Flintec FAA-28 User manual

FAA-28

Analog Amplifier

Technical Manual

Flintec GmbH

Bemannsbruch 9

74909 Meckesheim

GERMANY

www.flintec.com

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 1 of 21

Table of Contents

1. Safety Instructions .......................................................................................... 2

2. Front View, Features and Specifications....................................................... 3

3. Installation and Commissioning..................................................................... 6

3.1 Mechanical Installation .......................................................................................... 7

3.2 Load Cell Connection............................................................................................. 7

3.3 Analogue Output Connection................................................................................ 8

3.4 Changing the Analogue Output............................................................................. 9

3.5 Serial Port Connection........................................................................................... 9

3.6 Commissioning....................................................................................................... 9

4. Adjustments................................................................................................... 10

4.1 Adjustment with Rotary Switches........................................................................10

4.2 Fast Adjustment to Nominal Output Range.........................................................12

4.3 eCal Electronic Adjustment Via xFace Software.................................................12

4.4 Adjustment (eCal) With PLC.................................................................................13

4.5 Testing the Scale Performance ............................................................................15

5. Setpoints ........................................................................................................ 16

5.1 Setpoint Connection..............................................................................................16

5.2 Setpoint Adjustment..............................................................................................16

5.3 Adjustment to the Load on the Scale...................................................................16

5.4 Adjustment by Measuring the Analog Output.....................................................16

6. Operation Mode ............................................................................................. 17

7. Programming With xFace Software Over RS232 ........................................ 18

7.1 Installation of xFace Software ..............................................................................18

7.2 xFace Software......................................................................................................18

8. Trouble Shooting........................................................................................... 20

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 2 of 21

RIGHTS AND LIABILITIES

1. Safety Instructions

CAUTION! READ this manual BEFORE operating or servicing this equipment. FOLLOW

these instructions carefully. SAVE this manual for future reference. DO NOT allow untrained

personnel to operate, clean, inspect, maintain, service, or tamper with this equipment.

ALWAYS DISCONNECT this equipment from the power source before cleaning or

performing maintenance. CALL FLINTEC ENGINEERING for parts, information, and service.

WARNING! ONLY PERMIT QUALIFIED PERSONNEL TO SERVICE THIS EQUIPMENT.

EXERCISE CARE WHEN MAKING CHECKS, TESTS AND ADJUSTMENTS THAT MUST

BE MADE WITH POWER ON. FAILING TO OBSERVE THESE PRECAUTIONS CAN

RESULT IN BODILY HARM.

WARNING! FOR CONTINUED PROTECTION AGAINST SHOCK HAZARD CONNECT TO

PROPERLY GROUNDED OUTLET ONLY. DO NOT REMOVE THE GROUND PRONG.

WARNING! DISCONNECT ALL POWER TO THIS UNIT BEFORE REMOVING THE FUSE

OR SERVICING.

WARNING! BEFORE CONNECTING/DISCONNECTING ANY INTERNAL ELECTRONIC

COMPONENTS OR INTERCONNECTING WIRING BETWEEN ELECTRONIC EQUIPMENT

ALWAYS REMOVE POWER AND WAIT AT LEAST THIRTY (30) SECONDS BEFORE ANY

CONNECTIONS OR DISCONNECTIONS ARE MADE. FAILURE TO OBSERVE THESE

PRECAUTIONS COULD RESULT IN DAMAGE TO OR DESTRUCTION OF THE

EQUIPMENT OR BODILY HARM.

CAUTION! OBSERVE PRECAUTIONS FOR HANDLING ELECTROSTATIC SENSITIVE

DEVICES.

All rights reserved.

No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, mechanical, photocopying, recording, or otherwise, without the prior written permission of Flintec

GmbH.

No patent liability is assumed with respect to the use of the information contained herein. While every

precaution has been taken in the preparation of this book, FLINTEC assumes no responsibility for errors or

omissions. Neither is any liability assumed for damages resulting from the use of the information contained

herein.

The information herein is believed to be both accurate and reliable. FLINTEC, however, would be obliged to be

informed if any errors occur. FLINTEC cannot accept any liability for direct or indirect damages resulting from

the use of this manual.

FLINTEC reserves the right to revise this manual and alter its content without notification at any time.

Neither FLINTEC nor its affiliates shall be liable to the purchaser of this product or third parties for damages,

losses, costs, or expenses incurred by purchaser or third parties as a result of: accident, misuse, or abuse of

this product or unauthorized modifications, repairs, or alterations to this product, or failure to strictly comply with

FLINTEC operating and maintenance instructions.

FLINTEC shall not be liable against any damages or problems arising from the use of any options or any

consumable products other than those designated as Original FLINTEC Products.

NOTICE: The contents of this manual are subject to change without notice.

