Flexiheat FHATX25 Guide

TECHNICAL DOCUMENTATION

DTC ATX21-319 EN

1312DL6489

HIGH EFFICIENCY GAS HEATER

FHATX25/35/45/60/80

2

TABLE OF CONTENTS

1

GENERAL INFORMATIONS

1-1 General recommendations

1-2 Description of the gas heater

1-3 Instructions for use

1-4 Operation

1-5 Safety

1-6 Cut-off

1-7 Control board

6 à 7

28 à 12

3

INSTALLATION

3-1 Mounting brackets

3-2 Flue pipe connections

3-3 Gas connection

13 à 17

418 à 20

5

COMBUSTION SETTINGS

7-1 Changing gas

7-2 Selection table for nozzles and gas pressure

7-3 Burner combustion settings

21 à 22

6

COMMISSIONING AND SETTINGS

6-1 Checks before commissioning

6-2 Commissioning

6-3 Control board use

6-4 Control board settings

23 à 26

727-32

8MAINTENANCE 33

9USER RECOMMENDATIONS

8-1 Safety rules

8-2 What should be done in case of problems? 34

© Copyright

This range of products are constantly being updated and refined. We reserve the right to change our products and

their relevant technical data contained in this publication at any time and without prior notice.

TECHNICAL CHARACTERISTICS

2-1 Performances of high efficiency gas heater FHATX

2-2 Dimensions of FHATXH & FHATXV

2-3 Recommendations for FHATXH / FHATXV installation

2-4 Dimensions of FHATXC

2-5 Specific performances of FHATXC

2-6 Curves pressure/airflow of FHATXC

TROUBLESHOUTING

8-1 List of management box faults and problem solving

8-2 Bills of material for FHATXH and FHATXV

8-3 Bills of materials for FHATXC

N° Chapter Pages

ELECTRICAL WIRING

4-1 Electrical schematic of FHATX

4-2 Electrical connection between heater’s components

4-3 Basic connections schematic with pilot wire thermostats

3

Marquage CE

This equipment complies with the essential requirements of Regulation (UE) 2016/426 « Gas devices ». It is

registered under the No.1312DL6489 on the 19th of February 2021, standards EN17082:2019.

The devices in this manual comply also with following directives:

- Low voltage 2014/35/UE,

- Electromagnetic compatibility 2014/30/UE,

- Ecodesign 2009/125/CE, according the requirements of regulation (UE) 2016/2281-2282-2283 of the 30th

of November 2016.

Liability

The devices must be installed by qualified professional workers, respecting the regulations and decrees in

force, and in accordance with the instructions shown in this instruction manual. The installer is required to

establish installation conformity certificates produced by the ministries responsible for the construction and

safety of gas. References to standards, rules and directives mentioned in this manual are given for

information purposes and are only valid at the date of printing this manual.

Receipt and storage

The appliance is delivered on a wooden pallet protected by a cardboard packing and a plastic film. It is

essential to check the condition of the delivered equipment (even if the packaging is intact) and its

conformity with the order.

In case of damage or missing parts, you must report the observations on the transport company’s receipt

form in the most precise way possible, “subject to unpacking” has no legal value, and then you must

confirm those reservations by registered letter within 48h to the transport company. We remind you that it is

the responsibility of the buyer to check the delivered merchandise, no recourse will be possible if this

procedure is not respected.

Store the equipment in a clean and dry room, away from shocks, vibration, divergences in temperature and

in an ambient environment with a rate of hygrometry lower than 90%.

Recycling and end of product service life

This device is mainly built using materials that can be recycled, at the end of its service life, it is

important to pay particular attention to its destruction. Some components, such as electric

equipment, are subject to special legislation, applicable national regulations must be respected

when disposing of them.

1- For the disposal of the product and parts, use public or private waste disposal contractors.

2- For further information on the proper disposal of the product, contact the local authorities, the refuse

collection and processing department or the point of sale where the product was purchased.

Appliances or equipment bearing this symbol must not be disposed of with household waste, but must be

collected separately.

Proper recycling helps to prevent environmental damage and health risks.

This equipment must be used expressly for the purpose for which it has been designed and

manufactured for. Any contractual liability of Flexiheat is therefore excluded in case of damage undergone

by persons, animals or goods, following errors in installation, settings, maintenance and inappropriate use.

The devices must be equipped exclusively with genuine accessories. Flexiheat will not be held responsible

for any damage whatsoever arising from the use of an accessory which is inappropriate to the device.

Flexiheat is responsible for the conformity of the device to the rules, directives and standards of

construction in force at the time of marketing. The knowledge and compliance with the legal provisions and

standards inherent to the location, installation, commissioning and maintenance are the sole responsibility

of the design office, the installer or user.

