Linn-High-Therm HT-1500-GT-VAC Special GRAPHITE User manual

O p e r a t i n g I n s t r u c t i o n

High Temperature Furnace

HT-1500-GT-VAC

Special

with options

gas purging, graphite insulation, graphite heating elements,

gas recooling unit with HEPA-filter, second door with fan,

Eurotherm controller, Eurotherm recorder

and

vacuum pump stand

Serial-No. 10025533

EDV-Nr. 19332

L I N N - HIGH- T H E R M G M B H

Heinrich-Hertz-Platz 1 D-92275 Hirschbach Tel. 09665/9140-0 Fax 09665/1720

e-mail: info@Linn.de Internet: www.Linn.de

issue 30.10.2018

M:\1) Widerstand\Faser3 (FKH, FT, HT, VHT, FBV, GBV)\Sonder HT\Sonder HT-1500\HT-1500-GT-VAC-

Special_Graphit_Corning\HT-1500-GT-VAC-Special_Graphit_Corning-e.doc

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 2

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 3

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

Original operation manual

Herewith we declare, that the machine

in the delivered design complies with the following provisions:

EC-guide line for machines 2006/42/EC and following, annex I

EC-guide line for EMC 2014/30/EC and following

Following harmonized standards are used particularly:

EN 746 –Industrial thermo-processing units, part 1, part 3

EN 60 204-1 * EN 60 519-1

ISO 12100-1 * ISO 12100-2

EN 55 011 * EN 61 000-6-2

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 4

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

Contents

1. Safety 6

1.1 Designated application................................................................................6

1.2 Explanation of symbols ...............................................................................7

1.3 General advice for safe operation...............................................................8

1.4 Particular dangers.......................................................................................9

1.5 Packing .....................................................................................................10

1.6 Transportation...........................................................................................10

1.7 Storage......................................................................................................10

2. Installation 11

2.1 Place of installation...................................................................................11

2.2 Electrician’s preliminary work on customer’s responsibility .......................11

2.3 Preliminary work on customer’s responsibility for water installation ..........12

2.4 Mounting of heating elements by customer‘s electrician ...........................13

2.5. Electrical connections ...............................................................................15

3. Technical Data 17

4. Description of system 18

4.1 Furnace housing .......................................................................................18

4.2 Insulation...................................................................................................18

4.3 Furnace prepared for the lead –in off three extrusion die ........................18

4.4 Oxygen measurement in the exhaust gas line ..........................................19

4.5 Three zone heating...................................................................................19

4.6 Maximum admissible element temperatures and vacuum ........................19

4.7 Over temperature switch-off......................................................................20

4.8 Thermocouples .........................................................................................20

4.9 Thermocouple safeguard..........................................................................20

4.10 Gas feeding device suitable for vacuum .................................................21

4.11 Additional nitrogen fumigation..................................................................21

4.12 Two additional connections (1/4”) ............................................................21

4.13 Vacuum pump stand system for end pressure.........................................21

4.14 Gas cooling unit ......................................................................................21

4.13 Cooling water control and emergency water cooling...............................22

4.14 Control System........................................................................................23

5. Instructions for temperature controller 24

6. Operating the system 25

6.1 Advice .......................................................................................................25

6.1.1 General Advice..........................................................................................................25

6.1.2 Advice for operating with protective gas .............................................................26

6.1.3 Advice for loading......................................................................................................26

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 5

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

6.2 First start-up..............................................................................................27

6.3 Manual operation ......................................................................................28

6.3 Operation with gas feeding........................................................................28

6.4 Operation under O2atmosphere.............................................................29

6.5 Vacuum operation.....................................................................................29

7. Dew point diagram 30

8. Maintenance 31

9. Spare parts and consumables 32

10. Gas and water flow scheme 33

10.1 Gas flow scheme.....................................................................................33

10.2 Water flow scheme .................................................................................34

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 6

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

1. Safety

IMPORTANT ! Please read manual before installation and start up of system.

In addition to the following items the general safety instructions and accident

prevention regulations are applicable.

Any person who attends system in installation, start-up, operation and maintenance

(inspection, servicing, repair works) must have read and comprehended the whole

operating manual, particularly the safety section. It is recommended that the

proprietor obtains a written acknowledgement by the staff.

Please pass on the safety advices to other users.

1.1 Designated application

The furnace was designed for heat treatments of various materials.

Flammable or explosive materials or those, which release flammable or explosive

substances during the heat-treatment are only allowed to be heated under inert-gas

or reducing atmosphere in this furnace.

It is not permitted to use materials which release as much oxygen at their

decomposition that an explosive gas- or material mixing like explosives etc. is

generated in the furnace.