Copyright © 2016 by Flintec GmbH, 74909 Meckesheim, Bemannsbruch 9, Germany

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 3 of 21

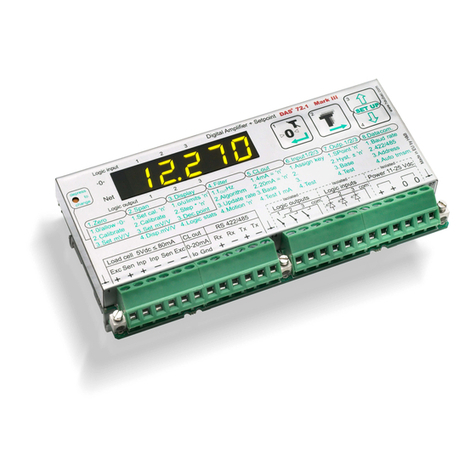

2. Front View, Features and Specifications

High speed analog load cell transmitter FT-28 has very high accuracy and long term

stability with its high tech design. Its high performance electronic calibration via

RS232C serial port without any test weight and fast calibration without measuring

output signal reduces commissioning and service times.

This high tech instrument gives the system designers a lot of advantages to increase

the system reliability and to reduce the installation and service times. Besides the

traditional analog output adjustment with any test weight, the electronic calibration

eCal and fast calibration with 20% max. test load reduces the calibration time.

All analog outputs of the instruments are matched in the production to perform

calibration at PLC and for changing the instrument without recalibration in service.

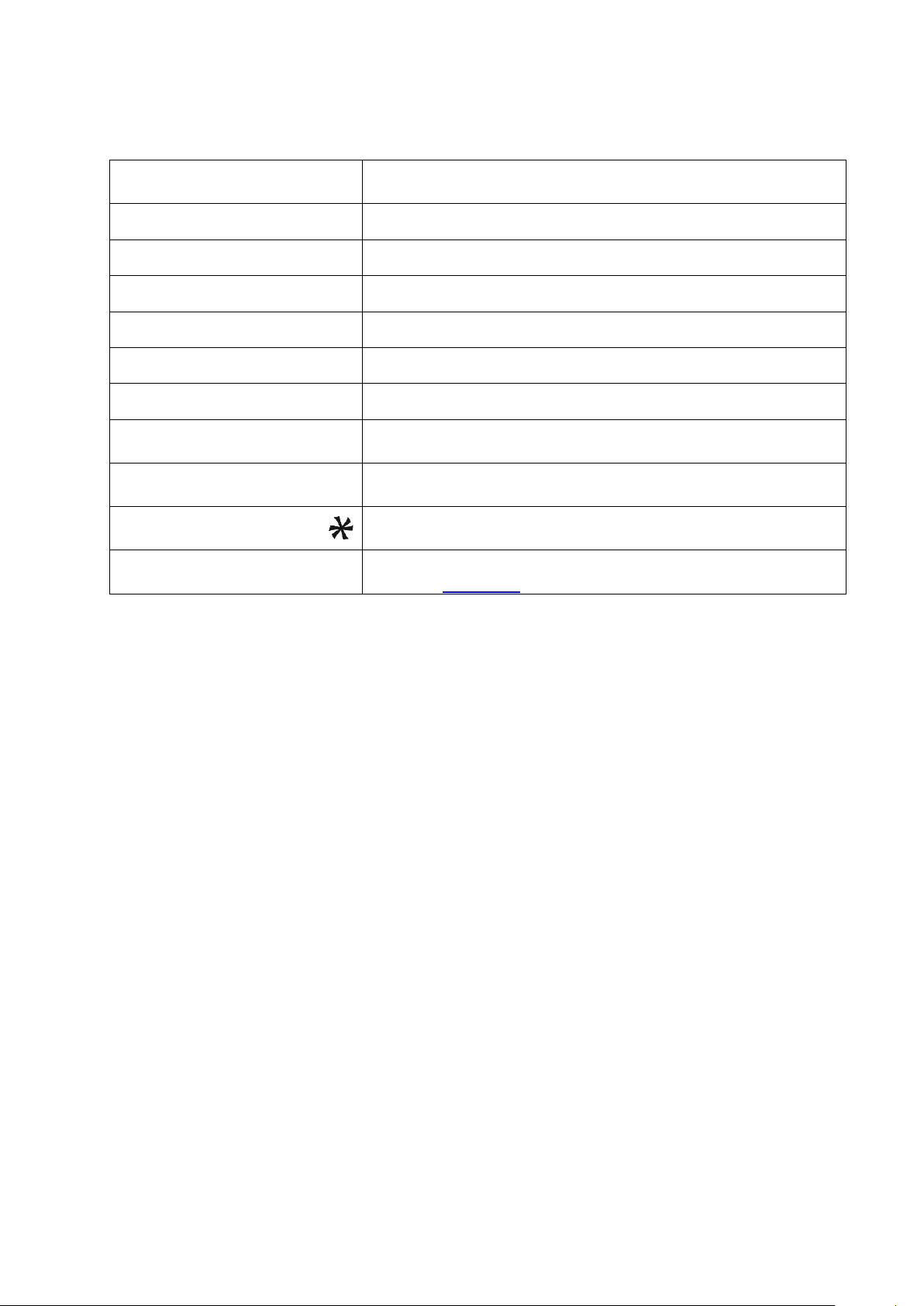

There are 8 positioned rotary switches and annunciator LEDs in front of the

instrument. The front view and pin descriptions of FAA-28 is shown below.

