Flow-Tek M1 Series User manual

SERIES M1

Severe Service

Metal Seated Ball Valves

Installation, Operation and

Maintenance Manual

Installation, Operation and Maintenance Manual

Series M1 - Severe Service Ball Valves

Date: October 2020/ Page 2 of 10

Subsidiary of BRAY INTERNATIONAL, Inc.

FLOW-TEK, Inc. Tel: 832.912.2300 © 2020 Flow-Tek, Inc.

8323 N. Eldridge Pkwy. #100 Fax: 832.912.2301

Houston, Texas 77041 www.flow-tek.com

Table of Contents

Safety Instructions - Definition of Terms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1. Bill of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

2. Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

3. Handling and Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4. General Warnings and Cautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

5. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Removing Valve from Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

6. Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Valve in Open Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Valve in Closed Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Visual Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

7. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

8. Valve Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

9. Transport and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Short Term Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Long Term Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

10. Service Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Installation, Operation and Maintenance Manual

Series M1 - Severe Service Ball Valves

Date: October 2020/ Page 3 of 10

Subsidiary of BRAY INTERNATIONAL, Inc.

FLOW-TEK, Inc. Tel: 832.912.2300 © 2020 Flow-Tek, Inc.

8323 N. Eldridge Pkwy. #100 Fax: 832.912.2301

Houston, Texas 77041 www.flow-tek.com

SAFETY INSTRUCTIONS DEFINITION OF TERMS

READ AND FOLLOW THESE INSTRUCTIONS:

WARNING indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury.

NOTICE

used without the safety alert symbol indicates a potential situation

which, if not avoided, may result in an undesirable result or state,

including property damage.

Installation, Operation and Maintenance Manual

Series M1 - Severe Service Ball Valves

Date: October 2020/ Page 4 of 10

Subsidiary of BRAY INTERNATIONAL, Inc.

FLOW-TEK, Inc. Tel: 832.912.2300 © 2020 Flow-Tek, Inc.