The manufacturer cannot consider to list all possible applications.

The user is obliged to check and evaluate the effects of heat treatment to each

material and the risks of possible reactions, to avoid injuries and damages.

Any exceeding operation is considered to be not to be designated. Manufacturer will

not warrant for damages resulting therefrom; the risk is fully on the user.

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 7

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

1.2 Explanation of symbols

This sign directs to important safety instructions.

Disregarding may lead to endanger your personal safety and/or

other’s properties.

Read and observe all instructions in this operation manual.

This sign directs to important safety instructions.

Disregarding may lead to endanger system’s safety

and/or other’s properties.

Read and observe all instructions in this operation manual.

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 8

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

1.3 General advice for safe operation

I) Limitations of application are listed in the corresponding sections of this

manual and the relevant directives must be considered and followed.

When dealing with gases it has to be followed to the corresponding safety

regulations. (UVV gases, ex guideline…)

The manufacturer cannot consider to list all possible applications.

The user is obliged to check and evaluate the effects of heat treatment to

each material and the risks of possible reactions, to avoid injuries and

damages.

Any exceeding operation is considered to be not to be designated.

Manufacturer will not warrant for damages resulting therefore; the risk is fully

on the user.

II) Any mode of operation must be avoided, which might reduce the system’s

safety.

Occuring changes at the system, which reduce safety must be immediately

reported, documented and repaired.

The local safety and accident prevention regulations are applicable.

Where necessary, operating staff is obliged to wear protective clothing

(gloves, goggles, etc.).

It is in the proprietor’s responsibility to ensure by appropriate instructions and

controls that the system and working place are kept clean and clear.

Safety devices may not be dismounted or set out of operation.

Switch system off mains before cleaning and repair works, in order to

ensure unauthorized switching on.

III) Subject to modifications by technical progress !

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 9

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

1.4 Particular dangers

Linn heat treatment systems are designed in compliance with the actual technical

status and safe in operation.

However, dangers may come for these heating systems :

I. Risk of unintentional chemical reactions

Material advice 1 :

Flammable or explosive materials or those, which release flammable or

explosive substances during the heat-treatment are not allowed to be heated

in this furnace.

Material advice 2 :

It is not permitted to use materials which release as much oxygen at their

decomposition that an explosive gas- or material mixing like explosives etc. is

generated in the furnace.

II. Risk of burnings

Risk of burnings arises when furnace casing is touched unprotected,

depending on furnace temperature. Proper protections ( gloves ) must be

worn resp. avoid contact of unprotected parts of the body with the furnace

casing.

III. Risk of fire

Do not place inflammable objects ( e.g. office materials ) on the furnace or in

close range.

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 10

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

1.5 Packing

The system is packed for transportation. Packing corresponds with the guidelines for

packings of VDMA and is only intended for transportation. It protects to a limited

extent from humidity, heat and mechanical impacts. Open and remove at place of

installation only.

Packing material must be disposed of properly after use.

1.6 Transportation

Transportation must be performed by specialists, who know and follow the safety

regulations. All advices on packaging and transport documents must be obeyed

during transport. Transportation packaging does not protect the contents against

improper handling !

1.7 Storage

When system has to be stored all safety precautions for transportation will apply.

Additionally the following protections must be provided :

condensed water ( generated by high changes of temperature )

dust

freeze

damage to packaging

vermins ( particularly rats and mice can destroy electric switchings )

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 11

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

2. Installation

2.1 Place of installation

Furnace system should be placed in a clear area, i.e. distance of 100 to 200 mm to

the wall should be considered. The room should be equipped with an exhaust

device, also a properly functioning exhaust hood will be suitable.

The bare heads of thermocouple connectors at the furnace’s rear may not be

exposed to a temperature considerably higher than ambient. E.g. avoid to place a

poor insulated furnace next to the system. When connector heads are becoming too

hot, temperature in muffle will be indicated lower than the actual temperature is. This

can, under extreme conditions, destroy the muffle.

2.2 Electrician’s preliminary work on customer’s responsibility

Works as described below may only by performed by

properly trained personnel.

1. Mounting of a three-pole lever switch, the furnace system must be firmly

connected.

2. Connecting of control system to mains supply according to the attached

circuit diagram.

3. Connecting of furnace casing and pump stand with control system according

to circuit diagram.

4. Connecting of all flexible vacuum tubings between gas –vacuum system,

pumpstand and furnace section.

