14/45Gas ranges (PCG/CFG/CVG/CFGE/CCG)

indicated on the rating plate (variation of ±10%

is allowed).

– Each appliance must be connected to an

independent mains supply of suitable capacity

(totalpower indicated in“Technical data” table)

viaan input terminalboard with flexible rubber

cable, insulated at a level not below H07RN-F

and protected by a metal or rigid plastic tube.

– Automaticomnipolarcutoutswitchesofsuitable

capacity (with contacts opening to at least 3

mm)and highly sensitive automaticdifferential

protective devices must be fitted. These must

ensure that there is no direct or indirect contact

between live components and fault currents

and the ground, in accordance with current

regulations (max-imum admissible leakage

current 1 mA/kW).

Earth and unipotential connections

– Appliancesmustbe earthedonterminalsmarked

with the symbol .

– Connectthemetallicstructureofeveryelectrical

appliance installed to the terminals, marked by

the symbol , and located next to the earth

terminals (unipotential system).

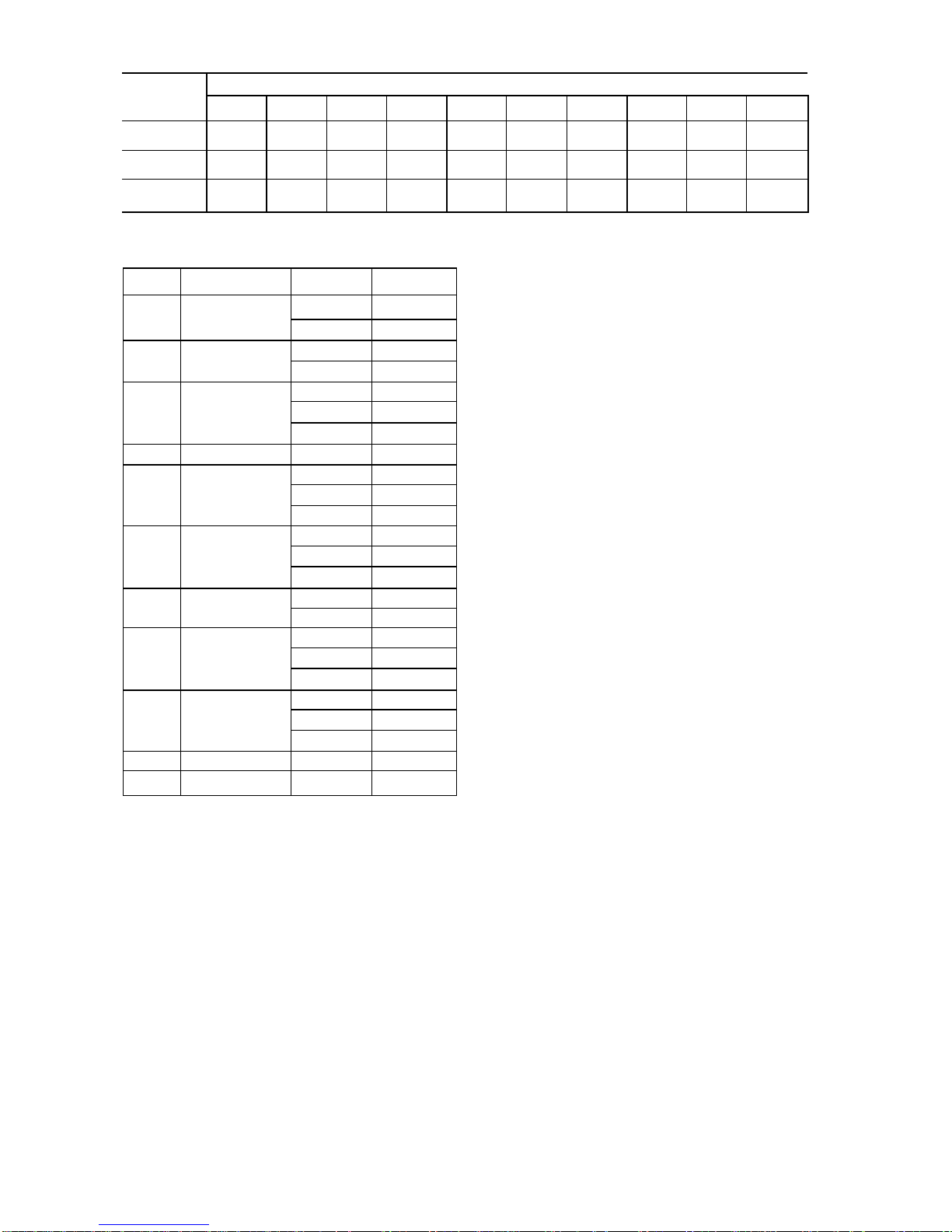

CONVERSION TO ANOTHER TYPE OF GAS

To adapt appliances to work with other types of

gas carry out all the operations stated below.

Nozzles, minimum adjustment screws and

adhesive labels are in the bag supplied with the

appliance.

