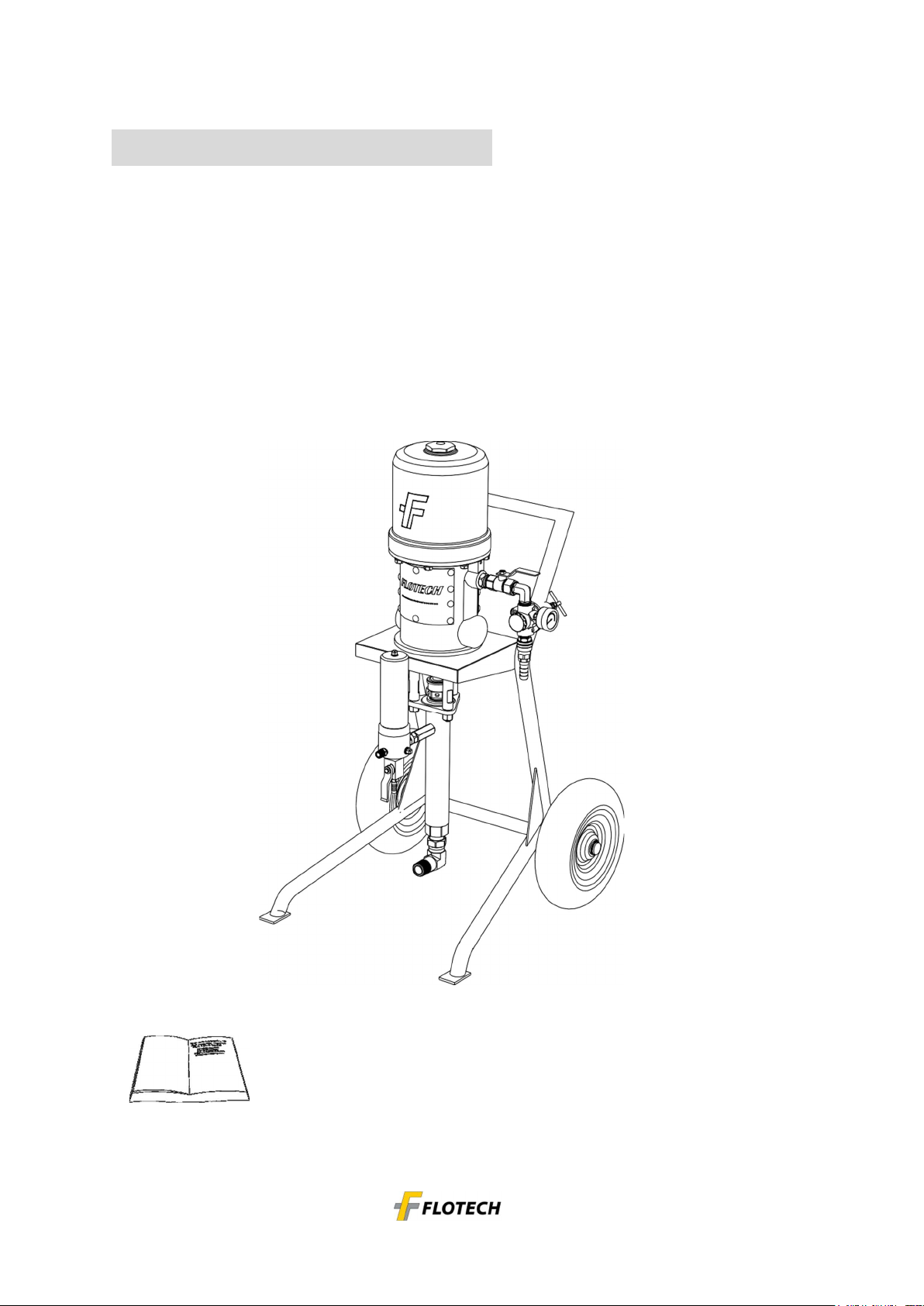

Flo-tech DK301-000 Setup guide

REPAIR INSTRUCTIONS

Rev 1

MODEL : DK301-000

30:1 Ratio Pump

3000PSI (21.0 MPa, 210 bar) Maximum Fluid Working Persure

100psi (0.7 MPa, 7bar) Maximum Air Input Pressure

This manual contains important warning and

information.

Read and keep reference.

WARNING

INJECTION

HAZARD

Spray from the spray gun, hose leaks or ruptured

components can inject fluid into your body and

cause extremely serious injury, including the need

for amputation. Splashing fluid in the eyes or on the

skin can also cause can also cause serious injury.

_ Fluid injected into the skin is a serious injury. The

injury may look like just a cut, but it is a serious

injury. Get immediate medical attention.

_ Do not point the gun at anyone or any part of the

body.

_ Do not put hand or fingers over the spray tip.

_ Do not stop or deflect leaks with your hand, body,

glove or rag.

_ Do not “blow back” fluid; this is not an air spray

system.

_ Always have the tip guard on the spray gun when

spraying

_ Check the spray gun diffuser (if so equipped)

operation weekly. Refer to the gun manual.

_ Be sure the spray gun safety knob operates

before operating the gun.

