Flow-Rite BA-MS-115 Manual

For Model:

BA-MS-115

Portable Watering Cart

Operation & Maintenance

Manual

BL-626-0520

2

General Information & Precautions

This publication provides detailed instructions for

installing the single point watering system kit.

Thoroughly review this document before any

installation procedures are performed.

The following safety statements relate to specific safety issues and must be

read, understood, and heeded before a kit is installed. Failure to do so could

result in personal injury and/or property damage.

DANGER

• Battery – Explosive gases! Do not smoke. Keep sparks and flames away from

the vehicle and service area. Ventilate when charging or operating vehicle in an

enclosed space. Wear a full face shield and rubber gloves when working on or

near batteries.

• Battery – Poison! Contains acid! Causes severe burns. Avoid contact with skin,

eyes, or clothing.

Antidotes

- External: Flush with water. Call a physician immediately.

- Internal: Drink large quantities of milk or water. Follow with milk of magnesia

or vegetable oil. Call a physician immediately.

- Eyes: Flush with water for 15 minutes. Call a physician immediately.

WARNING

• Follow the procedures exactly as stated in this instruction, and heed all

DANGER, WARNING, and CAUTION statements in this instruction as well as

those on the vehicle and battery charger.

• Only trained technicians should service or repair the single point watering

system. Anyone doing even simple repairs or service should have knowledge

and experience in plumbing, electrical, and mechanical repair. The appropriate

instructions must be used when performing maintenance, service, or accessory

installation.

• Prior to servicing the vehicle or leaving the vehicle unattended, turn the key

switch OFF, remove the key, and chock the wheels.

• Wear safety glasses or approved eye protection when servicing any part of the

watering system. Wear a full face shield and rubber gloves when working on

or near batteries.

• Do not wear loose clothing or jewelry such as rings, watches, chains, etc.,

when servicing the vehicle or battery charger.

• Moving parts! Do not attempt to service the vehicle while it is running.

• Use insulated tools when working near batteries or electrical connections. Use

extreme caution to avoid shorting of components or wiring.

• If wires are removed or replaced, make sure wiring and wire harness are

properly routed and secured. Failure to properly route and secure wiring could

result in vehicle malfunction, property damage, personal injury, or death.

3

Watering Procedures

1. Water After Charge

Electrolyte levels drop during discharge and rise during charge. In addition,

charging generates heat, fluid expansion and explosive gases. Watering a

battery before charge (or with a low charge level) can lead to boil over

resulting in potential damage of the watering system, battery and vehicle.

Water, when needed, must be added to a fully charged battery. Prior to

charging, there must be sufficient water to cover the plates. If the battery

has been discharged (partially or fully), the water level should still be above

the plates.

2. Watering Intervals

Watering intervals are dependent on the local climate, charging methods,

application, and age of batteries. Flow-Rite recommends that new batteries

be checked once a month and older batteries be checked weekly until you

get a feel for your water consumption rate.

Typically for a heavy use application, watering a maximum of once per week

is recommended, and for light use applications once per month. Do not

water a battery that has been sitting for an extended period of time with no

activity (non-use or not on charge) such as a battery that has sat idle over

the weekend. It is best to water a warm battery that has just been fully

charged.

Important: Water quality is important to maintain the life of your

battery and watering system. Always use water that

meets the quality requirements of your battery’s

manufacturer.

Operation

- Fill Tank

Ensure the water supply has ample water to fill battery. If necessary,

remove lid and fill cart with water. All carts are compatible with deionized

water.

Step 1

- Power Up Cart

Turn on the cart by pushing the on/off button. Check the battery indicator

lights to verify the battery is charged. The status is as follows:

Green - Ready to go, battery charged

Yellow - Battery is low, charge soon

Red - Battery must be charged or pump will not run

Recharging Battery: Plug in battery charger to a GFCI outlet.

Step 2

4

For successful operation of your Single Point Watering system always:

1. Only use Flow-Rite approved equipment.

Warning! Use of unapproved equipment or modification of

approved equipment can lead to system failure and will void your

warranty.

2. Always follow Flow-Rite’s required watering procedures.

3. Perform regular scheduled maintenance!

Warning! Only fill batteries after they have been fully charged

and require water.