5. Proper grounding of furnace and control system.

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 12

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

2.3 Preliminary work on customer’s responsibility for water installation

2.3.1 Cooling water supply between the furnace and the cooling unit type Typ

Sigma 18

The cooling water supply occurs through a cooling unit type Typ Sigma 18. For the

fresh water supply of the cooling unit type Typ Sigma 18, an installation of a ¾”

connection with pre-filter is necessary. Between the cooling unit type Typ Sigma 18

and the furnace are laid 1 1/4 ” water pipes for the cooling water run in or rather

cooling water drain.

The connections for the water run in and water drain have to be provided with hose

fittings. The furnace is already cased.

2.3.2 Emergency cooling water supply

The emergency cooling water supply of the furnace occurs over a separate

connection to the main water line mains of the user. The main water circuit will be

activated through special NO - water valves when the power supply system fall out.

At the same time it ensures also the cooling of the furnace. The emergency water

supply or rather the emergency water drain of the furnace occurs over a 1 1/2”

connection.

The emergency water access of the furnace is provided with a shut-off valve with

vane relay. If the shut-off valve do not open during furnace start the program of the

furnace will not start and an alarm will release.

The shut-off valve has to be closed at the end of the furnace program and by cooled

down and switched off furnace that no fresh water flows through the furnace

permanent.

The connections for the water run in and water drain have to be provided with hose

fittings. The furnace is already cased.

Please check the water pressure in your pipe mains before the connection of the

machine. The pressure has to be also in summer min. 3 bar but max. 5 bar. It has

to be used a circulation cooling unit if the water pressure is too low. The water

pipe which leads to the machine has to be provided with pressure reducing valve

if the water pressure is bigger than 5 bar.

The water flow should be min. 35 l/min. If the water flow is too low the silicone

flat seal will be destroyed very fast. A too big water flow has a negative influence

on the temperature distribution in the muffle. Ideal would be a water temperature

in the drain of 25-35°C by a max. furnace temperature. The water has to flow until

the furnace is cooled down to room temperature.

The water drain for the cooling water has to be work without back pressure.

By water supply mains which lead to deposits or incrustations, the installation of

a flow filter would be necessary.

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 13

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

2.4 Mounting of heating elements by customer‘s electrician

Works as described in the following may only be performed by specially

trained personnel

Switch furnace off mains and protect against unauthorized operation.

Heating elements are very sensitive to breakage

Preliminary Works

The cover casing can be unscrewed and taken off.

Looking from top into the furnace casing, the furnace chamber itself with bolted

cover is visible.

Dismantle the water cooling hoses if necessary

Remove furnace chamber cover after unscrewing. Cover of heating chamber

appears. Long holes in the cover are for heating elements. Number of heating

elements depends on the furnace version and varies between four and twelve.

Installation of heating elements

Move the heating element from heating chamber in the holes with the ceramic hull in

the ceiling with the connection ends. Then screw in from above the disc between

graphite connection end and power connecting bolt. Heating element is positioned.

Lift heating element slightly and fill in the gap with graphite fiber.

The next step is to put over the two connecting wires per heating element flank over

the connecting bolt and to fix it. It has to be acted according to connection plan of the

heating elements.

Install remaining heating elements the same way.