8323 N. Eldridge Pkwy. #100 Fax: 832.912.2301

Houston, Texas 77041 www.flow-tek.com

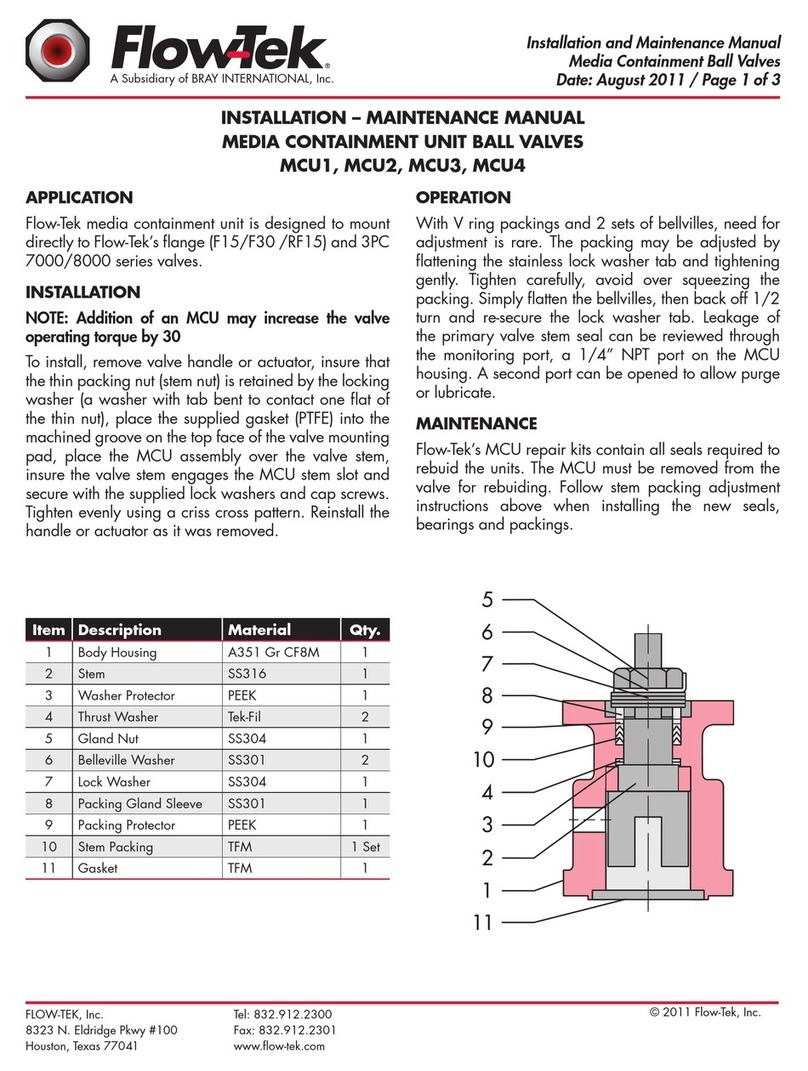

1. BILL OF MATERIALS

ITEM # Component

1 Body

2 Ball

3 Primary Seat Ring

4 Reverse Seat Ring

5 Seat Spring

6 Locking Ring

7 Stem

8 Inner Stem Bushings

9 Gland Flange (Follower)

10 Packing Set

ITEM # Component

11 Mounting Flange (Bracket)

12 Outer Stem Bushing

13 Stem Bushing Insert

14 Packing Studs

15 Belleville Washers

16 Packing Nuts

17 Closure

18 Body Studs

19 Body Hex Nuts

20 Body Gasket

NAMEPLATE

INFO

STAMP

MODEL: Valve Series Model

SIZE: Nominal End Size

B16.34 Pressure Class

BODY: Body Material

BALL: Ball Material

SEAT: Seat Material

NAMEPLATE

INFO

STAMP

STEM: Stem Material

B/S CTG: Ball/Seat Coating Code

MAX P: Maximum Pressure

MAX T: Maximum Temperature

S/N: Valve Serial Number

P/N: Valve Part Number

1

2

20

6

3

10

8

9

14

13

12

16

15

7

11

45

17

18

19

Installation, Operation and Maintenance Manual

Series M1 - Severe Service Ball Valves

Date: October 2020/ Page 5 of 10

Subsidiary of BRAY INTERNATIONAL, Inc.

FLOW-TEK, Inc. Tel: 832.912.2300 © 2020 Flow-Tek, Inc.

8323 N. Eldridge Pkwy. #100 Fax: 832.912.2301

Houston, Texas 77041 www.flow-tek.com

2. DESIGN

Our Series M1 Severe Service ball valve is designed as a “free

floating” ball valve with metal seats. It is important to install the

valve in the pipe considering its intended purpose to achieve best

performance. If thereare any questionsregardingthebestorientation

of the valve, contact Flow-Tek.

3. HANDLING AND LIFTING

The valve should be lifted in such a way that the body supports the

load. Use the lifting eyes provided on large valves

The end protector covers should be kept in place during handling.

Remove only during final installation of the valve.

!

CAUTION

Unless lifting eyes are provided, the end connection necks are

suitable places to attach lifting slings/straps. Never use hand

wheels or other protruding parts of the gearbox or actuator not

designated for this purpose.

!

CAUTION

During handling, protect the end connection faces and fittings

against damage from the lifting devices. Failure to cover faces

and fittings could cause damage to the valve.

4. GENERAL WARNINGS AND

CAUTIONS

1. During shipment, storage, and in operation, the valve should

be fully open or fully closed.

2. Ensure that the line is depressurized and drains are open/

monitored during installation

3. Beforeworkingonvalvemakesurethat servicemediahasbeen

flushed and line is safe. Ensure that all applicable MSDS sheets

are available. Follow all safety related procedures.

4. While line is under pressure, DO NOT remove packing gland

or any other valve parts.

5. Ensure that the valve is being used for its intended purpose, i.e.

suitable pressure/temp rating, to prevent valve failure.

WARNING

Before installing this equipment, confirm that it is suitable for the

intended service. The identification tags describe the maximum

allowable service conditions for this product. Be sure that the

installation is protected by appropriate pressure control and

safety devices to insure that acceptable limits are not exceeded.

Preferred

Isolation Orientation

High Pressure Side

Reverse Seat

Low Pressure Side

Primary Seat

Installation, Operation and Maintenance Manual

Series M1 - Severe Service Ball Valves

Date: October 2020/ Page 6 of 10

Subsidiary of BRAY INTERNATIONAL, Inc.

FLOW-TEK, Inc. Tel: 832.912.2300 © 2020 Flow-Tek, Inc.

8323 N. Eldridge Pkwy. #100 Fax: 832.912.2301

Houston, Texas 77041 www.flow-tek.com

5. INSTALLATION

WARNING

Reasonable precaution should be taken before beginning any

work on the valve.

Protectiveclothing, asrequired byspecificlinefluid,shouldbe worn.

Depressurize the line and close the valve before removing the

actuation device from the valve.

Do not pressurize the line without an actuation device properly

installed and working on the valve.

The valve may be installed in any position, vertically or horizontally,

on the pipeline. Before installing the valve, the valve should be

placed in the full open position.

!

CAUTION

All welding/grinding debris must be thoroughly flushed from all

associated piping before valve is installed or actuated.

Due to potential for packing consolidation, verify proper packing

torque adjustment prior to placing valve in service.

Larger valves and actuators may need external support to prevent

excess piping loads from effecting valve operation.

1. Verify operating position. Refer to Section 6 – Operation for

more information.

