SHIMGE QGYD User manual

Models: QGY(D)

Oil-filled Submersible Screw Pump

SERVICE MANUAL

I. Product Introduction

II. Operating Conditions

III. Structure Diagram

IV. Instructions for Installation and Use

V. Maintenance

VI. Troubleshooting

Contents

Thank you very much for choosing our products, and please read over the Operating Manual and

keep it properly before the installation and use.

Warning

• The Electric Pump must be grounded reliably before use, and shall be equipped with

an electrical leakage protection device;

• It's strictly prohibited to touch the Electric Pump during operation;

• It's strictly prohibited to run the Electric Pump without water;

• It's strictly prohibited to run the Electric Pump with the valve closed;

• For three phase-motors with integrated thermal protector shut down due to overload

or overheating, it is NOT allowed to re-connect the power until motor cooling for more

than 10 minutes.

I. Product Introduction

A QGY(D) oil-filled electric submersible screw pump (hereinafter referred to the “Electric

Pump”) is composed of two parts :pump set and motor. Pump set is lying upper of the Electric

pump, the main components are screw and rubber stator, which constitute an internally-engaged

sealed-rotor positive displacement pump with the operating principle of driving the screw via the

universal joint to make a rotational planet motion around the rubber stator with the eccentric

distance e as radius. A single-phase or three-phase asynchronous motor is at the bottom of the

Electric pump, adopting single-ended mechanical seal as dynamic seal in the motor, and at the

place of sealing of each fixed spigot is an O-shaped rubber seal ring used as the static seal.

The Electric Pump of this series, with no limit of minimum head, is able to operate as long as

above max head, its features like high head, high efficiency and wide high efficiency area make it

widely used in long-distance farm irrigation, spray irrigation, garden irrigation, deep well water

lifting, tower water delivery,, water supply and drainage for breeding industry, and efficient

oxygenation application, etc.

II. Operating Conditions

The Electric Pump shall be able to operate continuously and normally in the following

operating conditions:

1. The temperature of the medium does not exceed 40°C;

2. The pH value of the medium is 6.5~8.5;

3. The mass ratio of the solid impurities contained is not more than 3%, the particle size is

not bigger than 0.2mm, and the fiber length is not more than 0.3 time the screw pitch of the

rotator;

4. The maximum submersible depth of the Electric Pump is not more than 70m, while the

minimum depth is 0.5m.

