Flexit C2 User manual

ART. NO.:

700030

700031

700032

700033

C2

114529EN-05

2016-11

Assembly Instructions

Ceiling mounted air handling unit

and automatic control system

INSTALLATION

INSTRUCTIONS

2

This appliance may be used by children of 8 years or

above or by persons with reduced sensory capacity

or reduced physical or mental capacity, or by persons

with lacking experience or knowledge, provided they

have received instructions in the safe use of the

appliance or are supervised to ensure safe use and

providing they are aware of the risks. The product is

not suitable for use by children.

Children must not be allowed to play with the

appliance. Children must not carry out cleaning or

maintenance without supervision.

Our products are subject to continuous development

and we therefore reserve the right to make changes.

We disclaim all liability for printing errors.

See the following documents for more

information on the product:

114531 Spare parts list

114537 Wiring diagram without electric battery

114536 Wiring diagram with electric battery

110827 CI60

110828 CI600

SAFETY INSTRUCTIONS

• It is the installer's responsibility to

carry out a full safety and function

assessment of the appliance.

• To reduce the risk of fire, electric

shock or injury, read all the safety

instructions and warning texts before

using the unit.

• This unit is only designed for

ventilation air in homes and

commercial buildings.

• It must not be used to extract

combustible or flammable gases.

• Remove the power plug before

commencing any service and

maintenance work.

• Before opening the door: switch off

the heat, let the fans continue for

3 minutes to remove hot air, unplug

the unit and wait 2 minutes before

opening the doors.

• If the power cable is damaged, it must

be replaced by the manufacturer,

the manufacturer's service agent or

a similarly qualified person.

• The unit contains heating elements

that must not be touched when they

are hot.

• The unit must not be operated

without the filters being in place.

• Do not heat any combustible

substances under the cooker hood if

one is installed.

• Do not leave a saucepan or frying

pan containing oil or fat unsupervised

when using a cooker hood.

• Warranty claims will only be valid if

the instructions in the manuals have

been followed.

• To maintain a good indoor climate,

comply with regulations and avoid

condensation damage, the unit

must never be stopped except

during service/maintenance or in

connection with an accident.

• All electrical connections must be

carried out by qualified electricians.

• All plumbing work must be carried out

by an authorised plumber.

• The water battery must be located in

a room with a drain.

When servicing ceiling-mounted units, be aware of the

danger of components falling down.

3

Innhold

1 How to read the document....................................................................................................................................... 4

2 Planning and preparation work....................................................................................................................5

2.1 Joiner / fitter ...........................................................................................................................................................................................5

2.2 Plumber (if the unit has a water battery)................................................................................................5

2.3 Electrician...................................................................................................................................................................................................5

3 Installation........................................................................................................................................................................................................ 6

3.1 Mounting the safety strap................................................................................................................................................ 6

3.2 What is supplied?........................................................................................................................................................................... 6

3.3 Ceiling mounting..............................................................................................................................................................................7

3.4 Wall mounting...................................................................................................................................................................................13

3.5 Floor (attic) mounting.........................................................................................................................................................15

4 Duct connection.............................................................................................................................................................................. 16

4.1 Connection to the unit ...................................................................................................................................................... 16

5 Installation of the CI60/600 control panel.................................................................17

5.1 Contents......................................................................................................................................................................................................17

5.2 Installation of the CI60/600...................................................................................................................................17

5.3 Installation with a flush-mounted wall box.......................................................................................18

5.4 Surface mounting..................................................................................................................................................................... 18

5.5 Finishing off – C160................................................................................................................................................................ 18

5.6 Finishing off – C1600.......................................................................................................................................................... 18

6 Electrical work...................................................................................................................................................................................... 19

6.1 Supply air sensor for heating (B1) .................................................................................................................. 19

6.2 Frost sensor for water battery (B5) (if the unit has a water battery).... 19

6.3 Outdoor air damper (if the unit has a water battery)...................................................... 19

7 Plumbing work*.................................................................................................................................................................................. 19

8 Adjustment................................................................................................................................................................................................. 20

8.1 Adjustment with CI60......................................................................................................................................................... 20

8.2 Adjustment......................................................................................................................................................................................... 20

8.3 Adjusting the temperature....................................................................................................................................... 20

8.4 Adjustment with CI600 ................................................................................................................................................... 21

9 Installing the cooker hood...................................................................................................................................22

9.1 Installation of external cooker hood..........................................................................................................23

9.2 Adjusting the cooker hood.......................................................................................................................................23

10 General and system drawings.................................................................................................................24

10.1 System drawing (electric battery)................................................................................................................24

10.2 System drawing (electric battery)..............................................................................................................25

10.3 Nipple location...........................................................................................................................................................................26

11 Technical data...................................................................................................................................................................................27

11.1 Dimensioned drawing......................................................................................................................................................... 28

11.2 Capacity and sound data...........................................................................................................................................29

12 Final checks / Startup..................................................................................................................................................32

12.1 Final checks....................................................................................................................................................................................... 32

12.2 Startup....................................................................................................................................................................................................32

13 CE Declaration of Conformity................................................................................................................... 33