2. Identify the sealing direction of the pipeline/valve. High pressure

end is marked on valve end as “HP END”. The HP END side is

the preferred higher pressure side when the valve is in the closed

position.

Fully Closed Fully Open

Installation, Operation and Maintenance Manual

Series M1 - Severe Service Ball Valves

Date: October 2020/ Page 7 of 10

Subsidiary of BRAY INTERNATIONAL, Inc.

FLOW-TEK, Inc. Tel: 832.912.2300 © 2020 Flow-Tek, Inc.

8323 N. Eldridge Pkwy. #100 Fax: 832.912.2301

Houston, Texas 77041 www.flow-tek.com

3. Position and install the “HP END” side towards the pipeline side

with the higher pressure.

4. Position valve in piping. Verify that the valve and actuator or

handle orientation is correct.

Note: Support or lift as required, using lifting lugs or nylon

straps around the valve body. Do not lift or support by the

actuator alone. Refer to Section 3 – Handling and Lifting for

more information.

5. Install valve in line by bolting, welding or clamping.

6. After installation, the pipeline and valve must be flushed clean

of dirt, burrs, and welding residues or the seats and ball surface

will be damaged.

7. After installation, open and close several times to ensure

smooth operation.

Removing Valve from Service

Before the valve is removed from service it should be placed in the

open position to prevent internal damage to valve components.

P1=10 bar

HP END

XV-002

XV-001

HP END

V1=20 bar

XV-001 is installed

with the “HP END”

near pressure vessel

V1due to the vessel’s

pressure higher than

P1’s pressure; even

though the normal

flow direction is into

the vessel, opposite

the sealing direction

Installation, Operation and Maintenance Manual

Series M1 - Severe Service Ball Valves

Date: October 2020/ Page 8 of 10

Subsidiary of BRAY INTERNATIONAL, Inc.

FLOW-TEK, Inc. Tel: 832.912.2300 © 2020 Flow-Tek, Inc.

8323 N. Eldridge Pkwy. #100 Fax: 832.912.2301

Houston, Texas 77041 www.flow-tek.com

6. OPERATION

Operation of the valve is done by turning the valve stem 90° to 95°.

Clockwise (CW) to close, Counterclockwise (CCW) to open. The

operation requires greater angular movement than 90° to account

for clearances in the ball and stem.

Valve in Open Position

The valve handle, stem keyways or actuator indicator is parallel

with the pipeline.

Valves with actuators should be checked for alignment. Consult

actuator manufacturer’s instructions for proper setting of stops.

Valve in Closed Position

Thevalve handle, stemkeywaysoractuatorindicatorisperpendicular

to the pipeline.

Note: Valve keyways are in-line with valve bore. If keyway are

perpendicular to pipeline, then valve is in the closed position.

If keyway are parallel to pipeline, then valve is in the open position.

If the valve is in the “closed” position, the scribe line on the stem

shouldbealignedwiththescribelineontheglandandperpendicular

to the valve bore.

Visual Indicators

Thescribelineisusedtosetoperatoropen/closestopsiftheoperator

cannot be removed from valve

Scribe line on stem

Scribe line on flange

WARNING

Avoid 180° rotation of the ball and/or stem as this could cause

premature wear to the ball/seat lapping surface thus reducing

effective sealing / isolation which may lead to void of warranty.

WARNING

When stroking the valve, make sure that it is stroked from fully open

to fully closed or vice versa to wipe away any accumulation of

debris on the ball and seat sealing surfaces. This ensures optimal

performance and long valve life. Failure to fully stroke the valve

may lead to void of warranty.

Installation, Operation and Maintenance Manual

Series M1 - Severe Service Ball Valves

Date: October 2020/ Page 9 of 10

Subsidiary of BRAY INTERNATIONAL, Inc.

FLOW-TEK, Inc. Tel: 832.912.2300 © 2020 Flow-Tek, Inc.

8323 N. Eldridge Pkwy. #100 Fax: 832.912.2301

Houston, Texas 77041 www.flow-tek.com

7. MAINTENANCE

Check the bolting at these locations periodically. If bolting torque

is lower than the specified values, re-torque bolting as necessary.

1. Gland Flange (or Stem Packing)

2. Valve Operator Mounting

Refer to Test Certificate for proper bolting torque values or call your

local distributor or factory

!

CAUTION

Checkpackingglandnutsperiodically, and re-torqueifnecessary.

NOTICE

Open/Close thevalve intermittently(atleast once a year). Valves

should always be fully opened or fully closed to wipe away any

accumulation on the sealing surfaces.

Packing Procedure:

1. Mark any matching components with a marker or tape prior to

disassembly, for ease of reassembly.

2. Remove the operator, bracket (or

mounting flange adaptor), and stem

adaptor if present.

3. Remove stem keys.

4. Remove bearing retainer (12) and

stem bearing (13).

