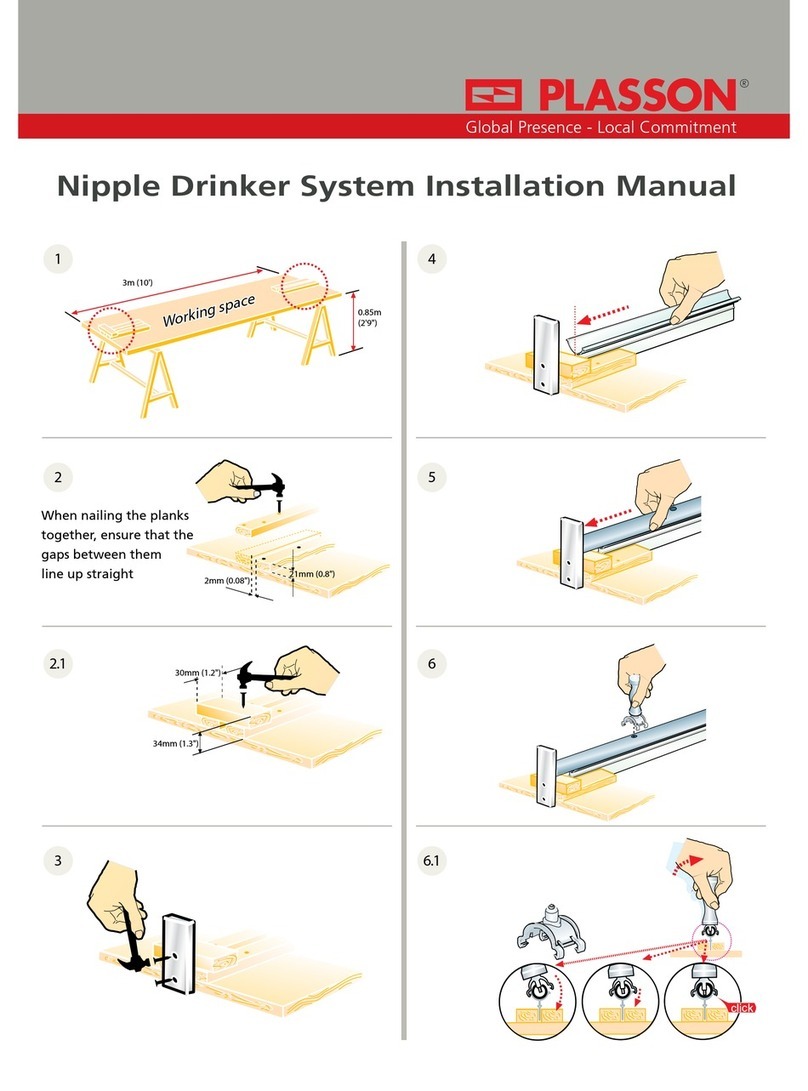

Section 4 – Y-Type™Belt Cleaner Installation Instructions...................................................................................5

Section 5 – Pre-Operation Checklist and Testing...................................................................................................8

5.1 Pre-Op Checklist ....................................................................................................................................................... 8

5.2 Test Run the Conveyor ............................................................................................................................................. 8

Section 6 – Maintenance .........................................................................................................................................9

6.1 New Installation Inspection..................................................................................................................................... 9

6.2 Routine Visual Inspection ........................................................................................................................................ 9

6.3 Routine Physical Inspection..................................................................................................................................... 9

6.4 Blade Replacement Instructions............................................................................................................................ 10

6.5 Maintenance Log ..................................................................................................................................................... 11

6.6 Cleaner Maintenance Checklist............................................................................................................................. 12

Section 7 – Troubleshooting .................................................................................................................................13

Section 8 – Specs and CAD Drawings...................................................................................................................14

8.1 Specs and Guidelines .............................................................................................................................................. 14

8.2 CAD Drawing - Y-Type Heavy-Duty with White or Purple Polyurethane Blades ......................................... 15

8.3 CAD Drawing - Y-Type Heavy-Duty with Tungsten Carbide Blades .............................................................. 16

Section 10 – Other Flexco Conveyor Products..................................................................................................... 17

2Y-Type™Standard-Duty Secondary Belt Cleaner

Section 1 – Important Information

1.1 General Introduction

We at Flexco® are very pleased that you have selected a Y-Type™Secondary Belt Cleaner for your conveyor

system.

is manual will help you to understand the operation of this product and assist you in making it work up to

its maximum efficiency over its lifetime of service.

It is essential for safe and efficient operation that the information and guidelines presented be properly

understood and implemented. is manual will provide safety precautions, installation instructions,

maintenance procedures and troubleshooting tips.