1 Lifting bolt

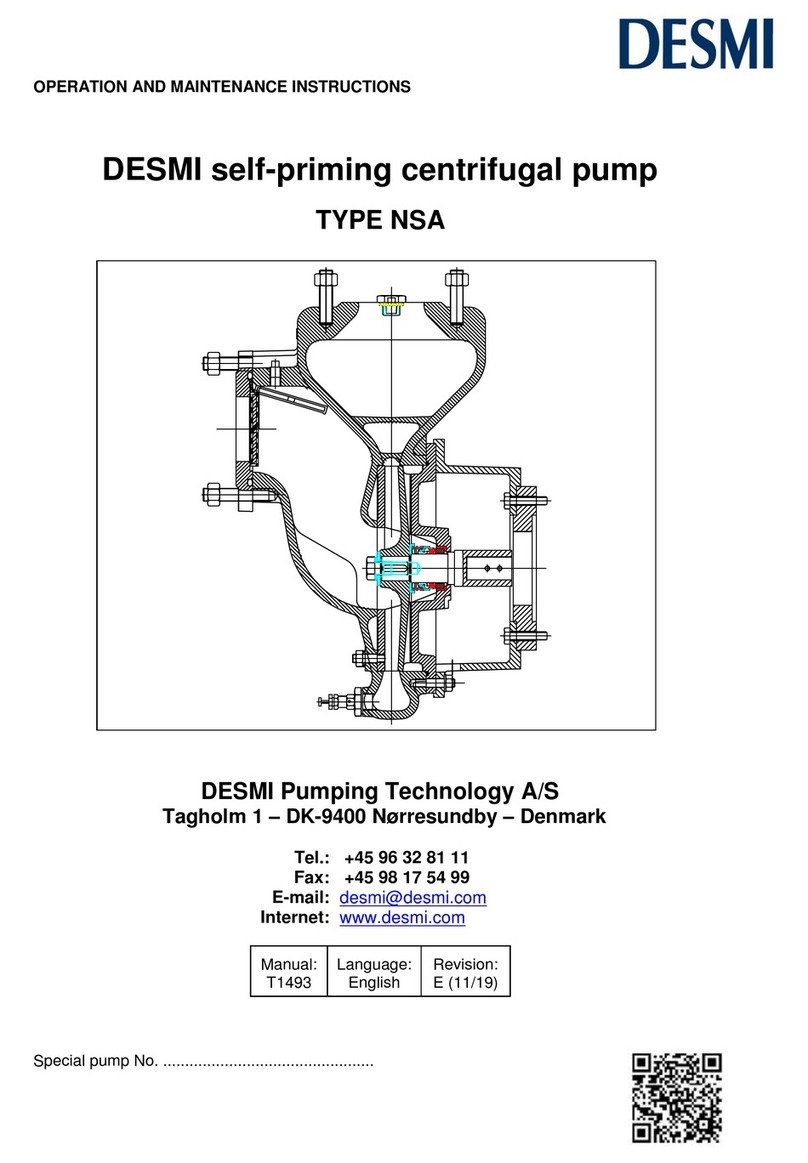

III. Structure diagram

2 Cap nut

3 Flat washer

4 Discharge chamber

5 Sand insulating sleeve

6 Rubber stator

7 Cable jacket

8 Cover plate

9 Water absorption

chamber

10 Mesh enclosure

11 Screw

12 Cable

13 Stud

14 Slotted cheese-head

screw

15 Oring

16 Sand throwing sleeve

17 Sand prevention

cushion

26 Deep groove ball

bearing

25 Flat washer

24 Mechanical seal

23 Oring

22 Round-hole rubber

jacket

21 Oil chamber

19 Cross recessed

countersunk head screw

20 Diamond-shaped

press plate

18 Sand prevention seat

27 Rotor

28 Shoulder ring

29 Deep groove ball

bearing

30 Upper retaining sleeve

31 Stator core with

winding sleeve

32 Bearing block

33 Cross recessed

countersunk head screw

34 Locating bush

35 Motor bracket

36 Capacitor (single

phase)

37 Regulating

membrane

38 Bottom cover

39 Retaining ring

MΩMΩ

Cold insulation resistance of the Electric Pump ≥50MΩ

0

25

50

75

100

0

25

50

75

100

Yellow-green line

AC 380V

~

Protection Device Wiring Diagram

Input

A B C A B C

IV. Instructions for Installation and Use

1. Before installation and use, please fully check whether the safety or performance of the

Electric Pump is affected or damaged during transportation or storage, for example, whether any

cable or plug is in a perfect condition. In case of any damage, please have a specialized person

making replacement or repair.

2. Before the Electric Pump operates, please completely inspect the insulation resistance of

the Electric Pump, of which the cold insulation resistance shall not be less than 50MΩ.

3. During wiring, please correctly install an electrical leakage protection device (Suppose the

device does not come with the pump, user should buy it by himself ) to the Electric Pump. In case

that the Electric Pump is a three-phase one, please draw the yellow-green line with the grounding

symbol, out of the cable involved, and ground this line reliably. Carry out the wiring as shown in

the following diagram. Ground in a reliable way the patch panel to be used with the Electric Pump

which is provided with a plug upon delivery.

Output

Fuse

Pump

The pump set shall be

completely submerged

in water.

4. Before putting the Electric Pump into water, please do a test run. Do not perform dry

running without water. Place the Electric Pump horizontally in a ditch or tank (bucket) (make sure

that the pump set is submerged in water) and check whether the Electric Pump works normally

and whether the rotational direction of the pump is the same as that of the indicating arrow. When

finding any reverse rotation of a three-phase electric pump (no water will be pumped upwards

when a three-phase electric pump operates reversely), please cut off the power supply and

exchange any two phases of the three-phase pump, or otherwise the rubber stator will be worn

out.

After power-on, there is

water flowing out of the

outlet.

5. Connect a delivery pipe (whose specifications are selected based on Table 1) matching

with the discharge chamber. For example, tighten a soft delivery pipe with the iron wire or clamp

or reliably connect a steel-type delivery pipe with the screwed joint, and then put a rope through

the lifting ring and tie it down for the purpose of lifting and placing.

6. Do not strike or press the cable or use it as a lifting rope. When the Electric Pump is

operating, do not arbitrarily pull the cable, so as to prevent the cable from being damaged

and causing any electric shock accident.