_ Lock the spray gun safety knob when you stop

spraying.

_ Tighten all fluid connections before each use.

_ Check the hoses, tubes and couplings daily.

Replace worn or damaged parts immediately.

Permanently coupled hoses cannot be

repaired.

_ Handle and route hoses and tubes carefully.

Keep hoses and tubes away from moving parts

and hot surfaces. Do not use the hoses to pull

equipment. Do not expose FLOTECH hoses to

temperatures

above 150_F (66_C) or below –40_F (–40_C).

EQUIPMENT

MISUSE

HAZARD

Equipment misuse can cause the equipment to

rupture, malfunction, or start unexpectedly

and result in serious injury.

_ This equipment is for professional use only.

_ Read all instruction manuals, tags, and labels

before operating the equipment.

_ Use the equipment only for its intended

purpose. If you are uncertain about the

usage, call your distributor.

_ Do not alter or modify this equipment. Use

only genuine FLOTECH parts and

accessories.

_ Check the equipment daily. Repair or replace

worn or damaged parts immediately.

_ Do not exceed the maximum working

pressure of the lowest rated system

component. This equipment as a 5000 psi

(345bar) maximum working pressure.

_ Do not lift pressurized equipment.

_ Route the hoses away from the traffic areas,

sharp edges, moving parts, and hot surfaces.

Do not expose FLOTECH hoses to

temperatures above 150_F (66_C) or below –

40_F (–40_C).

_ Do not use the hoses to pull the equipment.

_ Use fluids or solvents that are compatible with

the equipment wetted parts. See the

Technical Data section of all the equipment

manuals. Read the fluid and solvent

manufacturer’s warnings.

_ Fluid hoses must have spring guards on both

ends to protect them from rupture caused by

kinks or bends near the couplings.

_ Comply with all applicable local, state and

national fire, electrical and other safety

regulations.

TOXIC

FLUID

HAZARD

Hazardous fluids or toxic fumes can cause a

serious injury or death if splashed in the eyes or

on the skin, inhaled, or swallowed.

_ Know the specific hazards of the fluid you are

using.

_ Store hazardous fluid in an approved container.

Dispose hazardous fluid according to all local,

state and national guidelines.

_ Always wear protective eyewear, gloves, clothing

and recommended by the fluid and solvent

manufacturer.

FIRE

AND

EXPLOSION

HAZARD

Improper grounding, poor air ventilation, open

flames, or sparks can cause a hazardous

condition and result in fire or explosion and

serious injury.

_ Ground the equipment and the object being

sprayed.

_ Provide fresh air ventilation to avoid the

buildup of flammable fumes from solvent or

the fluid being sprayed.

_ Extinguish all the open flames or pilot lights in

the spray area.

_ Electrically disconnect all the equipment in

the spray area.

_ Keep the spray area free of debris, including

solvent, rags, and gasoline.

_ Do not turn on or off any light switch in the

spray area while operating or if fumes are

present.

_ Do not smoke in the spray area.

_ Do not operate a gasoline engine in the spray

area.

_ If there is any static sparking while using the

equipment, stop spraying immediately.

Identify and correct the problem.

MOVING

PARTS

HAZARD

Moving parts, such as the air motor piston and the

secondary pump lever and connecting rod area,

can pinch or amputate fingers.

_ Do not operate the equipment with the air motor

plates removed.

_ Keep your body and tools clear of any moving

parts when starting or operating the equipment.

Operation

1. Lock the spray gun trigger safety.

2. Close the red-handed bleed-type master air valve

3. Unlock the gun trigger safety.

4. Hold a metal part of the gun firmly to the side of a grounded metal pail, and trigger the gun to relieve pressure.

5. Lock the gun trigger safety.

6. Open the drain valve having a container ready to catch the drainage.

7. Leave the drain valve open until you are ready to spray again.

If you suspect that the spray tip or hose is completely clogged, or that pressure has not been fully relieved

after following the steps above, very slowly loosen the tip guard retaining nut or hose end coupling and relieve

pressure gradually, then loosen completely. Now clear the tip or hose.

Packing

nut

/

wet

-

cup

Before starting, fill the packing nut 1/3 full with TSL or compatible solvent. To

reduce the risk of serious injury whenever you are instructed to relieve

pressure, always follow the pressure relief procedure. The packing nut is

torqued at the factory and is ready for operation If is becomes loose and there

is leaking form the throat packings, relieve pressure, then torque the nut to

136-149N.m using a wrench. Do this whenever necessary. Do not over tighten

the packing nut.

Flush the Pump Before first Using

The pump is tested with lightweight motor oil, which is left in to protect the pump parts.

If the fluid you are using may be contaminated by the oil, flush it out with a compatible solvent before using the pump. If the

pump is being used to supply a circulating system, allow the solvent to circulate until the pump is thoroughly flushed.

Flush the pump.

- Before the first use.

- When changing colors or fluids.

- Before fluid can dry or settle out in a dormant pump(check the pot life of catalysed fluids)

- Before storing the pump

Flush whit a fluid that is compatible whit fluid you are pumping and whit the wetted parts in your system.