If, however, you have any questions or problems that are not covered, please visit our web site or contact our

Customer Service Department:

Customer Service: 91-44-6551-7771

Visit www.flexco.com for other Flexco locations and products.

Please read this manual thoroughly and pass it on to any others who will be directly responsible for

installation, operation and maintenance of this cleaner. While we have tried to make the installation and

service tasks as easy and simple as possible, it does however require correct installation and regular

inspections and adjustments to maintain top working condition.

1.2 User Benets

Correct installation and regular maintenance will provide the following benefits for your operation:

• Reducedconveyordowntime

• Reducedman-hourlabor

• Lowermaintenancebudgetcosts

• Increasedservicelifeforthebeltcleanerandotherconveyorcomponents

1.3 Service Option

e Y-Type™Secondary Belt Cleaner is designed to be easily installed and serviced by your on-site personnel.

However, if you would prefer complete turn-key factory service, please contact your local Flexco Field

Representative.

3

Section 2 – Safety Considerations and Precautions

Before installing and operating the Y-Type™Secondary Belt Cleaner, it is important to review and understand the

following safety information.

There are set-up, maintenance and operational activities involving both stationary and operating conveyors. Each

case has a safety protocol.

2.1 Stationary Conveyors

The following activities are performed on stationary conveyors:

•Installation •Bladereplacement •Repairs

•Tensionadjustments •Cleaning

DANGER

DANGER

WARNING

WARNING

WARNING

!

!

!

!

!

It is imperative that OSHA/MSHA Lockout/Tagout

(LOTO) regulations,29 CFR 1910.147, be followed before

undertaking the preceding activities. Failure to use LOTO

exposes workers to uncontrolled behavior of the belt

cleaner caused by movement of the conveyor belt. Severe

injuryordeathcanresult.

Before working:

•Lockout/Tagouttheconveyorpowersource

•Disengageanytakeups

•Cleartheconveyorbeltorclampsecurelyinplace

Use Personal Protective Equipment (PPE):

•Safetyeyewear

•Hardhats

•Safetyfootwear

Close quarters,springs and heavy components

create a worksite that compromises a worker’s

eyes, feet and skull.

PPE must be worn to control the foreseeable

hazards associated with conveyor belt cleaners.

Seriousinjuriescanbeavoided.

2.2 Operating Conveyors

There are two routine tasks that must be performed while the conveyor is running:

•Inspectionofthecleaningperformance

•Dynamictroubleshooting

Every belt cleaner is an in-running nip hazard. Never

touch or prod an operating cleaner. Cleaner hazards cause

instantaneous amputation and entrapment.

Neveradjustanythingonanoperatingcleaner.

Unforeseeablebeltprojectionsandtearscan

catch on cleaners and cause violent movements

of the cleaner structure. Flailing hardware can

causeseriousinjuryordeath.

Beltcleanerscanbecomeprojectilehazards.Stayasfar

from the cleaner as practical and use safety eyewear and

headgear.Missilescaninflictseriousinjury.

4Y-Type™Standard-Duty Secondary Belt Cleaner

3.1 Checklist

Section 3 – Pre-installation Checks and Options

•Checkthatthecleanersizeiscorrectforthebeltlinewidth

•Checkbeltcleanercartonandmakesureallpartsareincluded

•Review“ToolsNeeded”listonthetopofinstallationinstructions

•Checktheconveyorsite:

· Will the cleaner be installed on a chute

· Is the install on an open head pulley requiring mounting structure

5

+

Y-Type™Heavy-Duty Secondary Belt Cleaner

(Polyurethane or Carbide Option)

Section 4 – Installation Instructions

Tools Needed

• 16mm(5/8")Wrench

• 13mm(1/2")Wrench

• 19mm(3/4")Wrench

• TapeMeasure

• Ratchetwith19mm

(3/4")Socket

• (2)152mm(6")

C-Clamps (for

Temp or ar y

Positioning of

Mounting

Brackets)

• CuttingTorch

and/or Welder

• MarkingPen

Physically lock out and tag the conveyor at the power source

before you begin cleaner installation.

Before You Begin:

• Forchutemountingitmaybenecessarytocutanaccessholeto

allow for installation and inspections. (See dimensions in Step 1.)

• Followallsafetyprecautionswhenusingacuttingtorch.

• Ifwelding,protectallfastenerthreadsfromweldspatter.

• Forcleanerclearancerequirementsseechartatright.