4

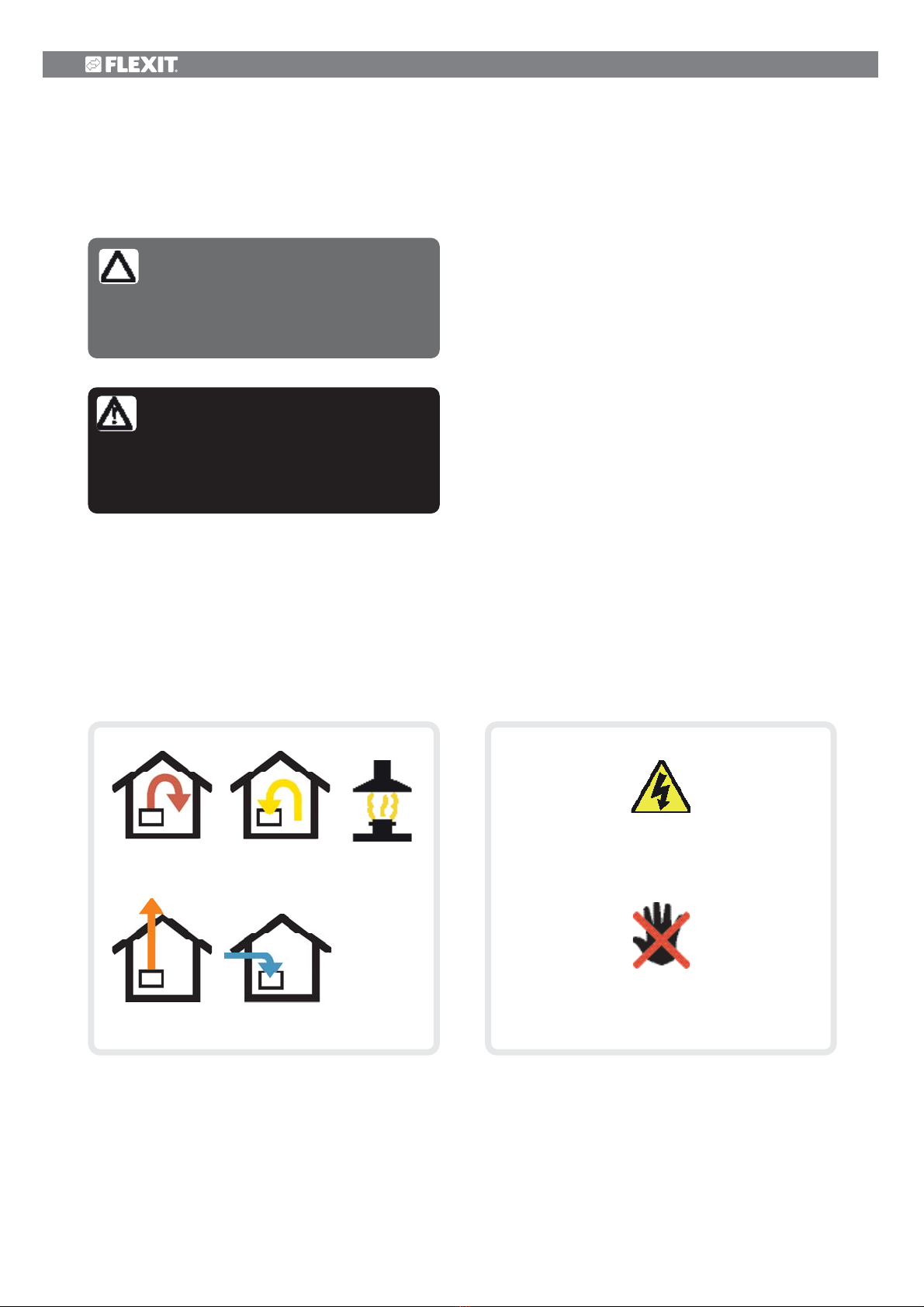

1 How to read the document

DANGER! DO NOT TOUCH

Symbols used

These products have a number of symbols that are used

to label the product itself and in the installation and user

documentation.

Extract air Extract

air from

kitchen

Outdoor air

Supply air

Exhaust air

CAUTION! When a text bears this

symbol, it means that personal

injury or serious damage to the equip-

ment may result if the instructions are

not followed.

NB! When a text bears this sym-

bol, damage to equipment or

poor efficiency may be the consequen-

ce of not following the instructions.

DANGER!

ELECTRICITY

5

2 Planning and preparation work

2.1 Joiner / fitter

Airflow

Check that the air moves from rooms with supply air

valves to rooms with extract air valves.

Kitchen

If a kitchen fan with a motor is included, sufficient

supply air must be ensured. See Chap. 9.1 Installation

of external cooker hood and Chap. 9.2 Adjusting

the cooker hood for more information.

Fireplace

When using a fireplace, sufficient air supply from

a separate supply air point must be ensured.

Location in the building

Location of the unit on an internal wall requires

insulation of the wall, interrupted studs and boards,

and double plasterboard or a wall structure of similar

quality (see Chap. 3.4.1 Positioning requirements).

Suspension of unit

See kap. 3 Installation på side 6.

Access

The unit must have good access for service/

maintenance. See kap. 3 Installation på side 6

for details.

Fire requirements

Any fire safety requirements must be clarified.

Location of heat sources must be coordinated with

extraction valves, so that heat is not sucked straight

out through the valves or door gaps.

2.2 Plumber (if the unit has a water battery)

Water pipe layout and location of the water battery

(duct battery) must be planned. These must be kept

warm to avoid frost damage. A closing damper with

spring must be used. See separate instructions that

accompany the water battery.

2.3 Electrician

Power supply

The units have an approx. 2 m cable with plug and

require a single-phase earthed socket nearby. Plug

requirements: 10 A. We recommend a separate circuit

for the unit. It is important that the plug is accessible

for servicing when the unit is fully installed.

If a cooker hood is to be connected to the ventilation

unit, a minimum Ø16 conduit must be installed for the

two-core signal cable.

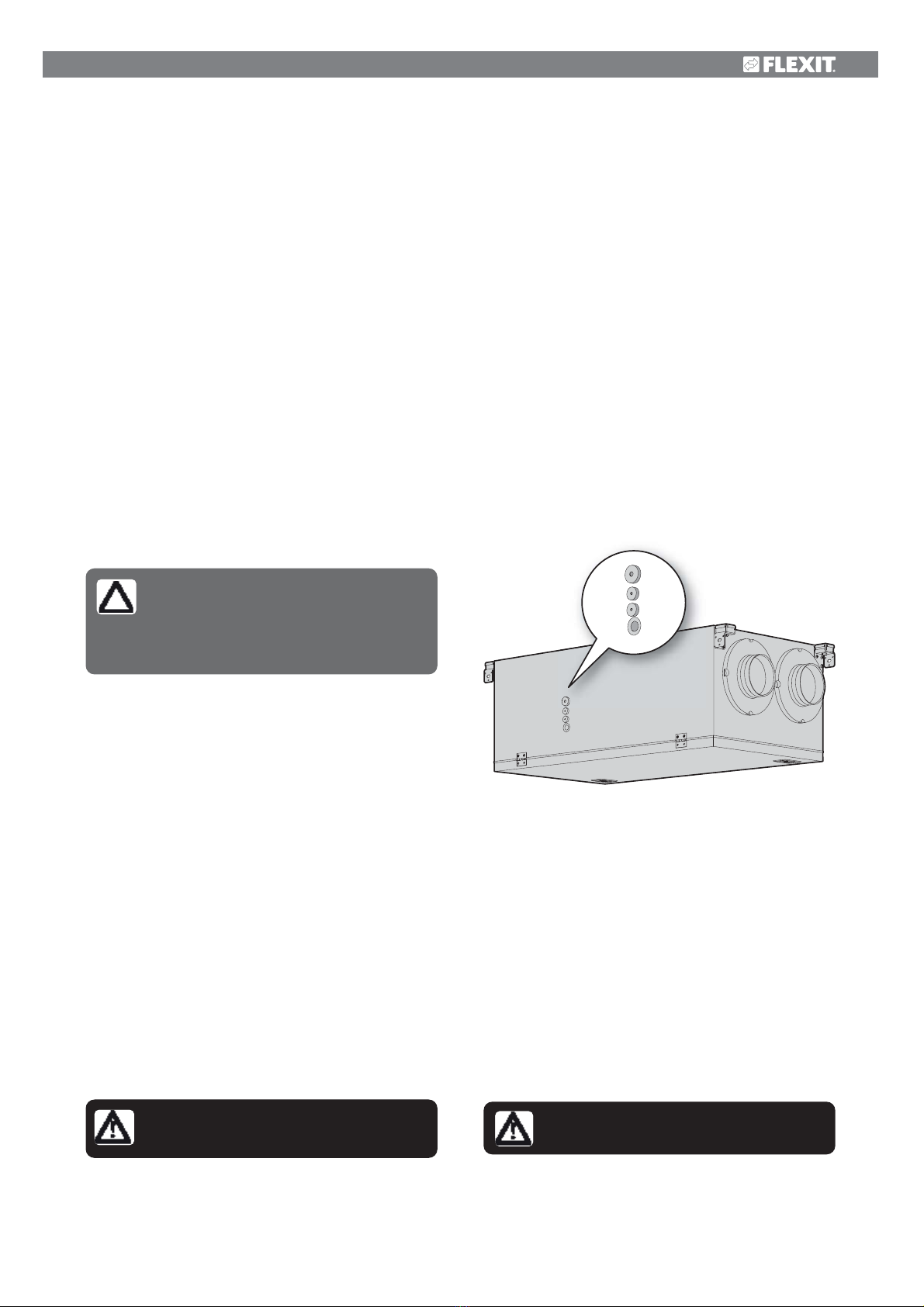

NB!

The PG nipple for the power cable must be tightened

with a torque of 2.0 Nm if the cable is replaced.

For exact positioning of the electrical bushings,

see 11.1 Dimensioned drawing.

The assembly instructions for the

product must be followed.

Wiring for control switches.

