Florite 990X Setup guide

D10137-012809

Florite International, Inc.

Model 990X Instrument Training Guide

Instrument Training Guide

Model 990X

P ro c e s s C o ntr o l b y De s i gn

1.0 Product Introduction

1.1 The System

The 990x is a versatile full-featured measurement and control instrument - with precision multiple port and

channel capabilities. Its operating control primarily supports point-n-click navigation.

It supports an optional mix of up to eight independent full function input measurement ports and advanced

technology output ports. Extensive local and remote information communication is provided.

Superior technology is combined with operating simplicity, versatility and ruggedness. Easy to install -

and easy to operate. An extensive open architecture enables a wide range of special operating

capabilities organized to meet the needs of nearly any high-accuracy precision measure, process, alarm

monitoring and communication application requirements.

1.2 The Technology

The system is all digital based on microcomputer technology - no power switch to be left off, no feature

selection switches or jumpers, no analog trimming potentiometers. Just all digital.

It employs surface mount technology and incorporates a powerful package of floating-point digital signal

processing arithmetic. Built-in test capabilities enable simple installation, and extensive self-tests insures

long term operating reliability. The rugged package is modular - and represents an ideal solution for use

in demanding applications and tough environments. Mounting options are available for rack-panel, desk-

top with support for various input and output signal types.

1.3 The Applications

This system suits applications requiring advanced multiple port and channel, supported by extensive

integrated information communication capabilities. It services nearly all process and sensor signal

measurements for manufacturing and batch processing, proportional blending, machine control, bio-

medical pressure and temperature, chemical and pharmaceutical, laboratory, ecologic, agriculture,

petroleum, heating and air conditioning, water filtration and purification, beverage and fluid delivery,

automatic billing systems, asset accounting and service programs, performance tracking and verification,

quality assurance programs, operations and maintenance management information gathering, regulatory

compliance, liability mitigation, and public safety programs.

1.4 The Organization

The system has port based architecture, modularly organized as independent ports, or ports combined as

channels, to meet present and future instrumentation requirements.

The systems ports support universal input and output signal types. Ports may be intermixed to support an

extremely wide variety of signal service requirements.

Input ports provide value measurements for quantity accumulation, rate measurements, scalar

measurements, supported by value scaling for process frequency, pulse, voltage, current or resistance

signals.

Independent value scaling and smoothing filters compensate for specific signal service requirements.

Signal acquisition uses digital signal processing to reject ambient noise and interference. Programmable

excitation selections are available to power most sensors. Advanced signal output ports provide

extremely stable voltages, currents, and supports isolated relay contacts.

1.5 Communication

The communication facilities provide data acquisition, command and control functions, and support

information gathering and reporting, and alarm signaling. It has a built-in EIA-TIA232 standard interface,

and is optionally configurable for EIA-TIA485 two wire multi-drop LAN operations. Wide Area Networking

is supported by optional built-in modem, or optional 10/100 BaseT Ethernet.

WAN capabilities support collision avoidance and error control capabilities, and may be user set with

multiple destination address used to send information to multiple computer. Communication is initiated by

command (solicited), alarms (unsolicited), and real-time scheduled reporting using its internal Y2K

compliant date-time clock.

1.6 Alarm Monitoring

Independent user-programmable alarm threshold limits are available for every measured value. Included

in each port are two independent quantity accumulators, scalar value, process rate and service time.

Alarms are programmable to activate local annunciation, local display alert, and drive relay or analog

output, instigate local and remote computer communication.

1.7 Process Controls

Batch delivery, proportional blending, and closed loop PID control are readily achieved using either the

front panel key controls or serial commands.

