Fliptop Slider Quick setup guide

Edition 1.2

www.iptop.se

info@iptop.se

2020

Slider

Safety and Assembly instructions

2

Thank you for purchasing a Fliptop Slider.

This document includes assembly instructions for the Fliptop Slider system. There are variants

depending on length, width and number of arches.

In case of uncertainty or questions, we or the reseller would be happy to provide you with support.

Important

Transport damage must be reported to

the carrier. It is important to check the

packaging when the goods arrive, if

it is damaged, a notication must be

made to the driver at the time of

delivery. It is the carrier that is

responsible for damage that occurs on

the goods during transport. The

mounting must be done according to

the mounting instructions for the

material warranty to apply.

Warranty

There is a 1 year material and function

guarantee from us. For the warranty to

apply, the product must be mounted

according to our instructions.

SafetySafety

The safety instructions must be read carefully before using the Fliptop Slider, as moving

parts move with the help of electric motor or manual power, without knowledge, serious

personal injury and damage to the system can occur.

Read the manual carefully!

2 3

Table of contents

Operating instructions for Fliptop Slider 4

General information 4

Operating instructions 4

Opening and closing the Fliptop Slider Manual (802-002) 4

Opening and closing of Fliptop Slider with electrical motor (802-003) 5

Important information 5

Automatic start with Time relay 5

Safety instruction 6

Performance of vehicles with Fliptop Slider 6

Ice and snow 6

In strong wind 6

Maintenance 6

Installation of Fliptop Slider 7

Mounting bracket for drive beam 8

Mounting drive beam 9

Mounting of the wire wheels 11

Mounting of the wire 12

Tensioning off the wire 13

End position adjustment 14

Drive unit 16

MANUAL 16

ELECTRICAL 17

Adjustment of automatic rear closing 18

Adjustment of stop arm 20

Wire cutting 21

Mounting option on drive beam 22

Post tensioning of wire 23

Wind protection Z-prole 24

Wind protection Exterior 25

Wind protection Inside 26

ELECTRICAL SCHEME 27

Replacement of fuse 40A 28

Drawings 29

Sparepartslist 31

4

Operating instructions for Fliptop Slider

General information

Fliptop Slider is a roof system to cover mainly tipper trucks and containers. Consisting of a

number of arches joined by a steel wire and covered by PVC cloth. The Fliptop Slider is opened

and closed manually, or with an electric motor. Fliptop Slider is mainly intended for the coverage of

tipper trucks and containers. This however does not exclude other uses.

Operating instructions

Read this documentation and familiarize yourself with the equipment before use. Fliptop Slider is

powered by electric motor 24V DC or a manual crank. The motor-driven alternative is controlled

by a remote control and/or buttons on the electrical cabinet. The manual option is operated with a

crank.

Opening and closing the Fliptop Slider Manual (802-002)

The roof opens and closes with a crank that sits on the drive beam. To be able to crank, push the

crank out of the backrest.

4 5

Opening and closing of Fliptop Slider with electrical motor (802-003)

To operate the sliding roof the main switch must be turned on. The roof is opened or closed by

remote or with push buttons on the electrical cabinet, normally the truck must be connected, or an

extern 24V battery is needed to operate the roof.

Fliptop Slider uses a power card that senses the power consumption, when the roof comes to a

stop, the power card senses the load and breaks the power. You can’t start in the same direction

as the power card cut the power, you can only move the roof system in the opposite direction in

this case. The power card inside the electrical cabinet is preprogrammed. Should the roof stop

earlier, please check that the load does not reach the platform edge, or lies against the Fliptop

Slider System.

The remote control is started by holding down the On button for a few seconds, when the middle

LED lights up green = The remote control is active. The remote control turns o with the O button

or automatically after a while to save battery. The buttons with arrows open and close the ceiling.

The roof can also be operated with the push buttons on the electrical cabinet. There is a main

switch on the back of the remote control as well as the electrical cabinet. It should always be in the

”on” position, the transmitter will not drain the battery.

When opening and closing the Fliptop Slider, you must be vigilant and make sure that there

is no chance of personal injuries. The electric or manually driven movements are very strong and

can cause very serious damage if you get pinched or hit by the system. If your Fliptop slider has a

remote control be extra careful, so that no one accidentally accesses it and maneuver when

someone is near moving parts. It is also important to not open or close while driving. If you need to

perform service or other work on the system, it is imperative to disconnect the power. If the system

is locked with straps, do not forget to release them before operating the Fliptop Slider.