Ø20 conduit for running the trailing cable for

controlling the unit should be laid between the

unit and an easily accessible place in the home

(e.g. outside the bathroom) and terminated with

a flush-mounted single wall box. The control switch

is located here. The control cable must be located

min. 30 cm away from any power cables. The control

cable must be max. 24 m to ensure a signal.

Control panel

The control panel is designed for flush mounting over

a single wall box or surface mounting on the wall.

figure 1

Positioning of bushings for

electrical conductors.

The water battery must be

located in a room with a drain.

Positioning must accord with

individual countries' electrical

safety legislation. Check which

rules apply in your country.

6

3 Installation

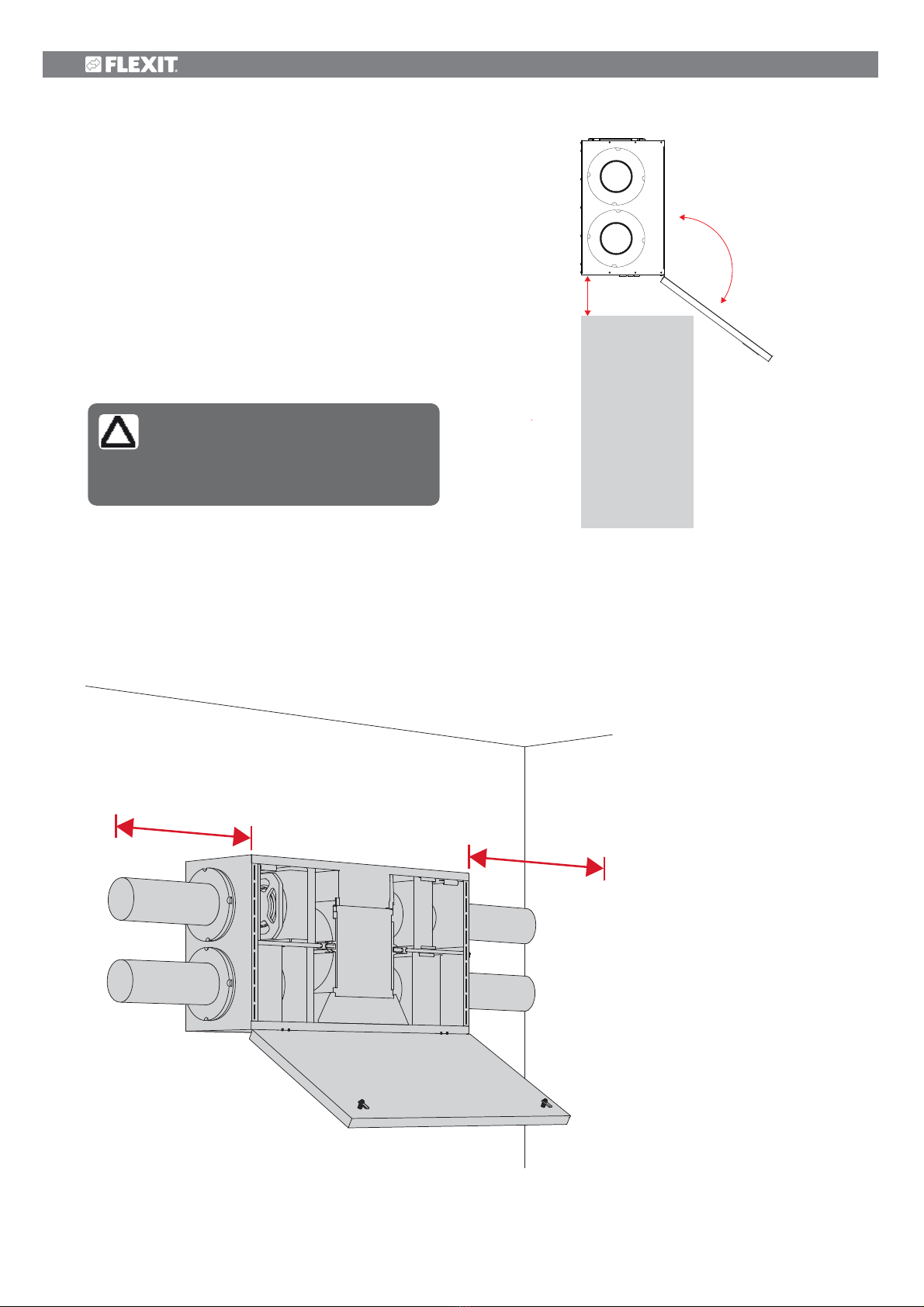

The unit can be installed in the following ways:

• On the ceiling.

• Horizontally on a wall.

Mounting devices for this can be purchased as

an accessory.

• On the floor (lying on its back).

In this case absorption feet are recommended

(available as an accessory).

The unit comes in both a left-hand and a right-hand

version, depending on what is best with regard to duct

positioning.

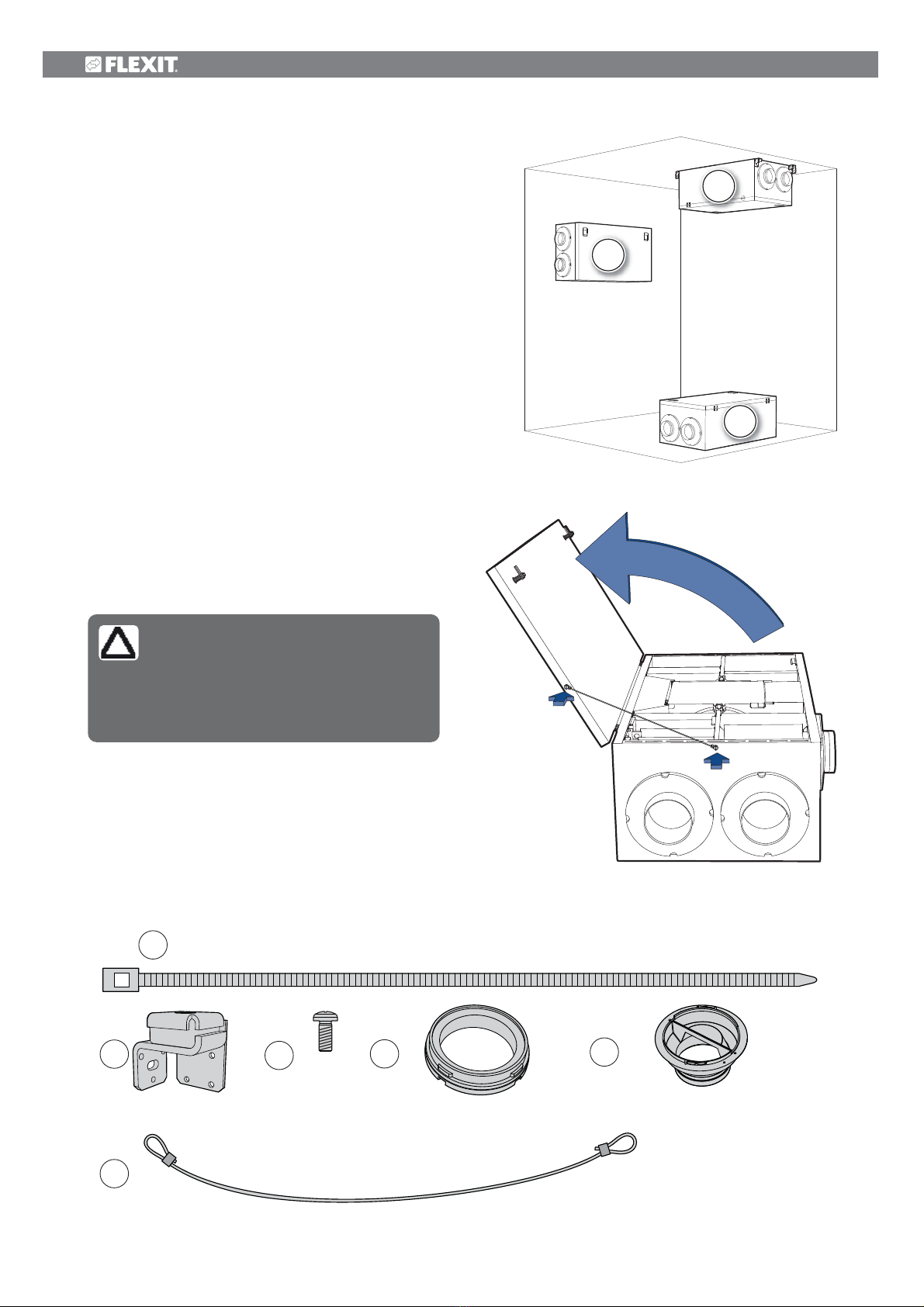

figure 2

Location options

1

2

3

3.1 Mounting the safety strap

Mount the safety strap as shown on figure 3.

figure 3

Fixed safety strap

When the unit is located on the

floor, this strap must always be

mounted.