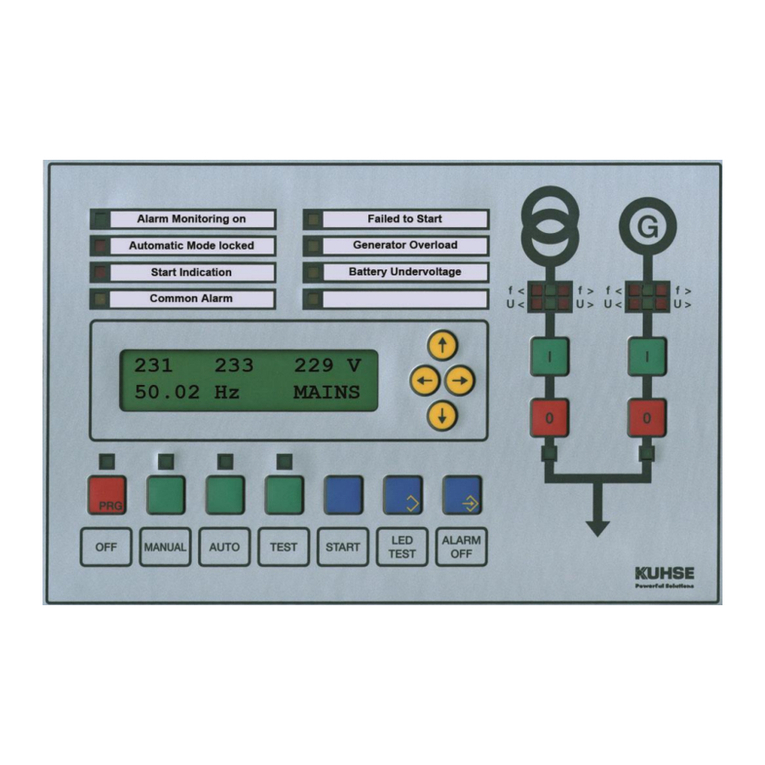

1.8 Operator Controls

The instrument has no power switch to be accidentally turned off. Operation may be completely controlled

from its integral eight key pad used to view operation and programmed operation values. Key activations

are single touch and repeat when the key is held. The key pad provides front panel splash proofing and

environment protection.

1.9 Operator Indicators

The primary indicator is a large variable-brightness back lit liquid crystal graphic display - visible at a

distance even in low light conditions for value viewing, programming, process state information, and

alarm status. A built-in audio indicator annunciates alarm conditions and key activations.

1.10 Diagnostic Capabilities

Powerful automatic built-in tests support easy installation and ensure a long, trouble-free operating life.

Tests include scans of all memory facilities, peripheral input-output status, communication adapter status,

clock and data logging operation, keypad tests, and proper operation of the display and audio indicator.

1.11 Table of Contents

Section Title

_________ _________________________________________

1.0 Product Introduction

1.1 The System

1.2 The Technology

1.3 The Applications

1.4 The Organization

1.5 Communication

1.6 Alarm Monitoring

1.7 Process Controls

1.8 Operator Controls

1.9 Operator Indicators

1.10 Diagnostic Capabilities

1.11 Table of Contents

1.12 Revision History

2.0 Installation

Signal Wiring

Accessories

3.0 Indicators

3.1 Normal home screen fields

3.2 Home Screen Alarm Fields

4.0 System Controls

4.1 Navigate Controls

4.2 Operation Controls

5.0 Navigation

5.1 System Navigate Map

5.2 Menu Selection

6.0 Process Value Set-Points

6.1 PV Measures

6.2 PV Programming

6.3 SP Status

6.4 SP Programming

7.0 Global Settings

7.1 Information Screen

7.2 System Power Control

7.3 Control Service Screen

7.4 Communication Screen

7.5 Date-Time Screen

7.6 Data Logging Screen

8.0 Process Controls

8.1 Manual Set-Point

8.2 Batch Delivery

8.3 Proportional Blending

8.4 Monitor

8.5 Proportional-Integral-Differential (PID)

9.0 Notices

9.1 Medical Alert

9.2 FCC Compliances

9.3 EU Compliances

9.4 Copy Rights

9.5 Hazardous Wastes

9.6 Legal Notices

1.12 Revision History

Effective Date Revision Enhancement

05Jul2007 1. Initial assembly of documents and organization

20Nov2007 1. Completion of pictorials

05Dec2007 1. Complete initial section text coordinated with pictorials

11Dec2007 1. Initial release revision complete - serial protocol exception

28Jan2008 1. Revised calibrate section pictorials

28Jan2009 1. General publication release

2.0 Installation and Accessories

This section describes the various system electrical wiring requirements, and provides information on the various

available mounting accessories including table top, panel and rack.

3.0 Indicators

The home screen is the instruments central information and navigation indicator. The home screen is

displayed following initial power application, and automatically follows the make-model screen banner. It

provides an over-all view of instruments normal operation, and includes display of alarm conditions.