4

1.5 Guarantee

The appliance is covered by a contractual warranty for any manufacturing defect. Refer to the General

terms and conditions of sales for the duration of the warranty.

Our liability as a manufacturer cannot be committed when incorrect use of a device has occurred, where

there is a defect or of an insufficiency in the maintenance of that device, or an incorrect installation of the

device. Only defects in manufacture or raw materials are concerned.

It is your responsibility to make sure that it is carried out by a qualified professional. In particular, we cannot

be held liable for material damage, intangible damage or personal accidents

resulting from an installation that is not compliant:

- with legal and regulatory provisions or those imposed by local authorities,

- with national, even local and specific provisions governing the installation,

- with our installation manuals and instructions, in particular the regular maintenance of the appliances,

- with standard industry practices.

Our warranty is limited to the exchange or repair of only those parts recognised as defective by our

technical services, excluding labour, travel and transport costs.

Our warranty does not cover the replacement or repair of parts due to normal wear and tear, misuse,

unqualified third party intervention, lack of or inadequate monitoring or maintenance, non-compliant power

supply and the use of inappropriate or poor quality fuel.

Sub-assemblies, such as motors, pumps, electric valves, etc., are only guaranteed if they have never been

dismantled.

Any replacement which takes place during the guarantee period, even if it necessitates the immobilisation

of the equipment, cannot in any circumstances extend the duration of the guarantee. No damages or

interest can be claimed for direct or indirect prejudice.

The devices must only be equipped with the original smoke system and air intake.

In case of use of accessories other than those proposed by our company, check that they are indeed

compatible with the devices.

5

The features, illustrations and descriptions contained in this document are, to our knowledge, accurate at

the time of their approval for printing. We reserve the right to modify, to no longer offer certain features or

to stop the production of a model without notice and does not constitute any commitment on our part.

This technical manual must be kept in good condition inside the appliance.

Security rules

- It is forbidden to plug and / or reduce the ventilation openings in the installation room or appliance.

- Never obstruct the smoke outlet and fresh air intake.

- Never make changes to the settings made by the qualified professional.

- Never spray water on the heater, or touch the appliance with wet and / or bare body parts.

- Never touch the hot parts of the heater, and / or moving parts.

- Do not put or hang anything on the device.

- Any intervention on the appliance is forbidden before disconnecting it from the mains and cutting off the

gas supply.

- Do not change the type of gas used, the device settings, the safety or control systems, as this could

create dangerous situations.

Notify the service technician in the event of a gas change, gas pressure, or change in supply voltage.

In case of a long period of non-operation, disconnect the power supply from the device. When returning

to operation, it is advisable to use qualified personnel. In general, any repair or maintenance work must

be carried out exclusively by authorized and qualified personnel.

Subscription to a maintenance contract is highly recommended, "see with your installer".

What should be done if you smell gas ?

-Close the external gas valve and the electrical supply then warn the maintenance technician

-Do not try to turn on the device again

-Do not operate the electrical switch, do not use a telephone located inside the building.

-Call your gas supplier from another phone. Follow the instructions provided for your provider.

-If you can not contact them, call your fire department.

Caution

Electrical components, drive mechanisms and fuel gas can cause injury. To protect against these

inherent risks during installation or maintenance, the power supply must be disconnected and the gas

supply valve must be closed. All persons involved in the installation or maintenance of this equipment

must comply with occupational health and safety standards.

PLEASE READ CAREFULLY BEFORE CONTINUING

6

1-GENERAL INFORMATIONS

1.1 General recommandations

The appliance can only be installed in rooms which are sufficiently ventilated, except if it has a sealed

connection.

The proper functioning of the gas heater depends on correct installation and commissioning.

Installation and maintenance must be carried out by qualified personnel in conformity with the regulatory

texts and the rules in force.

The non-compliance with such rules entails the rejection of all responsibility from the manufacturer.

DO NOT INSTALL GAS HEATERS IN :

- Rooms which have a risk of explosion,

- Rooms containing chlorinated combination steam,

- Rooms with a high content of combustible dust,

- Rooms which are excessively humid (electrical danger),

- Domestic premises

It is the responsibility of the installer, after having checked that the installation complies with the

requirements of this manual.

1- To inform users :

That they cannot make any alterations to the appliance design and installation; The slightest alteration

(exchange, removal, etc.) of safety components or parts affecting the performance of the appliance or

combustion hygiene systematically results in the removal of the CE marking for the appliance.

It is essential to have the prescribed cleaning and maintenance operations carried out. A preventive yearly

maintenance operation is mandatory.

