FlexLink X45 Operator's manual

Created by EBCCW 96:05Created by EBCCW 00:06Created by EBCCW 96:05Created by EBCCW 00:06

Conveyor system X45

C

r

eated by EBCCW 00:06

5113196-3

User Documentation

Created by EBCCW 96:05Created by EBCCW 00:06

Created by EBCCW 96:05Created by EBCCW 00:06Created by EBCCW 96:05Created by EBCCW 00:06

Conveyor system X45

C

r

eated by EBCCW 00:06

5113196-3

Created by EBCCW 96:05Created by EBCCW 00:06

Created by EBCCW 00:06

Conveyor system X45

5113196-3

© Flexlink AB 2010

All Rights Reserved

No part of this program and manual may be used, reproduced, stored or

transmitted in any form or by any means without the written permission of

FlexLinkComponentsAB.Thecontentsofthismanualareforinformational

use only. All information and specifications contained in this document

have been carefully checked to the best efforts of FlexLink Components

AB, and are believed to be true and accurate as of time of publishing.

However, due to continued efforts in product development FlexLink

Components AB reserves the right to modify products and its manuals

without notice.

FlexLink Components AB assumes no responsibility or liability on any

errors or inaccuracies in this program or documentation. Any kind of

material damages or other indirect consequences resulting from any

FlexLink Components AB´s product part, documentation discrepancies

and errors or non-anticipated program behavior are limited to the value of

appropriate products purchased from FlexLink Components AB. The

products are delivered to thecustomer at the ’as is’ state and revisionlevel

they are on the moment of purchasing, and are declared in detail in the

license agreements between FlexLink Components AB and user. User

accepts and is obliged to follow the guidelines stated in the separate

license agreement needed in using any parts of this product package.

User Documentation

5113196-3

Preface

Created by EBCCW 00:06

1

5113196-3

Preface

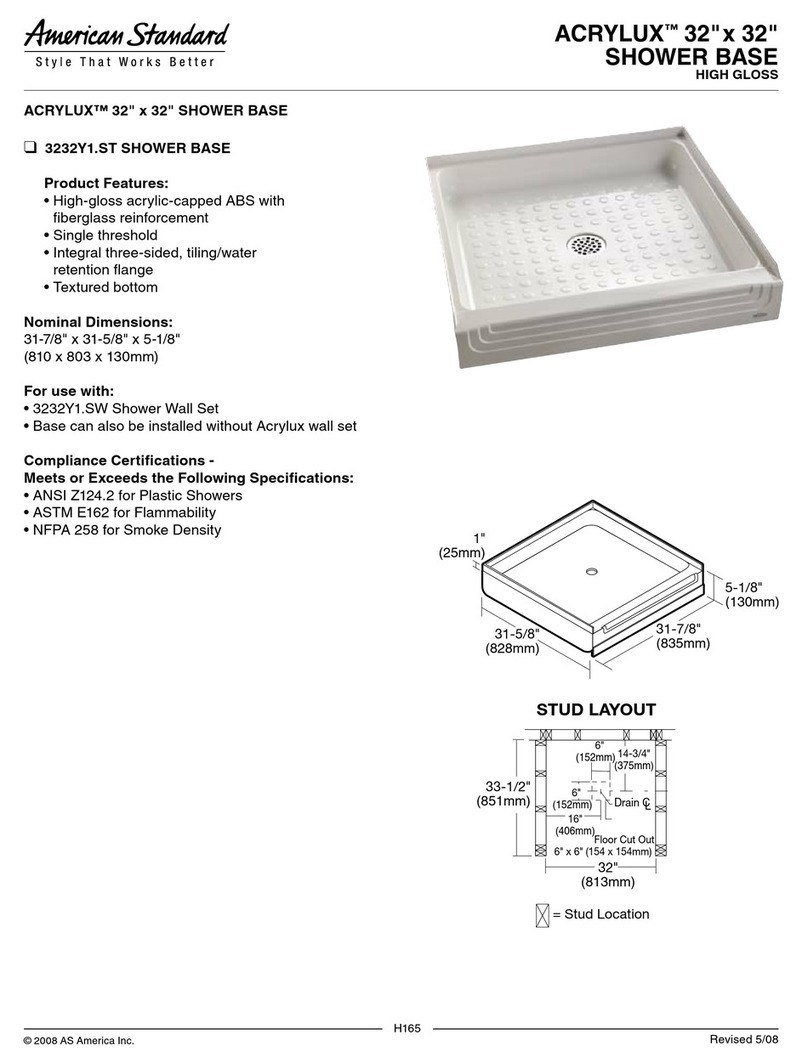

Purpose of this manual

The purpose of this manual is to describe a number of operations that are

intended for the user concerned. Here it becomes clear how the user can

work as well and as safely as possible. By making use of clear illustrations

and texts FlexLink wants to achieve a simple and safe way of working with

the X45 system. This document contains remarks that point out a risky or

specific situation to the user. In many cases this situation is provided with

one of the symbols given below.