Important information

Strong winds can seriously damage the system. Therefore, tighten down the roof with straps under

strong wind. It is important to be careful when loading and unloading so that the loaded material

does not end up on the roof of the system. If the cargo lls the entire cargo space and tends to

collapse into a coherent mass there is a risk of a vacuum forming, this can bend the arches and

seriously damage your system, if this is a risk, open then the ceiling to let in air before unloading.

When loading and unloading masses of heavy stone, roots or anything else that stands up, it is

important that the load does not come into contact with the roof system, it prevents opening and

closing of the roof. NOTE it is important to open the roof before tipping so that the load does not

get stuck in the roof, because the system can be damaged then.

Automatic start with Time relay

Slider has a time relay which can be switched on, this then opens the roof when tilting or when

opening the back door, so that the Slider will not be crushed by the tailgate/ tailboard. Operation of

the tailgate and when tipping should always be supervised to be able to cancel if something

unexpected should happen. The manufacturer accepts no liability for damage that occurs if

the time relay or other technology would not operate the slider system during tipping or

opening.

Main power switch

should always be ”on”

6

Safety instruction

The equipment may only be operated by personnel with sucient knowledge of the equipment and

have an understanding of the risks arising when operating the system. The minimum requirement

for operating the system is a review of this documentation and a review of the equipment before

any work with it starts.

For service and maintenance, electricity must be switched o so that the equipment cannot run, as

there is a high clamping risk when operating the equipment.

Please note that the operator must always be careful not to cause damage to the equipment or

harm to people nearby.

Performance of vehicles with Fliptop Slider

Prior to transport, make sure that the tarpaulin roof is closed or completely open. It is not permitted

to drive with the roof partyly open. The roof can be damaged.

Ice and snow

Before opening or closing, snow and ice must be removed. Fliptop Slider is not designed for much

snow, max 10cm when the roof is closed, when the roof is completely open, it can withstand more

snow.

In strong wind

We do not recommend opening the ceiling when it blows more than 25m per second, as it can

damage the system.

Maintenance

We recommend that the Fliptop Slider system be inscpected once a week when using the system

continuously.

CONTROL POINTS:

• That the tarpaulin is not damaged.

• That the tarpaulin is fastened to the system

• That no bolts or rivets are missing.

• The tarpaulin is clean of debris and loads.

• That the wire is tensioned enough. If not tighten the wire.

If you nd damage, it is important to repair,

Contact your nearest dealer or workshop if you have any problems.

Please note

that the roof must either be fully

open or closed when driving the vehicle.

6 7

Installation of Fliptop Slider

Fliptop Slider is delivered pre-assembled and tested by us, for easy mounting on your atbed truck

or container. All parts to be used are included. Note that it may be necessary to make some ad-

justments to t your tipper truck or container as there are many dierent designs. It is important to

ll the order form carefully for a better t and easier assembly.

Fliptop Slider is delivered in two versions, manual opening with crank or motor operation, and

there are also dierent closing alternatives. Manual closing with straps or Automatic rear closing

with a tilt bow.There are several heights on the arches from straight to 600mm high. Standard

height is 300mm. All of these parameters make the content of the delivery varies.