Pin Name

Definition

LOAD CELL CONNECTION

+ Ex

+ Excitation

- Ex

- Excitation

+Se

+Sense

-Se

-Sense

+ Si

+ Signal

- Si

- Signal

Shield and Protective ground

ANALOGUE OUTPUT

I

Current output

V

Voltage output

G

GND

SERIAL CONNECTION

TX

TxD ( RS232C )

RX

RxD ( RS232C )

G

Ground ( RS232C )

-

Zeroing input (0V)

+

Zeroing input (+24V)

SETPOINT CONNECTION

Q1

Digital Output 1

Q2

Digital Output 2

Com

Digital Outputs Common

POWER SUPPLY

24V

+24VDC

0V

0VDC

FAA-28

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 4 of 21

Meanings of the positions of rotary switches;

Programming (Prog)

switch

V

Voltage output type run

(refer to page 9)

I

Current output type run

(refer to page 9)

S1

Setpoint 1 adjustment

(refer to page 17)

S2

Setpoint 2 adjustment

(refer to page 17)

Z

Zero adjustment

(refer to page 11)

G

Gain adjustment with test weight

(refer to page 11)

ZF

Fast zero adjustment

(refer to page 13)

GF

Fast gain adjustment with 20% test

weight of Maximum scale capacity

(refer to page 13)

Adjustment (Adj)

switch

0

Operation mode (Run)

Special Functions in “Fast Adjustment, “Setpoint

Adjustment”

LEDs

Annunciator LEDs (Run, Output type, Error).

Refer to chapter 9

Features

•Minimized zero and span drifts due to its microcontroller technology and high

accuracy, very low temperature drift, 24 bits ADC and 16 bits DAC converters.

•Long time stability and low temperature drifts eliminate the frequent

readjustment period.

•Very easy and user friendly digital adjustment via rotary switches located on

the front of the instrument.

•Programmable digital adaptive anti-vibration filters to minimize environmental

vibrations.

•eCal- electronic calibration without weights and digital filter adjustment via

RS232C port and xFace PC software.

•Fast calibration feature to reduce the adjustment time and to minimize

adjustment error.

•Calibration at PLC does not require readjustment after changing instrument

because of matching in the production.

•1 zeroing input and 2 free relay contact outputs for alarm or controlling valves,

gate etc.

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 5 of 21

TECHNICAL SPECIFICATIONS

Analogue input range

-18 mV … +18 mV

Min. input range

< 0.8 mV

Linearity

< % 0.01

Temperature drift

< 0.005 % FSR / ºC

Converters

24 bit Delta-Sigma ratiometric ADC with integral analog and

digital filters, high EMC immunity

16 bit very low drift DAC

Internal resolutions

16 000 000 counts ADC

External resolution

Analogue output changes up to 60000 steps

Output update rate

Up to 800 conversions per second

Calibration

With rotary switches in the front with test load.

Fast calibration with 20% of max. weighing range

Electronic calibration via PC.

Preadjusted instrument for calibration at PLC

Digital Filter

Programmable 9 step adjustable digital adaptive filter.

Analogue outputs

Current output for 0-20 mA and 4-20 mA or

voltage output for 0- 5 V and 0-10 V.

Max. cable length

300 meter

Max. load resistance

(voltage output)

500 Ω

Set point

2 free programmable setpoints.

Digital Output

2 relay contacts for setpoints, 230 VAC or 30 VDC, 1 A.

Digital Input

1 opto-isolated input for zeroing, 12 … 28 VDC, 10mA

Load cell excitation

5 VDC

Number of coad cells

Up to 8 units of 350 or 18 units of 1100 (min. 43 )