2– Document to be given to the user :

This manual is an integral part of the appliance and must therefore be kept and always accompany the

appliance, even if it is transferred to another owner or user.

As we are committed to our product quality, we are constantly seeking to improve them. We therefore

reserve the right to modify the specifications indicated in this document at all times.

Supply grille

Blowing fan

Exhaust fan

Control board Gas burner

1.2 Description of the gas heater

The gas heater FHATX is an independent hot air generator, running on natural gas and on propane.

It constitutes a "direct" heating gas system ; it is a device for the production and the emission of heat

without an intermediate vehicular fluid. For the whole range described in these instructions, the

combustion products are evacuated out of the room by an extractor. The combustible air is taken from the

ambient environment or from outside. Those units can be connected with vertical or horizontal concentric

kit or single flue kit. The gas heaters of the FHATX range work with different gas indicated on the

identification plate in conformity with the European directive.

7

1.3 Instructions for use

- Please read the instructions in this manual carefully for the operation and maintenance of this device.

- Carry out maintenance at least once a year by qualified personnel. The frequency of the maintenance

operations depends on the environment in which the device is installed. More regular inspection must be

carried out in dusty locations.

- Regularly check that device, the chimney or the gas pipe are not damaged.

- Regularly check that air openings in the building and around the device are not obstructed.

- Check that hot air circulates normally in the room, and therefore that there is no obstacle on the suction

side (fan side), and in front of the blowing side of the unit (check that the grille is well opened).

- The control box must have a cut off electricity each 24 hours.

1.4 Operation

When heat is required (ambient temperature under thermostat setting temperature), the exhaust fan starts.

To avoid any gas into the combustion chamber, the exhaust fan ventilates during few seconds, then the

burner is igniting by the ignition sensor. When the heat exchanger is hot enough, the blowing fan starts. The

hot air is blown into the room.

When the setting temperature is reached, the burner is turned off. The fan continues to turn for about one

minute, until it has cooled the heat exchanger.

1.5 Safety

- If there is no flame, this is detected by an ionisation sensor and the gas vales are immediately closed.

This default can be reset remotely or on the appliance.

- The thermal protection of the heat exchanger is ensured by two thermostats. The first, which is

automatically reset, protects against insufficient air flow (obstructions, fan failure). The second, which has to

be manually reset, is set to a higher threshold than the first one. It protects the device against high excess

heating due to an operating problem or unsuitable use.

If the operation shows any difficulty whatsoever, please contact us.

Make sure that the device can be supplied normally with combustion air at atmospheric pressure (any

modification of the building after the installation of the device must be carried out taking this into account).

Excessively low pressure inside the room can harm the correct functioning of the device by depriving it of

the air necessary for combustion.

1.6 Cut-off

- To cut off the appliance during a short period, it is necessary only to cut off the thermostatic line (this

means turning the thermostat to a minimum setting point or turning off the thermostat switch) .

- For a prolonged stoppage, switch off the thermostatic line, close the gas valve and cut off the electrical

supply, taking care to wait for the fan to stop running.

- Gas and electricity must only be turn off in case of emergency or for long stoppage periods.

IMPORTANT : Never cut off the power supply while the gas heater is running or when the heat exchanger

is cold down. The non-compliance with these instructions may cause damage to the heat exchanger and

cause the loss of the warranty.

1.7 Control board

The appliance is equipped with an integrated control board for smart operating management. In case of any

unit failure, the board indicates the source of the problem and support the technician for troubleshooting.