Check whit a fluid manufacturer or supplier for recommended flushing fluids and flushing frequency.

Technical Data

Category

P

-

TYPE

AIR

MOTOR

M

-

TYPE

AIR

MOTOR

301

Maximum fluid working pressure

21

MPa

210

bar

10

MPa

100

bar

Maximum air input pressure 0.7 MPa, 7 bar

Ratio 30:1 15:1

Air inlet size 1/2 in. npt(f)

Fluid inlet size 3/4 in npt

Maximum operating temperature 82°C (180°F)

Wetted parts

Carbon Steel; Alloy Steel; S45C, 415,440: Zinc and

Nickel Plating; Ductile Iron; Tungsten Carbide; PTFE;

Leather

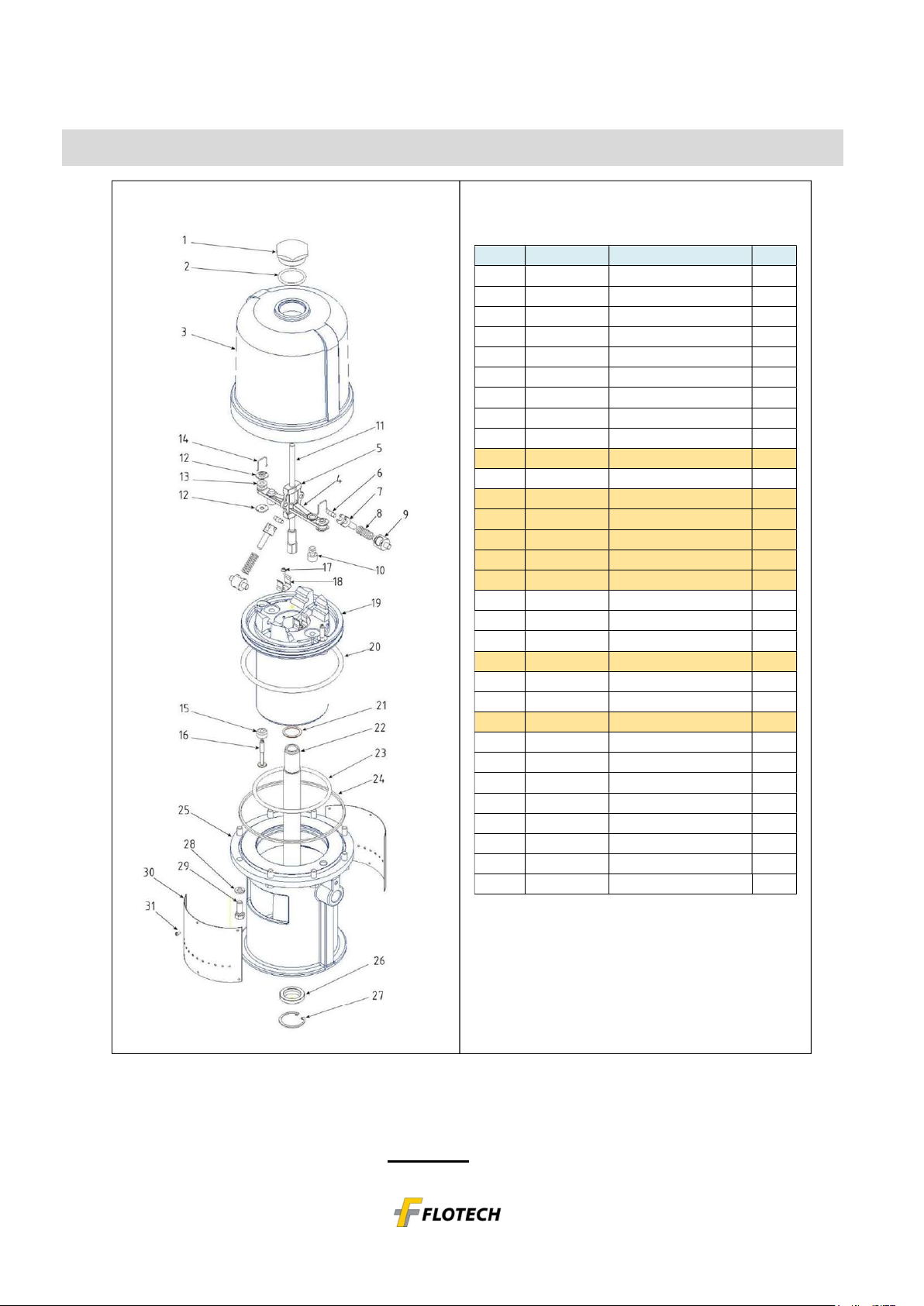

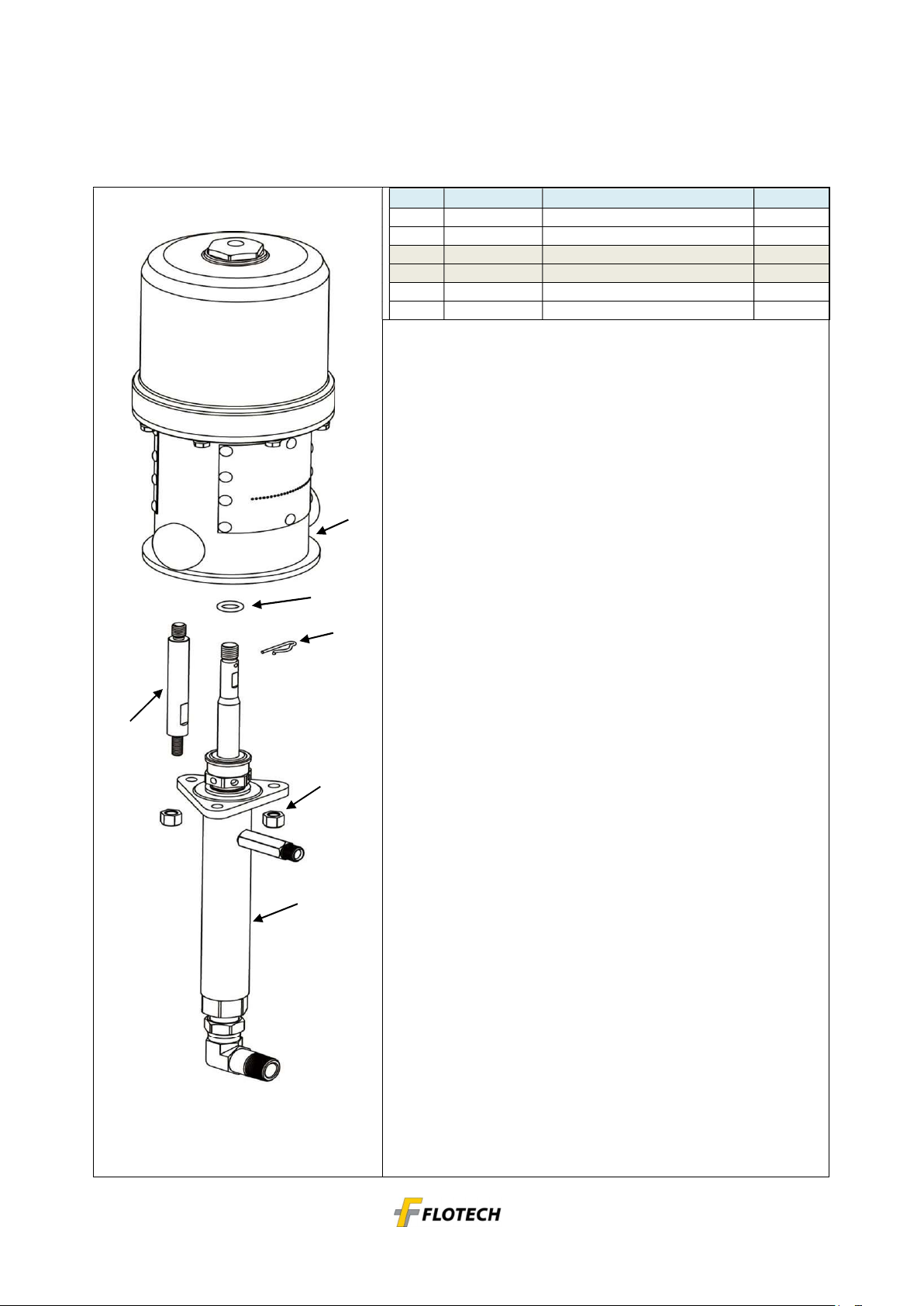

Parts drawing and Parts List for Air Motor DK301-100

No

Part

No

Description

Qty

1 DK30-101 NUT, cylinder cap 1

2 DK254-22 O-RING 1

3 DK30-103 CYLINDER, motor 1

4 DK30-104 ACTUATOR, valve 1

5 DK30-105 YOKE 1

6 DK30-106 PIN, toggle 2

7 DK30-107 ARM, toggle 2

8 DK30-108 SPRING 2

9 DK30-109 ROCKER, toggle 2

10 DK30-110 POPPET, valve 2

11 DK30-111 TRIP ROD 1

12 DK30-112 NUT, adjusting 4

13 DK30-113 GROMMET, rubber 2

14 DK30-114 LOCKWIRE 2

15 DK30-115 POPPET, valve 2

16 DK30-116 STEM, valve 2

17 DK30-117 SCREW 2

18 DK30-118 CLIP, spring 2

19 DK30-119 PISTON 1

20 DK30-120 O-RING ,piston 1

21 DK254-30 GASKET, copper 1

22 DK30-122 ROD, piston 1

23 DK30-123 O-RING 1

24 DK30-124 SEAL 1

25 DK30-125 BASE 1

26 DK30-126 RETAINER 1

27 DK30-127 SNAP RING 1

28 DK30-128 WASHER 8

29 DK30-129 SCREW 8

30 DK30-130 PLATE, muffler 2

31 DK254-48 SCREW 20

Note : part marked in color are the repair parts

Replacement Danger and Warning labels, tags and cards

are available at no cost.

These parts are included in repair kit : DK301-AM which may be purchased separately.

Always use genuine FLOTECH parts.