Load cell connection

4- or 6- wire technique

Power supply

12 … 28 VDC, 0.2 A

Operation Temperature

-15°C …+55°C at 85% RH max, non-condensing

EMC Immunity

Class E2

Enclosure

Polyamide, for DIN-rail mount, IP20

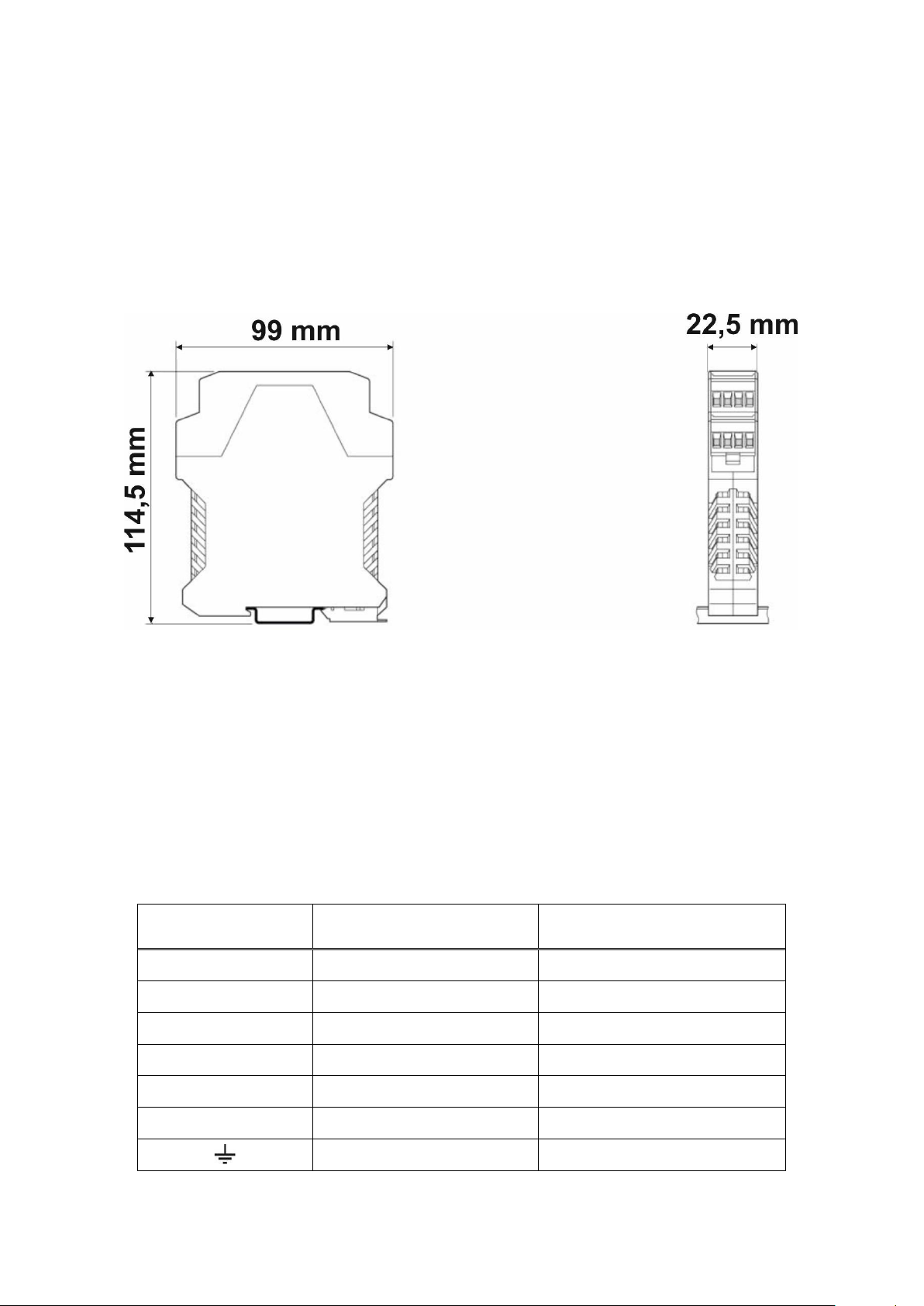

Dimensions

Front Width:22,5 mm, Front Length: 99 mm , Height:114,5mm

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 6 of 21

3. Installation and Commissioning

Recommendations

Warning:Please care the following warnings for designing the control cabinet which

will increase your system reliability.

The control cabinet should be designed so that instrument can operate safely.

The panel should be placed in clean area, if possible not getting direct sun light, with

a temperature between -15 ºC and +55 ºC, humidity not exceeding 85% non-

condensing. All external cables should be installed safely to avoid mechanical

damages.

FAA-28 instruments are very low level signal measuring instruments. To avoid

electrical noise, FAA-28 should be separated from the equipments that produce

electrical noise. Preferable use metal cabinet against radio frequency interference

and the cabinet shall be connected to ground against the electromagnetic

disturbances. Load cell cable and analog output cable trays must be separated from

others, if possible. If there are noise-generating equipments such as heavy load

switches, motor control equipments, inductive loads etc., please be careful against

the EMC interference in the cabinet. Connect parallel reverse diodes to the DC

inductive loads like relays, solenoids etc. to minimize voltage peaks on the DC power

lines.

All load cell and analogue output cables coming to the control cabinet shall be

shielded.

Warning: Control cabinet design and proper installation increases reliability and

performance of the instrument. Please do not forget that the instrument must be

powered off before inserting or removing any peripheral connector.

Follow the installation and commissioning steps described below carefully to prevent

unwanted results after installation.

