FLM Centerball 38 FT User manual

Manual

Tripodheads

mk-messtechnik GmbH | Division FLM | Zeppelinstraße 1 | 73274 Notzingen | Germany

mk-messtechnik GmbH | Division FLM | Zeppelinstraße 1 | 73274 Notzingen | Germany

Operating and care instructions

NOTICE: Before mounting your camera, please read this manual carefully!

All knobs are secured against unscrewing. Please unscrew only until you feel resistance (stop).

Please always allow your tripod head time to adjust to the respective temperature. Moisture or con-

densation water can temporarily impair the velvety smooth running of the ball.

1

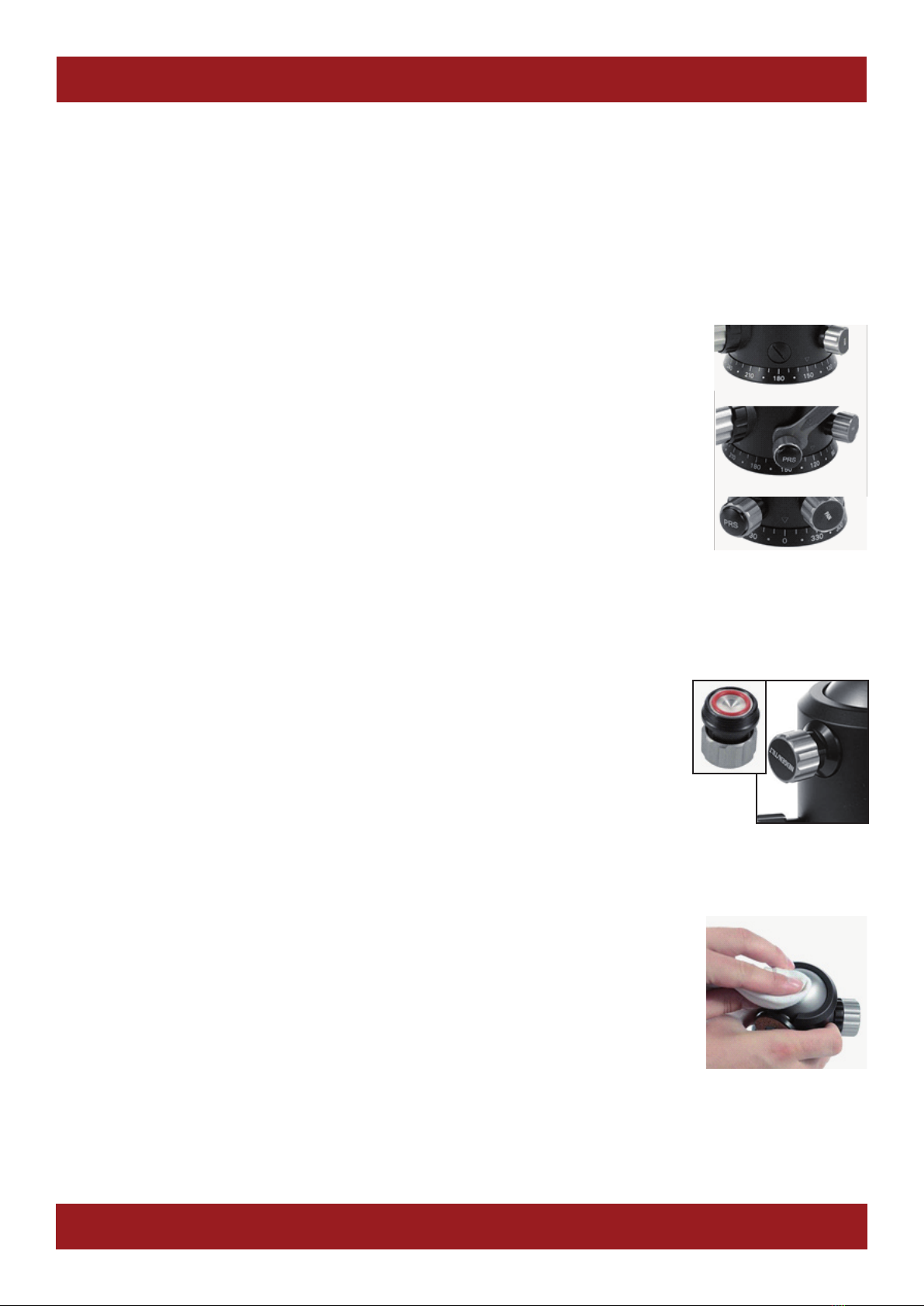

AllFTmodelscanberetrofittedlaterwiththenew15°stopsystem.Theprotective

cover is removed with the help of a suitable screwdriver or with a coin (picture 1).

In its place the 15°-stop button is fixed with a 10mm open-end wrench (picture 2).

The locking function of the 15°-stop button is activated by turning the grey

handle to the right until it stops. Deactivation is done by turning the grey handle

to the left. An audible and perceptible click of the raster during panorama ro-

tation now enables single image recordings at the smallest distance of 15°.

By pressing the black 15°-stop button at position “0” the panorama base locks

into place (picture 3). Now the tripod head is screwed onto the tripod or remo-

ved by holding the pressed button simultaneously. Especially with changing

temperatures, this additional function allows quick and safe handling.

Using the tilt function

By tightening the tilt button it is possible to lock the rotation and left/right tilt of

the ball. The ball can now only move in one plane, similar to a 2-way tilt.

However, the load for horizontal rotation of the center ball is limited by the

O-ring. If the O-ring is damaged, it must be replaced immediately.