>5m

>5m ≤70m

The submersion depth shall not

exceed 70m.

7. When the Electric Pump is submerged in water, its depth shall not exceed 70m and shall

be at least 5m, and it shall not be caught in sludge. Simultaneously keep the mesh enclosure or

the inlet from being blocked by water plants or sundries, for such blocking may result in the

Electric Pump's failure to operate normally. During operation, please frequently check the water

level and do not make the operating Electric Pump appear above the water surface.

The Electric Pump shall not

appear above the water

surface.

The Electric Pump shall not

be caught in sludge.

8. When the Electric Pump to be used is far away from the power supply, cable should be

thickened according to the distance(the diameter of the cable line shall be bigger than that of the

Electric Pump)

9. Please arrange a safety warning sign on the site where the Electric Pump is operating,

which reads “DANGER: ELECTRIC SHOCK RISK AND NO ENTRY FOR PEOPLE OR

ANIMAL”, so as to prevent any accident.

30m

DANGER: ELECTRIC

SHOCK RISK AND

NO ENTRY FOR

PEOPLE OR ANIMAL

10. A single-phase electric pump with integrated automatically-reset thermal protector, when

the thermal protector works, automatic reset will happen after the temperature of the motor

decreases to a certain value, In the event of frequent protection actions, please cut off the power

supply and find out the causes and then operate the Electric Pump until the relevant trouble is

cleared.

For a three-phase electric pump with integrated power failure-reset thermal protector, upon

the protection action of the protector, please first cut off the power supply and turn on the power

supply again after 10 minutes, Electric Pump will operate normally. In the event of frequent

protection actions, please cut off the power supply and find out the causes and then use the

Electric Pump until the relevant trouble is cleared.

11. This series is filled with No. 10 white food machinery oil so as to ensure that the

mechanical seal is effectively lubricated and cooled, which might leak in case of any damage or

fault of the Electric Pump. The leaked white oil might damage the botany planted or the animal

bred or pollute the drinking water or food involved in any application relating to planting, breeding,

or delivery or processing of drinking water or food. To select this product, the user shall evaluate

the relevant application and the consequence of the use of this product so as to confirm whether

this product is suitable and even invite a related specialized person to do such confirmation when

necessary. In case of any leakage of white oil, please immediately stop using and properly dealing

with it.

12. When the content of solids in the medium pumped exceeds the specified one, the flow

rate of the Electric Pump will obviously decline, the screw and the rubber stator shall be replaced

in time if such dramatic decline continues, make sure that the screw properly fits with the rubber

stator.

13. When the Electric Pump is being used, please first cut off the power supply in case that

the Electric Pump is to be relocated or touched, so as to avoid any accident.

≥60mm

①

②③

At least 10 times as the diameter of the conductor.

To touch the Electric Pump, please cut off

the power supply first.

14. When the Electric Pump is operating, its cable head or plug board shall not be put into

water; when such submersion is necessary due to the addition of a cable, the connection shall be

sealed strictly to prevent water seepage and electrical leakage. pply in case that the Electric

Pump is to be relocated or touched, so as to avoid any accident.

1.Remove the insulating layer

without damaging the conductor.

2.Stagger long and short wires.

3.Ensure that no oil, water or any

oth er polluta nt ex ist at th e

connection.

1.Divide each connector into

several strands evenly (no less

than 6 ones) and tighten them.

2.Cross the two connectors so that

the overlapping length will make

the two ends aligned with the

insulating layer.

1.Clench each strand. First get one strand from

the middle and make it wind to one end (the

wound core wire shall include the remaining

strands) and then make each of the remaining

strands wind successively as well.

2.Follow the same procedure at the other end.

3.Use plier to tighten the connectors. The best

effects can be achieved by wrapping the

connectors with tin.

4.Remark: For other methods, please refer to the

attached Drawing 1 and Drawing 2.

30mm

④

Plastic insulating tape

10mm

30mm

⑤

1.First use the black tape to tightly wrap the connector area and

make two layers; do not expose copper wire head. Please see the

attached Drawing 3.

2.Then use the pressure sensitive tape (self-adhesive tape) to

make a three-layer wrapping, 10mm longer at the two ends should

be needed based on previous layer wrapping. Do not do wrapping

until the length of the tape drawn out is twice the original length.

3.Finally apply the plastic insulating tape (yellow transparent) to

make the last layer wrapping.