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 7 of 21

3.1 Mechanical Installation

The place where you will use/install your instrument should be clean, not getting

direct sunlight if possible, with a temperature between -15ºC and +55ºC, 85%

maximum relative humidity non-condensing. Install the instrument on the DIN rail in

the cabinet.

The instrument mechanical drawing

3.2 Load Cell Connection

The load cell wiring should be made carefully before energizing to avoid damages of

the instrument and load cells. In 4-wire installations the sense and excitation pins

with the same polarity should be short circuited at the connector side. If you have

junction box, use 6 wire cable between FAA28 and the junction box, and short circuit

these pins at junction box for better performance. The input resistance of the load

cells that you want to connect should be more than 43 Ω.

Pin Name

6 Wire Load Cell

Connection

4 Wire Load Cell

Connection

+Ex

+ Excitation

+ Excitation

+Se

+ Sense

Short circuit to + Excitation

-Ex

-Excitation

Short circuit to - Excitation

-Se

-Sense

- Excitation

+Si

+ Signal

+ Signal

-Si

-Signal

- Signal

Shield

Shield

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 8 of 21

3.3 Analogue Output Connection

Only one of the analog output types can be used at the same time and has to be

selected in the setup type. Install the analog output measuring instrument for

adjustment, e.g. multimeter.

Pin Name

Definition

I

Current Output

V

Voltage Output

G

GND

Shield

Current output connection

Voltage output connection

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 9 of 21

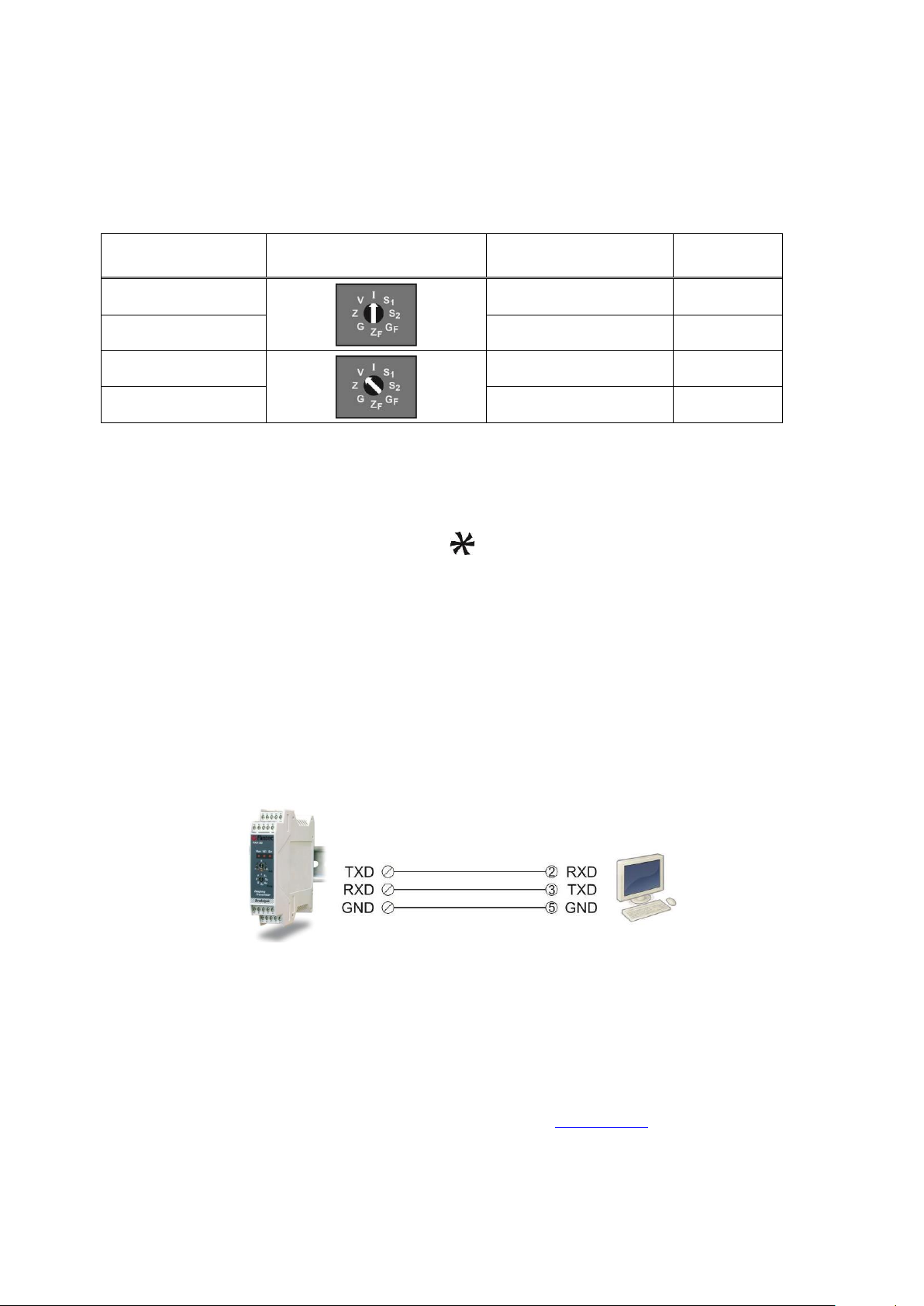

3.4 Changing the Analogue Output

FAA-28 sets its analog output according to the table below at power on. Turn the

programming switch and connect TxD and RxD pins as indicated in the table below

before power on the instrument to set analog output type and its signal level.