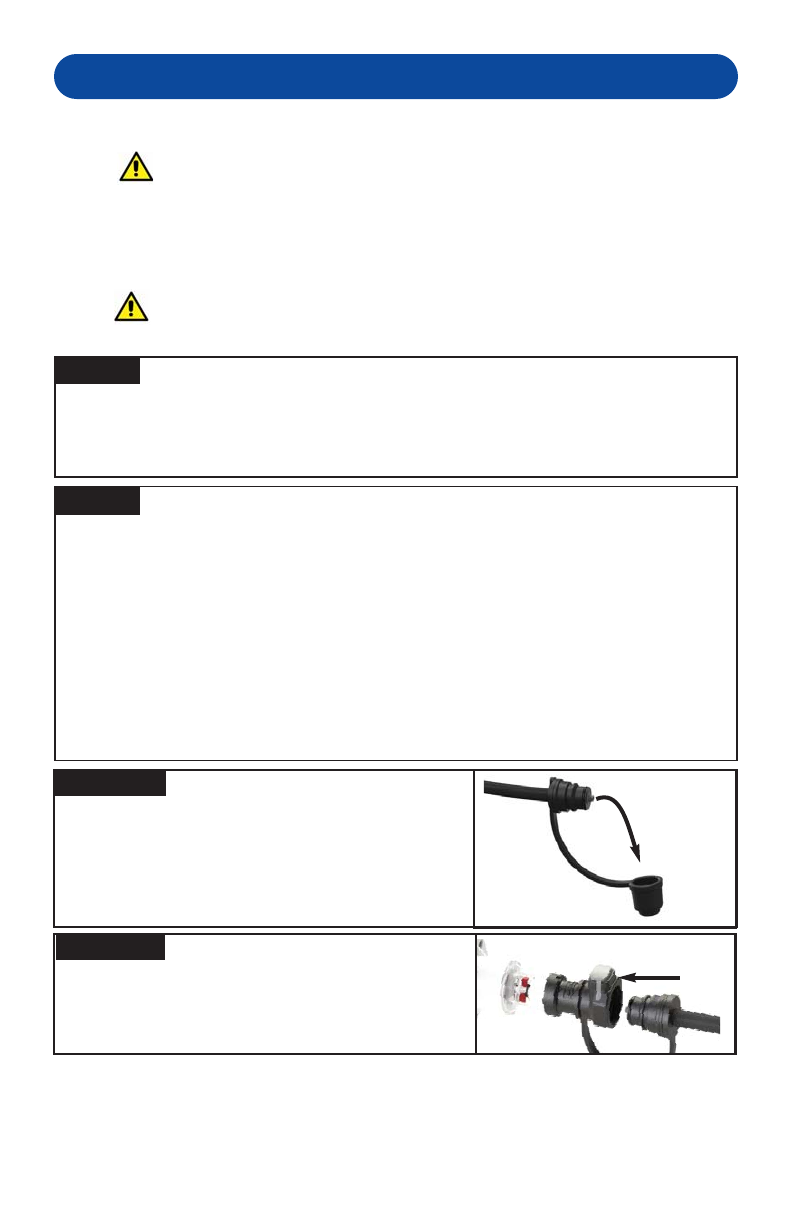

Step 3 - Remove Dust Cover from

water supply.

-Mate Couplers

Insert the male coupler on the SPW

system into the female coupler on the

end of the water supply.

