1 INTRODUCTION .................................................................................................1

1.1 IMPORTANT SAFEGUARDS AND WARNINGS....................................2

1.2 Models .........................................................................................................2

2 QUICK START......................................................................................................3

2.1 Overview......................................................................................................3

2.2 Installation Components ..............................................................................3

2.3 Basic Setup Steps.........................................................................................4

3 INSTALLATION & INITIAL SETUP ................................................................5

3.1 Pan-Tilt Mounting........................................................................................5

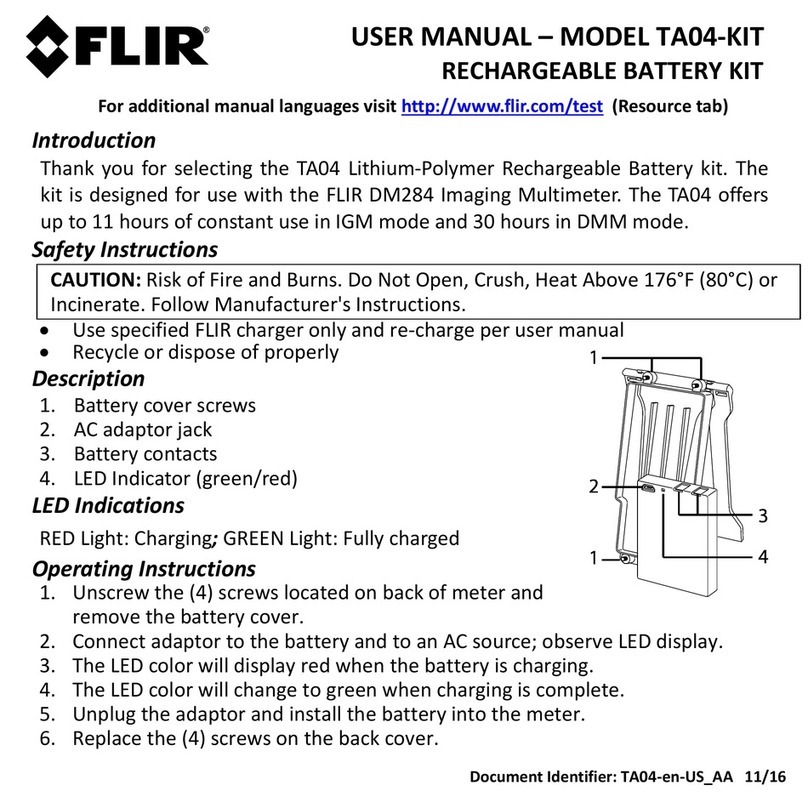

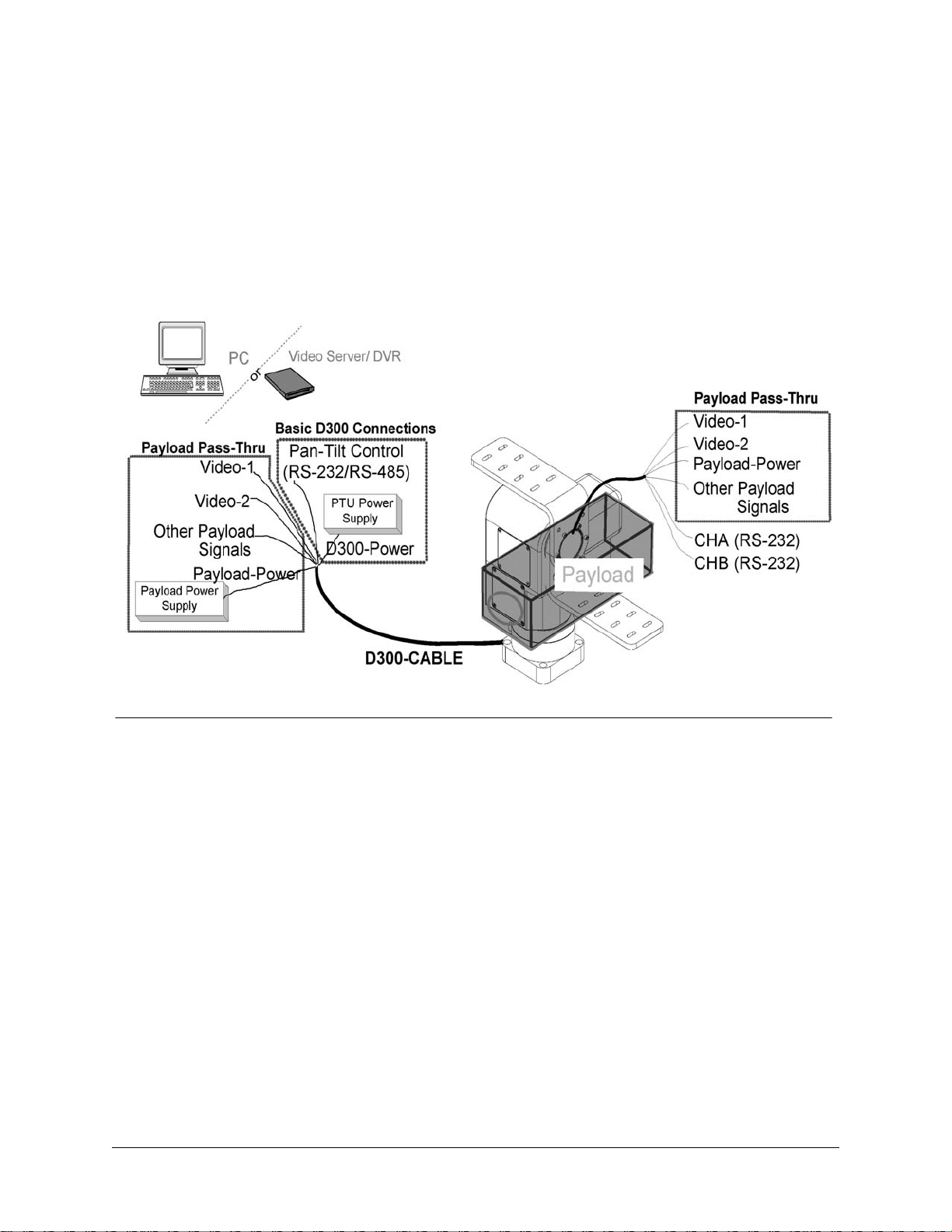

3.2 Wiring and Connectors ................................................................................5

3.3 Power Sources..............................................................................................6

3.4 RS-232 Interface and Host Settings.............................................................7

3.5 Initial Power-up and Test.............................................................................8

3.6 Basic Pan-Tilt Unit Commands ...................................................................8

3.7 Mounting Your Payload...............................................................................8

3.7.1 Over-the-Top Bracket Mounting......................................................9

3.7.2 Side-Mount Bracket Mounting........................................................9

3.8 Payload Wiring Connections .....................................................................10

4 COMMAND REFERENCE................................................................................11

4.1 Binary Command Format ..........................................................................11

4.2 General ASCII Command Format.............................................................11

4.3 Positional Control Commands & Queries .................................................11

4.3.1 Position (absolute) .........................................................................11

4.3.2 Offset Position (relative offset)......................................................12

4.3.3 Resolution per Position..................................................................12

4.3.4 Limit Position Queries...................................................................13

4.3.5 Position Limit Enforcement...........................................................13

4.3.6 Immediate Position Execution Mode.............................................14

4.3.7 Slaved Position Execution Mode...................................................14

4.3.8 Await Position Command Completion ..........................................15

4.3.9 Halt Command...............................................................................15

4.3.10 Monitor (Autoscan) Command......................................................16

4.3.11 Position Presets..............................................................................16

4.4 Speed Control Commands & Queries........................................................17

4.4.1 Speed Control & Relevant Terms..................................................17

4.4.2 Speed (absolute).............................................................................17

4.4.3 Delta Speed (relative offset) ..........................................................18

4.4.4 Acceleration...................................................................................19

4.4.5 Base (Start-Up) Speed....................................................................19

4.4.6 Speed Bounds ................................................................................20

4.4.7 Speed Control Modes.....................................................................20

4.5 Unit Commands.........................................................................................21