We also recommend its use for

ceiling mounting.

5x

4x 1x 1x16x

1x

A

BCDE

Ffigure 4

What is supplied?

3.2 What is supplied?

7

3.3 Ceiling mounting

3.3.1

Positioning requirements

The unit is designed to be installed in boiler rooms,

laundry rooms, stores, lofts or other suitable areas.

The unit should be positioned in such a way that there

is no danger of noise nuisance in nearby rooms.

If the unit is located in a warm room where a lot of

moisture is generated, condensation may form on the

outside of the unit during periods when the outside

temperature is low.

The base should be stable and level.

3.3.2

Space requirements

The unit must be installed with suitable space for

servicing and maintenance such as filter replacement

and cleaning of fans and recovery system.

See figure 5. The control cable with plug for

automatic control must be easily accessible when the

unit is fully installed.

These are minimum requirements and only take

service needs into account.

figure 5

Space requirements for ceiling mounting

figure 6

Opening the door in case of ceiling mounting

530mm

400mm

400mm

200mm

*

In the case of mounting in an

enclosure or a suspended ceiling,

remember that the door must be

able to open by 120°.

Ensure there is servicing access

to electrical bushings. See the

dimensioned drawing for exact

location.

Positioning must accord with

individual countries' electrical

safety legislation. Check which

rules apply in your country.

* required

for access to

electrical bushings

8

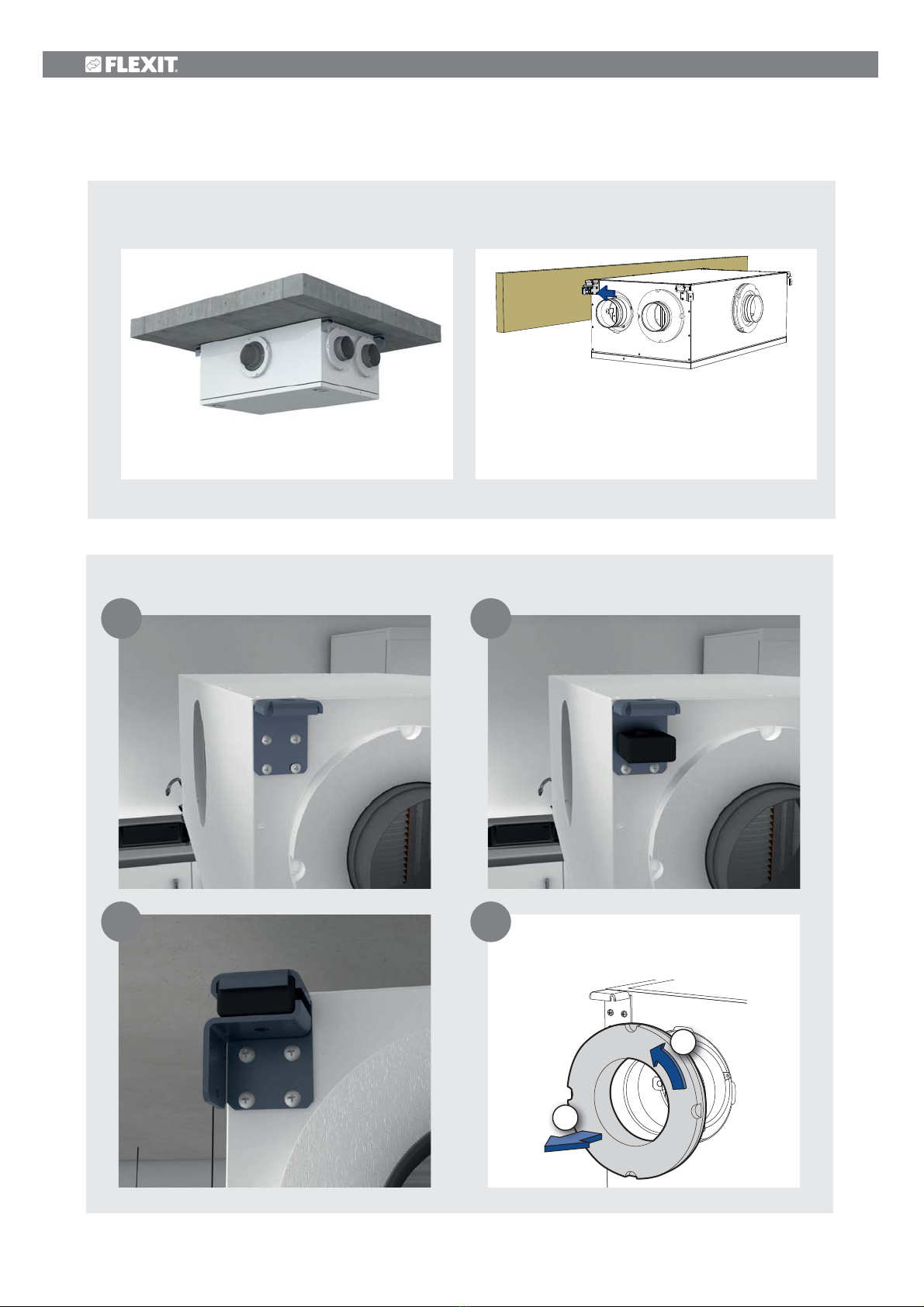

Fixing brackets to be mounted in the same way regardless of top or side mounting

1 2

43

The air handling unit can be mounted in the ceiling in several different ways.

Alternative 1 - Top mounting Alternative 2 - Side mounting

To facilitate access to the fixing bracket,

the polystyrene rings round the bosses

may be removed.

3.3.3

Mounting of fixing bracket

1

2

9

Alternative 1 - Top mounting

3mm

The unit must always

be mounted at

min. 3mm distance

from the mounting

substrate, as shown in

figure 12. This is to

prevent structural

sound.