8

2– TECHNICAL CHARACTERISTICS

2.1 Performances of high efficiency gas heaters ATX

Heat input HHV kW 29.14 40.38 51.40 67.83 88.58

Heat input LCV kW 26.25 36.38 46.31 61.11 79.80

Nominal output (Prated,h) kW 24.18 33.54 42.69 55.98 72.94

Minimal power (Pmin) kW 13.80 19.13 24.43 32.27 42.14

Efficiency at nominal heat output (ƞnom) %92.1 92.2 92.2 91.6 91.4

Efficiency at minimal power (ƞpl) %94.8 94.8 95.1 95.2 95.2

Gas flow at 15°C

Natural G20

Groningen G25

Propane G31

m3/h

m3/h

Kg/h

2.50

2.68

2.05

3.47

3.73

2.84

4.41

4.74

3.61

5.82

6.25

4.77

7.60

8.17

6.23

NOx with 0% O2 mg/kW < 69

CO Value in ppm ppm < 120

Seasonal energy efficiency (ƞs,h) %78.7 78.1 78.5 78.6 78.5

Supply voltage Single –phase 230 V 50 Hz

Amperage A1.05 1.75 23.25 3.95

Maximum electrical power with fan W230 380 430 700 850

Consumption at P Maxi without fan elmax 18 W 32W 47 W 58 W 77 W

Consumption at P Mini without fan elmin 10 W 18 W 22 W 24 W 30 W

Standby consumption elsb 3 W 3 W 3 W 3 W 3 W

Air flow at 15 °C m3/h 3 580 4 250 5 800 7 700 10 000

ATE803S ATE804S ATE805S ATE808S4P ATE808S4PModel of fan

Air temperature increase at maximum power °C 19.9 23.2 21.6 21.4 21.5

Air temperature increase at minimum power °C 11.3 13.2 12.4 12.3 12.4

Acoustic power - Lw (+/- 4 dB) dBa 71.2 79.5 77.5 86.7 83.4

Sound pressure level - Lp (+/- 4 dB) dBa 49.2 57.5 55.5 64.7 61.4

Fumes mass flow at 8% O2 Kg/h 49 68 86 113 148

Available pressure loss air / fumes Pa 120 200 250 300 240

Maximum condensation produced l/h No condensate

* Only available for ATXH

MODELES FHATX25 FHATX35 FHATX45 FHATX60 FHATX80

FHATX Gas heater are equipped with axial or centrifugal fan

and 2-stages gas burner.

FHATXH heaters are available in 5 models from 25 to 80kW

and are intended for horizontal mounting and direct

blowing.

FHATXV heaters are available in 4 models from 35 to 80kW

and are intended for vertical mounting and direct blowing.

FHATXC heaters are available in 4 models from 35 to 80kW

and are intended for horizontal mounting and duct network

blowing.

9

Amm 1 060 1 060 1 060 1 060 1 060

Bmm 800 800 875 875 875

Cmm 495 545 600 710 912

Dmm 72 72 72 72 82

Emm 746 746 746 746 746

Fmm 250 250 250 250 250

Gmm 170 170 170 249 249

Hmm 100 125 153 208 273

Ø Fumes mm 80 80 80 80 100

Ø Air 80 80 80 80 100

Ø Gas ‘’ 3/4 3/4 3/4 3/4 3/4

Weight kg 82 95 108 132 152

2.3 Recommendations for ATXH and ATXV installation

1000 mm

mini

200 mm

mini

2000 mm

mini

200 mm

mini

700 mm

mini

200 mm

mini

500 mm

mini

Hauteur d’installation

1000 mm

mini

Top view

Back view Lateral view

2.2 Dimensions of FHATXH and FHATXV

TYPES FHATX25 FHATX35 FHATX45 FHATX60 FHATX80

Mini/Maxi 4/6 m 5/8 m 6/10 m 6/10 m

TYPES FHATX35V FHATX45V FHATX60V FHATX80V

* Only available for FHATXH

10

2-4 Specific performances of ATXC

2.4 Dimensions of ATXC and accessories

TYPES ATX35C ATX45C ATX60C ATX80C

Model of the fan AT10-10 AT10-10 AT12-12 AT15-15

Supply voltage Single phase 230 V 50 Hz

Air flow at 15 °C m3/h 4 250 5 250 7 000 9 000

Air temperature increase at maximum power °C 23.2 °C 23.9 °C 23.5 °C 23.9 °C

Air temperature increase at minimum power °C 13.2 °C 13.7 °C 13.6 °C 13.8 °C

Noise level at 5m free field dBa

Noise level LwoA dBa 80.9 84.8 84.7 85

TYPES ATX35C ATX45C ATX60C ATX80C

Amm 1 060 1 060 1 060 1 060

Bmm 1460 1460 1530 1560

Cmm 545 600 710 912

Dmm 787 787 787

Fmm 100 100 95 95

Gmm 205 205 205 205

G1 mm 700 700 700 700

G2 mm 485 540 650 853

Rmm 130 130 130 130

R1 mm 630 630 630 630

R2 mm 430 430 530 530

Ø Fumes mm 80 80 80 100

Ø Air 80 80 80 100

Ø Gas ‘’ 3/4 3/4 3/4 3/4

Weight kg 145 200

11

Airflow Available pressure Delta T Motor power dBa (LwoA)

4500 190 22 770 82.0

4250 211 23 720 80.9

4000 226 25 670 80.0

3750 241 26 600 79.0

3500 250 28 540 78.2

3250 259 30 485 77.5

3000 267 33 475 76.8

2750 270 36 400 75.8

2500 271 39 350 75.0

2250 275 44 300 74.4

Airflow Available pressure Delta T Motor power dBa (LwoA)

6000 180 21 1400 87.0

5750 208 22 1330 86.4

5500 226 23 1250 85.8

5250 253 24 1200 84.8

5000 273 25 1050 84.1

4750 289 26 980 83.3

4500 304 28 880 82.2

4250 312 30 820 81.4

4000 326 31 780 80.4

3750 332 33 700 79.4

2.4 Curves pressure/airflow for FHATXC

FHATX35C Heater

It is equipped with a belt driven centrifugal fans AT10-10 (transmission of 90/118) with three-phase

motor of 750 W (Rotation : 1140 rpm). The motor is connected to a frequency converter single-

phase 230V IN and three-phase 230V OUT. The frequency converter allows the protection and the

control of motor speed to reach the requested performances.