Compliance with the operations described in this document is important in

ordertopreventdangeroussituationsandunnecessarydamagetothe X45

system.Carefullykeepthisdocument!It isrecommendedtokeeponecopy

near the conveyor system and one copy with your technical documenta-

tion.

Structure of the manual

The user’s manual has been composed in such a way, that a number of op-

erations can quickly and easily be found. This manual will not describe op-

erations that are notmeant for the user. It does, however, indicate what the

user must do when carrying out a certain operation, for example calling in

technical staff. FlexLink would like to point out to the user that section 1

Safety is to be read carefully.

.

General warning for danger!

.

Warning for electrical voltage!

.

Attention, this is an important notice!

Preface

25113196-3

Requirements of the user

The X45 Conveyor system must be operated by any adult person who has

become acquaintedwith section 1 Safety. If the user is not technically qual-

ified, he or she may not carry out any maintenance or repair activities on

the system.

. Note! Maintenance activities on the system may only be carried

out by a technically qualified person.

. NB: Technically qualified employees means: employees that

have followed an adequate training for carrying out the activities

involved and have a good ability to read and understand the

English language.

Safety

Created by EBCCW 00:06

3

5113196-3

1 Safety

The X45 conveyor system has been designed in such a way, that it can be

used and maintained in a safe way. This holds for the application, the cir-

cumstances and the instructions described in the manual. Any person

working with or on this system should study the manual and follow the in-

structions. It is the responsibility of the employer to make sure that the em-

ployee is familiar with and follows these instructions.

The company or the country in which the system is used may require extra

safety measures. This particularly applies to the working conditions. This

manual does not describe how these are to be complied with. In case of

doubt, consult your government or safety officer!

1.1 System information

The project number and/or general drawing number shall always be spec-

ified when communicating with FlexLink with respect to the module.

Figure 1 Module nameplate

The modules nameplate is located on the module nearthe electrical motor

for the drive unit.

Project number See module nameplate

Supplier FlexLink Systems Polska Sp z o.o.o

Module type: See module nameplate

Date of manufacture See module nameplate

Identification. no. See module nameplate

Safety

45113196-3

1.2 The most important safety conditions

At the moment that the X45 system is going to be operated by a user, the

following safety conditions must be met:

• Only persons who have read and understood the operating in-

structions are allowed to operate, maintain and clean the system.

• Provide good ambient lighting to enable the operator to work well

and orderly with the system.

1.2.1 General

. • Incorrect use of the equipment can cause personal injury.

• Do not wear clothing or other articles that can fasten.

• Follow the instructions in this user manual when transporting the

machine. FlexLink Components AB must approve all modifica-

tions or changes to this system.

• Only use recommended spare parts.

• Only authorised personnel may open electrical units.

• FlexLink is not responsible for damage if service on the equip-

ment is not performed in accordance with this user manual.

1.2.2 Service technicians

. Service technicians must have:

• Sufficient knowledge for reading technical information

• Ability to comprehend technical drawings

• Basic knowledge of mechanics

• Sufficient knowledge in the use of hand tools

Safety

Created by EBCCW 00:06

5

5113196-3

1.2.3 Electricians

. Electricians must have:

• Experience from similar installations

• Sufficient knowledge to work from drawings and wiring diagrams

• Knowledge of local safety regulations for electrical power and au-

tomation

To avoid risks, only experienced personnel with technical knowledge and

experience may perform repair work on the electronics components.

1.2.4 Operators

. To correctly use the equipment, operators must have appropriate training

and/or experience.

Safety

65113196-3

1.3 Description of safety provisions

Before putting the system into operation some safety provisions are to be

taken care of. The purpose of these safety provisions isto protect the user,

theproductandthesystemagainstundesiredsituations(damage).Without

these safety provisions FlexLink cannot give a guarantee on any damage

caused in absence of these safety provisions.

The table below gives a general description of the safety provisions re-

quired. Here it should be noted that only technically qualified employees

are allowed to work on the settings of the safety provisions!

Control Remark

Emergency stop switch It is recommended that the X45 conveyor system should be provided with

one or more emergency stop switches that can be operated within reach

of the user.

The switch must have the standard red colour.

Motor protection Should the motor be overloaded for certain reasons, this should be

detected. Without this protection there is a chance that the Motor or other

components of the X45 system will be damaged.

Safety

Created by EBCCW 00:06

7

5113196-3

. . . 1.3.1 Noise level

. The noise level produced by the X45 conveyor system is under 65 dB(A).

1.3.2 Electrical cabinet

. Ensure that the electrical cabinet is closed and locked after working in the

electrical cabinet.