Parts drawing and Parts List

101

103

104

106

105

102

No

Part

No

Description

Qty

101

DK301-100 AIR MOTOR

1

102

DK301-200 DIS. PUMP ASS’Y

1

103

DK30-201 SEAL(O-RING)

1

104

DK30-202 COTTER PIN

1

105

DK30-203 NUT

3

106

DK30-225 TIE ROD

3

DISCONNECTING THE DISPLACEMENT PUMP

1.

Flush the pump if possible. Stop the pump at the bottom of

its stroke. Relieve the pressure.

2.

Disconnect the air and fluid hoses. Remove the pump from

its mounting. Note the relative position of the pump’s fluid

outlet to the air motor’s air inlet.

3.

Unscrew the tie rod locknuts (105) from the tie rods (106).

Remove the cotter pin (104). Unscrew the displacement

rod (13) from the air motor (101).

Carefully pull the displacement pump (102) off the air

motor (101).

4.

Refer to for displacement pump service.

To service the air motor, refer to the air motor service.

RECONNECTING THE DISPLACEMENT PUMP

1.

Place it on the rod. The align pump’s fluid outlet to the air

motor’s air inlet was noted under Disconnecting the

Displacement pump. Position the displacement pump on

The tie rod.

2.

Screw the locknuts onto the tie loosely.

Screw the displacement rod into the shaft of the air motor

until the pin holes align the cotter pin.

3.

Mount the pump and reconnect all hoses. Reconnect the

ground wire if it was disconnected during repair. Torque the

packing nut/wet–cup (24) to 18–20 ft–lb (24–27 N.m). Fill

the wet–cup with FLOTECH Throat Seal Liquid or

compatible solvent.

4.

Tighten the tie rod locknuts (105) evenly, and torque to 25–

30 ft–lb (34–41 N.m).

5.

Start the pump and run it at about 40 psi (280 kPa,2.8 bar)

air pressure, to check that it is operating properly.

Displacement

Pump Service

Disassembly

When disassembling the pump, lay out all removed

parts in sequence, to ease reassembly.

Clean all the parts thoroughly when disassembling.

Check them carefully for damage or wear, replacing

parts as needed.

1.

Remove the displacement pump from the air

motor

as explained.

2.

Unscrew the intake valve housing (19) from the

pump housing (9). If it is difficult to remove, squirt

penetrating oil around the threads and gently tap

around the valve housing with a plastic hammer

to

loosen it.

3.

Remove the ball stop pin (15), o–ring(17),

retainer (16), and ball (18), ball guide(22), from

the intake housing (19).

4.

Loosen the packing nut (24). Push the

displacement

rod (12) down as far as possible, then pull it out

the bottom of the pump housing (9).

5.

Secure the flats of the displacement rod (12) in a

vise. Screw the piston stud(14) out of the rod .

Remove the ball(13), reatainer(21), packings(5,6)

And glands(4,7).

6.

Remove the packing nut (24), throat packings

(5.6)

and glands (4,7) from the pump housing (9).

7.

Inspect all parts for damage. Clean all parts and

threads with a compatible solvent before

assembling. Inspect the polished surfaces of the

displacement rod (12) and sleeve (11) for

scratches,

scoring or other damage, which can cause

premature packing wear and leaking. To check,

run a finger over the surface or hold the part up

to the

light at an angle. Be sure the ball seats of the

piston and intake housing are not chipped or

nicked. Replace any worn or damaged parts.

NOTE: If the sleeve (11) needs replacement and is

hard to remove, contact your FLOTECH

distributor.

Reassembly

1.

Lubricate the throat packings and install them in

The outlet housing (9) one at a time as follows,

with the lips of the v–packings facing down: the

male gland (4), one teflon (6), two leather(5),

one teflon (6), one leather (5), one teflon (6),

and the female gland (7). Install the packing nut

(24) loosely. See the throat packing detail.

2.

If you removed the sleeve (11), reinstall it in the

pump housing (9), making sure to replace the

gasket (10). Be sure the tapered end of the

sleeve

faces down, toward the pump intake.

3.

Lubricate the piston packings and install them

onto

the piston stud (14) one at a time in the

following

order, with the lips of the v–packings facing up:

the

female gland (7), one Teflon (6), two leather (5),

one Teflon (6), one leather (5), one Teflon (6),

the male gland (4), and the packing retainer

(21). See the piston packing detail.

4.

DO NOT use thread sealant on the piston

stud(14)

Install the piston ball (13) on the piston and

screw

the piston valve assembly into the displacement

rod (12). Torque to 65–75 ft–lb (88–102 N.m).

5.

Insert the displacement rod (12) into the bottom

of

the pump housing (9), being careful not to

scratch

the sleeve (11). Push the rod straight up until it

protrudes from the packing nut (24).

6.

Install the ball (18), o–ring (17), retainer(16),

and ball stop pin (15), ball guide(22), in the

intake valve housing (19). Apply thread

lubricant and Screw the intake housing into the

pump housing (9). Torque to 75–100 ft–lb

(102–136 N.m).

7.

Reconnect the displacement pump to the air

motor as explained.