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 14

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

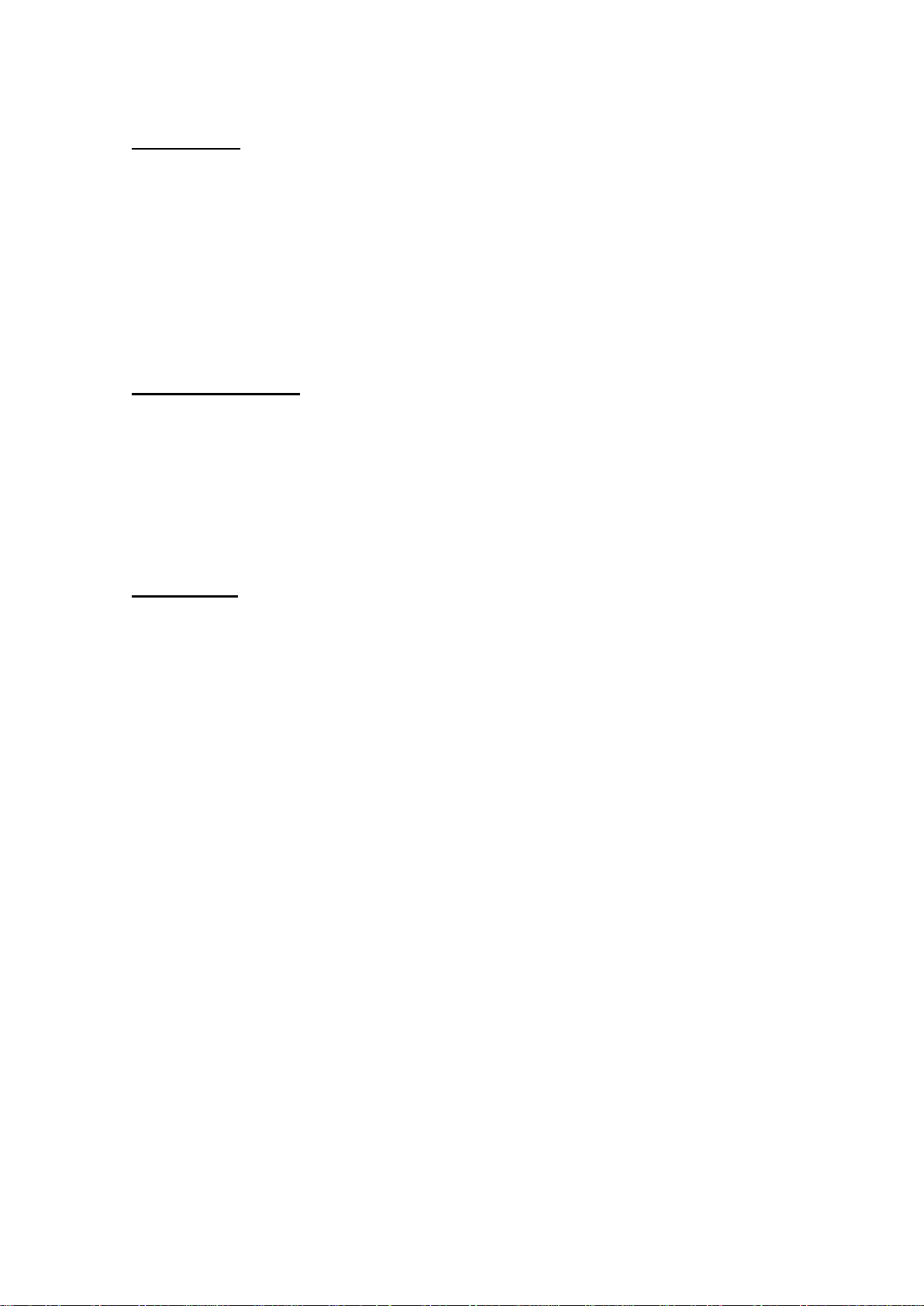

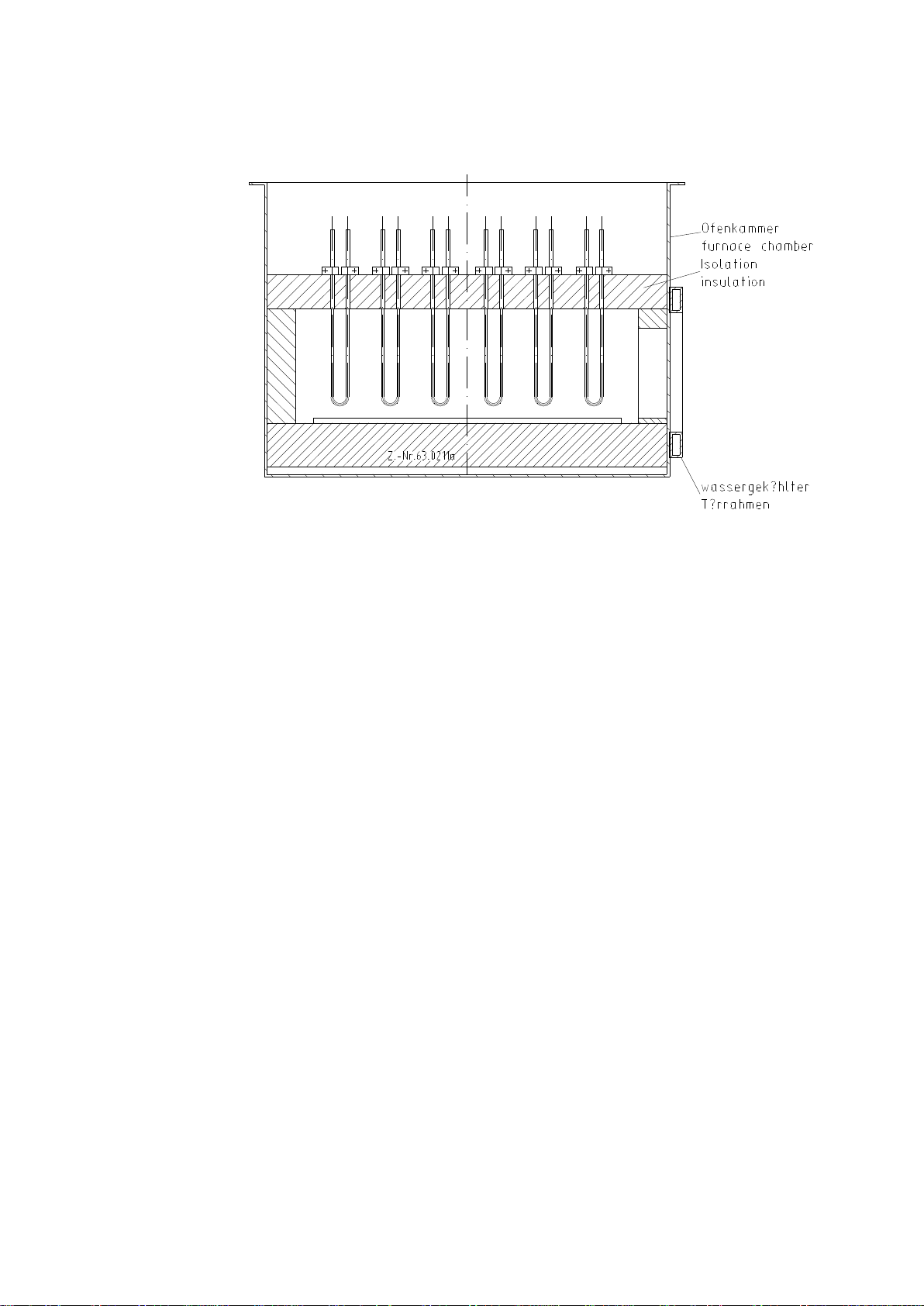

GT version

pic. 2.4 Mounting of heating elements GT version

Connect to mains, mounting of connecting clamps

Depending on the version connecting clamps can vary in length and bores. Most

clamps are premounted and are used to connect two heating elements. Also, contact

rails can be included in supply to shunt two heating elements. Pictures explaining

electrical connection are attached to this section.

At first, plastic section which secured for transportation must be unscrewed from the

connecting clamp. Push clamp carefully over the heating element, connecting ends

will take place of plastic section. Position connecting clamps according to the

matching picture and then close screws tightly.

Mount contact rails if indicated.

Mounting is finished after having checked picture for connecting and that all screws

are fitting tightly.

Remaining assembly

Mounting cover of furnace chamber, make sure that silicon sealing remains clean in

furnaces with protective gas operation and that it fits to sealing area between furnace

chamber and it’s cover.

Installation of fanning cover and rear wall of furnace casing same as dismounting in

opposite order.