Blowing unit performances:

FHATX45C Heater

It is equipped with a belt driven centrifugal fans AT10-10 (transmission of 112/140) with three-

phase motor of 1500 W (Rotation : 1140 rpm). The motor is connected to a frequency converter

single-phase 230V IN and three-phase 230V OUT. The frequency converter allows the protection

and the control of motor speed to reach the requested performances.

Blowing unit performances:

12

Airflow Available pressure Delta T Motor power dBa (LwoA)

8000 175 21 1800 87.0

7750 206 21 1700 86.7

7500 222 22 1600 85.8

7250 238 23 1500 85.0

7000 253 24 1420 84.7

6750 264 24 1340 84.0

6500 274 25 1275 83.5

6250 284 26 1220 82.7

6000 294 27 1140 82.1

5750 298 29 1070 81.6

ATX80C Heater

It is equipped with a belt driven centrifugal fans AT15-15 (transmission of 118/224) with three-phase

motor of 2200 W (Rotation : 745 rpm). The motor is connected to a frequency converter single-phase

230V IN and three-phase 230V OUT. The frequency converter allows the protection and the control of

motor speed to reach the requested performances.

Blowing unit performances:

Airflow Available pressure Delta T Motor power dBa (LwoA)

10500 180 20 2150 88.0

10000 209 21 1950 86.9

9500 228 23 1800 86.0

9000 247 24 1650 85.0

8500 264 25 1500 83.8

8000 277 27 1400 82.9

7500 289 29 1280 81.7

7000 296 31 1150 80.8

6500 302 33 1050 79.8

6000 307 36 900 79.0

2.4 Curves pressure/ariflow for ATXC

ATX60C Heater

It is equipped with a belt driven centrifugal fans AT12-12 (transmission of 112/170) with three-phase

motor of 1500 W (Rotation : 940 rpm). The motor is connected to a frequency converter single-phase

230V IN and three-phase 230V OUT. The frequency converter allows the protection and the control of

motor speed to reach the requested performances.

Caution: over 7 250 m3/h of airflow, the high airflow option with 2.2 kW frequency converter

should be provided. Please consult us.

Blowing unit performances:

13

3– INSTALLATION

3.1 Mounting brackets

The appliances can be fixed on the wall or on the building's structural framework. Before fixing the unit,

make sure of the strength of the support/bracket. It is possible to design its own bracket but preliminary

studies must be realized to ensure the resistance of the structure.

To use the manufacturer brackets, always refer to the notice supplied with the product.

ATXH—Axial heater :

Wall mounting bracket

Upper position

ATX25H to ATX60H

Directional wall-mounted

bracket

Upper position only

ATX25H à ATX60H

Standard brackets

Lower position

ATX80H

ATXV—Vertical heater :

Vertical wall-mounted bracket

FHATX25V to FHATX60V

14

2

1

3

4

3

3.2 Flue pipe connection

Connection of single roof flue kit B22

The combustion air is taken directly into the room and the smoke exhaust is done to the exterior thanks to a

single flue kit through the roof.

The use of roof chimney implies the to take the air combustion from the room where the heater is installed.

Caution : Foresee a sufficient ventilation into the room. The required fresh air for combustion must be at

least of 2 times the power of the unit. Example for a heater of 80 kW/h = 80 x 2 = 160 m3/h.

The tee located on the lower part of the kit allows for possible condensate recovery into the flue pipe and an

access for chimney sweeping.

The flue pipe must be solidly fixed to be stable. The flue pipe cannot solely be held by the unit in any case.

CAUTION

Accumulated losses cannot exceed available losses.

The given losses are made with the accessories we sale or recommend with our range of heaters.