1.Properly arrange the connectors of core wires and

make a four-layer wrapping by use of the pressure

sensitive tape with two ends wrapping a length of 30mm

on the cable sheath and 10mm longer at the two ends

should be needed based on previous layer wrapping

2.Then make a three-layer wrapping with the plastic

insulating tape with the next layer about 10mm longer

than the first layer at the two ends.

Pressure sensitive tape

Plastic insulating

tape Pressure sensitive tape

Black tape Connector of

several wires

First layer

Last layer

Cable Connection Diagram

Drawing 1

An electric arc welded joint is

preferred.

Drawing 2 Drawing 3

A joint made by cold welding of casing

is also acceptable.

When the first layer of the black tape is made,

no copper wire shall be exposed or the tape

shall not be punctured.

15. Do not lift the Electric Pump out of water immediately after the power supply of the

Electric Pump is cut off, so as to ensure safety.

V. Maintenance

1. The matters needing attention prior to the disassembly of the motor for maintenance: First

wait until the motor is cool, then unscrew the oil filler bole, to release the high-pressure gas

generated inside due to burn-in, for the purpose of preventing the upper cover from jumping out to

hurt people.

2. Regularly inspect the insulation resistance between the motor bracket and the winding of

the Electric Pump, which shall be greater than 1MΩ when the operating temperature is nearly

achieved, or otherwise usage shall not be allowed until the relevant inspection and maintenance is

completed.

3. After 2000-hours normal usage of the Electric Pump, the Electric Pump shall be

maintained as per the steps below:

Disassemble the Electric Pump and inspect various easy broken parts such as the roller

bearing, mechanical seal, screw, and rubber stator. Please immediately replace those in case

there are damaged ones.

After 2000-hour operation,

please inspect quick-wear parts.

Screw

Rubber stator

Mechanical seal

Bearing

Screw

0

0.2

0.1

0.3

0.4

0.5

0.6

MPa

0

0.2

0.1

0.3

0.4

0.5

0.6

MPa

Air pressure test:

After disassembly is

done for repairing or

replacing mechanic

seal, an air pressure

test shall be carried

out under the testing

pressure of 0.2 MPa

for 3 minutes, there

is no phenomenon

of leakage or

sweating.

Rubber stator

Bearing

Mechanical seal

Air pressure test: After disassembly is done for repairing or replacing mechanic seal, an air

pressure test shall be carried out under the testing pressure of 0.2 MPa for 3 minutes, there is no

phenomenon of leakage or sweating.