Clearance Requirements for Installation

Vertical Horizontal

Y-Type Polyurethane 248mm (9-3/4") 133mm (5-1/4")

Y-Type Carbide 241mm (9-1/2") 133mm (5-1/4")

150 - 200mm

(6" - 8")

150 - 200mm

(6" - 8")

100mm

(4")

150 - 200mm

(6" - 8")

150 - 200mm

(6" - 8")

Chute wall

Vertical

Horizontal

Pole

Polyurethane Blade Option

Carbide

Blade Option

Blade Angle

Angle Clamp

Push-Up

Tensioning

Position

Optional

Pull-Up

Tensioning

Position

Adjusting Bracket

Adjusting Bolt

Mounting

Bracket

Clamp Block

6Y-Type™Standard-Duty Secondary Belt Cleaner

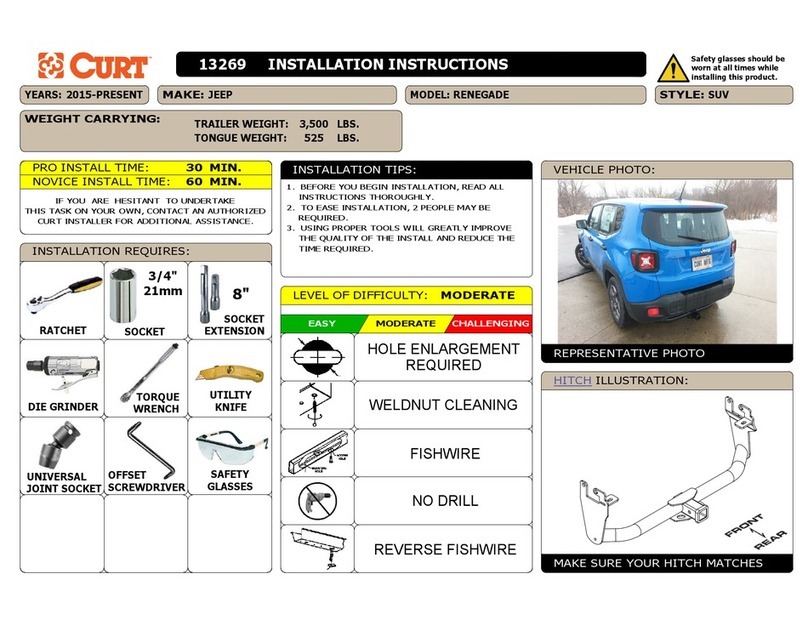

Section 4 – Installation Instructions (cont.)

Y-Type™Heavy-Duty Secondary Belt Cleaner

1. Install the mounting brackets. Position the mounting bracket to locate the cleaner pole centerline 190mm

(7-1/2")belowthebeltlineforpolyurethanecleanersor170mm(6-3/4")belowthebeltlineforcarbidecleaners.

The pole must be installed so the blades do not touch the belt.Positioning the brackets perpendicular to the belt is

recommended (Fig.1b).

Mounting

Bracket

Adjusting

Bracket

Lock Bolt

Clamp Block

Lock Bolts

Split

Clamp

Block

190mm (7-1/2")

Polyurethane

170mm (6-3/4")

Carbide

Belt Direction

Fig. 1b

90°

2. Choose the tensioner position. The tensioner is shipped

mounted in the push-up position.Depending upon the space

constraints of the installation,the tensioner can be optionally

mounted in a pull-up position.To do this, loosen the threaded

rodlocknut,unscrewthethreadedrodandremoveadjusting

bracketlockbolt.Thenmovetheadjustingbracketand

threaded rod to the top of the clamp blocks (Fig. 2) and tighten

threaded rod lock nut.

Adjusting

Bracket

Lock Bolt

Fig. 2

Push-up

Tensioning

Position

Pull-up

Tensioning

Position

Fig. 1a

Belt Direction Belt Direction

3. Install the pole. Remove the outer half of the clamp block on

one side,and on the opposite side,loosen the two clamp block

bolts. Slide the pole across and into the loosened clamp block,

replace the outer clamp block, center the blades on the belt and

tighten all four clamp block bolts finger tight.

Fig. 3

7

Section 4 – Installation Instructions (cont.)

Fig. 4

Y-Type™Heavy-Duty Secondary Belt Cleaner

Rotate blades

perpendicular to belt;

No blade-to-belt contact

Clamp

Block Bolts

5. Set the blade tension. Loosen the 4 clamp block lock

bolts (on the back of the mounting brackets) and turn the

topadjustingjamnutoneachsideuntilthebladesmake

light contact across the entire width of the belt. Make an

additional5fullturnsontheadjustingnutstotensionthe

blades.Tightenthebottomadjustingnutsandtheclamp

block bolts (Fig. 5).