Technical

Data

Maximum fluid working pressure 3600 psi (25.0 MPa, 250 bar.

Maximum air input pressure 120 psi (0.8 MPa, 8 bar.

Pump cycles per 1 gallon (3.8 liters) 60.

Maximum flow at 60 cycles/min 1 gallon (3.8 liters) ..

Recommended speed for optimum pump life 15–25 cycles/min;.

0.25 to 0.42 gpm (0.9 to 1.6 liters/min)

Air consumption approx. 35 scfm (0.98 min)

at 1 gpm (3.8 liters/min) at 100 psi (0.7 MPa, 7 bar) air pressure

Weight approx. 24 lb (11 Kg)

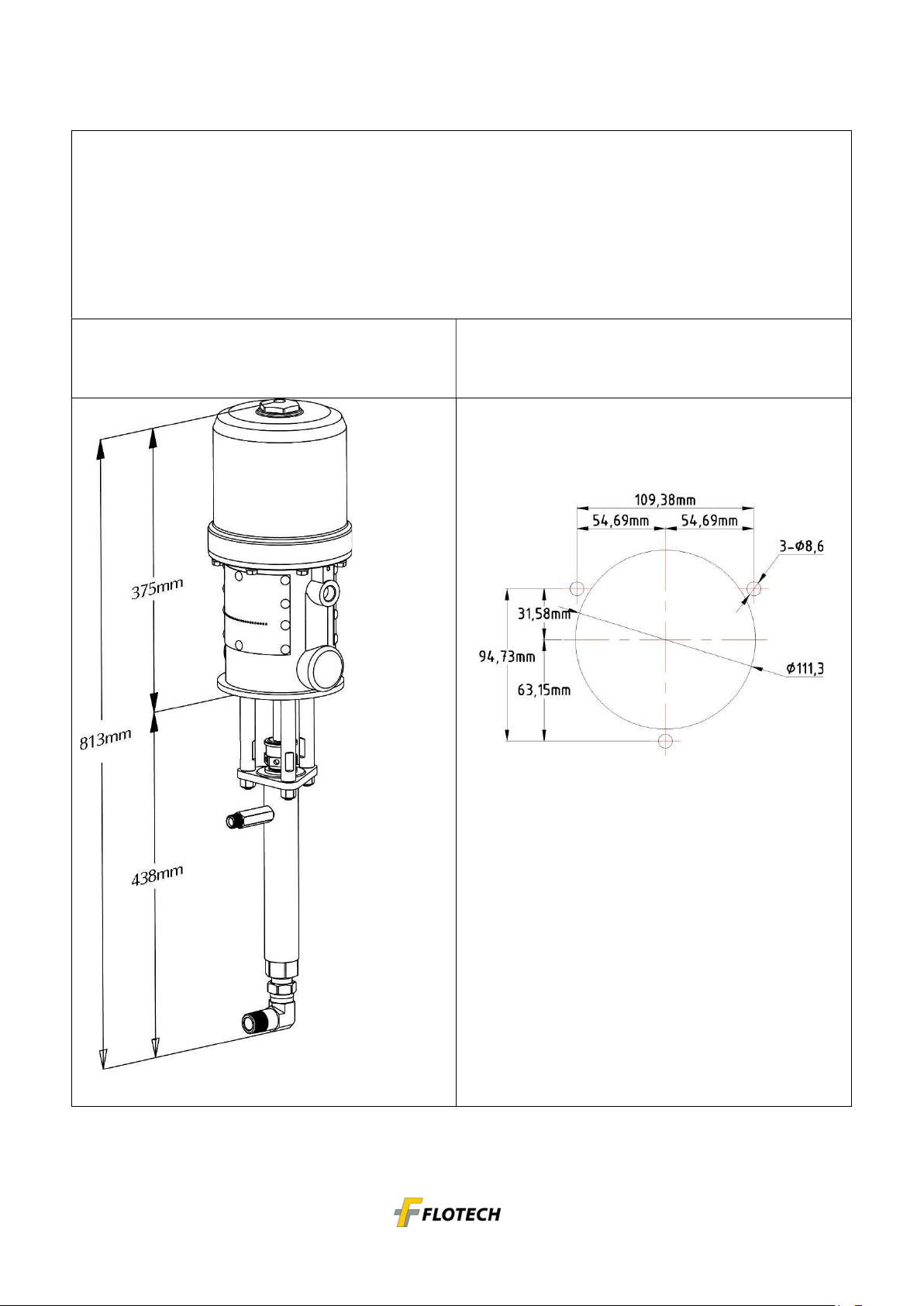

Dimensions

Mounting

Hole

Layout

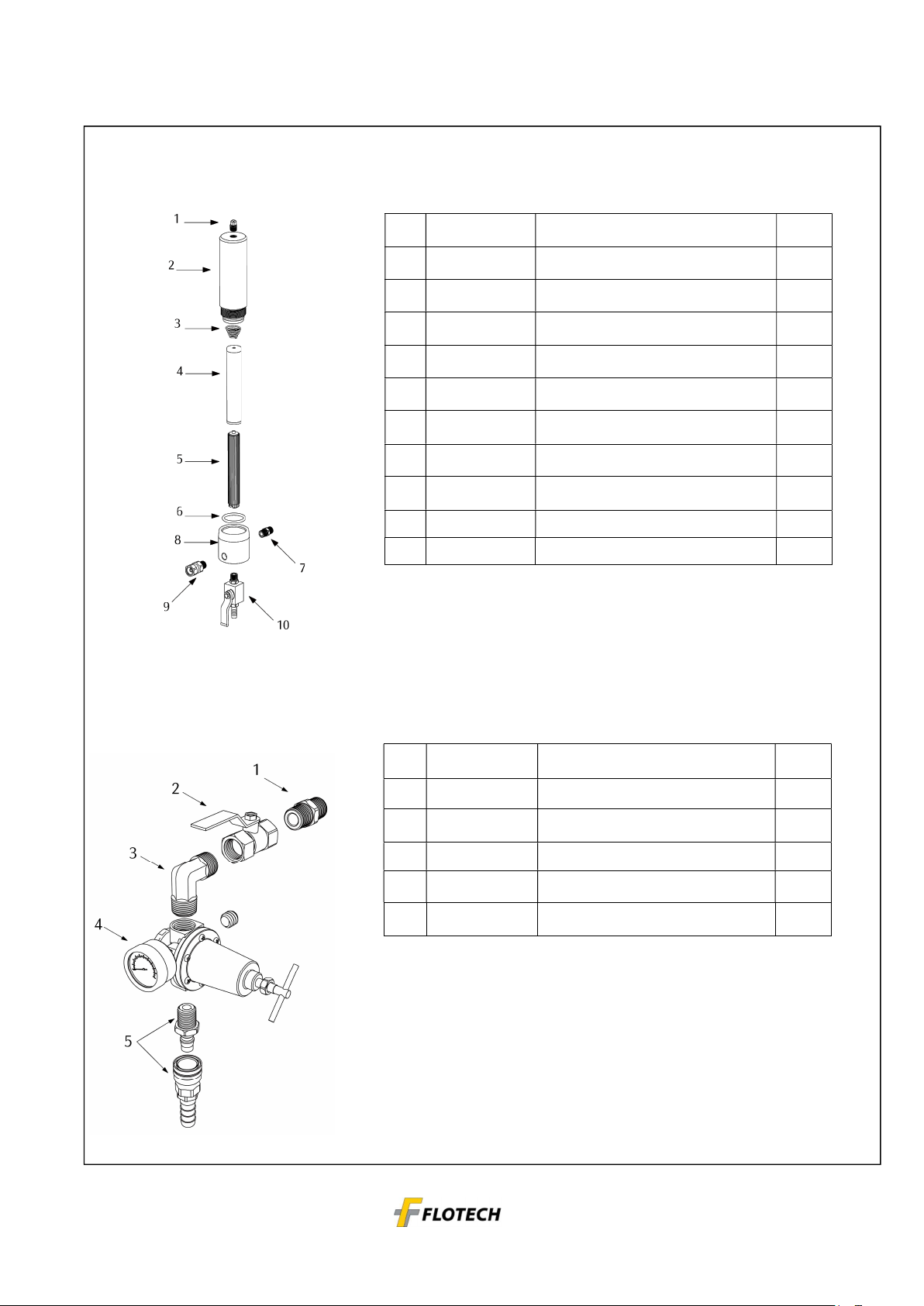

Parts drawing and Parts List

301 DISPLACEMENT PUMP

Note : part marked in color are the spare parts

These parts are included in repair kit : DK301-LA

which may be purchased separately.

Always use genuine parts

No

Part

No

Description

Qty

4

DK30-204 GLAND , male

2

5

DK30-205 V-LEATHER

6

6

DK30-206 V-TEFLON

6

7

DK30-207 GLAND , female

