Flight Systems 56-5961-00 User manual

Table of contents

Other Flight Systems Control Unit manuals

Popular Control Unit manuals by other brands

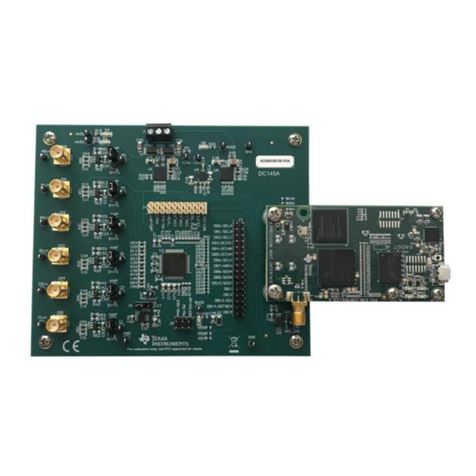

Texas Instruments

Texas Instruments ADS8555EVM-PDK user guide

Enclustra

Enclustra Mercury+ XU1 user manual

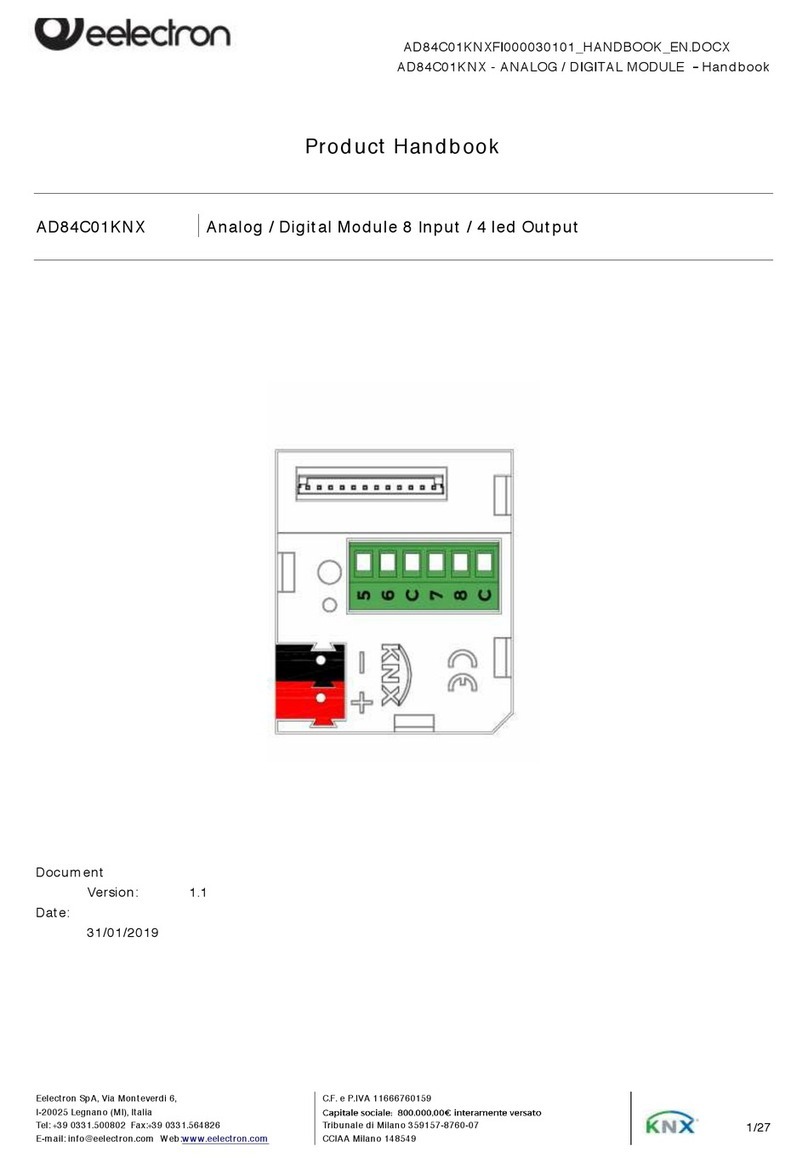

Eelectron

Eelectron AD84C01KNX Product handbook

Thermo Scientific

Thermo Scientific Nicolet iS50 GC-IR user guide

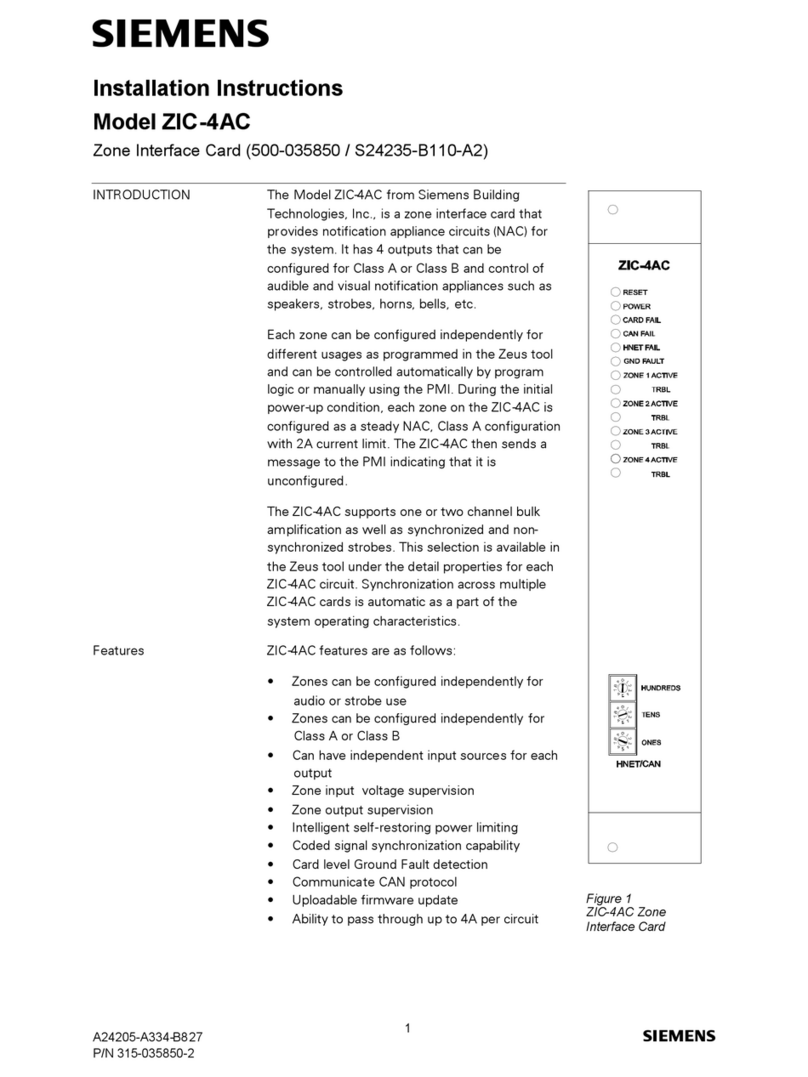

Siemens

