Flo-Tite MPF15 Owner's manual

Installation, Operation & Maintenance

IOM-MPF15-01

2. USE

Maximum results and long life of valves can be maintained under normal working conditions and in accordance with

proper pressure/temperature and corrosion data.

3. MANUAL OPERATIONS

5. DISASSEMBLY & CLEANING PROCEDURES

1. ON-SITE INSTALLATION

The manual operation for the proper flow plan is done by turning the handle a 1/4 turn (90 degree turn).

Visual indication of position is done by visual inspection of the markings on the top of the stem.

If the valve has been used to control hazardous media, it must be decontaminated before disasembly. It is

recommended that the following steps are taken for safe removal and reassembly.

1. Relieve the line pressure

2. Place valve in half-open position and flush the line to remove any hazardous material from valve

3. All persons involved in the removal and disassembly of the valve should wear the proper protective clothing, such as face

shield, glove, apron and etc.

The valve may be fitted to any position on the pipeline.

Before installation, pipes must be flushed clean of dirt and debris that could result in damage to hard or soft parts of the valve.

Piping must be supported so as not to add undue stress to the valve.

MPF15 3-Way Ball Valves

Valves come shipped from the factory containing a lubricant. This is for break-in and may be removed if it is objectionable to

a particular application by disassembly and cleaning with a proper solvent.