3.1 Normal home screen fields

3.1.1 Cursor - points to port even when port is Off

3.1.2 Channel - numbers 1-4 (Ports 1-8)

3.1.3 Description - process value text name

3.1.4 Value - numeric process value

3.1.5 Unit / Time-base - combined measure units and rate time-base

3.1.6 Control - process control state indicators

3.2 Home Screen Alarm Fields

3.2.1 Alarm conditions are displayed in the display Value field every four seconds, for one

second, when one or more alarms are enabled for an input port, and when one or more alarms are

detected.

3.2.2 Alarm Type Definitions

Abbreviated indicators for each alarm type are shown on the display and are defined as shown below.

The strings of one or more indicators are justified to begin in the least-significant position of a value field.

TM Service Time

Q1 Quantity 1

Q2 Quantity 2

LO Low rate

HI High rate

4.0 System Controls

The primary instrument controls consists of eight front panel tactile snap-action keys - and a serial

communication capability. Every function that can be accomplished by using the keys can also be

accomplished by serial communication commands - the aspects of which are described in the Protocol

section.

4.1 Navigate Controls

Navigation functions performed from the home screen are follows:

4.1.1 Select a port using the and keys

4.1.2 Select a port process value to be shown show on the home screen

4.1.3 Change the value of a channel program variable

4.1.4 Enter the Global System Settings selection menus

4.1.5 Quickly navigate to certain special values requiring frequent changes

4.1.6 Start and stop control functions

4.1.7 Select a blend control master

4.1.8 Perform analog signal calibration

Instructions for the using the above are described in their respective sections.

4.2 Operate Controls

The control function of the keys is dependant on the context of the function that has been requested to be

accomplished as follows:

4.2.1 Home Screen - navigates to port I-O Screen

Port I-O Screen - selects view or program

View Screen - selects home screen value

Program Screen - programs value cursor points to - then saves the value

4.2.2 Home Screen - press 3X to enter Global System Settings

NOT Home Screen - navigates immediately to previous screen

4.2.3 Home Screen - press 3X to start batch and-or blend control operation

Power Down - press to restore power

4.2.4 Home Screen - terminate controls operation if any operating

4.2.5 Cursor Control - move cursor up

Program Screen - increase blinking program selection to succeeding choice

4.2.6 Cursor Control - move cursor down

Program Screen - decrease blinking program selection to preceding choice

4.2.7

Cursor Control - move cursor left

Home Screen - select input port pointed to by cursor as blend master

unless the port is already the master in which case the

existing master is deselected and no master is chosen

View Screen - zero quantity when cursor points to quantity

Program Screen - move blinking program selection to next left choice

4.2.8

Cursor Control - move cursor right

5.0 Navigation

This navigation section provides an overview of the various values that are available to set-up desired

operating characteristics that establish how the instrument is desired to perform, and to review the

operating state of the desired performance.

Although navigation is described for keypad operation - the same operating characteristics set using the

keypad are supported by serial communication - for which a detailed description is contained in the Serial

Protocol section of this document.

A complete system map is provided to support the overview of the instrument. It shows the entire

organization of all of the instrument process values (PV), all set-point (SP) values, and all system global

settings.

5.2 Navigate Select

The selection screens provide a secondary navigation layer for the operator to specify whether viewing or

programming is desired for a port that is an input, an output or is now OFF. The screens shown below are

displayed as a result of having pressed the [SELECT] key while viewing the home screen.

The <Name> following the Port number allows the operator to program an application specific purpose,

type, location, or other - so the port is more easily identified with respect to its function. Name is a free-

form open space consisting of up to twenty alpha-numeric characters. Name may be independently

programmed for each port.

5.2.1 Input Port Function Select

The screen below is shown as port 4 which had previously been programmed as an input port. Use the

cursor keys to point to either view Input Viewing (PV Measurements), or Input Programming (PV

Programming) and then press [SELECT] to proceed to the desired selection.

5.2.2 Output Port Function Select

This screen below is shown as port 5 which had previously been programmed as an output port. Use the

cursor keys to point to either Output Viewing (SP Status), or Output Programming (SP Programming) and

then press [SELECT] to proceed to the desired selection.

Table of contents

Popular Control System manuals by other brands

Carlin

Carlin EZ-Temp 90320 quick start guide

McCue

McCue Pedestrian Barrier installation instructions

Electronics Line 3000

Electronics Line 3000 iConnect installation manual

Worthington

Worthington CS200 Operation & maintenance instructions

Chamberlain

Chamberlain SENTEX Infinity Series installation instructions

Vaillant

Vaillant sensoHOME VRT 380/2 Operating and installation instructions