Step 4

5

Operation Continued

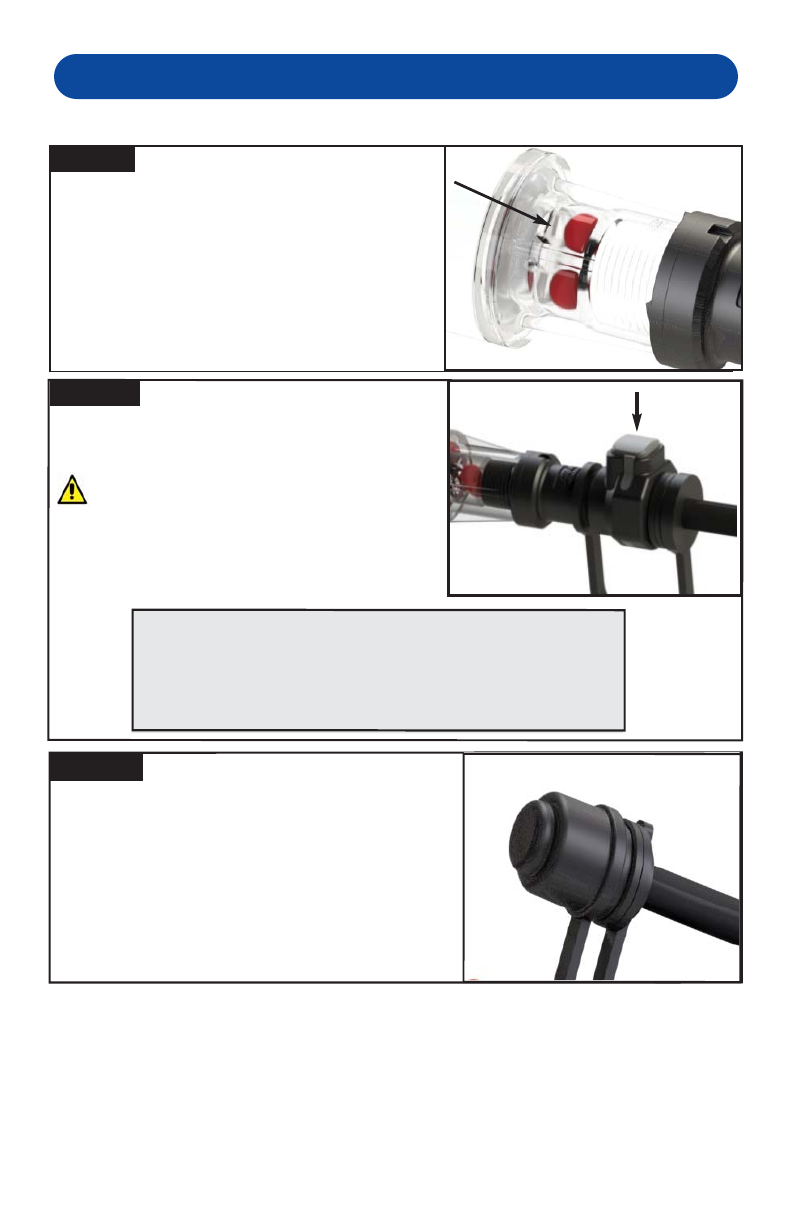

Observe Flow Indicator

The red balls inside the flow indicator will

begin to spin indicating that water is

flowing into the battery.

Step 5

Replace Dust Cover

Place dust cover back over the male

coupler.

NOTE: Cart will automatically turn off

after 10 minutes of inactivity.

Disconnect

When the balls stop spinning, immediately

disconnect the couplers.

Warning!If the water supply is left

connected after the filling process is

finished, it could lead to an overfill.

Disconnecting before the balls come to a

complete stop will lead to underfilled cells.

Step 6

CAUTION:If at any time during the filling process

you have a valve failure, disconnect immediately

and refer to the troubleshooting section.

Step 7

Your single point watering system requires regular preventative maintenance

on at least a quarterly basis.

1. Check all screens

Clean or replace all strainers as necessary. Failure to do so can cause a

reduction in the water pressure and flow rates needed to operate the system

properly.

2. Inspect the condition of all tubing connections, red end caps, swivel

Tees, and couplers.

Make sure that all parts are in good working condition and are secure, leak

free, and properly connected. The coupler must have an O-ring and dust

cover properly attached.

3. Electrolyte Levels

Flow-Rite recommends checking the electrolyte level in each cell for

accuracy after the system has been installed and operational for three

months.

4. Never operate when plugged in. When not in use, plug it in.

6

Regular Maintenance

Line Strainer (A)A

Note: Pictures may differ slightly from your specific application.

Seasonal Maintenance

Water Supplies

Water supplies must be drained and stored in an empty state if they will be

exposed to freezing temperatures. Failure to do so can cause permanent

damage. If out of use for more than 4 weeks, make sure the cart has

been plugged in and charged before use.

Watering Systems

If you have vehicles that are taken out of service or put into storage for a

period of 6 weeks or longer, your single point watering system will require

seasonal maintenance. Check yoursystem instructions for details.

7

Operating Specifications

FLOW-RITE CONTROLS

1 YEAR WARRANTY

1

Visit www.flow-rite.com for details.