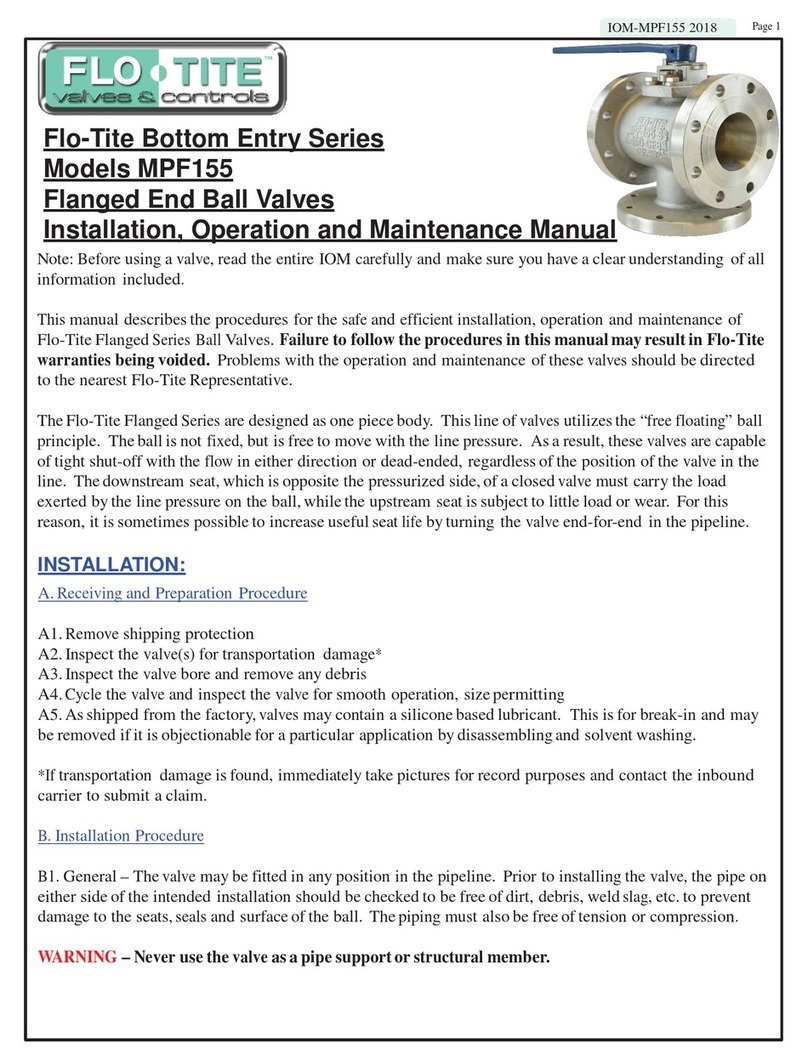

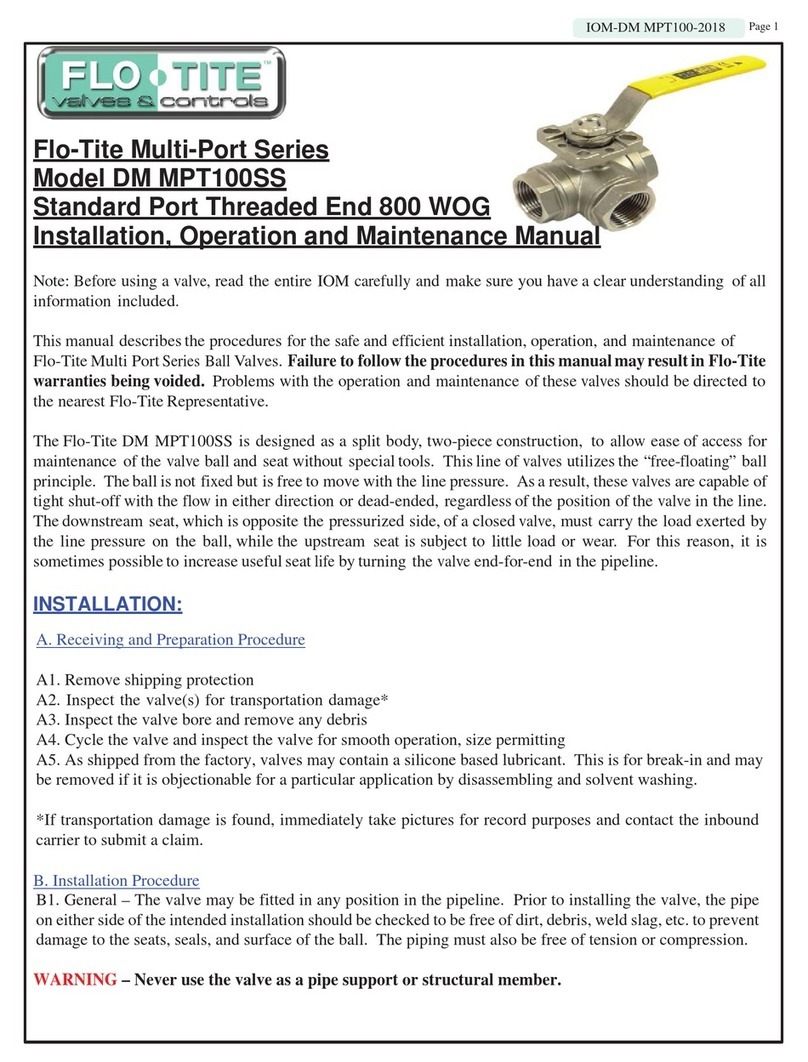

DESIGN:

Central body design, three-flanged end piece construction, allows ease of maintenance, without special tools. This type

of valve utilizes a true trunnion ball principle. The ball is fixed, it is not free to move with line pressure. This particular

feature allows tight shut-off to flow in either direction or dead ended, regardless of the position of the valve in-line.

4. AUTOMATED OPERATIONS

Valves with actuators should be checked for actuator/valve alignment. Angular or linear mis-alignment will result in high

operational torque and premature packing failure.

6. DISASSEMBLY FOR STEM AND SEAL REMOVAL

Stem seal leakage may be corrected without disassembly by tightening the packing gland bolts until such leakage stops.

If the leakage continues or valve operating torque becomes excessive, or the stem seals are worn, replacement will be

necessary.

Remove flange bolts and nuts and lift valve from line for servicing. NOTE: care should be taken to avoid scratching or damag-

ing serrated flange faces. Valves can be heavy, they should be adequately supported before removal from the line has begun.

Loosen handle set screw and remove handle and stop plate. Remove gland nuts and packing gland. Mark each flange to the

body joint (3 flanges). Mark top cap to the body joint. This is to allow ease of alignment in reinstallation.