Example of delivery

8

95

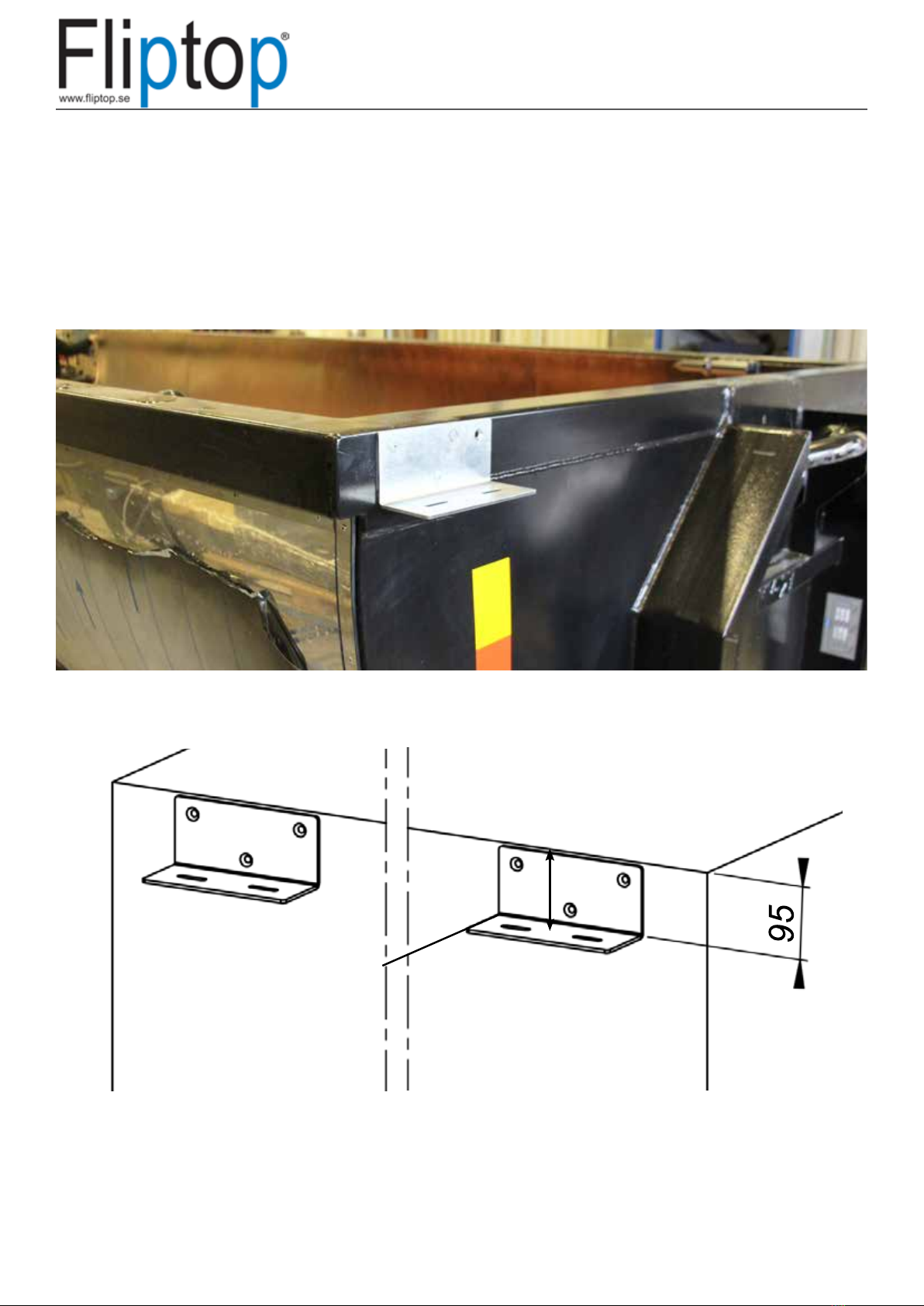

Mounting bracket for drive beam

The brackets for the drive beam are mounted according to the accompanying instructions.

Brackets mounted either with countersunk screw M8x20 or welded to the platform, it is important

that they are in parallel with the platform body side.

The measurement is taken

from the top of the platform

body to the bracket

95

8 9

Center the drive beam

Mounting drive beam

Lift the entire package up on the platform body top, remove the packaging from the Slider sys-

tem and release the wire so that the drive beam can be lifted down and placed on the drive beam

brackets, without loosening the wire locks on the wire.

34 34

Nr.

Ant

Ändring

Datum

Inf.

Godk.

10

A

98765

B

C

D

4321

A

B

C

D

E

F

G

H

1098765

E

F

4321

G

H

Godk.

Skala

1:15

ISO 2768-C

Tolerans där annat ej anges

~

SE-380 42 Målerås

SWEDEN

Tel: +46 481 31222

Konstr.

Ritad

Format

Ytjämnhet

Vikt

Ytbehandling

Dat.

Ritn.nr

802-001

Fliptop Slider utan drift

JÅG

A3

52.37 kg

This drawing, or parts thereof, may not be reproduced in any form, by any method,

for any purpose, without permisson of Målerås Mekaniska AB

Revision

Flatbed / Container

Drive beam

10

The drive beam is screwed in with two bolts on each side. 4 X M8X20 and 4 X BRB 8.5x40x3.

10 11

40

Nr.

Ant

Ändring

Datum

Inf.

Godk.