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 15

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

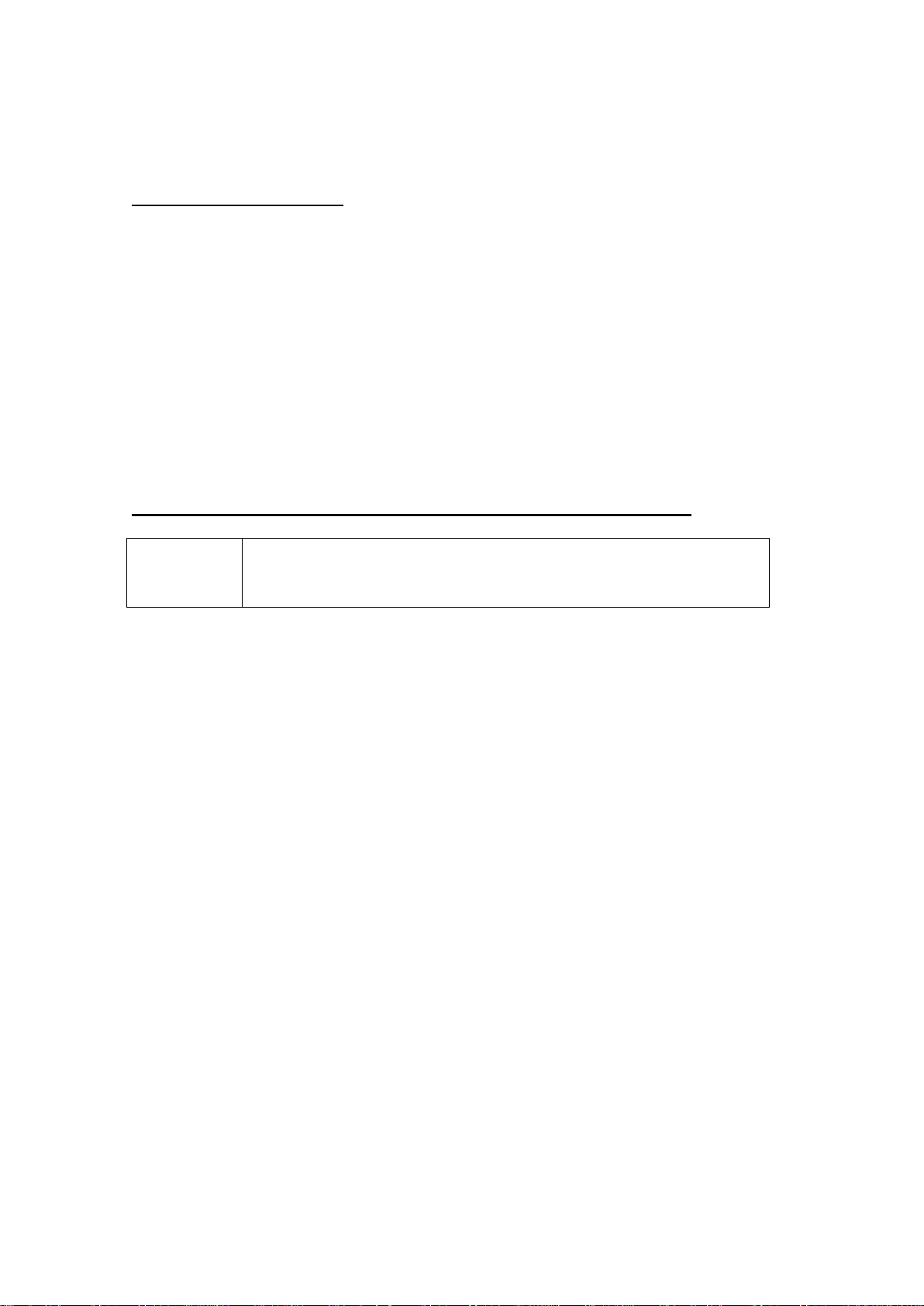

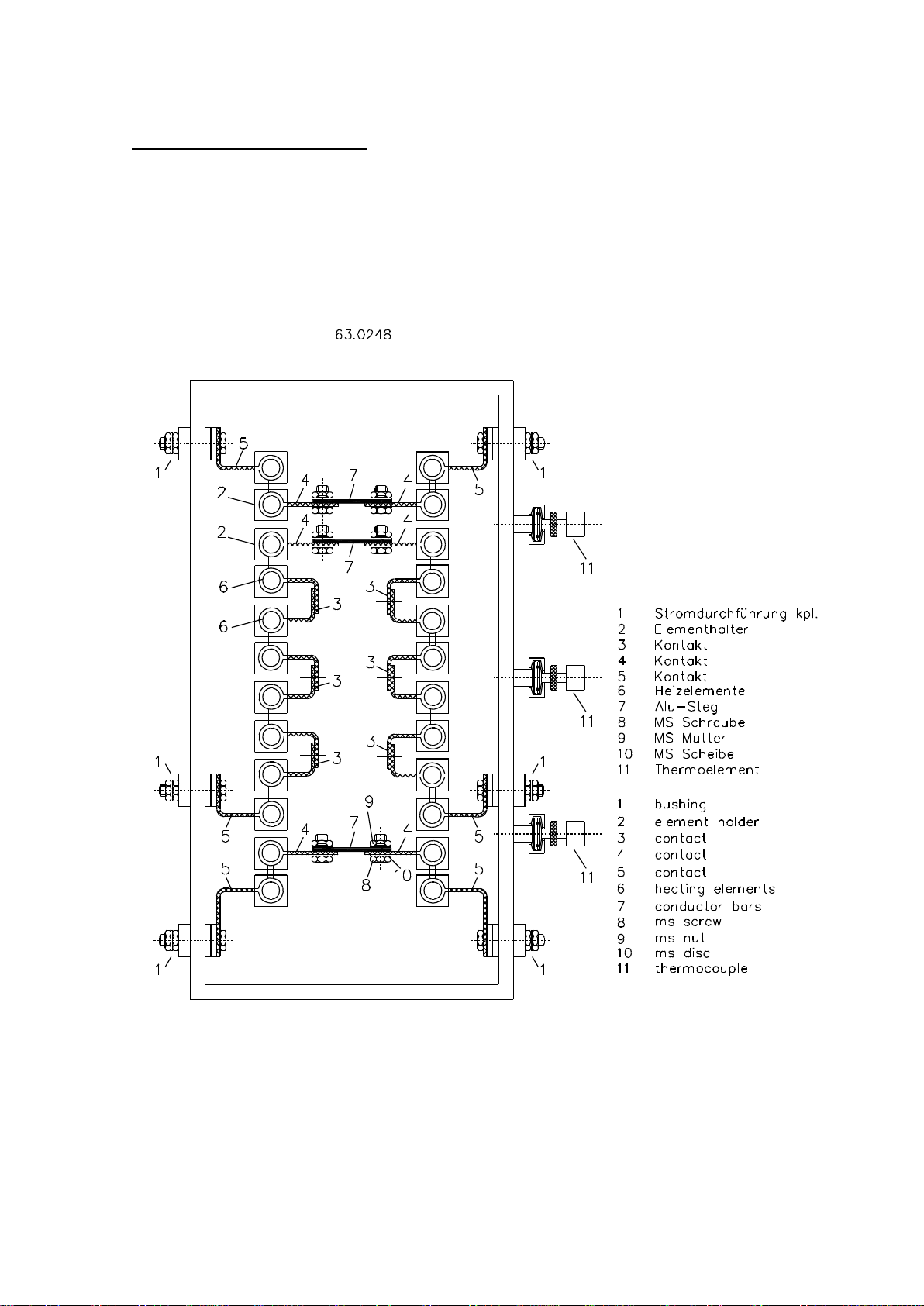

2.5. Electrical connections

Heating elements are connected by configured flat strip laces and rectangular

Aluminium strips. Heating elements are switched with these according to drawing

pic. 2.5 Electrical connection for GT-version (Scheme presentation)

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 16

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

pic. 2.5 Electrical connection for HT-1500-GT-VAC Graphit

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 17

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

3. Technical Data

Electrical connection

Mains: 400 V AC, 3 Ph, N, PE, 50 Hz

Connected power: 140 kVA / 200 A

Dimensions

useful chamber in mm (wxdxh): 430 x 680 x 450

useful volume (liter): 131

outer dimensions furnace in mm (wxdxh): 1200 x 2000 x 2350

outer dimensions with re-cooling unit:

in mm (wxdxh): 2300 x 2400 x 2650

outer dimensions of control unit:

in mm (wxdxh): 1200 x 600 x 2200

outer dimensions of cooling water recooler:

in mm (wxdxh): 730 x 730 x 1600

Temperatures

max. temperature in neutral atmosphere

(short time): 1500 °C

continuous temperature

in neutral atmosphere: 1500 °C

max. temperature in neutral atmosphere

with recirculation fan (short time): 750 °C

relative temperature uniformity: approx. ± 10°C and better in the

middle depending of the load and

the optimization of the control unit

Vacuum

max. Vacuum < 1 mbar

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 18

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

4. Description of system

4.1 Furnace housing

The proper furnace housing is made of stainless steel and is provided in touchproof

condition in the outside housing. It is cooled by a fan (plugged sideways on the

bottom on a separately stored housing) so that also during continuous operation a

wall temperature of 180°C is not exceeded. Because of changed position of the fans