10

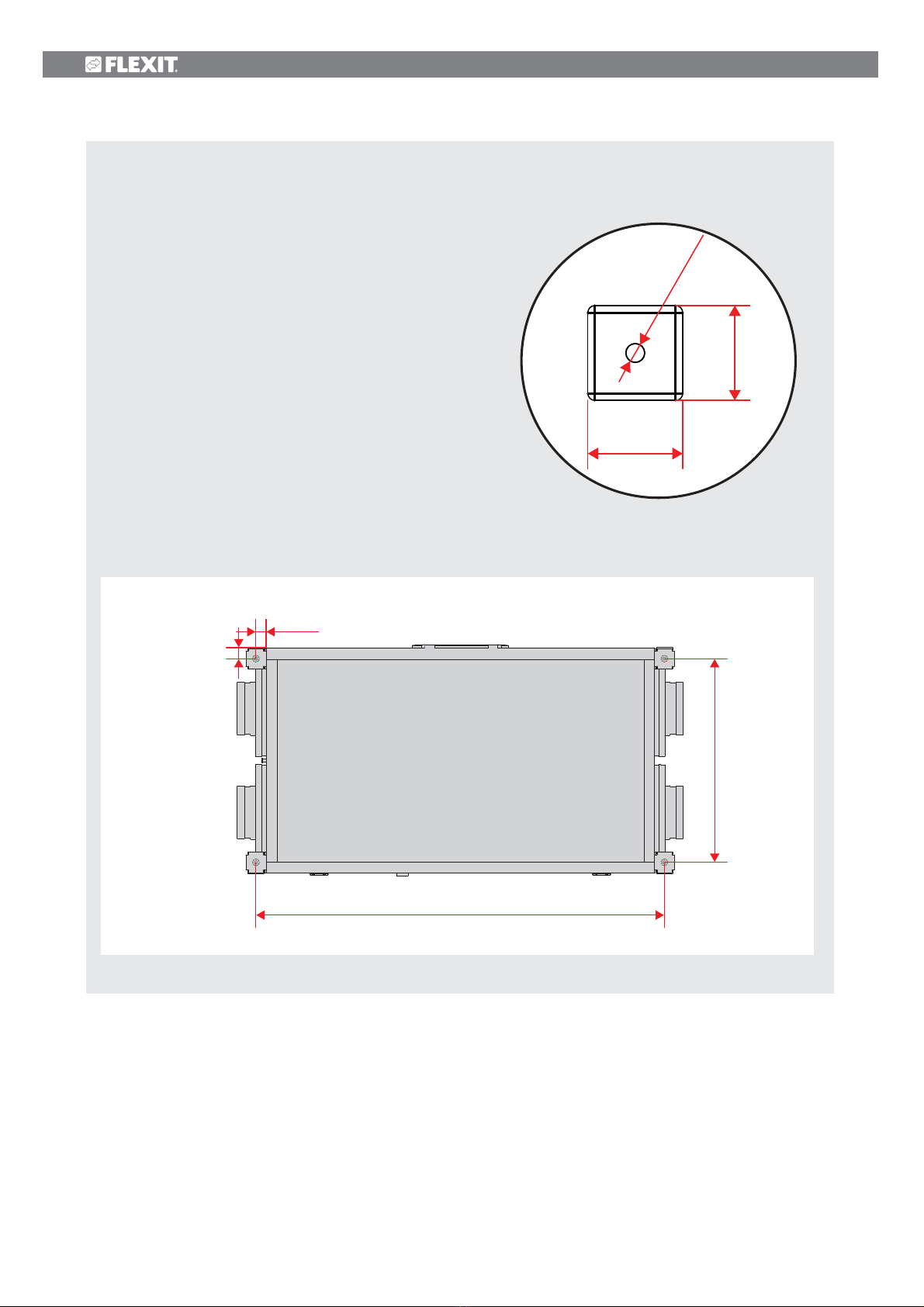

Alternative 1 - Top mounting

If it is necessary to pre-drill your mounting substrate,

the drilling pattern is given here:

Select a suitable fixing device which matches your mounting

substrate.

Remember that the unit weighs 46 kg and the fixing device

must be able to support this.

40 mm

40 mm

Ø8 mm

472mm

947mm

26mm

24mm

figure 7

Hullbilde topp

11

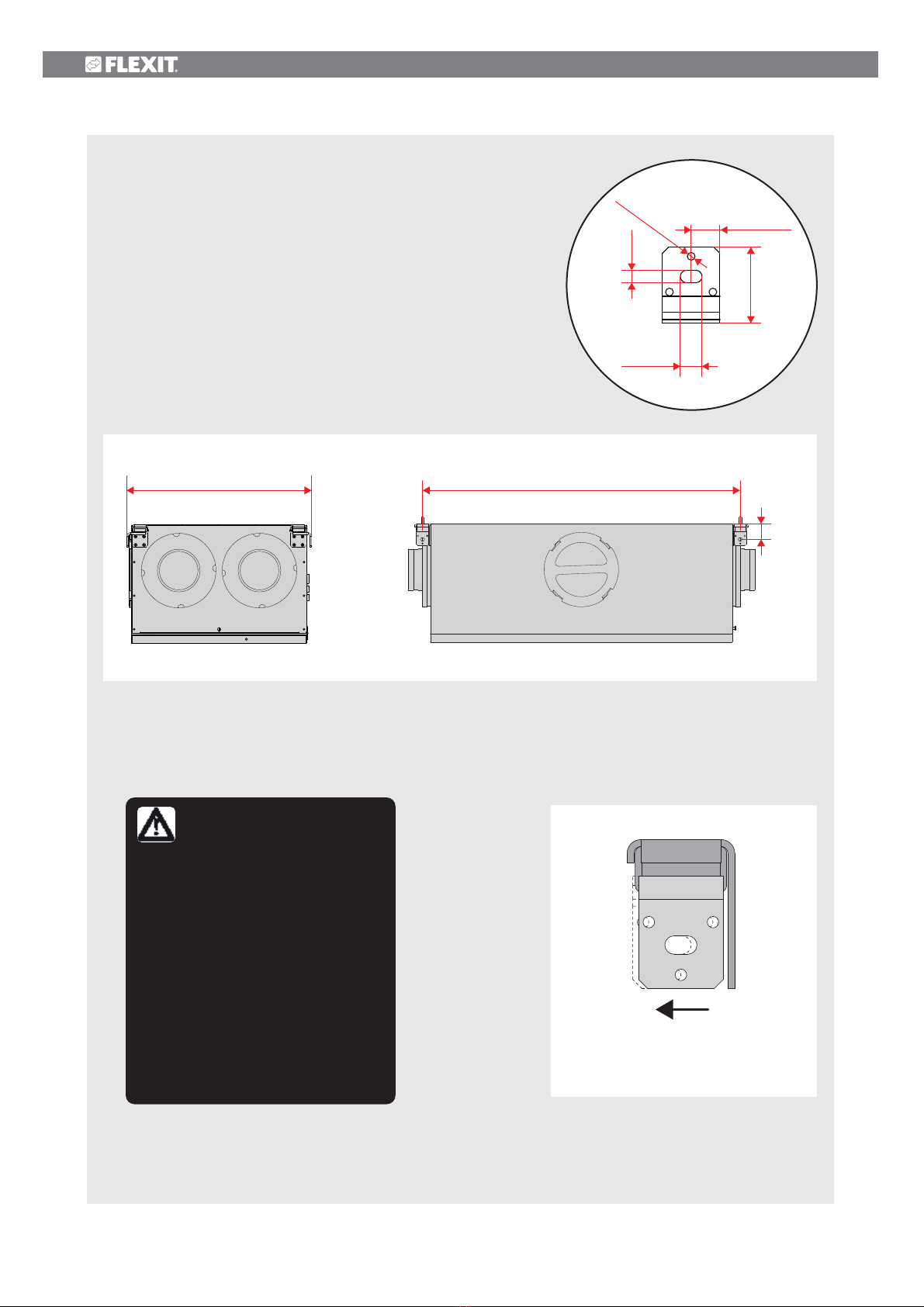

Alternative 2 - Side mounting

12

Alternative 2 - Side mounting

Select a suitable fixing device which matches your mounting substrate.

Remember that the unit weighs 46 kg and the fixing device must be

able to support this.

If it is necessary to pre-drill your mounting substrate, the drilling

pattern for the two mounting alternatives is given here:

figure 8

Hole pattern at side

46 mm

947 mm

524-550 mm

49 mm

8 mm

14 mm

18,5 mm

Ø5 mm

figure 9

Make sure the mounting

substrate only touches

the fixing brackets and

not the unit.