A

B

C

D

E

F

G

H

I

J

K

M

L

M

L

K

J

I

H

G

F

E

D

C

A

B

1918171615141312111098765431 2

1918171615141312111098765431 2

This drawing, or parts thereof, may not be reproduced in any form, by any method,

for any purpose, without permisson of Målerås Mekaniska AB

Godk.

Skala

1:20

ISO 2768-C

Tolerans där annat ej anges

~

SE-380 42 Målerås

SWEDEN

Tel: +46 481 31222

Konstr.

Ritad

Format

Ytjämnhet

Ersatt av

Ytbehandling

Dat.

Ritn.nr

A0

337.002 kg

Revision

Mounting of the wire wheels

The position of the wire wheels is determined when ordering the Fliptop Slider. It comes with an

instruction where to place the wire wheel to order. The bracket for the wire wheels should be

attached CC 40mm from top edge of the platform body to the holes in the bracket, then the wire

will end up 3mm below the top edge of the platform body.

If your system does not have automatic rear closing, follow the mounting instructions but

ignore the instructions for the chain and tilt arch, in the automatic rear closing solution.

Nr.

Ant

Ändring

Datum

Inf.

Godk.

10

A

98765

B

C

D

4321

A

B

C

D

E

F

G

H

1098765

E

F

4321

G

H

Godk.

Skala

1:10

ISO 2768-C

Tolerans där annat ej anges

~

SE-380 42 Målerås

SWEDEN

Tel: +46 481 31222

Konstr.

Ritad

Format

Ytjämnhet

Vikt

Ytbehandling

Dat.

Ritn.nr

A3

0.0 kg

This drawing, or parts thereof, may not be reproduced in any form, by any method,

for any purpose, without permisson of Målerås Mekaniska AB

Revision

Nr.

Ant

Ändring

Datum

Inf.

Godk.

10

A

98765

B

C

D

4321

A

B

C

D

E

F

G

H

1098765

E

F

4321

G

H

Godk.

Skala

1:10

ISO 2768-C

Tolerans där annat ej anges

~

SE-380 42 Målerås

SWEDEN

Tel: +46 481 31222

Konstr.

Ritad

Format

Ytjämnhet

Vikt

Ytbehandling

Dat.

Ritn.nr

A3

4410.7 kg

This drawing, or parts thereof, may not be reproduced in any form, by any method,