the cover will additionally be designed watercooled. The correspondingly designed

outer housing remains relatively cold (max. 40°C over ambient temperature), except

the door front plate. On both sides a blind flange DN 40 is provided which serves as

lead through for 9 customer –provided thermocouples. For the enforcement of max.

9 thermocouples two adapter DN for max. Ø 1,5 mm thermocouples with vacuum

tight fittings will be installed. The swivelling door with silicone rubber sealing is

provided with turn-locks (spring press capacity). The door flange is water - cooled.

The door is locked until the temperature in the furnace is less than 250°C

(temperature programmable). The status of the door switch can be controlled over a

potential free signal. The furnace door has a guidance in order to avoid damages of

the door insulation during opening and closing. The current connections are installed

on the furnace rear side. The furnace housing is connected separately over feet with

the furnace. Under the furnace housing will be placed a second housing for gas

installation, vacuum, fan for furnace housing, oxygen measuring device etc.

The transformers get an additional housing and will be positioned behind the

furnace.

This housing has legs with a length of appr. 160 mm. A guidance for the customers

loading device is welded or screwed by Linn High Therm. The guidance part is

supported by Corning.

The cover sealing will be designed as circular O-ring sealing. To this the cover and

the furnace housing will be adjusted correspondingly.

The tube lines will be provided with compensators in order to reach a low vibration

load.

4.2 Insulation

The inner housing is lined with graphite fibre boards. The use of this lightweight, low

heat storage material enables extremely short heating up –and cooling down times.

The bottom insulation is reinforced by fibre light bricks and designed for a max. 50 kg

loading on an area in the furnace centre of 300 x 400 mm.

Additionally the furnace chamber contains an outside wall water cooling (cooling

coil).