2

8

DK30-208 NIPPLE

1

10 DK30-209 PUMP HOUSING

1

11 DK30-210 SEAL(TEFLON)

1

12 DK30-211 SLEEVE

1

13 DK30-212 DIS. ROD

1

14 DK30-213 BALL(5/16”)

1

15 DK30-214 VALVE PISTON

1

16 DK30-215 PIN

1

17 DK30-216 RETAINER

1

18 DK30-217 SEAL(TEFLON)

1

19 DK30-218 BALL(1/2”)

1

20 DK30-219 INTAKE

1

22 DK254-02 UNION

1

23 DK30-221 WASHER

1

24 DK30-222 GUIDE , BALL

1

25 DK30-223 PLUG

1

26 DK30-224 PACKING , NUT

1

SURGE TANK ASS’Y (DK301-

300)

REGULATOR ASS’Y(DK301-400)

No PART NO. DESCRIPTION Q’TY

1 DK301-301 PLUG 1

2 DK301-302 BOWL 1

3 DK254-303 SPRING 1

4 DK-KS2202 STRAINER #60 1

5 DK186-075 SUPPORT 1

6 DK301-306 PACKING,O-RING 1

7 DK301-307 NIPPLE 1

8 DK301-308 MANIFOLD 1

9 DK301-309 UNION 1

10 DK254-308 BALL VALVE 1

No PART NO. DESCRIPTION Q’TY

1 DK301-401 NIPPLE 1

2 DK301-402 VALVE 1

3 DK301-403 ELBOW 1

4 DK301-404 AIR REGULATOR & GUAGE

1

5 DK301-405 AIR COUPLER 1

SUCTION ASS’Y(DK301-500)