for any purpose, without permisson of Målerås Mekaniska AB

Revision

Example wire wheels without

automatic rear closing

Example wire wheels with

automatic rear closing

M10 MF6S M8 M6S

12

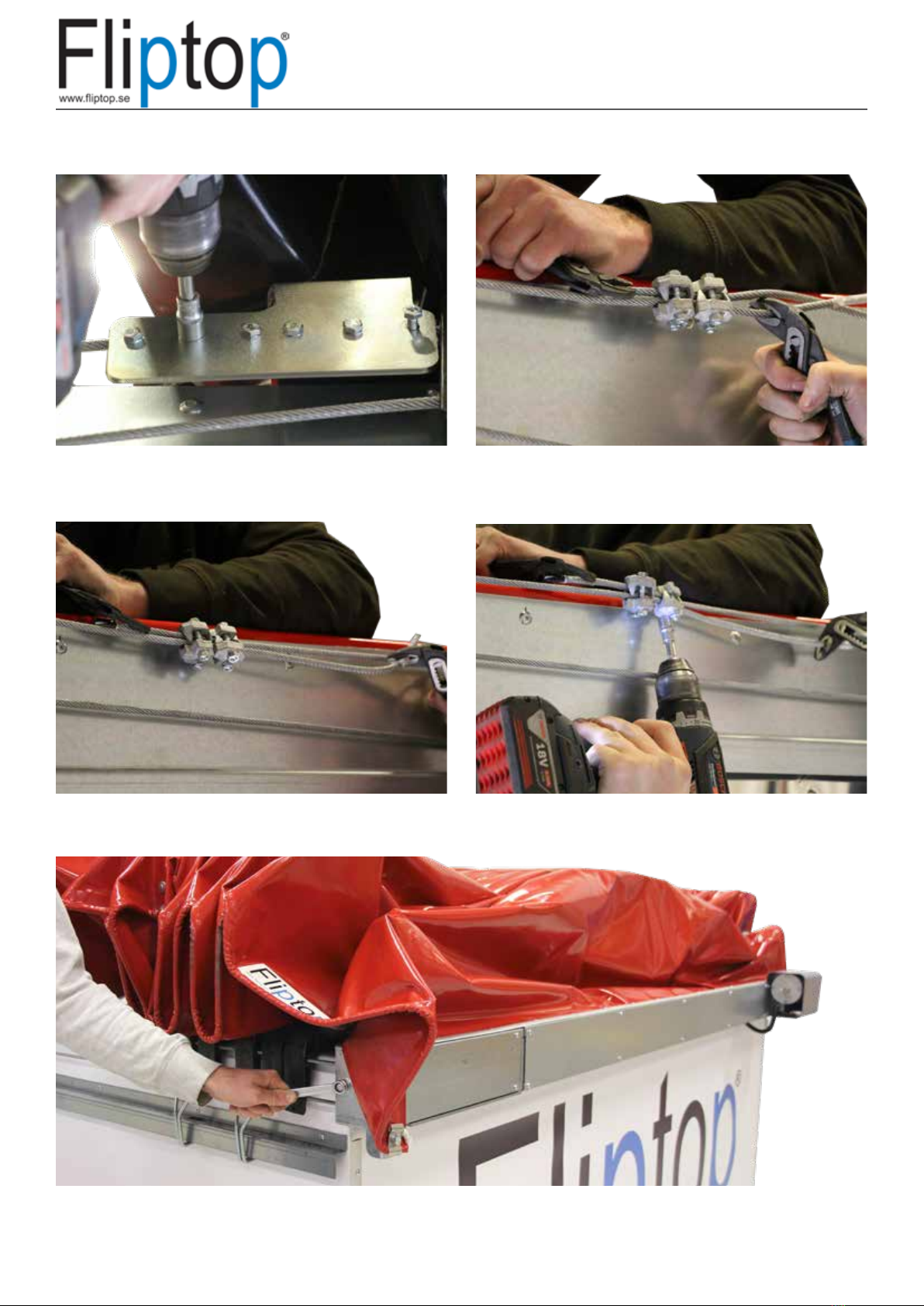

Mounting of the wire

Screw the cover and the wire wheel into the

bracket, make sure the wire is not tangled

together.

Thread the wire around the wire wheel. Place the two washers between the cover and

wire wheel. Thread through the bolt.

22

44

Place the wire wheel with the wire in cover.

NOTE! two washers

11

33

12 13

Loosen the two wire locks around the wire and

tighten it rmly.

Screw the two wire locks around the wire as in

the picture, while you tighten it.

Tensioning o the wire

Loosen the bolts to the wire holder on the end

arch on both sides so that the wire goes freely

through the system.

Tighten the wire by pulling at both ends of the

wire with maximum manual power.

Tighten the wire with the built-in wire tensioner on the drive beam. NOTE! Do not span the wire.

Appropriate tension is reached when the wire hangs down approx. 20-30mm on a 6 meter

system.(Post-tensioning may be needed)

1122

3344

55

14

Tighten the Slider system with the help of manual power so that

the end arch ends up close to its nal position, but without the tilt

arc with automatic closing closes.

End position adjustment

It is important that the wire locks come as close to the end arch as possible, see picture above.

14 15

Check that the Fliptop Slider stands

straight by measuring on both sides of

the end arch to the desired end

position.

Screw the end arch into the wire

bracket on both sides of the end arch.

It is important that the wire ends in the

grooves in the wire holder.

This is a good example of a good

positioning of the wire locks against

the end arch adjacent to the wire

wheel.

16

Drive unit

MANUAL

Fit the lock to the crank, then fas-

ten the crank, or alternatively cut

it to the desired length and tighten

the stop screws.

16 17

ELECTRICAL

The electric motor is mounted on the drive beam with 4 X M8X20 and 4 X M8 BRB with

the motor facing the center.

We recommend lubricating the shaft with grease before mounting.

The shaft with wedges are packed separately.

Fit the engine cover. When mounting, the motor protective cover must be clamped

between the aluminum strip and the drive beam bracket.

18

Adjustment of automatic rear closing

For the automatic closing to work well, the springs may need to be adjusted. The springs that lift

up the tilt arch with automatic closing should be as weak as possible. The force should only just be

able to lift up the tilt arch of the automatic rear closing. There are many possibilities to adjust the

springs.

The spring can be repositioned to reduce or increase the force.