5. Loosenandremovenuts(16)holding

gland flange (9) in place.

6. RemoveBelleville washers(15),studs

(14), andglandretainer/flange(9).

7. Usingasmall pick or scribe, carefully

remove stem packing set (10) which

includes anti-extrusion rings from the

packing box. Make sure that all of

the packing is removed.

8. Clean packing box before installing

the new packing set.

!

CAUTION

Do not scratch the stem or the packing bore in the body. Scratches

could cause a leak.

Before installing the new packing, make sure the packing box

is clean. Use of an air hose to clean debris from packing box is

permitted.

9. Install the new packing set (10); install the rings one at a time.

Packing set should have an anti-extrusion ring on each end.

Use the gland flange (9) as a packing tool to stuff each packing

ring all the way down against the previous ring.

10. Verify that the scribe line on the stem (7) is facing the body/

closure joint.

2.

1.

10

9

14

13

12

16

15

7

Installation, Operation and Maintenance Manual

Series M1 - Severe Service Ball Valves

Date: October 2020/ Page 10 of 10

Subsidiary of BRAY INTERNATIONAL, Inc.

FLOW-TEK, Inc. Tel: 832.912.2300 © 2020 Flow-Tek, Inc.

8323 N. Eldridge Pkwy. #100 Fax: 832.912.2301

Houston, Texas 77041 www.flow-tek.com

11 . Install the gland flange (9) over the stem (7) so that one of its

scribe lines is facing the body closure joint. If necessary rotate

the stem so that the two scribe lines are aligned.

WARNING

A gland flange must be pulled down evenly to prevent cocking

or side loading, as this could cause damage to the packing and

prevent the valve from operating properly.

Make sure that the gland flange remains perpendicular to the

stem, and the gap around the stem remains concentric during

tightening process.

Do not over-tighten nuts. Torque all nuts evenly per specified

packing torque.

12. Apply lubricant to stud threads (14) and bottom face of hex

nuts (16).

13. Insertstuds(14),intothreadedholes.Insert theBellevillesprings/

washers (15) onto each stud. Belleville

washers shall be stacked in alternating

direction (series stack). Install nuts (16)

onto each stud and torque to specified

value.Besuretotorqueina crosspattern

to avoid uneven loading. Packing

assembly torques are given on

the Valve Test Form.

14. Install bearing retainer (12) and stem bearing (13) into the

mounting flange (11). If necessary, tap gently into place using a

soft hammer.Valveisreadyforinstallingtheactuator,orhandle.

15. Insert keys into the stem (7). Ensure key length provides and

maintains full engagement.

8. VALVE DISASSEMBLY

YourM1valveshavebeencarefully fittedandassembledforoptimum

performance and long life. It is not recommended that the valves

be disassembled without factory supervision or specific instructions

provided by the Flow-Tek Service Department.

9. TRANSPORT AND STORAGE

Valves will be shipped in a manner to minimize damage during

transit Upon arrival at the site, valves general condition shall be

inspected right away for any shipping damage. Any damage shall

be reported to Flow-Tek.

Short-Term Storage:

Short-term storage is defined as storage of products and

equipment to be used in the construction of a project for periods

of one to three months. Short-term storage must be carried out in a

controlled manner as follows:

1. Valves must be stored in a closed, clean, and dry environment.

2. Ball valves should be stored in the fully open position to

protect the ball and seats.

3. Ball valves should remain in the original shipping container

and be placed on pallets of wood or other suitable materials.

End protectors should remain on the valve ends to prevent

the entrance of dirt, and removed only at time of installation.

Long-Term Storage

Long-term storage is defined as storage of products and/or

equipment for periods longer than 3 months. Long-term storage

must be carried out in a controlled manner as follows:

1. Valves must be stored in a closed, clean, and dry environment.

2. Ball valves should be stored in the fully open position to

protect the ball and seats.

3. Ball valves should remain in the original shipping container

and be placed on pallets of wood or other suitable materials.

End protectors should remain on the valve ends to prevent

the entrance of dirt, and removed only at time of installation.

4. Periodically, the valves should be checked to ensure the

above conditions are maintained.

These are general guidelines for valve storage. Please consult the

factory for information regarding specific requirements.

10. SERVICE CONTACT

Flow-Tek Service may be reached 24 hours per day / 7 days per

week.

Table of contents

Other Flow-Tek Control Unit manuals

Popular Control Unit manuals by other brands

Seneca

Seneca VPN BOX 2 installation manual

Unitronics

Unitronics Uni-I/O UIS-04PTN installation guide

Pickering

Pickering PXI BRIC 40-569B user manual

Whelen Engineering Company

Whelen Engineering Company WeCan Series installation guide

Digilent

Digilent PmodCLP Reference manual

Robostar

Robostar N1 Series Option DeviceNet manual