Remove the nuts holding flanged pieces and top cap for disassembly.

Remove all three end pieces, then the top cap, leaving the ball to last.

Take extreme care when removing ball as not to scratch seating surface or the stem, which will result in leakage after reassem-

bly.

Remove all seats, seals and the thrust bearing.

Note: If the valve is supplied with body cavity fillers:

Cavity filler is supplied in two parts: top and bottom. They are removed after the top cover and end caps are removed. Remove

top half then valve ball, then bottom cavity filler.

(CAUTION: Ball valves can trap fluids in ball cavity when closed)

(Warning: Do not remove the packing gland while line is under pressure! )

Page 1

Please carefully review all important procedures in this manual. If anything is

not clear, please feel free to contact Flo-Tite directly

7. RECOMMENDED SPARE PARTS

The recommended spare parts for normal service conditions are the “soft” parts contained in the repair kit available from FTI;

stem seals, body seals and seats. For more severe conditions, spare balls and stems may be needed.

8. VISUAL INSPECTION

Clean and inspect metal parts. It is not necessary to replace the ball and stem unless the seating surface have been damaged by

abrasion or corrosion. We strongly recommend of all soft parts whenever the valve is disassembled from reconditioning. This

is the best protection against valve leakage after assembly. Replacement parts can be ordered in kit form. NOTE: the valve

may be assembled and operated dry where no lubricants are allowed in the system; however, a light lubrication of mating

parts will aid in assembly and reduce initial operating torque. Lubricant used must be compatible with intended line content.

9. ASSEMBLY

Install the thrust bearing in the bottom center of the body.

Install the ball in the body, making sure the trunnion of the ball goes into the thrust bearing.

Install the seats in each of the flanged end pieces with spherical curvature facing the mating ball.

Install the top cap and body gasket making sure to align the marks made during disassembly. Tighten down in a criss-cross

pattern. Keep gap even. This will insure the valve stop or actuator is in the proper position.

Now install the packing and packing gland with packing gland bolts. Tighten bolts evenly.

The installation of the flanged end pieces must be done in the following way to insure damage.

First install the left and right end pieces with the nuts aligning the marks made during disassembly. This is to insure flange-

to-flange mating and alignment of the valve bolt holes. Make sure the ball ports are aligned with the end pieces as not to

pinch the seats during tightening. Do not tighten one end piece fully until both ends are installed. Due to the location, the nuts

should be torqued down evenly using a criss-cross pattern and alternating between each end until metal-to-metal contact is

achieved. During this step, check body to end piece gap and keep gap consistent. Uneven tightening may result in pinching of

the seats and subsequent leakage after reassembly.

The installation of the center end piece is done first by rotating the ball until the blind side of the ball is facing area where the

end piece is being installed, aligning previous marks. Tighten the nuts using a criss-cross pattern. Make sure the gap of the

end piece to valve remains consistent metal-to-metal contact is achieved.

Cycling the valve slowly back to the proper flow plan by turning the ball slowly insures the seal lips assumes a permanent seal

against the ball. A fast turning motion may not allow proper mating to occur.

Test valve, if at all possible, prior to placing valve back into line.

WARNING: Not properly securing valve may cause it to separate from the pressure source and result in injury. Always join

the valve to the companion flanges of the same pressure rating as the valve. Use a full set of proper bolts.