Never bypass the safety system.

Before working in the electrical cabinet, the main switch to the motor must

be turned off and locked. The key is retained by the service technician until

work is finished.

Examples of service work include:

• Disconnection of wiring

• Replacement of motors, etc.

• Service work in the electrical cabinet, terminal boxes, etc.

• Service work performed on the machine that cannot be seen from

the electrical cabinet.

For adjustment of photo-electric cells, inductive sensors, etc., power is re-

quired:

- Stop the system andwait until the moving parts have come to

a complete stop.

Safety

85113196-3

1.4 Safety measures to be taken

For a safe operation of the conveyor system a number of safety measures

are to be taken. These include the following measures:

•Clean floor surface - With a clean floor surface the operator will

not be hindered while operating the system. This can prevent trip-

ping or slipping, so that the operator doesnot unexpectedly come

into contact with the system.

Technical specification

Created by EBCCW 00:06

9

5113196-3

2 Technical specification

2.1 Technical characteristics X45

Beam width 45 mm

Chain width 43 mm

Chain pitch 12,7 mm

Drive unit capacity 100- 200 N

Chain tension limit 100-200 N

Item width 10-100 mm

Maximum conveyor length 6 m

Maximum weight on conveyor 30 kg

Maximum load per 100 mm conveyor length (see picture below) 800 g (100 g/ link)

Maximum single item weight, horizontal transport (see picture

below)

800 g

Conveyor speed 5-20 m/min

Horizontal bends: 30°/45°/90°/180°

Radius 150 mm

Note! Maximum 2 bends/conveyor

Vertical bends: 5°/15°

Radius 400 mm

Note! 2 bends/conveyor

Electrostatic discharge feature (ESD) Standard/conductive

Max permissible puck weight

Example:

Max

100 g/ link

>= 100 mm (8 links)

Max permissible single item weight 800 g

Puck Ø 43,7

Max 250 g/ puck

Max permissible

(base, fixture, product)

product weight 200 g

Technical specification

10 5113196-3

2.2 Operating conditions

The circumstances under which the X45 conveyor system can be applied

partly depend on the materials selected. FlexLink has defined a number of

parameters within which the system would be allowed to function. Should

the system still be applied beyond these limiting values, FlexLink cannot

guarantee the good functioning of it.

Ambient temperature (in operation) -20° to +60°C

During transport / storage 5 to +40°C

Relative air humidity (RH) 10% to 95%, not condensing

Lighting Normal ambient lighting

Functions

Created by EBCCW 00:06

11

5113196-3

3 Functions

3.1 Motors

The control system of the platform X45e is structured in an object oriented

way. All motors in the platform have embedded control units and local sen-

sors are connected directly to each motor unit. This layout gives a big ad-

vantage regarding software developing, electrical design and electrical in-

stallation.

3.1.1 Function control

The motor unit consists of a motor, circuit boards and eight connectors in

an encapsulated housing. There are two types of motor units, the drive unit

and the functionunit. All that differs on these variants are the motor andthe

mechanical housing.

The drive unit has a permanent magnetic (PM) motor and the function unit

has a stepper motor with an analogue position feedback sensor. An em-

bedded microprocessor is dedicated for the application control. Local sen-

sors are connected directly to this unit.

The motors can be autonomously controlled only by the input of the local

sensors or controlled from a line controller over a CANopen network.

The motor unit has also a LED on each side indicating its status. If the mo-

tors are in autonomous mode they only need power (24VDC) to work prop-

erly.

3.1.2 Line control

If a line controller is used up to 127 motors can be interlinked via an exter-

nal CANopen network. RFID reader/writers can be connected to the line

controller via a separate network (Profibus, DeviceNet or Ethernet). All dy-

namic route handling has to be implemented in the line controller.

The main electrical cabinet supplies the motor units with power, 24 VDC.

Thepower is divided insafe andcontinuouspower inorderto have the pos-

sibilities to implement emergency or safety stops

Functions

12 5113196-3

3.2 Diverters, Mergers, Combined Diverter/

Mergers, Transfers, Stop and Locating

station for Puck handling

3.2.1 Diverters

Diverters are used to split a flow of pucks from one line into two. The lines

can be parallel or in a 90° angle.

The diverter is an active unit with one infeed and two outfeed conveyors.

There are four different variants of the diverter.

• Diverter, Parallel, Left

• Diverter, Parallel, Right

• Diverter, 90°, Left

• Diverter, 90°, Right

DL DLDR DR

90° 90°

Functions

Created by EBCCW 00:06

13

5113196-3

Figure 2 Diverter, parallel and 90°

The unit has two positions for photoelectric sensors. The first one is used

for sensing the queue status of the infeed conveyor. This sensor can be re-

placed by a RFID read/write head.