4. Secure pole. Center pole/blades on belt and rotate pole

until blades are perpendicular to belt. Tighten clamp block

bolts equally on each tensioner assembly to lock pole in

place (Fig. 4).

Note: make sure there is no tip-to-belt contact while

making this alignment. If contact occurs, lower the pole

by loosening the clamp block lock bolts and raising the top

adjustingjamnut(fig.5).Whentipsareloweredandnot

touching the belt, repeat this step.

Test run the cleaner and inspect the performance. If more cleaning efficiency is desired, the blade tension can be

increasedin1/2turnsontheadjustingnuts(seeStep5).

Clamp Block

Lock Bolts

Adjusting

Nuts

Light tip

contact

Fig. 5

8Y-Type™Standard-Duty Secondary Belt Cleaner

Section 5 – Pre-Operation Checklist and Testing

5.1 Pre-Op Checklist

•Recheckthatallfastenersaretightenedproperly.

•Addpolecaps.

•Applyallsuppliedlabelstothecleaner.

•Checkthebladelocationonthebelt.

•Besurethatallinstallationmaterialsandtoolshavebeenremovedfrombeltandconveyorarea.

5.2 Test Run the Conveyor

•Runconveyorforatleast15minutesandinspectcleaningperformance.

•Ifvibrationoccursormorecleaningefficiencyisdesired,increasebladetensionbymaking1/2turnsonthe

adjustingnuts.

•Checkadjustingbracketsandtipsforpropertensioning.

•Makeadjustmentsasnecessary.

NOTE: Observing the cleaner when it is running and performing properly will help to detect problems and

determinewhenadjustmentsareneeded.

9

Section 6 – Maintenance

Flexco belt cleaners are designed to operate with minimum maintenance. However, to maintain superior performance

some service is required.When the cleaner is installed, a regular maintenance program should be set up. This program

will ensure the cleaner operates at optimal efficiency and problems can be identified and fixed before the cleaner stops

working.

All safety procedures for inspection of equipment (stationary or operating) must be observed.TheY-Type™

Secondary Belt Cleaner operates at the discharge end of the conveyor and is in direct contact with the moving belt.

Only visual observations can be made while the belt is running. Service tasks can be done only with the conveyor

stopped and by observing the correct lockout/tagout procedures.

6.1 New Installation Inspection

After the new cleaner has run for a few days, a visual inspection should be made to ensure the cleaner is

performingproperly.Makeadjustmentsasneeded.

6.2 Routine Visual Inspection (every 2-4 weeks)

A visual inspection of the cleaner and belt can determine if:

•Beltlookscleanorifthereareareasthataredirty.

•Bladeiswornoutandneedstobereplaced.

•Thereisdamagetothebladeorothercleanercomponents.

•Fugitivematerialisbuiltuponcleanerorintransferarea.

•Thereiscoverdamagetothebelt.

•Thereisvibrationorbouncingofthecleaneronthebelt.

•Thereismaterialbuilduponsnubpulley(ifused).

•Significantsignsofcarrybackexist.

If any of the above conditions exist, a determination should be made on when the conveyor can be stopped

for cleaner maintenance.

6.3 Routine Physical Inspection (every 6-8 weeks)

When the conveyor is not in operation and properly locked and tagged out, perform a physical inspection of

the cleaner through the following tasks:

•Cleanmaterialbuildupfromcleanerbladeandpole.

•Closelyinspectbladeforwearandanydamage.Replaceifneeded.

•Ensurefullbladetobeltcontact.

•Inspectcleanerpolefordamage.

•Inspectallfastenersfortightnessandwear.Tightenorreplaceasneeded.

•Replaceanywornordamagedcomponents.

•Checktensionofcleanerbladetobelt.Adjusttensionifnecessaryusingthestepsonpage7.

•Whenmaintenancetasksarecompleted,testrunconveyortoensurecleanerisperformingproperly.