This is to prevent

structural sound.

The fixing bracket can

therefore be adjusted

sideways in both

directions to avoid this.

13

3.4 Wall mounting

3.4.1

Positioning requirements

The unit is designed to be installed in boiler rooms,

laundry rooms, stores, lofts or other suitable areas.

The unit should be positioned against a wall that

has no room on the other side that is sensitive to

noise. The wall should be soundproofed, e.g. with

mineral wool, to reduce the transfer of sound.

Double plasterboard on the wall, interrupted studs

and interrupted plasterboard are recommended.

See figure 10.

If the unit is located in a warm room where a lot of

moisture is generated, condensation may form on the

outside of the unit during periods when the outside

temperature is low.

The base should be stable and level.

BOILER ROOM

BOILER ROOM

LIVING ROOMS

LIVING ROOMS

suitable

insulation

figure 10

Recommended wall construction

figure 11

Recommended direction

See separate instructions

for mounting the wall fixing.

Positioning must accord with

individual countries' electrical

safety legislation. Check which

rules apply in your country.

Mounting devices for this can be

purchased as an accessory.

14

figure 12

Space requirements for wall

mounting

figure 13

Space requirements for wall mounting

400mm

400mm

Ensure there is servicing access

to electrical bushings. See the

dimensioned drawing for exact

location.

* required

for access to

electrical bushings

200 mm*

min 90°

3.4.2

Space requirements

The unit must be installed with space for servicing and

maintenance such as filter replacement and cleaning

of fans and rotary heat exchangers. The control

cable with plug for automatic control must be easily

accessible when the unit is fully installed.

These are minimum requirements and only

take service needs into account.

15

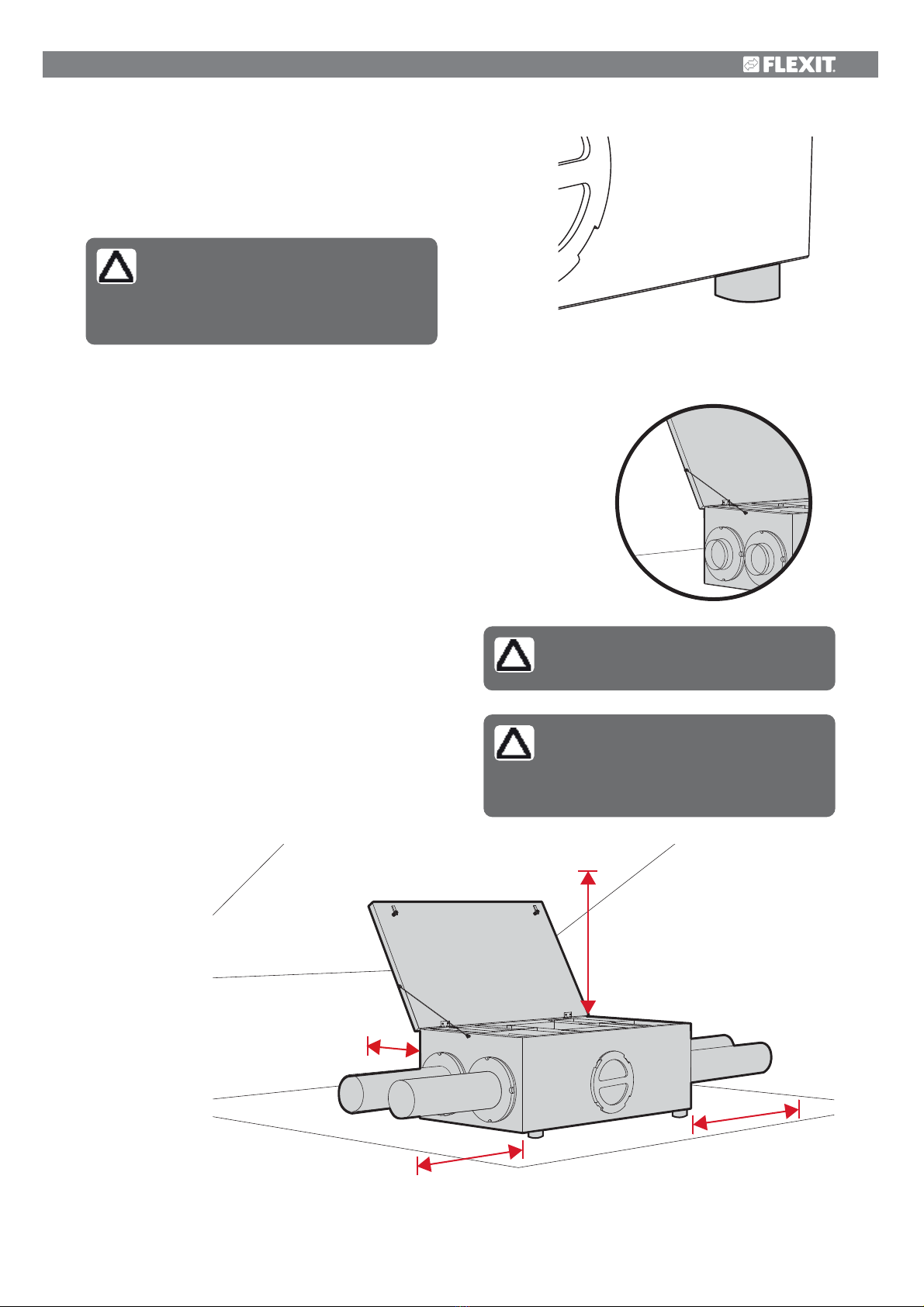

3.5 Floor (attic) mounting

3.5.1

Positioning requirements

The unit is designed to be installed in boiler rooms,

laundry rooms, stores, lofts or other suitable areas.

When installing on the ceiling, absorption feet should

be used, for the sake of noise and vibrations. Flexit

offers suitable absorption feet as accessories, see

figure 15. The unit should be positioned in such a way

that there is no danger of noise nuisance in nearby

rooms. It is especially important not to position the

unit directly above bedrooms.

If the unit is located in a warm room where a lot of

moisture is generated, condensation may form on the

outside of the unit during periods when the outside

temperature is low.

3.5.2

Space requirements

The unit must be installed with space for servicing and

maintenance such as filter replacement and cleaning

of fans and rotary heat exchangers. The control

cable with plug for automatic control must be easily

accessible when the unit is fully installed.

The base should be stable and level.

These are minimum requirements and only

take service needs into account.

figure 14

Space requirements for ceiling (floor) mounting

figure 15

Absorption feet

530mm

200mm*

400mm

400mm

Floor-mounted units must always

be fitted with a safety strap.

Ensure there is servicing access

to electrical bushings. See the

dimensioned drawing for exact

location.

Positioning must accord with

individual countries' electrical

safety legislation. Check which

rules apply in your country.