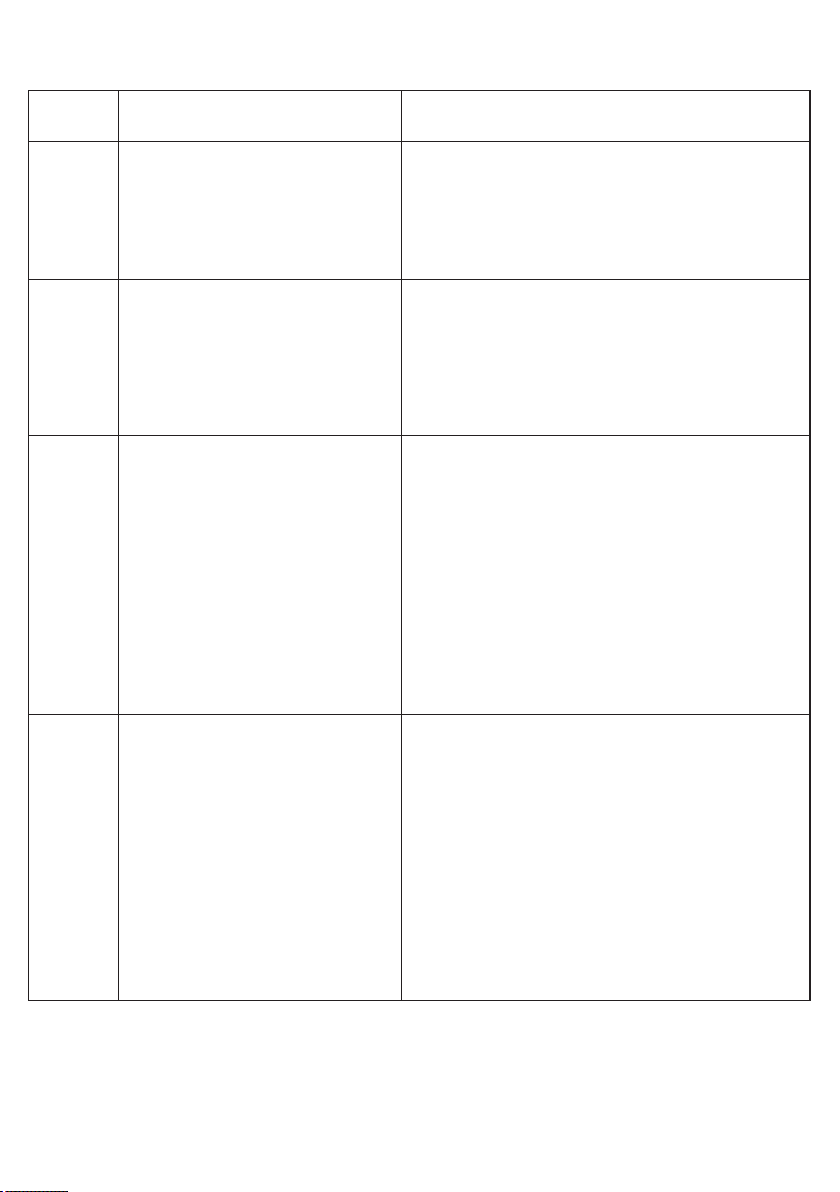

Fault

VI. Troubleshooting

Cause Remedy

Difficulty

in startup

1. The supply voltage is too low.

2. The Pump suffers a phase loss.

3. The screw is blocked.

4. The voltage drop of the cable is

too high.

5.The stator winding is burnt.

1. Adjust the voltage to ±10% of the rated value.

2. Inspect the plug, the cable, and the head of the

outgoing line of the switch.

3. Correct the part blocked.

4. Use a thickened cable.

5.Re-insert the winding or carry out overhaul.

Low

water

yield

1. The mesh enclosure is blocked.

2. The screw or rubber stator is

seriously worn.

3. The submersion depth of the

Electric Pump is less than

standard and air is absorbed.

4.The screw rotates reversely.

1. Clear away sundries like water plants.

2. Replace the screw or rubber stator.

3. Adjust the submersion depth of the Electric

Pump, which shall not be less than 0.5m.

4.Exchange any two phases of a three-phase

electric pump.

No flow

suddenly

1. The switch is disconnected or

the fuse is burnt.

2. The power supply is cut off.

3. The screw is blocked.

4. The stator winding is burnt.

5. The protector trips.

6. The outlet pipe falls off.

7.The impact by backwater exists

in the pipeline and the screw gets

loose.

1. Inspect whether the head range or the voltage

of the power supply conforms to the relevant

provisions and make adjustments.

2. Find out the cause of power failure and clear

the relevant fault.

3. Clear away sundries.

4. Re-insert the winding or carry out overhaul.

5. Find out the relevant cause (too low supply

voltage, overload, or blocked screw) and remove

the fault.

6. Re-connect the pipeline.

7.Disassemble the Electric Pump and re-tighten

the screw, and add a check valve to the pipeline.

Stator

winding

burnt

1. The Electric Pump suffers from

a phase loss and operates for a

long time.

2. Water leakage occurs due to the

damaged mechanical seal,

causing the interturn or interphase

short circuit.

3. The screw is blocked.

4. The Electric Pump start

frequently or operates without

water for a long time.

5.The Electric Pump makes

overload operation.

Disassemble the winding and re-insert the

winding as per the concerned technical

requirements as well as immerse and dry the

insulating varnish or deliver the winding to the

repair station for repair.

Notes:

1. All the diagrams in this Operating Manual shall be only for reference, the Electric Pump

purchased and its accessories might be different from those indicated in this Operating Manual.

Your understanding is really appreciated.

2. This series of products is subject to continuous improvements and changes without further

notice and a product (including its appearance and color) in kind shall prevail.

This manual suits for next models

1

Table of contents

Other SHIMGE Water Pump manuals

Popular Water Pump manuals by other brands

Polygroup

Polygroup SFX600 user guide

Grundfos

Grundfos CU 301 Installer manual

Stuart Turner

Stuart Turner AQUABOOST iBolt Pump Installation, operation & maintenance instructions

Desmi

Desmi NSA Series Operation and maintenance instructions

Kripsol

Kripsol S2-025M owner's manual

Defort

Defort DSP-752N user manual