10 Y-Type™Standard-Duty Secondary Belt Cleaner

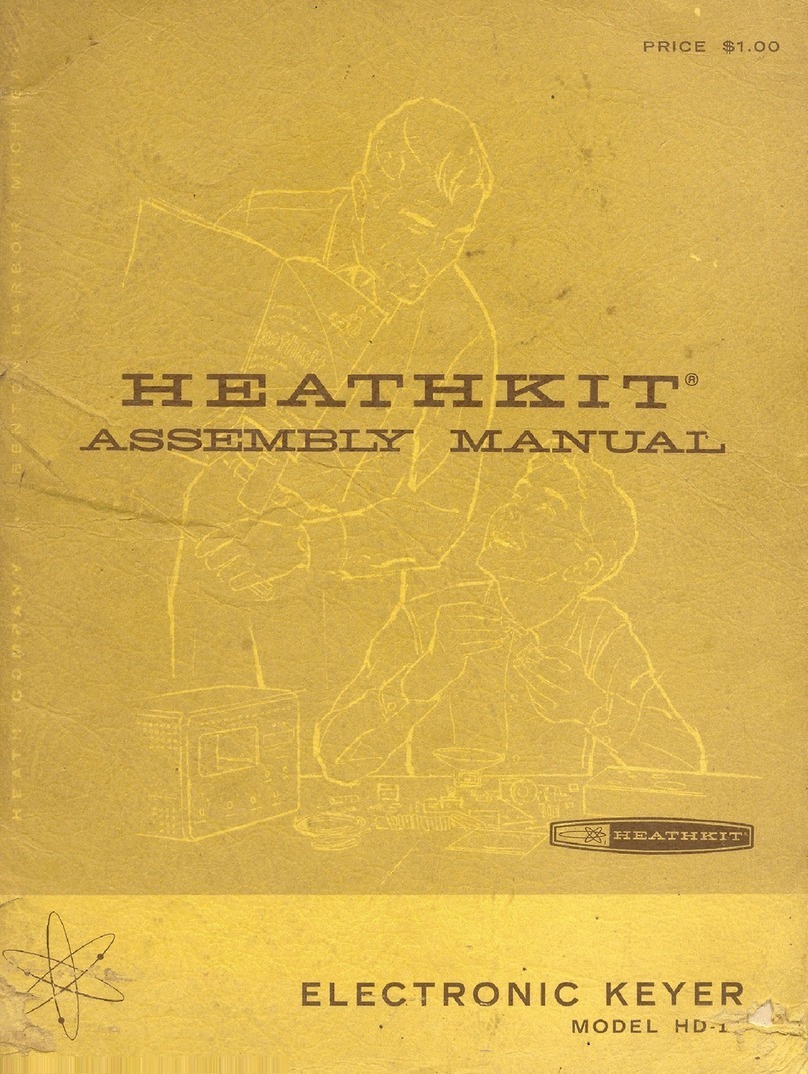

6.4 Blade Replacement Instructions (Carbide or Polyurethane)

Section 6 – Maintenance (cont.)

Fig. 1a

25mm (1")

Gap

Adjusting

Bracket

Top Adjusting

Bolt Jam Nut

Fig. 1b

Clamp Block

Lock Bolts

25mm (1")

Gap

Top Adjusting

Bolt Jam Nut

Fig. 2

Angle Clamp

Set Screws

and Lock Nuts

Angle

Clamp

Blade Angle

Assembly

1. Release the blade tension and remove worn blade tips.

a. Loosenandturnthetopadjustingboltjamnuts25mm(1")abovethetopsoftheadjustingbrackets(Fig.1a).

b. Loosen the clamp block lock bolts on both sides and allow the pole to move down and rest on the raised top

adjustingboltjamnuts(Fig.1b).

2. Remove blade angle from pole.

Loosen angle clamp lock nuts and set screws on both sides of cleaner

(Fig. 2). Slide angle clamps off each end of angle and remove blade

angle assembly from pole.

3. Replace the cushions.

Cushions may be removed from the angle by sliding them off each end,

or entire angle with all cushions may be replaced at once.

4. Reinstall blade angle.

Set new cushions and angle back on pole and slide angle clamps back

onto the angle (Fig. 3). Tighten angle clamp set screws and lock nuts on

both sides.Verify blades are centered and perpendicular to belt.

Fig. 3

Angle Clamp

Set Screws

and Lock Nuts

Angle Clamp

Blade Angle

Assembly

5. Set blade tension. Turnthetopadjustingjamnutoneachside

until the blades make light contact across the entire width of

the belt. Makeanadditional5fullturnsontheadjustingnutsto

tensiontheblades.Tightenthebottomadjustingnutsandthe

clamp block bolts (Fig. 5).

Test run cleaner and inspect cleaning performance. If vibration

occurs or more cleaning efficiency is desired, increase blade

tensionbymaking1/2turnsonadjustingnuts..

Clamp

Block

Bolts

Top

Adjusting

Nut

Bottom

Adjusting Nut

Light tip

contact

Fig. 5

11

6.5 Maintenance Log

Section 6 – Maintenance (cont.)

Conveyor Name/No.

Date: Work done by: Service Quote #

Activity:

Date: Work done by: Service Quote #

Activity:

Date: Work done by: Service Quote #

Activity:

Date: Work done by: Service Quote #

Activity:

Date: Work done by: Service Quote #

Activity:

Date: Work done by: Service Quote #

Activity:

Date: Work done by: Service Quote #

Activity:

12 Y-Type™Standard-Duty Secondary Belt Cleaner

6.6 Cleaner Maintenance Checklist

Section 6 – Maintenance (cont.)