* required

for access to

electrical bushings

16

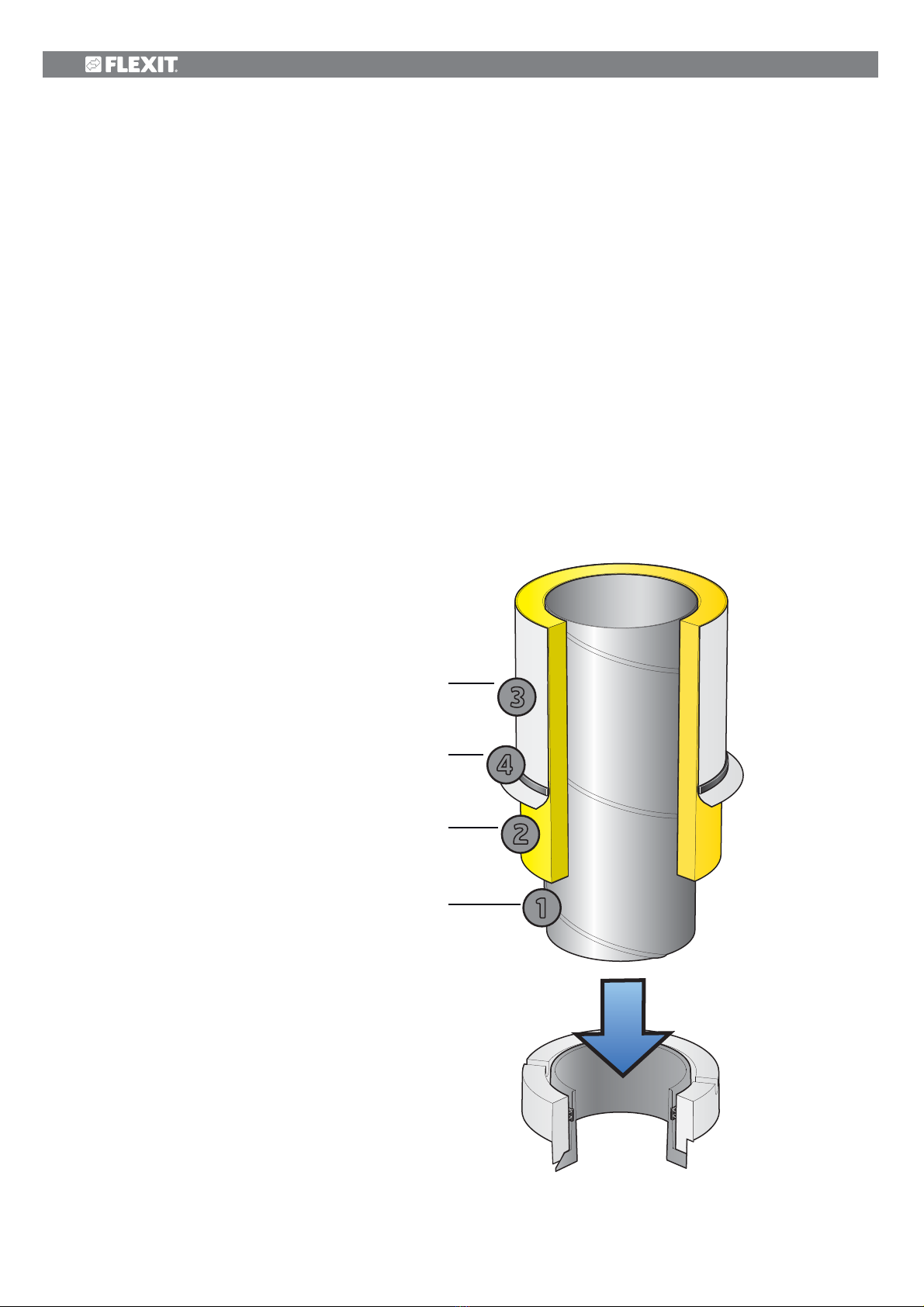

4 Duct connection

4.1 Connection to the unit

See figure 16.

Ensure that the ducts are fitted to the correct nipple -

see the markings on top of the unit and kap. 10

General and system drawings på side 24

Pull the duct insulation well up to the unit.

To avoid the formation of condensation, it is

particularly important for the outdoor and exhaust air

ducts to have insulation and a plastic sleeve pulled

right down to the unit. Seal the plastic sleeve against

the unit with ties.

All ducts that pass through a cold zone must be

insulated.

The ducts normally require min. 50 mm insulation, with

an efficiency corresponding to Ȝ 0.035 W/m.°C or

The duct insulation with plastic jacket is

pulled right down to the polystyrene around

the nipple. It is very important that there are

no gap between the duct insulation and the

polystyrene, as this could lead to condensation

and/or the formation of ice.

Pull the spiral pipe well down over the seal on

the nipple.

The plastic sleeve is pulled right down to the unit.

Fix the sleeve with ties.

figure 16

Duct connection

3

4

2

1

better.

The project engineer is responsible for use of the

required insulation and vapour-proof sleeves in

accordance with location/temperature.

Lay the outdoor air duct with a slight fall towards the

outdoor air cap so that any water that enters drains

out again.

Ducts should have good sound insulation, particularly

above the unit.

17

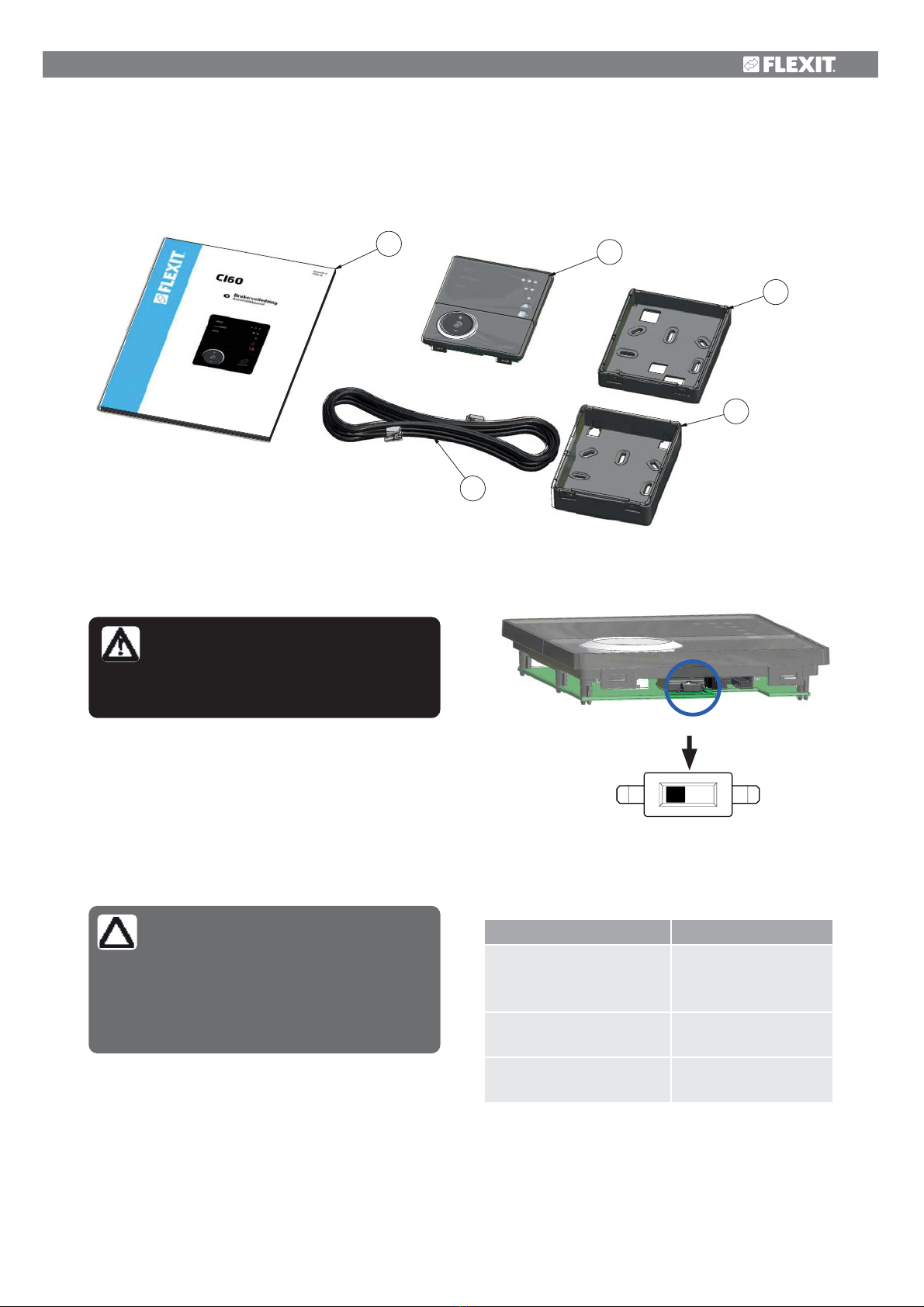

The control units must be

connected to the unit before

power is connected to the unit in

order to ensure communication.