Operating Requirement of SPW system

Pressure Range: 3.0 - 35.0 PSI (no flow, static)

0.21-2.4 bar

Power Requirements: 100-140 VAC 50/60 HZ

All product specifications and requirements should be met for proper

operation of your Flow-Rite SPW system. Contact your battery supplier or

Flow-Rite Controls if you have any questions regarding product

specifications or how to verify a water supply.

*Flow rate should be measured at the end of a purger (female / male

coupler combination).

Flow-Rite Controls

960 74th Street

Byron Center, MI 49315

phone: 616.583.1700

fax: 616.878.5151

Printed in USA 0520

Protected under U.S. & foreign patents and paten

Table of contents

Popular Lawn And Garden Equipment manuals by other brands

Costway

Costway NP10912 manual

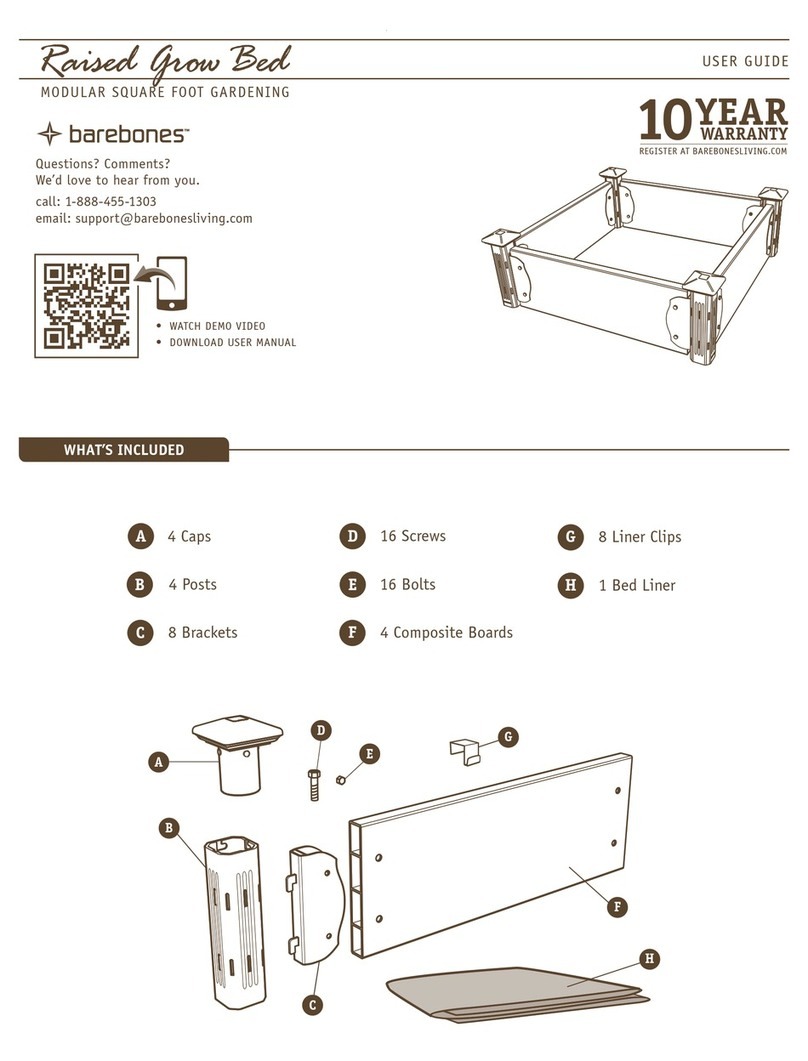

barebones