Site: __________________________________ Inspected by: _________________________________ Date: ______________________

Belt Cleaner: _____________________________________________ Serial Number: _________________________________________

Beltline Information:

Beltline Number: ____________________ Belt Condition: _______________________________________________________________

Belt Width: ¨900mm ¨1050mm ¨1200mm ¨1350mm ¨1500mm ¨1800mm

(36") (42") (48") (54") (60") (72")

Head Pulley Diameter (Belt & Lagging): __________

Belt Speed:________fpm Belt Thickness: __________

Belt Splice:___________ Condition of Splice:__________ Number of splices:_________ ¨Skived ¨Unskived

Material conveyed: ________________________________________________________________________________________________

Days per week run:_______________ Hours per day run:_______________

Blade Life::

Date blade installed:______________ Date blade inspected:______________ Estimated blade life:______________

Is blade making complete contact with belt? ¨Yes ¨No

Blade height: Left _________ Middle _________ Right _________

Blade condition: ¨Good ¨Grooved ¨Smiled ¨Not contacting belt ¨Damaged

Was Cleaner Adjusted: ¨Yes ¨No

Pole Condition: ¨Good ¨Bent ¨Worn

Lagging: ¨Slide lag ¨Ceramic ¨Rubber ¨Other ¨None

Condition of lagging: ¨Good ¨Bad ¨Other

Cleaner's Overall Performance: ( Rate the following 1 - 5, 1=very poor - 5= very good )

Appearance:¨Comments:____________________________________________________________________________________

Location:¨Comments:____________________________________________________________________________________

Maintenance:¨Comments:____________________________________________________________________________________

Performance:¨Comments:____________________________________________________________________________________

Other Comments:

________________________________________________________________________________________________________________

________________________________________________________________________________________________________________

________________________________________________________________________________________________________________

________________________________________________________________________________________________________________

_____________________________________________________________________________________________________

13

Section 7 – Troubleshooting

Problem Possible Cause Possible Solutions

Vibration

Cleaner secure bolts not set Ensure all locking nuts are tight (Loctite)

Cleaner not set up correctly Ensure cleaner set up properly (check tip angle)

Belt tension too high Ensure cleaner can conform to belt, or replace with alternate

Flexco® secondary cleaner

Belt flap Introduce hold-down roller to flatten belt

Cleaner over-tensioned Ensure cleaner is correctly tensioned

Cleaner under-tensioned Ensure cleaner is correctly tensioned

Material buildup

on cleaner

Cleaner not set up correctly Ensure cleaner set up properly (check tip angle)

Buildup on chute Ensure cleaner is not located too close to back of chute,

allowing buildup

Cleaner being overburdened Introduce Flexco precleaner

Excessive sticky material Frequently clean unit of buildup

Cleaner not

conforming to belt

Cleaner not set up correctly Ensure cleaner set up properly (check tip angle)

Belt tension too high Ensure cleaner can conform to belt, introduce hold-down

roller, or replace with alternate Flexco secondary cleaner

Belt flap Introduce hold-down roller to flatten belt

Cleaner cannot conform Ensure cleaner can conform to belt, introduce hold-down

roller, or replace with alternate Flexco secondary cleaner

Material passing

cleaner

Cleaner not set up correctly Ensure cleaner set up properly (check tip angle)

Cleaner tension too low Ensure cleaner is correctly tensioned

Cleaner blade worn/damaged Check blade for wear, damage and chips, replace where

necessary

Cleaner being overburdened Introduce Flexco precleaner

Belt flap Introduce hold-down roller to flatten belt

Belt worn or grooved Introduce water spray pole

Cleaner cannot conform Ensure cleaner can conform to belt, introduce hold-down

roller, or replace with alternate Flexco secondary cleaner

Missing material in

belt center only

Cupped Belt Install hold-down roller and reset blade angle

Cleaner blade worn/damaged Check blade for wear, damage and chips, replace where

necessary

Missing material on

outer edges only

Cupped Belt Install hold-down roller and reset blade angle

Cleaner blade worn/damaged Check blade for wear, damage and chips, replace where

necessary

Tensioners binding Tensioners not aligned properly Adjustmountingbasesuntiltensionerstravelwithoutbinding