The spring must be adjusted so that the automatic rear closing knocks down where the

wire wheel ends.

If the automatic rear closing goes down too soon, extend the chain between the spring and the

rocker. If the back end of the automatic rear closing goes down too late, shorten the chain

between the spring and the back end.

NOTE. It is important not to have the chain and springs too tight, as they tend to reverse

the Slider system.

18 19

When the back end of the automatic rear closing closes softly, it will look like this.

When the automatic rear closing is adjusted correctly, the s-hooks should be pinched.When the automatic rear closing is adjusted correctly, the s-hooks should be pinched.

1122

3344

20

Adjustment of stop arm

Adjust where to put the stop arm, it should be a gap of approx. 5CM.

Table of contents

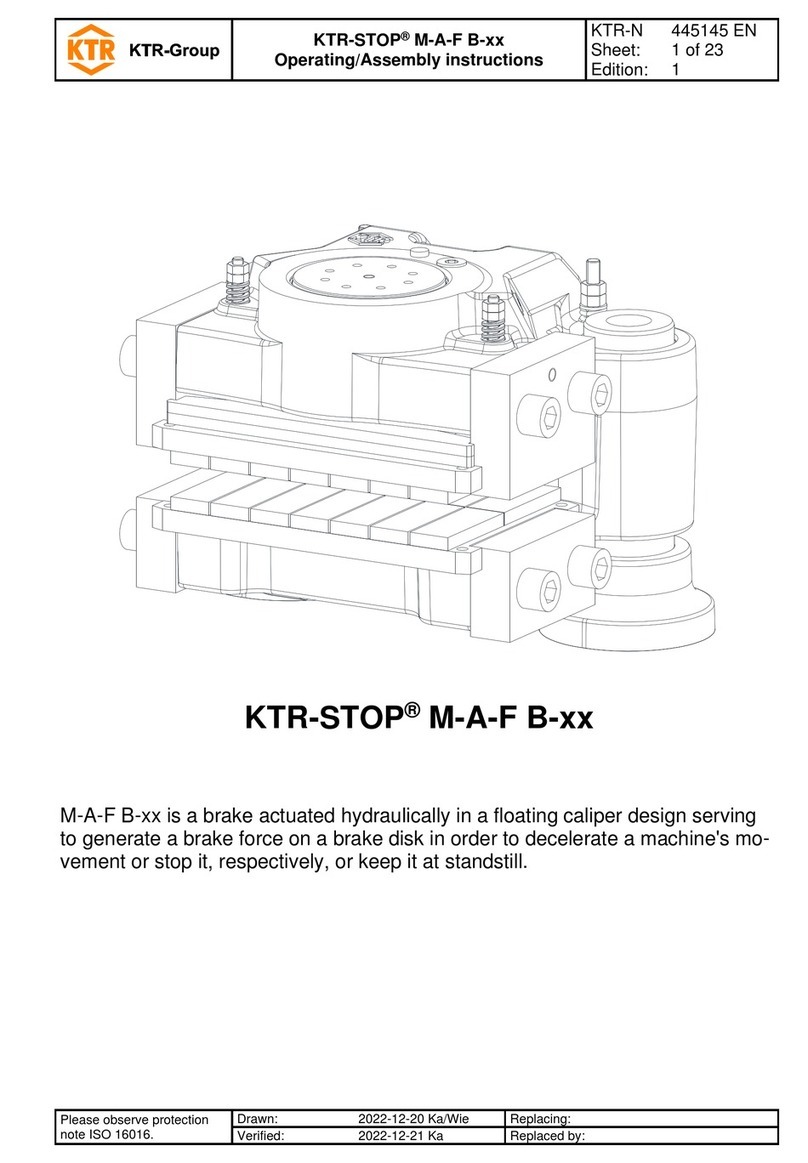

Popular Industrial Equipment manuals by other brands

KTR-Group

KTR-Group KTR-STOP M-A-F B Series Operating & assembly instructions

Innova

Innova PantoVision T2 USER INTERFACE MANUAL

schmersal

schmersal AZM300Z-I2-ST-1P2P-T Operation instructions

Linn-High-Therm

Linn-High-Therm HT-1500-GT-VAC Special GRAPHITE operating instructions

Eaton

Eaton PKE-XTUACP-36 Instruction leaflet

Grundfos

Grundfos TPE 2 Series instructions