barebones raised grow bed user guide

Buhler

Buhler Landscape Rake FK349 Operator's & parts manual

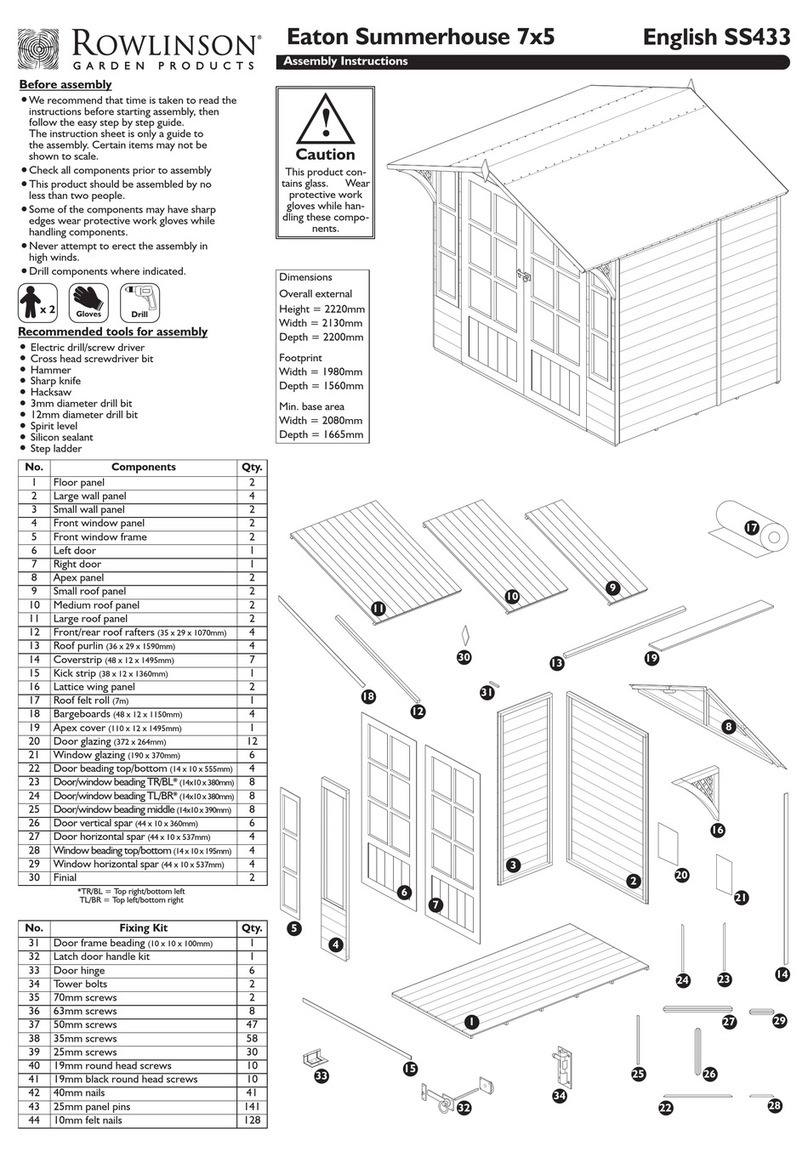

Rowlinson Garden Products

Rowlinson Garden Products Eaton Summerhouse 7x5 Assembly instructions

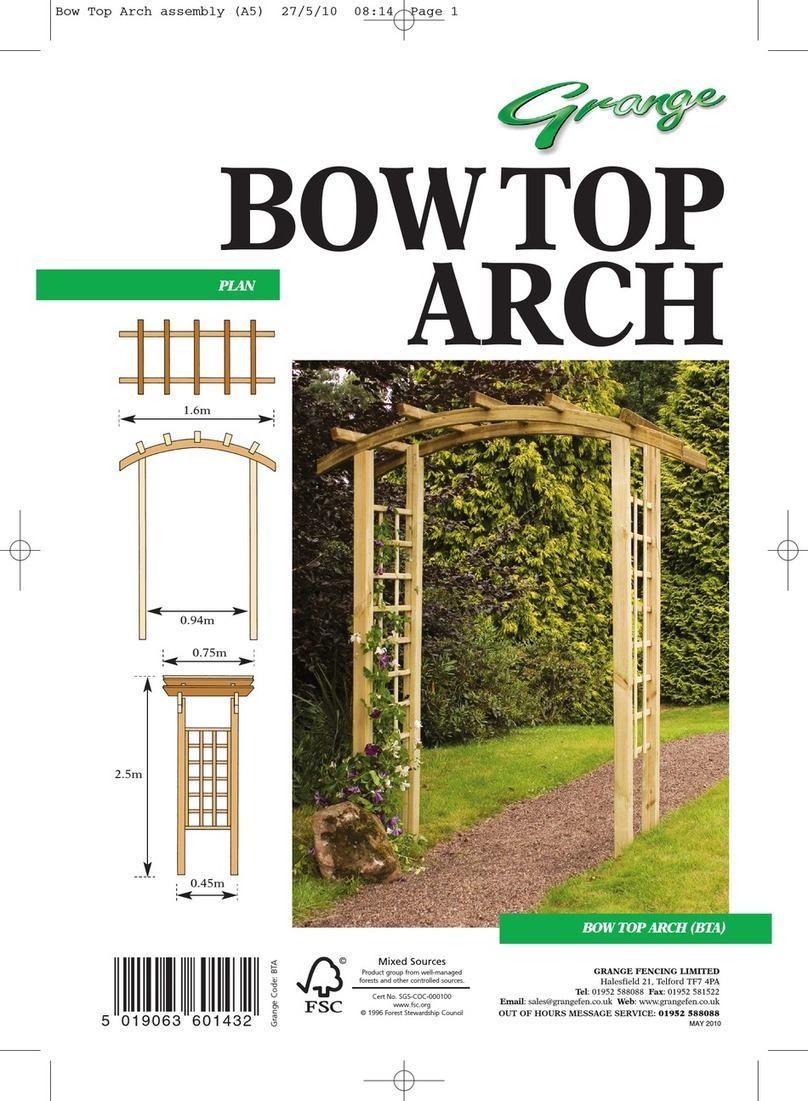

Grange

Grange ELITE BOW TOP ARCH Assembly instructions

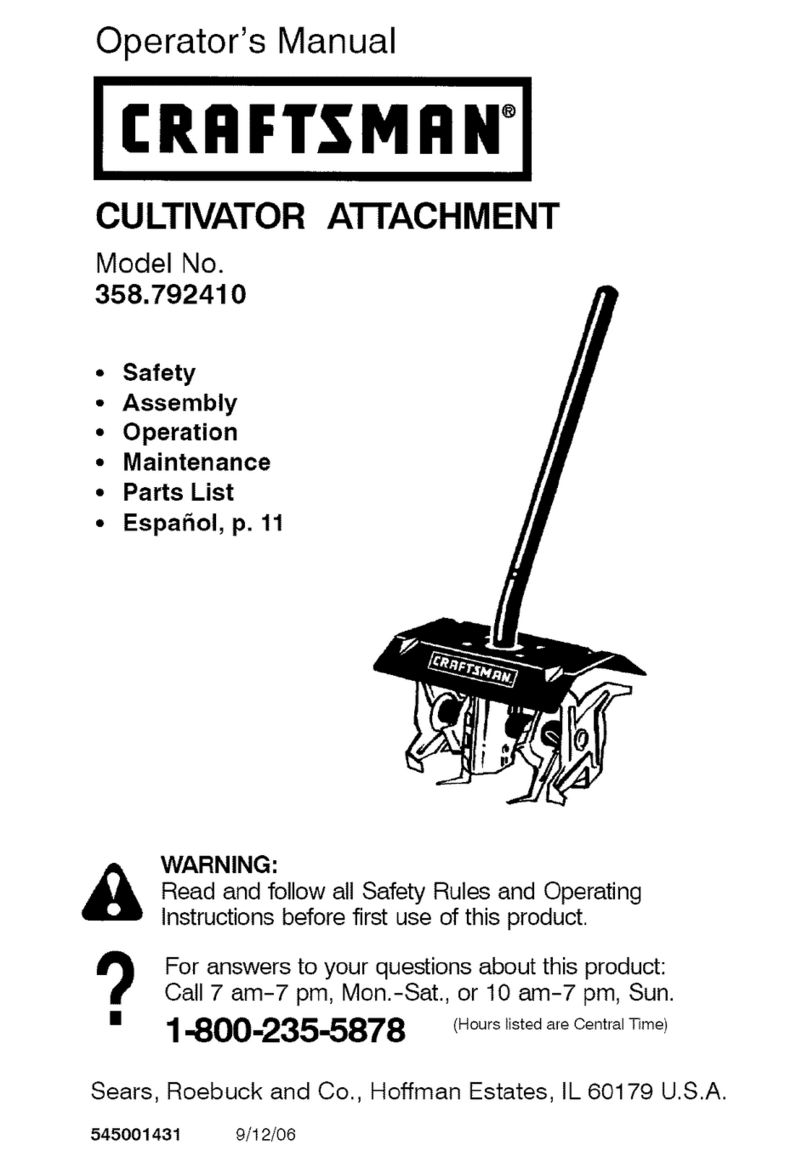

Craftsman

Craftsman 358.792410 Operator's manual