The FLM Centerball requires no maintenance, but regular care. If the preload

force (FRIKTION) of the ball decreases or the ball is dirty, clean the ball tilted

into the slot with a lint-free cloth soaked in pure alcohol (spirit). To rotate the ball,

loosentheadjustmentknob,andifpresent,alsotheTILT/TILTknob.Neveruseoil!

Due to the new design, the FLM Centerball can also be completely disassem-

bled for possible repairs or cleaning - but only by the manufacturer, otherwise

the manufacturer’s warranty is void.

Assembly and function of the 15° stop button

Maintenance and cleaning of the FLM Centerball

mk-messtechnik GmbH | Division FLM | Zeppelinstraße 1 | 73274 Notzingen | Germany

Instructions for adhesive mounting QRB and PRP

The stud bolt supplied with the center ball can be screwed into the ball in two

ways. With the 1/4” thread on top, the single plate can be screwed on, so

that the protruding 1/4” thread represents the camera connection. For the

construction of special camera plates, however, the 3/8” thread must point

upwards - the 1/4” thread of the stud bolt disappears in this case in the ball.

To avoid damage to the bottom thread of the camera, it is es-

sential to pay attention to the protruding thread length.

To connect the Quick Release Base or the Power Release Base (pic-

ture 2) firmly and non-rotatably to the center ball, the stud screw is

glued to the base and center ball. Please use metal adhesive with a

temperature resistance of up to approx. 100° C to enable subsequent

replacement of your Base. We recommend UHU plus endfest 300.

Apply the adhesive at the end of the 3/8” thread approx. 3 turns all around

(no adhesive on the screw head - see picture 1) and screw this screw end

into the Power Release Base as far as it will go. With the Quick Release

Base, however, the screw must not protrude from the top of the base plate.

After curing (see instructions for use of your adhesive), the base is glued

to the center ball in the same way (picture 3). A later replacement of your

old base plate can be done by completely dipping the base plate - but

only the base plate - into boiling hot water. This will soften the metal adhe-

sive and the plate can be easily removed. Protect your hands from burns.

2

Adhesive joints at the FLM Centerball

Please make sure that no sand or salt water gets inside the tripod head

Note:

Bild 1

Bild 2

Bild 3

Bild 4

mk-messtechnik GmbH | Division FLM | Zeppelinstraße 1 | 73274 Notzingen | Germany

Operation of the stop ring and adjustment handle

3

1. Friction and fixation

Hold the ball head so that you are looking directly at the FLM logo. Now

the fixed button is on the right side. The black scale ring acts as a lock-

nut and serves as a stop for the grey fixed knob, which is thus protected

against being turned out completely counterclockwise.

As soon as you turn the scale ring clockwise as far as it will go, the ring

and knob are fixed and can no longer be turned. To release the fixation,

turn the knob slightly clockwise. Now you can turn the ring and knob si-

multaneously counterclockwise to the stop. The ball is now freely mova-

ble again.

2. Adjustment of the friction with mounted camera and released ball

Turn the adjustment handle clockwise until the camera stops automatically in any position.

If you now turn the black scale ring also clockwise until it stops, you have saved the position value

of the friction setting. This procedure is carried out once for each camera/lens combination. The

number on the scale ring below the arrow shows the set position value for this camera/lens com-

bination. By setting to this numerical value, you can safely repeat the friction setting for a specific

camera/lens combination at any time.

3. Readjusting the friction fine adjustment

First turn the adjustment handle clockwise to release the lock with the scale ring. Then turn the scale

ring clockwise to a higher value. This increases the friction. Turning it counterclockwise reduces the

friction. Then turn the adjusting handle counterclockwise until it stops. Only now have you changed

the friction. Please note, as mentioned under point 2, that a 100% friction setting is only guaranteed

if the adjusting handle is turned back to the stop of the adjusted scale ring and locked.

4. Adjusting the friction of different cameras or lenses

Proceed as described under point 2. With the help of the number displayed on the scale ring, the

friction setting can be safely repeated for each camera/lens combination at any time.

Now change the camera/lens combination and adjust the friction as described in point 2. Note the

number on the scale ring for the camera/lens combination that is now mounted. Repeat this proce-

dure for all camera/lens combinations.

5. finding the individual friction positions again

Tighten the adjustment knob so that the mounted camera/lens combination cannot be moved. Now

set the scale ring to the value determined for this camera/lens combination under point 3. Then turn

the adjustment knob counterclockwise until it stops.

Points 1-5 are one-time settings.

Point 6 describes the adjustment procedure of the ball head immediately before taking a picture.

6. Fixation

At the friction value set in point 2, the camera/lens combination is determined by turning the ad-

justment knob clockwise. Since the ball head for the specific camera/lens combination is already

preloaded, a half to full turn of the knob is usually sufficient to fix the camera correctly. When turning

the adjustment handle back, you automatically reach the set friction position. Even in darkness, the

set position cannot be missed. This prevents unintentional release of the head with the camera/lens

combination mounted.

stop ringstop ring

adjustment handleadjustment handle

This manual suits for next models

2

Table of contents

Other FLM Camera Accessories manuals

Popular Camera Accessories manuals by other brands

Trojan

Trojan GC2 48V quick start guide

Calumet

Calumet 7100 Series CK7114 operating instructions

Ropox

Ropox 4Single Series User manual and installation instructions

Cambo

Cambo Wide DS Digital Series Main operating instructions

Samsung

Samsung SHG-120 Specification sheet

Ryobi

Ryobi BPL-1820 Owner's operating manual