Model of the heater ATX25*ATX35 ATX45 ATX60 ATX80

Diameter of flue pipes 80 mm 80 mm 80 mm 80 mm 100 mm

Fumes mass flow 8 % O2 49 Kg/h 68 Kg/h 86 Kg/h 113 Kg/h 148 Kg/h

Available losses of fumes 120 Pa 200 Pa 250 Pa 300 Pa 240 Pa

Losses of Kit B22 30 Pa 50 Pa 80 Pa 135 Pa 50 Pa

Losses for additional single extension of 1 meter 2 Pa 4 Pa 7 Pa 12 Pa 5 Pa

Losses for additional 90° single elbow 2 Pa 4 Pa 7 Pa 12 Pa 15 Pa

2

1

3

Composition of the kit B22 :

(1) 1 tee with purge and removable cap

(2) 1 single extension to adjust

(3) 1 single roof terminal with flashing

Additional accessories :

Single elbow 90°

Single extension of 1 m

Composition d’un kit B22 :

(1) 1 single elbow 90°

(2) 1 tee with purge and removable cap

(3) 2 single extensions

(4) 1 single roof terminal with flashing

Accessoires complémentaires:

Coude monotube

Longueur d’un mètre

Axial gas heater : Vertical gas heater :

* Only available for ATXH

15

Connection of concentric roof flue kit C32

The combustion air is taken directly into the room and the smoke exhaust is done to the exterior thanks to a

concentric flue kit through the roof.

The use of roof chimney implies the to take the air combustion from the room where the heater is installed.

Caution : The flue pipe must be solidly fixed to be stable. The flue pipe cannot solely be held by the unit in

any case.

It is possible to extend or divert the concentric kit with approved accessories.

The use of flues involves a parfait sealing. To facilitate the installation, it is necessary to use a lubricant, non

-aggressive for the gasket, example: soapy water.

CAUTION

Accumulated losses cannot exceed available losses.

The given losses are made with the accessories we sale or recommend with our range of heaters.

With concentric pipes, accumulate the losses of air combustion intake and smoke exhaust.

1

5

2

34

1

3

4

2

Axial gas heater : Vertical gas heater :

Composition of the kit C32 :

(1) 1 tee with purge and removable cap

(2) 1 single elbow at 90°

(3) 1 single extension to adjust

(4) 1 concentric roof terminal with flashing

Additional accessories :

Concentric elbow

Single elbow

Single extension of 1 meter

Concentric extension of 1 meter

Composition of the kit C32 :

(1) 2 single extensions

(2) 1 tee with purge

(3) 1 single elbow at 90°

(4) 2 single elbows at 45°

(5) 1 concentric roof terminal with flashing

Additional accessories :

Concentric elbow

Single elbow

Single extension of 1 meter

Concentric extension of 1 meter

* Only available for ATXH

Model of the heater FHATX25*FHATX35 FHATX45 FHATX60 FHATX80

Diameter of flue pipes 80 mm 80 mm 80 mm 80 mm 100 mm

Fumes mass flow 8 % O2 49 Kg/h 68 Kg/h 86 Kg/h 113 Kg/h 148 Kg/h

Available losses of air / fumes 120 Pa 200 Pa 250 Pa 300 Pa 240 Pa

Losses of Kit C32 30 Pa 50 Pa 80 Pa 135 Pa 60 Pa

Losses for additional single extension of 1m 2 Pa 4 Pa 7 Pa 12 Pa 5 Pa

Losses for additional concentric extension of 1m 4 Pa 6 Pa 9 Pa 15 Pa 10 Pa

Losses for additional 90° single elbow 8 Pa 15 Pa 25 Pa 40 Pa 15 Pa

Losses for additional 90° concentric elbow 10 Pa 18 Pa 33 Pa 50 Pa 25 Pa

16

Caution : It is possible to extend or divert the concentric kit with approved accessories.

The use of flues involves a parfait sealing. To facilitate the installation, it is necessary to use a lubricant,

non-aggressive for the gasket, example: soapy water.

Connection of concentric wall flue kit C12

The connection for combustion air intake and smoke exhaust is made horizontally towards the outside of the

room.

CAUTION : it is necessary to realized a slope of 2 degrees towards the outside to allow the possible

evacuation of condensate.

CAUTION

Model of the heater ATX25 ATX35 ATX45 ATX60 ATX80

Diameter of flue pipes 80 mm 80 mm 80 mm 80 mm 100 mm

Fumes mass flow 8 % O2 49 Kg/h 68 Kg/h 86 Kg/h 113 Kg/h 148 Kg/h

Available losses of air / fumes 120 Pa 200 Pa 250 Pa 300 Pa 240 Pa

Losses of Kit C32 30 Pa 50 Pa 80 Pa 135 Pa 20 Pa

Losses for additional single extension of 1m 2 Pa 4 Pa 7 Pa 12 Pa 5 Pa

Losses for additional concentric extension of 1m 4 Pa 6 Pa 9 Pa 15 Pa 10 Pa

Losses for additional 90° single elbow 8 Pa 15 Pa 25 Pa 40 Pa 15 Pa

Losses for additional 90° concentric elbow 10 Pa 18 Pa 33 Pa 50 Pa 25 Pa

Accumulated losses cannot exceed available losses.