Analogue

Output Range

Prog. Switch Position

TxD & RxD pins

V / I LED

4 - 20 mA

Open circuited

On

0 - 20 mA

Short circuited

Off

0 - 10 VDC

Open circuited

Flash

0 - 5 VDC

Short circuited

Blinking

You can also set the analog output type after power on as;

•Turn the programming switch to the analog output type (to V or I position)

•Connect or disconnect TxD and RxD pins according the table above to set the

output range

•Turn the adjustment switch to the position. After 2 seconds turn in back to

the “0“- position (if the instrument is powered on before)

The analogue output type can be followed by the V/I LED on front of the instrument

after running it (refer to table above ) .

After set up the analog output of the instrument according to the table above go to

the next step.

3.5 Serial Port Connection

3.6 Commissioning

Double check the following issues before energizing the instrument.

•Check Mechanical installation, grounding, load cell connection and power

supply connection

•Check the analogue output set up described in chapter 4.4

•The analogue output cabling should be done for the same analogue output

type

•The adjustment (Adj) rotary switch shall be at “0“ - position

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 10 of 21

4. Adjustments

4.1 Adjustment with Rotary Switches

To start the adjustment the programming switch should be at analog output type

position, Vor I.

Zand Gpositions of the programming switch are used for performing zero and gain

adjustments in sequence. Analog output is changed by turning the adjustment switch

as described in the table below.

Adjustment rotary

switch position

Rotary switch description

Run

LED

No change, operation mode

On

Decrease ( - ) / Increase ( + ) in slow steps

Flash

Decrease ( - ) / Increase ( + ) in medium steps

Flash

Decrease ( - ) / Increase ( + ) in big steps

Flash

RUN LED flashes to indicate the instrument is not in operation mode.

Zero Adjustment

•Connect the measurement instrument (Multimeter is recommended) to the

analog output

•Unload the scale (the scale must be empty)

•Turn the programming switch to the Zposition from the analog output type

position

•Increase or decrease the analog output by adjustment rotary switch.

Never bring the adjustment switch to position in this adjustment. Turn the

adjustment switch to 0- position at the end of the adjustment.

•Turn the programming switch to analog output type position (Vor I) to start the

operation mode or to the Gposition to start gain adjustment

Gain Adjustment

•Connect the measurement instrument (Multimeter is recommended) to the

analog output

•Load the scale with a known load

•The analog output value should be calculated for the applied load

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 11 of 21

Use the following formula for calculating the analog output value

Analog

Output

=

Minimum output

+

Maximum output –Minimum output

*

Load

Scale capacity

Example:

Scale capacity 100kg

Output range 4 –20 mA

Known Load 25kg

The 4-20mA analog output current will be at 25kg ;

Iout = 4mA + (( 20mA –4mA ) / 100kg ) * 25kg = 4 + 0.16 * 25 =

Iout = 8mA

The 0 –10VDC analog output voltage will be at 25kg:

Vout = 0 + (10V / 100kg ) * 25kg = 0,1 * 25 =

Vout = 2.5VDC

•Turn the adjustment switch to the Gposition from the analog output type

position you set before

•Increase or decrease the analog output by adjustment rotary switch to the

calculated output value

Never bring the adjustment switch to position in this adjustment. Turn the

adjustment switch to 0- position at the end of the adjustment

•Turn the programming switch to analog output type position for operation

mode (to V or I)

Important note: The instrument saves 4 different adjustments in its memory for the

voltage and current outputs and their ranges. Changing the analog output type it

automatically set the adjustment to the output range used before.

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 12 of 21

4.2 Fast Adjustment to Nominal Output Range

You may perform fast adjustment method if you will set zero and gain to analog

output nominal values. This feature gives advantage to the instrument for small and

medium capacity weighing systems’ fast and easy adjustment.

Fast Zero Adjustment:

•Unload the scale

•Turn the programming switch to ZF position

•Turn the Adj. switch to position and turn it back to 0- position 2 seconds

later

•Turn the programming switch to analog output type position to start operation

mode or to GF position for gain adjustment.

For example, for 4 –20mA range and for 100kg capacity scale, unload the scale and

perform fast adjustment to set the output to 4mA.

Fast Gain Adjustment:

•Load the scale to the 20% of the maximum capacity (if scale capacity is

100kg, load 20 kg)

•Turn the programming switch to GF position.