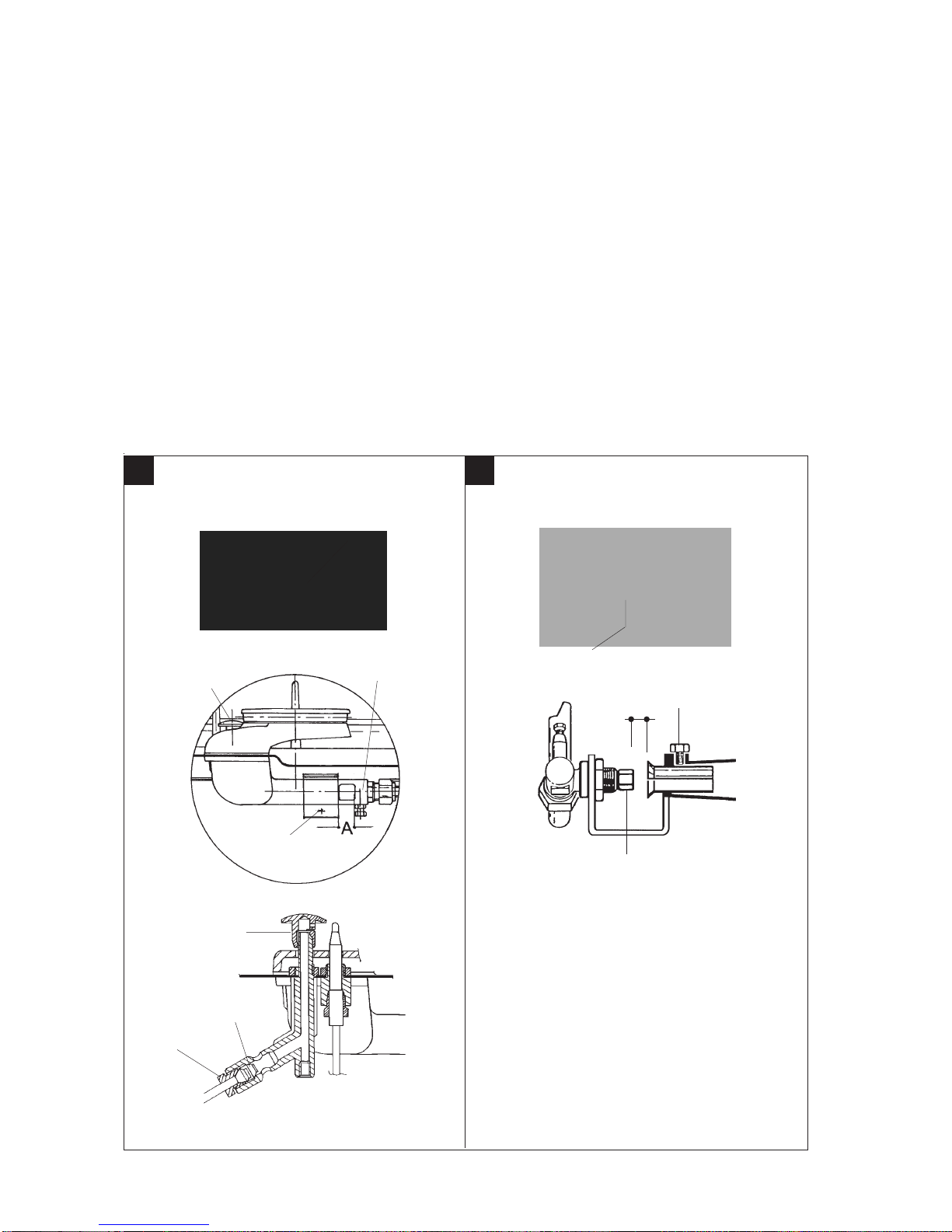

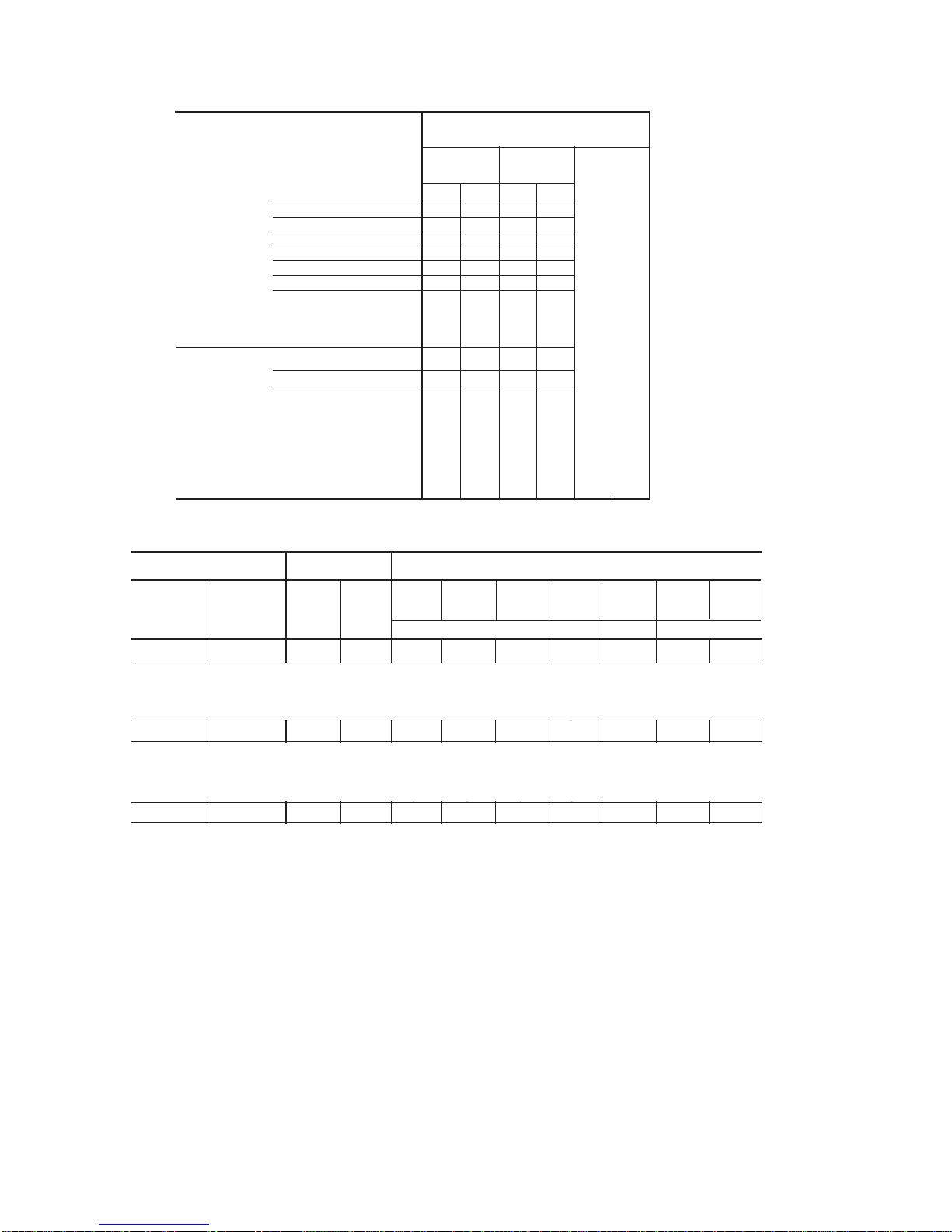

Replacement of nozzle and burner primary air

adjustment (Fig. 1 - 2)

– Remove cooking hob control panel

– Remove the oven floor

– Unscrew nozzle U and change it with the proper

one according to Table T1.

– LoosefixingscrewVand operating on the shutter

adjust primary air inlet at the distance “A”

indicated on Table T1.

– Screw down fixing screw V and seal it with red

paint.

Replacement of gas cock minimum adjustment

screw (Fig. 1 - 2)

– Remove cooking hob control panel

– Unscrew the minimum screw VM and replace it

with the proper one indicated in table T1.

Replacement of pilot burner nozzle (Fig. 1 - 2)

– Remove cooking hob control panel

– Unscrew pipe fitting R and replace nozzle UP

with the proper one indicated in Table T1.

– Screw down pipe fitting R.

Replacement of gas preset adhesive label

– Applythe correct adhesive labelwhich indicates

the new type of gas for which the appliance is

now set.

INSTALLATION INSTRUCTIONS

WARNINGS

Installation, adjustments and maintenance of the

appliances must be done by authorized installers,

in accordance with the safety standards in force.

The manufacturer declines any responsibility

if such obligation is not observed.

NOTE

Combination ranges (with electric heated oven)

are in accordance with the EEC Directive 89/336

on the radio interference suppression.

Soundlevelduring operationsdoesnotexceed70 dB.

INSTALLATION

Positioning

– The overall/connection dimensions and the

technical data are stated in the pages in the

appendix.

– Install the appliances only in sufficiently aired

rooms.

– Cooking ranges are type “A” appliances and for

this reason the rooms must be ventilated in

accordancewiththetechnicalstandardsinforce.

– Position appliances at least 10 cm from the

nearby walls. Such distance can be less when

the walls are incombustible or protected by a

thermal insulator.

– The appliances are not suitable for built-in

installation.

Assembly

– Remove the film which protects the external

panels. Any glue remaining on these is to be

removed with a suitable solvent.

– Level appliance by means of the adjustable feet.

– Assemble the stack extension (if foreseen) by

following the instructions enclosed with the

extension itself.

In line union of the appliances

– Put the appliances next to eachother and level

them at the same height.

– Unite the appliances using the special union

joint-coverings supplied upon request.

Connection to the gas piping

– Before carrying out the connection consult the

gas delivery body.

– Install a fast-closing cut-off cock upstream from

the appliance in an easily accessible place.

– Check for any leaks in the connection points.

– Check if the appliance is set for the type of gas

with which it will be fed. If it is not, read

paragraph “Adaptation to another type of gas”.

Electrical connections (combination ranges)

– The ovens are designed to operate at the voltage