The given losses are made with the accessories we sale or recommend with our range of heaters.

With concentric pipes, accumulate the losses of air combustion intake and smoke exhaust.

Composition of the kit C12 :

(1) - 1 concentric wall terminal

Additional accessories :

Concentric elbow

Single elbow

Single extension of 1 meter

Concentric extension of 1 meter

For direct concentric wall connection, the installation must be realized with an opposite slope at the

unit of 2° minimum.

1

Axial gas heater :

17

First of all it is necessary to check that the device is in conformity with the type of gas distributed. For this

purpose, you must refer to the indications shown on the identification plate.

The gas supply must be appropriated to the power of the heater and be equipped with all the security and

inspection devices required by current standards.

A precise study must be carried out on the diameters of the piping depending on the type and the flow of

gas and the length of the piping. It is necessary to make sure that pressure drops in the piping do not

exceed 5 % of the supply pressure.

The gas connections must be made in conformity with the recommendations for indoor installations

whatever the type of gas, by qualified personnel holder of necessary approvals.

Check the tightness of gas fittings after each maintenance operation till the gas valve of the heater

Gas connection type:

A- Over 50 mbar natural gas supply

B- Under 50 mbar natural gas supply

C- LPG supply

Composition of heater gas kit*

1– Gas seal (supplied with the heater)

2– Gas connection 3/4-1/2 (supplied with the unit till 45 kW)

3– Gas regulator

4– Gas filter

5– 1/4 turn gas valve

*For more information about component details, refer to the notice given with the gas kit connection.

A

C

B

3.3 Gas connection

18

4– ELECTRICAL WIRING

4.1 Electrical schematics of ATX :

19

12

4

5

9

7

3

8

11

13

14

B5 B6 B4 B2 B3 B1

10 987624314 13 12 11 10 9843

54321121765432132121

Carte RFP21

1

2

1211459

10

6

8

7

13

14

4

3

REF. ARXE532

CODE

TYPE NDM31

TP15s TS 5 s

OPT. Y2 G1

220-240 V 50-60Hz 30 VA

PIN0476CQ0671

EN 298:2012 compliant

4.2 Electrical connections between heater’s components :

1

2

Back side of control board

6

8

20

1

2

3

Heater’s connection :

A : Neutral (blue or grey) - B: Phase (brown) - D: pilot wire (black) - C: Earth ( green/yellow)

4.3 Basic connection schematic with pilot wire thermostats:

1 - Switch disconnector

2 - Unit heaters

3 – Thermostat

- The ATX gas heater is equipped as standard with a receiver for pilot wire, which enables using a single

conductor to carry the functions of the ambient thermostat, the forced ventilation and remote resetting.

- Several models of thermostat (3) are available. The use of these thermostats will provide you with

supplementary functions such as remote resetting and forced ventilation.

The electrical connection of the devices must be in conformity with the regulations in force in the country

concerned.