•Turn the Adj. switch to position and turn it back to “0”- position 2 seconds

later

•Turn the programming switch to analog output type position for operation

For example, for 4 –20mA range and for 100kg capacity scale, load the scale 20kg

test weight and perform fast gain adjustment to set the output to 7,2mA at this load.

The output will be 20mA at 100kg loading.

4.3 eCal Electronic Adjustment Via xFace Software

The adjustment of high capacity tanks and silos are very difficult in practice and takes

very long time. You may save a lot of time by eCal adjustment by entering theoretical

scale and load cell values to the instrument instead of loading the scale. Due to the

production process of FAA-28, eCal accuracy is very high. Adjustment with eCal is

performed via RS232 port of the instrument and can be comfortable executed with

xFace software. Refer to chapter 8 for installation and using the software.

For increasing the eCal accuracy you must enter the specific load cell rated output,

which is printed on “Final Data Summary” attached to every Flintec load cell. Using

more than one load cell an arithmetic average of all load cells must be calculated.

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 13 of 21

4.4 Adjustment (eCal) With PLC

All instruments are adjusted in the production to operate in its analog output range

between 0mV and 10mV load cell signal as default. For example, if the instrument is

at factory default values and programmed to operate 4 –20mA output range, the

output will be 4mA at 0mV and 20mA at 10mV load cell signal (only for 2mV/V load

cells).

Changing the FAA-28 instrument a recalibration is not required due to matching

instruments in production by Flintec.

Warning: If the instrument was adjusted before and its factory defaults are changed,

you should load factory defaults with xFace.

FAA-28 Programming via RS232C

FAA-28 can be electronically calibrated via RS232C serial interface by commands or

by xFace software. If you want to use your own software to calibrate the FAA-28 from

your PLC or PC, you may use the commands below. The yellow colored bytes are

the data in the command and blue colored bytes are check sum in this document.

Output type setting and eCal electronic calibration should be done in sequence.

RS232C PORT SETTING :

Adjust your PC or PLC serial port as 9600, 8 None 1.

DATA STRUCTURE :

ASCII, HEX DATA and CR (Carriage Return) at the end of the command.

COMMANDS: Descriptions

1. Analog output type setting:

a) 4 - 20mA setting:

Command: @01100000000102000BE1 Set to 4-20 mA range

Response: @011000000001EE ACK

b) 0 - 20mA setting:

Command: @011000000001020014D8 Set to 0-20 mA range

Response : @011000000001EE ACK

c) 0 - 10VDC setting :

Command: @01100000000102000AE2 Set to 0-10 VDC range

Response : @011000000001EE ACK

d) 0 - 5VDC setting :

Command: @011000000001020013D9 Set to 0-5 VDC range

Response : @011000000001EE ACK

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 14 of 21

2. eCal procedure steps: Descriptions

Step 1 START eCal

Command: @011000000001020001EB Start the eCal process.

Response: @011000000001EE ACK

Step 2. Total Load cell Emax entry

Command: @01100003000204000001F4F1 Total LC is 500kg.

Response: @011000030002EA ACK

Step 3. Average Load cell mV/V entry

Command: @0110000500020400004E2F67 LC sensitivity: 2.0015mV/V.

Response: @011000050002E8 ACK

Step 4. Estimated Dead load entry

Command: @0110000700020400000000E2 Dead load is 0kg.

Response: @011000070002E6 ACK

Step 5. Scale Capacity entry

Command: @01100009000204000000FAE6 Scale capacity is 250kg.

Response: @011000090002E4 ACK

Step 6. SAVE with estimated dead load value

Command: @011000000001020007E5 Save the eCal values.

Response: @011000000001EE ACK

Or SAVE with automatic zero adjustment.

Unload the scale and send the command below

to start the zero adjustment.

Command: @011000000001020015D7 Save eCal with Zero Adj

Response: @011000000001EE ACK

Step 7. APPLY

Command: @011000000001020009E3 Apply the calibration.

Response: @011000000001EE ACK

Step 8. STOP eCal

Command: @011000000001020002EA Stop the eCal process

Response: @011000000001EE ACK

3. Digital Filter Setting:

Command: @011000220001020000CA Set the Fast filter

Command: @011000220001020001C9 Set to Medium filter

Command: @011000220001020002C8 Set to Slow filter

Response: @011000220001CC ACK

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 15 of 21

4. Load Factory Defaults: Descriptions

Command: @011000240001025AA5C9 Set to factory default.

Response: @011000240001CA ACK

CHECKSUM CALCULATION :

CSUM = 0 –(Slave_Add + Function + … + Last_data)

(STX and CSUM are neglected while calculating CSUM)

Example

For Medium (1) filter: @011000220001020001XX

CSUM = 0 –( 01+10+00+22+00+01+02+00+01)

= 0 –37

= C9

Command is @011000220001020001C9 < Carriage Return >

4.5 Testing the Scale Performance

You have to check the scale performance by testing the scale eccentricity, scale

linearity at loading up to maximum loading value, repeatability etc. before using it.