When a puck arrives the rotation disc opens up to receive the puck. The

second sensor is used for detecting that the puck has reached the gap of

the rotation disc. This is the trigger signal for the main rotation of the rota-

tion disc, with a puck in the gap.

The decision of which outfeed conveyor to release the puck on can be re-

ceived from the external bus, via a local sensor or from a predetermined

pattern.

Functions

14 5113196-3

3.2.2 Mergers

Mergersare usedto combinethe flow fromtwolinesintoone.The lines can

be parallel or in a 90° angle.

The merger is an active unit with two infeed and one outfeed conveyor.

There are four different variants of the merger.

• Merger, Parallel, Left

• Merger, Parallel, Right

• Merger, 90°, Left

• Merger, 90°, Right

Figure 3 Merger parallel and 90°

The unit has two sets of guide brackets each containing two photoelectric

sensors. The first sensor position on each side is used for sensing the

queue status of the infeed conveyors. These queue sensors are the trigger

signal for the merger to moving the rotation disc to one of the two receive

positions. This is done either clockwise or counter clockwise depending on

which conveyor to receive pucks from.

The last sensor is used for sensing pucks in the gap of the rotation disc.

This is the trigger signal for the main rotation of the rotation disc, with a

puck in the gap. When the rotation disc has reached the release position

the cycle is complete and the unit waits for a new puck to arrive.

ML MLMR MR

90° 90°

Table of contents

Other FlexLink Accessories manuals

Popular Accessories manuals by other brands

HB Products

HB Products HBOC quick guide

Whirlpool

Whirlpool GT4175SPB - Countertop Microwave installation instructions

Marport

Marport Seine Service manual

PCB Piezotronics

PCB Piezotronics 353B14 Installation and operating manual

Roland

Roland UM-1EX Driver installation guide

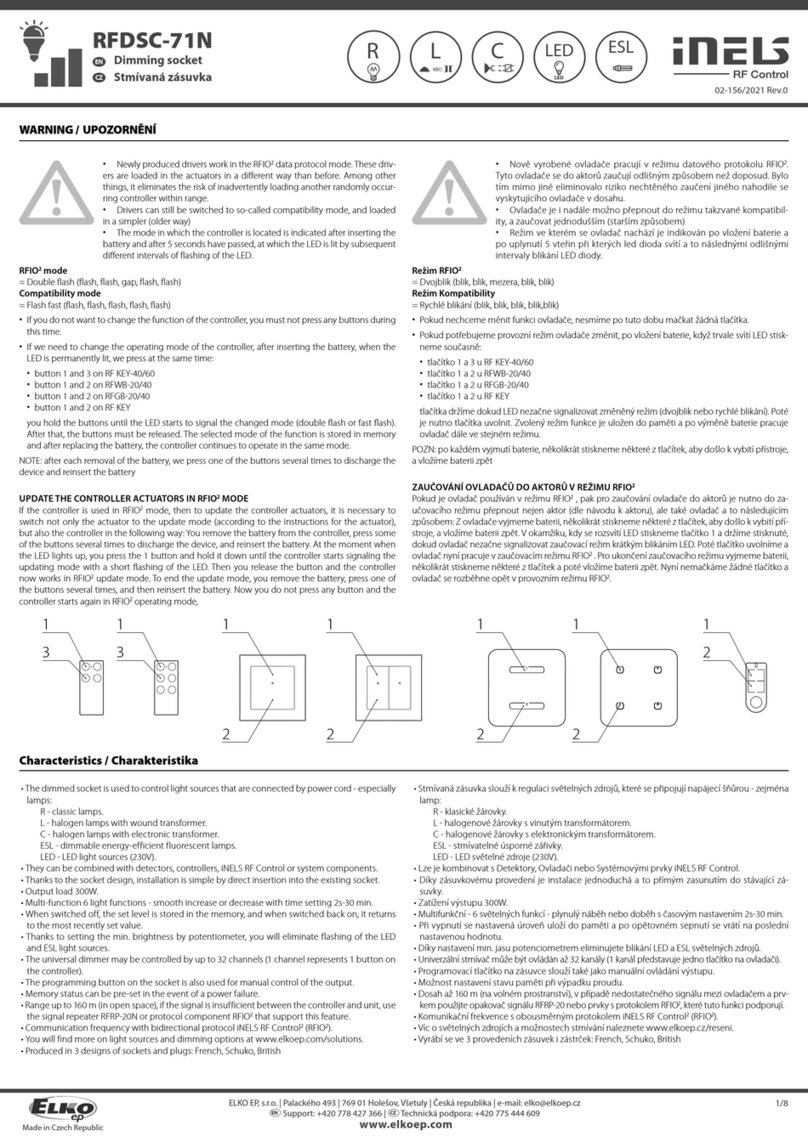

Elko

Elko iNels RFDSC-71N quick start guide