The joints (labyrinth) of the insulation will be treated with graphite coating in ordert o

minimize a fibre input in the useful chamber.

4.3 Furnace prepared for the lead –in off three extrusion die

In the centre of the furnace roof a water –cooled blind flange DN 40 KF is provided.

On demand it can be used for lead –in of an extrusion die (pressure force max. 80

kg). From the centre of the furnace roof 2 other water –cooled blind flanges DN 40

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 19

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

KF are provided. On demand it can be used for lead –in off an extrusion die

(pressure force max. 60 kg). The insulation below the flange is provided with a

removable insulating plug d= 40 mm. The furnace bottom is reinforced by fibre light

bricks so that it can carry on 320 x 560 mm a weight of 100 kg or rather per 50 kg

floor loading could be beard on the area of each of both further ducts.

4.4 Oxygen measurement in the exhaust gas line

In the exhaust gas line a gas outlet is foreseen for the separate arrangable oxygen

measurement unit Zr-Ox MK II. On this the unit measures the oxygen content of the

exhaust gas. The measuring range goes from 1 ppm to 99,9 % O2. The display of

the oxygen content is effected also over the temperature programme controller. The

measurement device will be placed on the top control housing. By the separate

construction a fast change of the units for calibration is possible. The signal output to

the controller is 4-20mA (breakdown information).

4.5 Three zone heating

The heating is effected by 12 changeable graphite heating elements which are

operated by 3 three –phase current thyristor units in phase angle control and 3 three

–phase current transformers. The heating element connections are brought out at

the side (zone 1 with 2 heaters, zone 2 with 8 heaters, zone 3 with 2 heaters).

Sidewise, approximately in the centre of each zone, a double thermocouple type

PtRhPt type S each measures the temperature per zone. A thermopair is lead to the

temperature controller and the second one is lead to the safety controller.

4.6 Maximum admissible element temperatures and vacuum

For protective gas operation the maximum admissible temperatures of the heating

elements made of graphite are listed in following table.

The maximum admissible temperature for the furnace chamber is approximately

50°C to 70°C lower than the corresponding value in the table, see also below

remark.

Reaction graphite / CFC with process gases

atmosphere

Start of reaction

reaction

Air

500 ~ 600 °C

Oxidation

Water vapour

700 ~ 750 °C

Oxidation

CO2

800 ~ 900 °C

Oxidation

H2

1000 ~ 1200 °C

Methanisation

N2

2000 ~ 2500 °C

Cyanid - formation

Cl2

2500 °C

evaporation

Ar

3000 °C

evaporation

vacuum

2200 °C

evaporation

Linn High Therm GmbH HT-1500-GT-VAC-Spezial GRAPHITE page 20

operating instruction issue 30.10.2018

_____________________________________________________________________________________________________

* Remark: The information in the tables refer to the heating elements

independent from the furnace. Therefore it can be written a higher

value in the table than this furnace allows due to its construction

type and adjusted safety controller.

The highest admissible furnace temperature is approximately

50°C to 70°C lower than the element temperature.

Graphite heating elements can be applied up to max. 2200 °C in vacuum. The

element temperatures to be achieved are depending on how high the vacuum is(see

vapor pressure diagram). Due to the risk of sublimation (the transition from solid to

gas condition) of the graphite in vacuum (lower than 10-3 ) above of 2.200°C an

operation over 2.200°C in vacuum is not to be recommended.

Operation up to 3000°C is possible in non-oxidizing, reducing, or inert protection gas

atmosphere.

4.7 Over temperature switch-off

Safety controller will switch-off heating after approx. 10 seconds when chamber

temperature exceeds the safety controller’s set value. Red „failure“ ( Störung ) bulb

in button will light.

Re-start can only be effected after pressing button „failure“ ( Störung ); it can only be

initiated when temperature is back in the permitted range, i.e. below value set at

safety controller.

Furnace heating is also switched off in case of breakage of safety thermocouple. In

this case system cannot be re-started when pressing button „failure“ ( Störung ).

4.8 Thermocouples

A double thermocouple S-type, installed from the side in each heating zone,

measures the temperature in furnace chamber. One thermocouple is lead to the

temperature controller, the second to correspondent safety controller.

Thermocouples are exposed to wear, i.e. deviations from standard voltage will occur

in the course of operating hours, and they deviate. Therefore, we recommend to

check thermocouples on regular basis with a calibration thermocouple, to reveal

deviations early.

4.9 Thermocouple safeguard

In case of defective control thermocouple temperature controller will set output power

automatically to 0 %. This avoids uncontrolled heating of the furnace.

Table of contents