Siemens ZIC-4AC installation instructions

Ingersoll-Rand

Ingersoll-Rand MHD56177 Operation instructions and parts list

Vimar

Vimar 00801 instruction sheet

Emerson

Emerson Anderson Greenwood 81 Series Installation and maintenance instructions

IFM Electronic

IFM Electronic AS-Interface AS-i Series installation instructions

DMP Electronics

DMP Electronics RoBoard RM-G212 manual

AMOT

AMOT C Installation, operation and maintenance manual

Honeywell

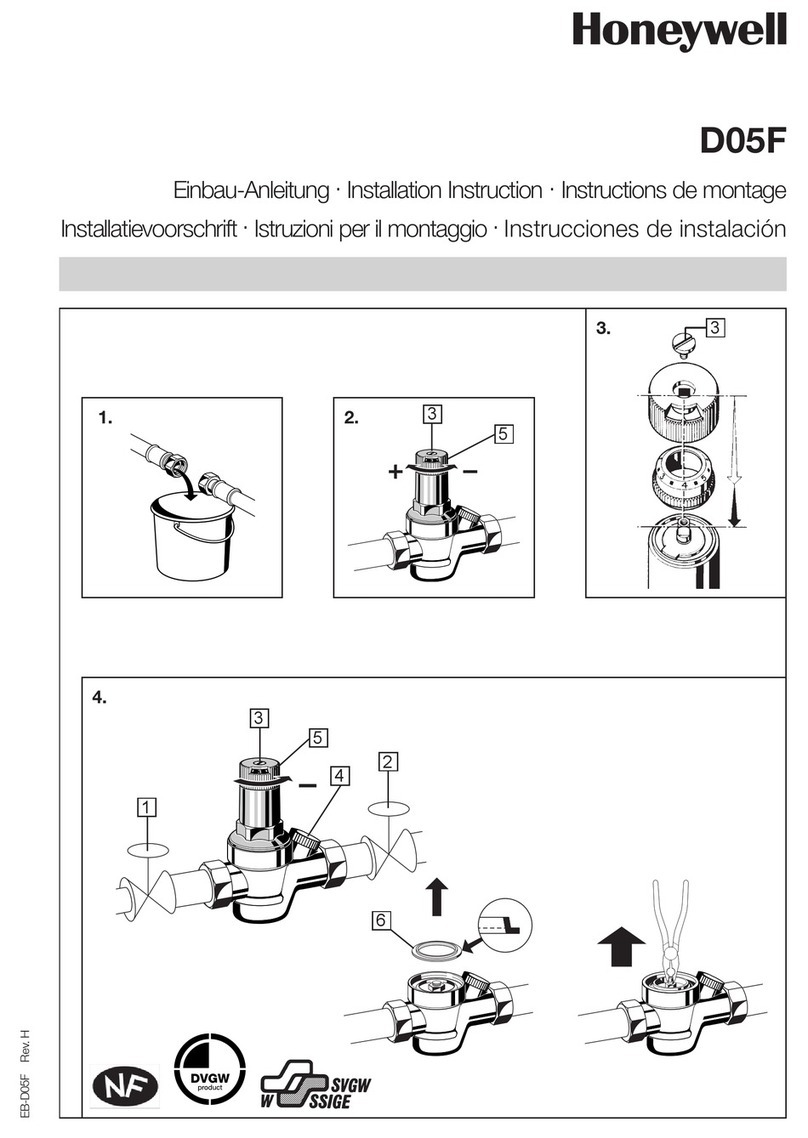

Honeywell D05F Installation instruction