Caution : 8 gas heaters maximum per 1 thermostat

TFP1ET85P2 TFP2TS TFP3TS

BSAT4P2

This manual suits for next models

9

Table of contents

Popular Gas Heater manuals by other brands

Comfort Glow

Comfort Glow CCL3924NRA owner's manual

Alva

Alva GH312 Training manual

Empire

Empire RH-25-2 Installation instructions and owner's manual

ReddyHeater

ReddyHeater BWH30NLTE-2 OWNER'S OPERATION AND INSTALLATION MANUAL

Allen + Roth

Allen + Roth VFL3-RO24DRL instructions

Desa

Desa Comfort Glow CGN10RL OWNER'S OPERATION AND INSTALLATION MANUAL

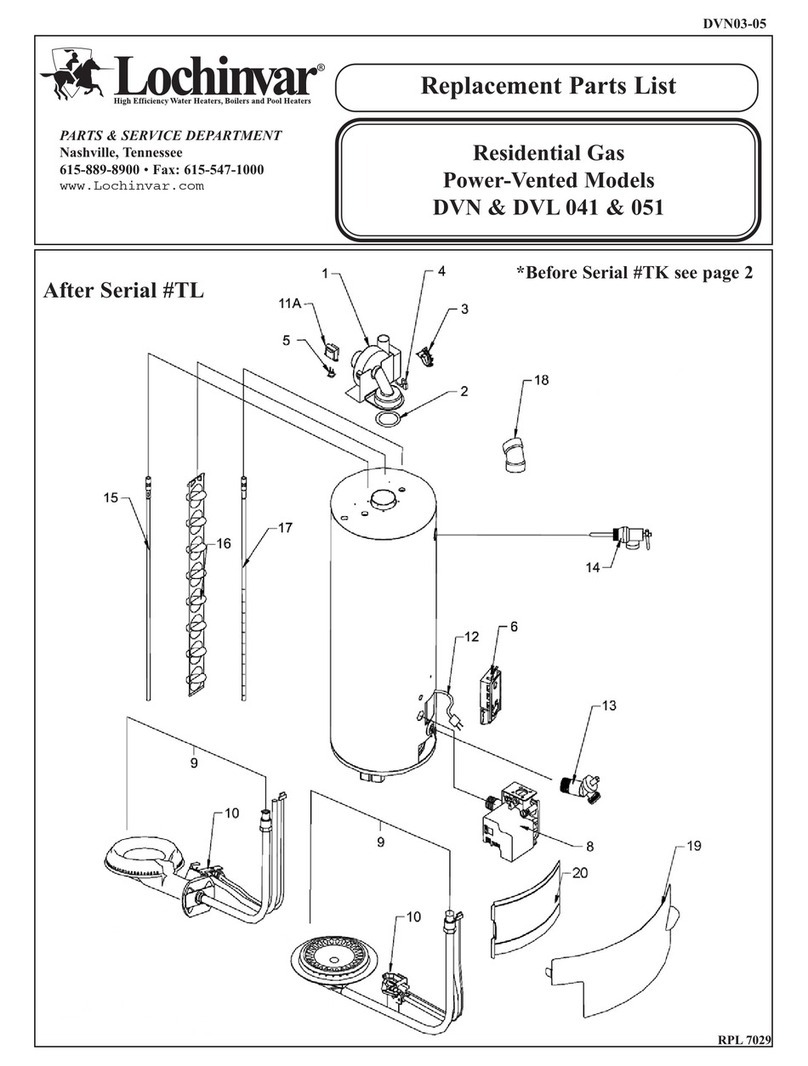

Lochinvar

Lochinvar DVL 041 Replacement parts list

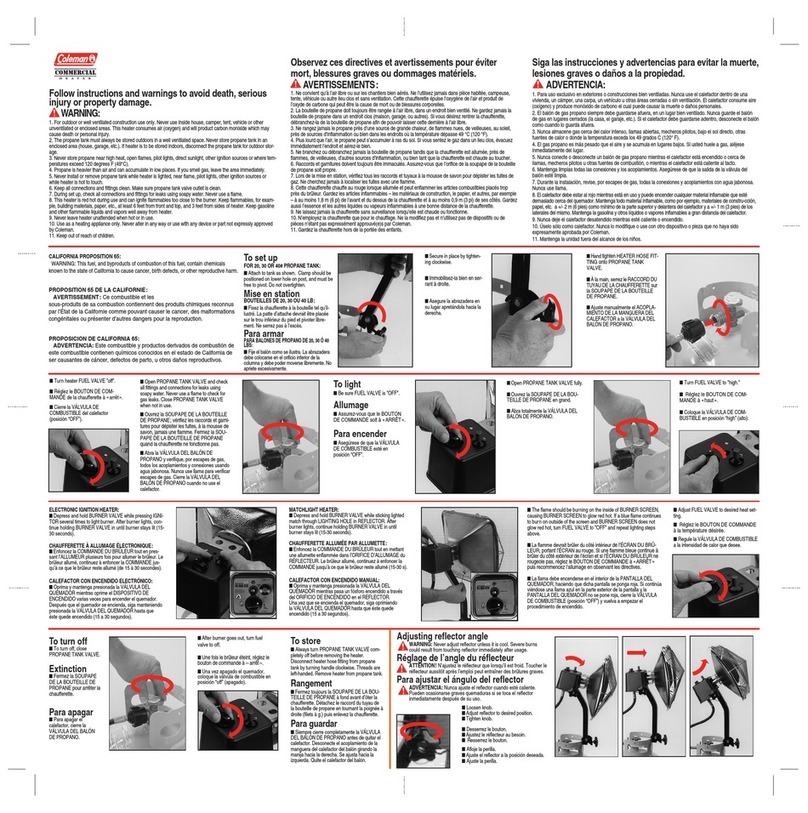

Coleman

Coleman 5035 Instructions for use

Aurora

Aurora IS900 Installation and operating instruction

Nu-Flame

Nu-Flame THE HOTBOX H.E. Use, installation & servicing instructions

HearthStone

HearthStone TUCSON Owner's manual & installation guide

Coleman

Coleman 5045C751 Instructions for use