The low-voltage cable must be at

least 30 cm from power cables

and not exceed 24 m in length.

In the case of flush mounting the

cable is run in a 20 mm wiring

conduit.

Configuration Setting

CI 600 (MASTER)

CI60 1 (SLAVE)

CI60 2 (SLAVE)

Automatic

OFF

ON

CI60 1 (MASTER)

CI60 2 (SLAVE)

OFF

ON

CI 600 (MASTER)

CI60 (SLAVE)

Automatic

Any

5.2 Installation of the CI60/600

Run the cable for the control panel between the

ventilation unit and the control panel. The control

panel is designed for flush mounting over a single wall

box (use low backpiece (2)) or for surface mounting

on the wall (use high backpiecee (3)).

The cable clicks into the contact on the control panel

from the back and into the contact on the top of the

ventilation unit.

It is possible to connect two CI60 panels and one CI600

panel to each unit. If several CI60 panels are used,

each panel must have a separate identity. This can be

selected by means of a switch on the panel's circuit

board, see figure 18. Use relevant settings from the

table. The panels can be connected in series in any way.

OFF = MASTER

ON = SLAVE

1

2

3

4

5

5 Installation of the CI60/600 control panel

5.1 Contents

ON OFF

Control panel

Backplate for flush mounting

Backplate for surface mounting

Installation instructions

Cable for control panel

figure 17

Contents control panel

figure 18

Switch circuit board

18

5.3 Installation with a flush-mounted wall box

Run the cable between the wall box and the ventilation

unit in the pre-installed wiring conduit. Fit the backplate

(2) over the wall box and click the cable in straight

from the back as shown in the illustration,

see figure 19.

5.4 Surface mounting

Run the cable between the backplate (3) and the

ventilation unit. Cut out the most suitable perforation

in the corner of the backplate. Secure the backplate

to the wall with suitable screws. Click the cable into the

control panel from below where there is a socket in

the circuit board, see figure 22.

5.5 Finishing off – C160

Slide the panel off in the direction of arrow no. 1, see

figure 20, and guide the control panel straight into

the backplate, in the direction of arrow no. 2 see

figure 21, until it clicks into place. Slide the panel back

on.

5.6 Finishing off – C1600

Guide the control panel over the hooks in the backplate,

in the direction of arrow no. 1 and click the panel into

place at its lower edge in the direction of arrow no. 2

see figure 23.

figure 19

Installation of flush-mounted wall box

1

1

1

1

2

2

2

2

figure 20

figure 21

figure 22

Surface mounting

figure 23

Finishing off

19

The plug for the unit must not be

boxed in.

Temperature sensor B1 must be

positioned after the water

battery

The control cable must be max.

24 m long. It must be at least

30 cm from power cables and

should be laid in a 20 mm wiring

conduit at installation.

The unit must be installed with

a separate earth fault breaker.

All electrical connections must

be carried out by qualified

electricians.

6 Electrical work

The unit is supplied with a 2 m cable with plug.

The cable exits the long side of the unit and is

connected to a 230 V 50 Hz single-phase earthed

power point that is placed in an easily accessible

position close by. The power plug should be used as

the service switch. See kap. 11 Technical data på

side 27 for fuse sizes.

The control panel is designed for flush mounting over

a single wall box or for surface mounting on the wall.

The unit has a control cable (with joint) that is

intended for the control panel. It is important that

this plug is easily accessible afterwards for possible

faults, or when changing the unit. The control cable is

enclosed in the packaging for the control panel.

The control panel is in a box in the unit's packaging.

The low-voltage cable must be run between the unit

and the switch unit. See kap. 5 Installation of the

CI60/600 control panel på side 17.

6.1 Supply air sensor for heating (B1)

This must be located in the supply air duct.

• Where electric heating is retrofitted,

the supply air sensor must be

mounted in the supply air nipple.

• When mounting a water battery,

the supply air sensor must be

positioned approx. 1 m from the water battery.

Roll out the marked coil of cable on the unit near

the supply air nipple. Drill a Ø 7 mm hole in the

duct where the sensor can be inserted. Seal the

hole with sealant and tape the cable in place on

the outside of the duct so that it stays in place.

See the wiring diagram enclosed with the unit

and the instructions that come with the water

battery.

6.2 Frost sensor for water battery (B5)

(if the unit has a water battery)

To avoid frost in the battery, a water battery sensor

(B5) must be installed in the water battery pipe where

the cold water leaves the battery.

For more information, see instructions for water

battery.

6.3 Outdoor air damper (if the unit has

a water battery)

To avoid frost damage to the water battery during

outages/power cuts, a closing damper must be

installed on the outdoor air duct. The damper motor

must have a spring so that it closes when power is

disconnected.

7 Plumbing work*

*If the unit is designed for heating with a water battery.

All plumbing work must be carried out by an

authorised plumber. See instructions for water battery.

20

The unit's air supply MUST be

adjusted before the unit is used

for the first time. This should be

done in accordance with the

project engineering documents.

Adjust the values according to

the projected values.

figure 24

Adjustment

8 Adjustment

8.1 Adjustment with CI60

8.2 Adjustment

Only stage 2 (NORMAL) needs to be adjusted. Stages

1 and 3 have fixed settings, while stage 2 must be

adjusted as required in the individual home.

The function of the different stages:

MIN Must not be used when the home is in

use. Must not be used in the first year of

operation.

NORMAL Used under normal conditions. With this

setting, the air supply must be adjusted

according to current regulations.

MAX Used if there is a need for increased air

supply on account of higher occupancy

or a raised humidity level, for example

during showering or when clothes are

being dried. This setting is normally used

for limited periods.

The ventilation unit's air supply is adjusted at speed

level NORMAL, using the knobs on the back of the

cover. Knob 9 is used for supply air level and knob 8

for extract air level, see figure 24. The adjustment

range is 20-100% of the maximum level according to

the scale on the knob.

Factory settings for supply air/extract air:

MIN 50% (fixed)

NORMAL 75% (variable)

MAX 100% (fixed)

8.3 Adjusting the temperature

The temperature required for the supply air can be

set with knob 11. The adjustment range is 10-30°C.

It should normally be set to around 18°C. Use of the

factory setting is recommended.

8

9

10 11

If necessary, the ventilation unit's additional heating

can also be switched ON/OFF with switch 10. In this

case only the rotary heat exchanger is used as a

source of heat. It is best to leave it in ON position,

as the unit will then respond automatically when there

is a need for additional heating.

Other manuals for C2

1

This manual suits for next models

4

Table of contents

Popular Air Cleaner manuals by other brands

Honeywell

Honeywell QUIETCLEAN HFD230 Series owner's manual

Sharper Image

Sharper Image 203182 user guide

Sundstrom

Sundstrom SR 99 quick start guide

cecotec

cecotec TOTALPURE CONNECTED 2500 instruction manual

Breville

Breville BAP009X Instructions for use

Periso

Periso SOLS Propacare JoyBion 400 User manual and maintenance