IOM-MPF15-01

Page 2

IOM-MPF15-01

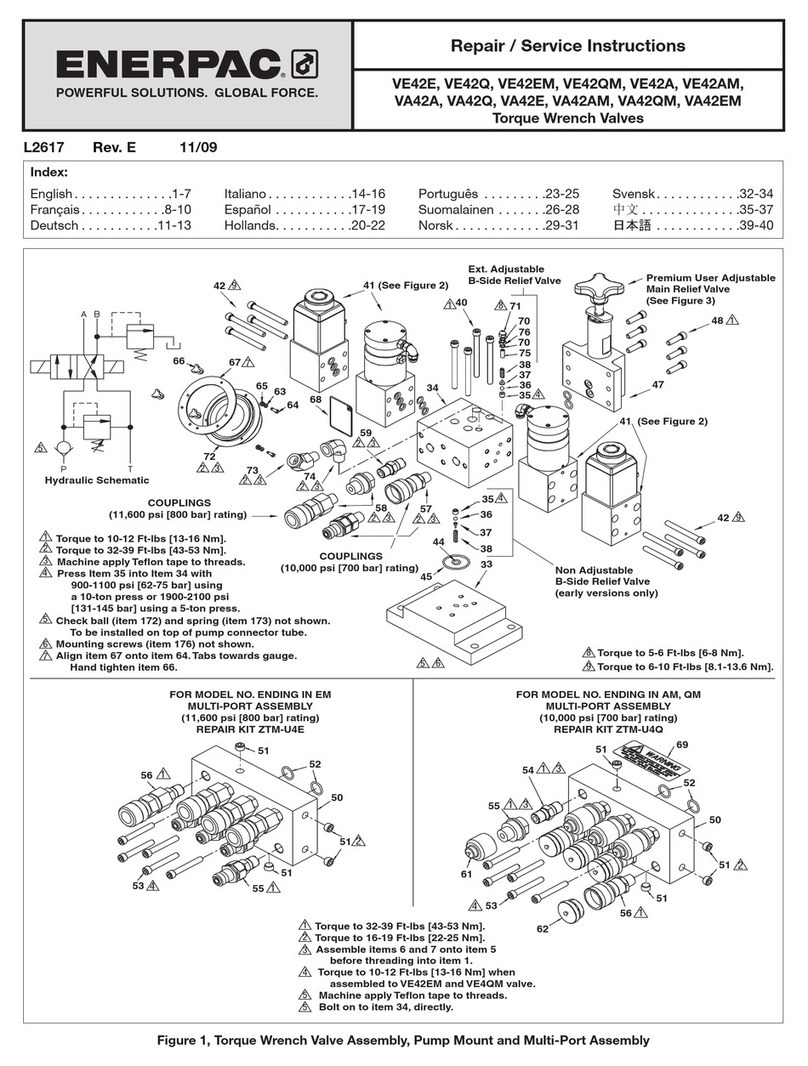

Typical 3 Way MPF15 / MPF30

Item No. Part Name

1Body

2EndCap

3 Ball

4Seat

5 Cap Gasket

6 Body Nut

7 Body Stud

8 Anti-Static

9rust Bearing

10 Stem Packing

11 Packing Follower

12 Gland

13 Gland Bolt

14 Stop Housing

15 Housing Bolt

16 Travel Stop

17 Lever Handle

18 Snap Ring

19 Cover

20 Cover Gasket

21 Cover Stud

22 Cover Nut

23 Port Sign

24 Sign Nut

25 Washer

Page 3

Typical 4 Way MPF15 / MPF30

Item Part Name

1Body

2EndCap

3 Ball

4Seat

5 Cap Gasket

6 Body Nut

7 Body Stud

8 Anti-Static

9rust Bearing

10 Stem Packing

11 Packing Fol-

lower

12 Gland

13 Gland Bolt

14 Stop Housing

15 Housing Bolt

16 Travel Stop

17 Lever Handle

18 Snap Ring

19 Cover

20 Cover Gasket

21 Cover Stud

22 Cover Nut

23 Port Sign

24 Sign Nut

25 Washer

IOM-MPF15-01

Page 4

Table of contents

Other Flo-Tite Control Unit manuals

Popular Control Unit manuals by other brands

Vag

Vag GA Industries FIGURE 200 Installation, operation and maintenance manual

AbleNet

AbleNet Pilot Pro operating instructions

CityGrow

CityGrow CG800H Series user manual

Asco

Asco 290 Series General Installation and Maintenance Instructions

Hioki

Hioki U8793 instruction manual

Meec tools

Meec tools 080-202 Operating instructions in original