CART ASS’Y(DK301-600)

No PART NO. DESCRIPTION Q’TY

1 DK-KS22903 3/4" FILTER 1

2 DK301-502 SUPPORT PIPE 1

3 DK301-503 ELBOW 1

4 DK301-504 SUCTION HOSE 1

No PART NO. DESCRIPTION Q’TY

1 DK301-601 CART & HANDLE 1

2 DK301-602 TIRE 2

3 DK301-603 SANP RING 2

1

3

2

FLOTECH Standard Warranty

FLOTECH warrants all equipment referenced in this document which is manufactured by FLOTECH and bearing its name to be

free from

defects in material and workmanship on the date of sale to the original purchaser for use. With the exception of any special,

extended,or limited warranty published by FLOTECH, FLOTECH will, for a period of twelve months from the date of sale, repair

or replace any part of the equipment determined by FLOTECH to be defective. This warranty applies only when the equipment

is installed, operated and maintained in accordance with FLOTECH written recommendations.

This warranty does not cover, and FLOTECH shall not be liable for general wear and tear, or any malfunction, damage or wear

caused by faulty installation, misapplication, abrasion, corrosion, inadequate or improper maintenance, negligence, accident,

tampering, or substitution of non–FLOTECH component parts. Nor shall FLOTECH be liable for malfunction, damage or wear

caused by the incompatibility of FLOTECH equipment with structures, accessories, equipment or materials not supplied by

FLOTECH, or the improper design, manufacture, installation, operation or maintenance of structures, accessories, equipment

or materials not supplied by FLOTECH.

This warranty is conditioned upon the prepaid return of the equipment claimed to be defective to an authorized FLOTECH

distributor for verification of the claimed defect. If the claimed defect is verified, FLOTECH will repair or replace free of charge

any defective parts. The equipment will be returned to the original purchaser transportation prepaid. If inspection of the

equipment does not disclose any defect in material or workmanship, repairs will be made at a reasonable charge, which

charges may include the costs of parts, labor, and transportation.

THIS WARRANTY IS EXCLUSIVE, AND IS IN LIEU OF ANY OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT

NOT LIMITED TO WARRANTY OF MERCHANTABILITY OR WARRANTY OF FITNESS FOR A PARTICULAR

PURPOSE.

FLOTECH sole obligation and buyer’s sole remedy for any breach of warranty shall be as set forth above. The buyer agrees

that no other remedy (including, but not limited to, incidental or consequential damages for lost profits, lost sales, injury to

person or property, or any other incidental or consequential loss) shall be available. Any action for breach of warranty must be

brought within one (1) years of the date of sale.

FLOTECH MAKES NO WARRANTY, AND DISCLAIMS ALL IMPLIED WARRANTIES OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, IN CONNECTION WITH

ACCESSORIES, EQUIPMENT, MATERIALS OR COMPONENTS SOLD

BUT NOT MANUFACTURED BY FLOTECH. These items sold, but not manufactured by FLOTECH (such as electric

motors, switches,

hose, etc.), are subject to the warranty, if any, of their manufacturer. FLOTECH will provide purchaser with reasonable

assistance in making any claim for breach of these warranties.

In no event will FLOTECH be liable for indirect, incidental, special or consequential damages resulting from FLOTECH

supplying equipment

hereunder, or the furnishing, performance, or use of any products or other goods sold hereto, whether due to a breach of

contract, breach of warranty, the negligence of FLOTECH or otherwise.

FLOTECH Information

TO PLACE AN ORDER OR FOR SERVICE, contact your FLOTECH distributor, or call these numbers to identify

the nearest

distributor.

SPEEDO MARINE (PTE) LTD

No.11 Tuas Link 2 Singapore 638559

TEL: +65-68631998 FAX: +65-68631667

E-mail : [email protected]

http://www.speedo.com.sg

Table of contents

Popular Water Pump manuals by other brands

Speck pumpen

Speck pumpen Zismatic 40/10 WE Operation manual

Techni-flow

Techni-flow 200 FDA Instructions-parts list

Stuart

Stuart Jet 55-45 Installation, operation & maintenance instructions

MagnaFuel

MagnaFuel PRO STAR 500 Series Installation and operating instructions

T.I.P.

T.I.P. EXTREMA 400/11 CX Translation of original operating instructions

CEMO

CEMO CENTRI SP30 operating instructions

Graco

Graco ChemSafe 205 Instructions - parts

Agilent Technologies

Agilent Technologies IDP-15 Quick reference card

Zoeller

Zoeller AqyaNot 508 Active installation instructions

EINHELL

EINHELL BG-GP 1146 NM operating instructions

mr. steam

mr. steam AromaFlo Installation, operation & maintenance manual

Edwards

Edwards XDS 5 instruction manual