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 16 of 21

5. Setpoints

5.1 Setpoint Connection

FAA-28 has 2 free relay contact output. These outputs can be connected to

maximum 230VAC or maximum 30VDC, maximum 1A loads. Reverse diode

connection to the DC loads is recommended to increase the relay contact life and to

reduce the disturbances. Outputs connection is;

5.2 Setpoint Adjustment

The instrument closes the relay contacts if the weight value is higher than the

adjusted setpoint. These contact signals can be used to stop charging or discharging

or produce alarm signal. You can apply two methods to adjust setpoints.

5.3 Adjustment to the Load on the Scale

Setpoint can be adjusted to the load value on the scale:

•Load the scale to the value you want to produce setpoint signal

•Turn the programming switch to S1 (or S2) position from operation position

(from Vor Iposition)

•Turn the Adj. switch to positions position and turn it back to 0- position

2 seconds later

•Turn the programming switch to analog output type position for operation

mode (Vor Iposition) or to other setpoint position to adjust it

5.4 Adjustment by Measuring the Analog Output

You can adjust the setpoint by measuring the analogue output value without loading

the scale:

•Connect the measuring instrument to the analog output.

•Turn the programming switch to S1 (or S2) position from operation position

(from Vor Iposition).

•Increase or decrease the analog output by adjustment rotary switch (refer to

table in chapter 5.1 ).

Do not bring the adjustment switch position to position in this adjustment.

The adjustment switch must be at 0- position at the end of the adjustment.

•Turn the programming switch to analog output type position to start operation

(Vor Iposition) or to other setpoint position to adjust it.

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 17 of 21

6. Operation Mode

There are 3 LEDs and 2 rotary switches on the front panel of FAA-28. The rotary

switches are being used for adjustment as described in chapter 4.4 and the LEDs

have different meanings in operation and setup type as indicated below.

Analogue

Output Range

Prog. Switch

position

Adj. Switch

position

TxD & RxD

pins

V / I LED

(after power

on)

4 - 20mA

Open circuited

On

0 - 20mA

Short circuited

Off

0 - 10VDC

Open circuited

Flash

0 - 5VDC

Short circuited

Blinking

The status of the LEDs in the operation type is given in the table below. Refer to

chapter 9 in case of the Err LED turns on.

The analogue output signal also gives information about the status of the system and

the weighing process to inform PLC as:

Condition

4-20mA

output

0-20mA

output

0 –10V

output

0 –5V

output

Operation mode

X

X

X

X

Programming

X

X

X

X

The weight is over the range

(Over signal to PLC)

24mA

24mA

11V

5,5V

The weight is under the range

(Under signal to PLC)

0mA

0mA

-4.0V

-4.0V

“Error” signal to PLC

0mA

0mA

0V

0V

“ADC is out of operating range” error to

PLC

24mA

24mA

11V

5,5V

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 18 of 21

7. Programming With xFace Software Over RS232

FAA-28 has RS232C serial interface to perform eCal electronic calibration and to

adjust filter, setpoint values and to follow status by using xFace software installed on

a PC.

For installing the xFace software, which is supplied with the instrument or can be

downloaded from www.flintec.com, follow the steps described below.

7.1 Installation of xFace Software

•Close all applications on your PC

•Insert the CD that contains the xFace software v2.03 or higher into the CD-

ROM drive

•Double click “Setup.exe” to start the installation. The setup Wizard will be

displayed

•Follow the menus in the setup wizard step by step

•After finishing the installation, the Setup Wizard will inform you about the

success of the software installation. Click the OK button

•After closing the Setup Wizard you can start to use the xFace software

7.2 xFace Software

For programming instrument via xFace follow the instructions below;

1. Power off the instrument.

2. Connect the instrument to PC as

shown in chapter 4.5 to use xFace

software and run the software.

Select FAA-28 and press “OK”

button.

3. Select the Com-port and press

on “Connect” to connect to

the instrument.

FAA-28, Technical Manual, Rev.1.1.0 February 2022

Page 19 of 21

4. Select the analog output type.

5. Enter Total Load Cell capacity,

Average Load Cell Output,

Scale Capacity and

Estimated Dead Load.

6. Press “Write eCal Data to

Transmitter” button on the

monitor to perform eCal.

7. Unload the scale and Press

“eCal with Zero Adjustment“

button on the monitor.

8. Adjust filter value and setpoints in section “Setup”.

9. In section “Status” instrument information are available.

10.Power off the instrument before disconnecting from PC. Bring the

programming switch to the analog output type position and apply the

connection between TxD and RxD pins which is described in chapter 7 to set

the analog output type.

11. Turn the adjustment switch position to “0“ - position.

12.Power on the instrument for operation.

After performing eCal as described in the software, check the performance of your

system.

You may adjust to instrument to factory default by xFace, if it is changed before.

Table of contents

Other Flintec Amplifier manuals