14 Y-Type™Standard-Duty Secondary Belt Cleaner

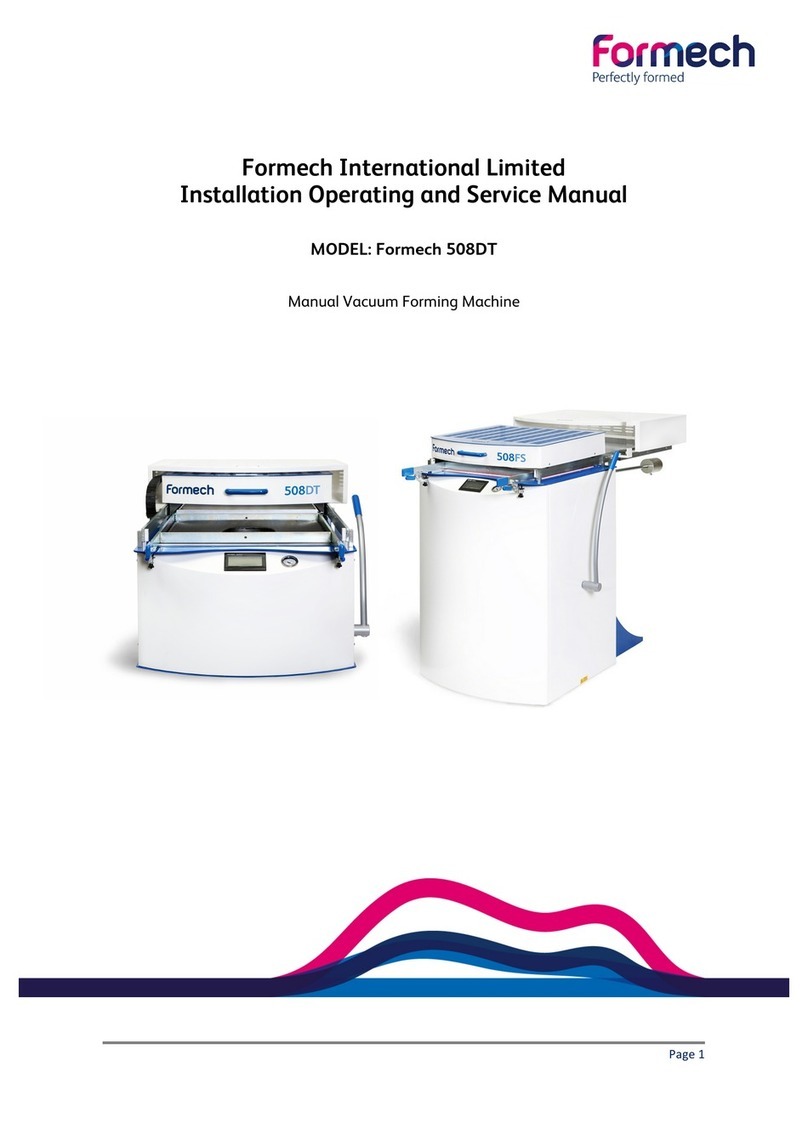

8.1 Specications and Guidelines

Section 8 – Specifications and CAD Drawings

Specifications:

• MaximumBeltSpeed..........................................3.8M/sec (750 FPM)

• TemperatureRating.............................................-35°C to 82°C (-30°F to 180°F)

• UsableBladeWearLength..................................75mm(3")(Polyurethane)

10mm(3/8")(Carbide)

• BladeMaterials.....................................................Purple: Polyurethane (proprietary blend for abrasion resistance and long wear)

White: Polyurethane (chemical resistant/food grade)

Carbide: Tungsten Carbide

• AvailableforBeltWidths....................................900to1800mm(36"to72").Othersizesavailableuponrequest.

Overall Pole Length

Maximum Conveyor Span

Vertical

Horizontal

Y-Type Blade Specifications

Cushion Durometer

Temperature

Range

Purple

(Standard) 86A -35° to 82° C

(-30° to 180°F)

White

(Food Grade) ‡ 83A -35° to 82° C

(-30° to 180°F)

Carbide n/a -35° to 82° C

(-30° to 180°F)

Pole Length Specifications

Cleaner

Size

Pole

Length

Maximum

Conveyor

Span

mm in. mm in. mm 82

900 36 2286 90 2083 88

1050 42 2438 96 2235 94

1200 48 2590 102 2388 100

1350 54 2743 108 2540 106

1500 60 2895 114 2692 118

1800 72 3200 126 2997 70

Pole Length - Belt +1350mm (54")

Pole Diameter - 73mm (2-7/8")

Clearance Guidelines for Installation

Cleaner

Type

Belt Width/

Cleaner Size

Horizontal

Clearance

Required

Vertical

Clearance

Required

mm in. mm in. mm in.

Y-Type®

Polyurethane 900 - 1800 36 - 72 133 5-1/4 241 9-1/2

Y-Type Carbide 900 - 1800 36 - 72 133 5-1/4 248 9-3/4

‡ All ingredients used in the polyurethane formulation of this blade

comply with the relevant requirements of 21 CFR (FDA Code of

Federal Regulations) for use in repeated bulk dry food applications

15

8.2 CAD Drawing – Y-Type™HD Polyurethane

Section 8 – Specifications and CAD Drawings (cont.)

SPECIFICATIONS

BLADE

TYPE

ORDER

NUMBER

ITEM CODE

BELT WIDTH 'A'

POLE LENGTH 'B'

(IN)

(mm)

(IN)

(mm)

36 900

78.75

2000

PURPLE

YTHD-900

83092

CARBIDE

YTCHD-900

83099

WHITE

YTWHD-900

83113

42 1050

92.50

2350

PURPLE

YTHD-1050

83093

CARBIDE

YTCHD-1050 83100

WHITE

YTWHD-1050

83114

48 1200

104.30

2650

PURPLE

YTHD-1200

83094

CARBIDE

YTCHD-1200 83101

WHITE

YTWHD-1200

83115

54 1350

106.30

2700

PURPLE

YTHD-1350

83095

CARBIDE

YTCHD-1350 83102

WHITE

YTWHD-1350

83116

60 1500

116.14

2950

PURPLE

YTHD-1500

83096

CARBIDE

YTCHD-1500 83103

WHITE

YTWHD-1500

83117

64 1650

122.05

3100

PURPLE

YTHD-1650

83097

CARBIDE

YTCHD-1650 83104

WHITE

YTWHD-1650

83118

72 1800

127.95

3250

PURPLE

YTHD-1800

83098

CARBIDE

YTCHD-1800 83105

WHITE

YTWHD-1800

83119

POLE LENGTH 'B'

BELT WIDTH +127mm (5") MIN

BELT WIDTH +482mm (19") MAX

2.56

65

POLE LENGTH 'A'

1.61

40.8

3.98

101.2

17.00

431.8

13.65

346.80

.59

15

16 Y-Type™Standard-Duty Secondary Belt Cleaner

8.3 CAD Drawing – Y-Type™HD Carbide

Section 8 – Specifications and CAD Drawings (cont.)

17

Flexco® provides many conveyor products that help your conveyors to run more efficiently and safely. These

components solve typical conveyor problems and improve productivity.

Hereisaquickoverviewonjustafewofthem:

• PatentedConShear™bladerenewsitscleaningedgeasitwears

• VisualTensionCheck™foroptimalbladetensioningandsimple

retensioning

• Quickandeasyone-pinbladereplacement

• MaterialPathOption™foroptimalcleaningandreduced

maintenance

Inspection Door

• Patented“pivot&tilt”designforsuperiortrainingaction

• Dualsensorrollersoneachsidetominimizebeltdamage

• Pivotpointguaranteednottoseizeorfreezeup

• Simplebracketsandcomponentconstructionensureaquickand

easy installation

• Abeltcleanerforthetailpulley

• Exclusivebladedesignquicklyspiralsdebrisoffthebelt

• Economicalandeasytoservice

• Availableinveeordiagonalmodels

PT Smart™ Belt Trainer

Flexco Slider and Impact Beds

Belt Plows

• Multipledoorsizesavailableforavarietyofapplications.

• Dust-tightsiliconesealbetweenmountingplateandchutewall.

• Latchmechanismisdesignedtoalloweasyadjustabilityto

tightness of door seal.

• Optionalhinged,boltedscreenallowssafevisualinspection

and does not require removal for authorized workers to access

the chute.

• “Limitedspace”cleanersfortightconveyorapplications

• HighTempcleanersforsevere,high-heatapplications

• Arubberfingeredcleanerforchevronandraised-ribbelts

• Multiplecleanerstylesinstainlesssteelforcorrosiveapplications

EZP1 Precleaner

Flexco Specialty Belt Cleaners

• Adjustingtroughinganglesforeasyinstallationandadjustability

• Long-wearingUHMWforsealingtheloadzone

• OfferedinbothLight&Medium-dutydesignstoaffordablyfit

your application

Section 10 – Other Flexco Conveyor Products

No. 71, Vanagaram Village • Ambattur Taluk, Thiruvallur District • Chennai, Tamilnadu – 600 095 • India

Tel: +91-44-6551-7771 • E-mail: info.india@exco.com

Visit www.flexco.com for other Flexco locations and products.

©2016 Flexible Steel Lacing Company. 05/04/16. For reorder: X3987

The Flexco Vision

To become the leader in maximising

belt conveyor productivity for our customers worldwide

through superior service and innovation.

Table of contents