Flow-Tek M4 Series Instruction Manual

INSTALLATION - MAINTENANCE MANUAL

Severe Service Series M4 Ball Valve

Installation and Maintenance Manual

Series M4 - Severe Service Ball Valves

Date: May 2016/ Page 2 of 12

®

Subsidiary of BRAY INTERNATIONAL, Inc.

1. SAFETY INFORMATION - DEFINITION OF TERMS

READ AND FOLLOW THESE INSTRUCTIONS:

!

WARNING Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

!

CAUTION Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

NOTICE Used without the safety alert symbol indicates a potential situation which

may result in damage to the valve and void of warranty.

Table of Contents

1. Safety Information - Definition of Terms . . . . . . . . . . . . . . . . . . . . . . . . . .2

2. Bill of Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3. Nameplate Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4. Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5. Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6. Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Visual Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

7. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Post Weld Heat Treatment (PWHT) . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Valve Insulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

8. Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Repacking Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

9. Removing Valve from Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

10. Handling and Lifting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

11. Transport and Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Short Term Storage (Up to 3 Months). . . . . . . . . . . . . . . . . . . . . . . . . . 12

Long Term Storage (Over 3 Months) . . . . . . . . . . . . . . . . . . . . . . . . . . 12

JamiesonEquipmentCompany

www.jamiesonequipment.com

tollfree800.875.0280

Installation and Maintenance Manual

Series M4 - Severe Service Ball Valves

Date: May 2016/ Page 3 of 12

®

Subsidiary of BRAY INTERNATIONAL, Inc.

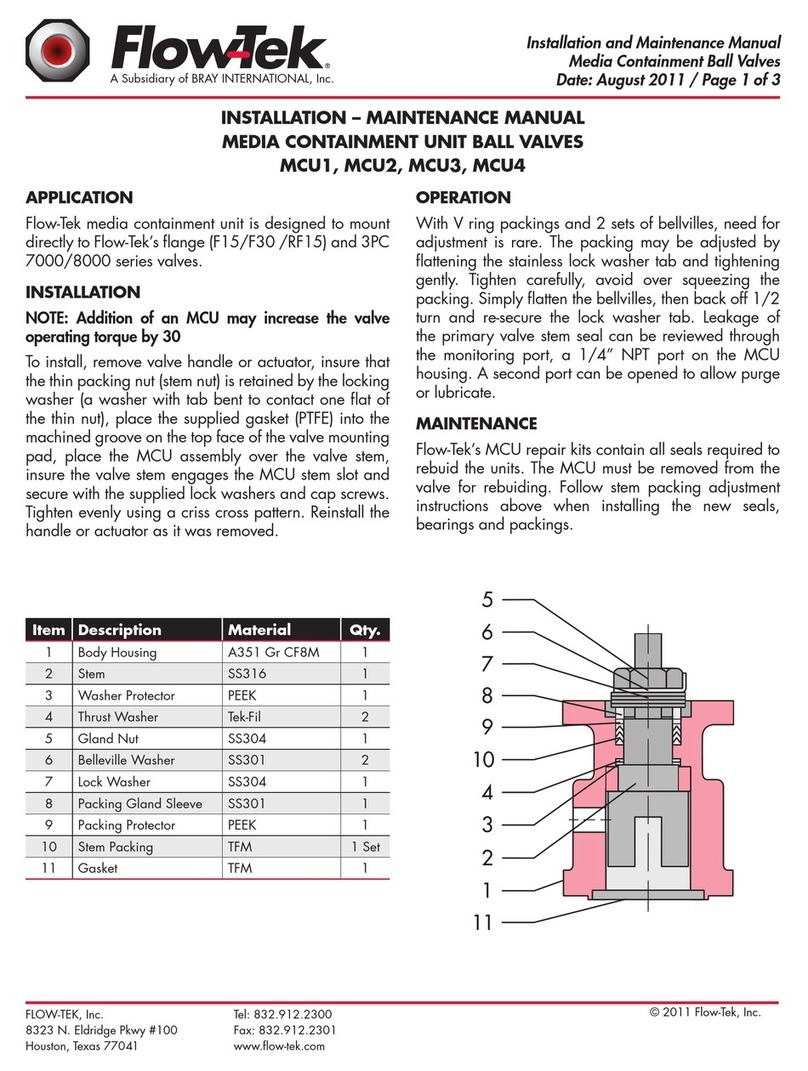

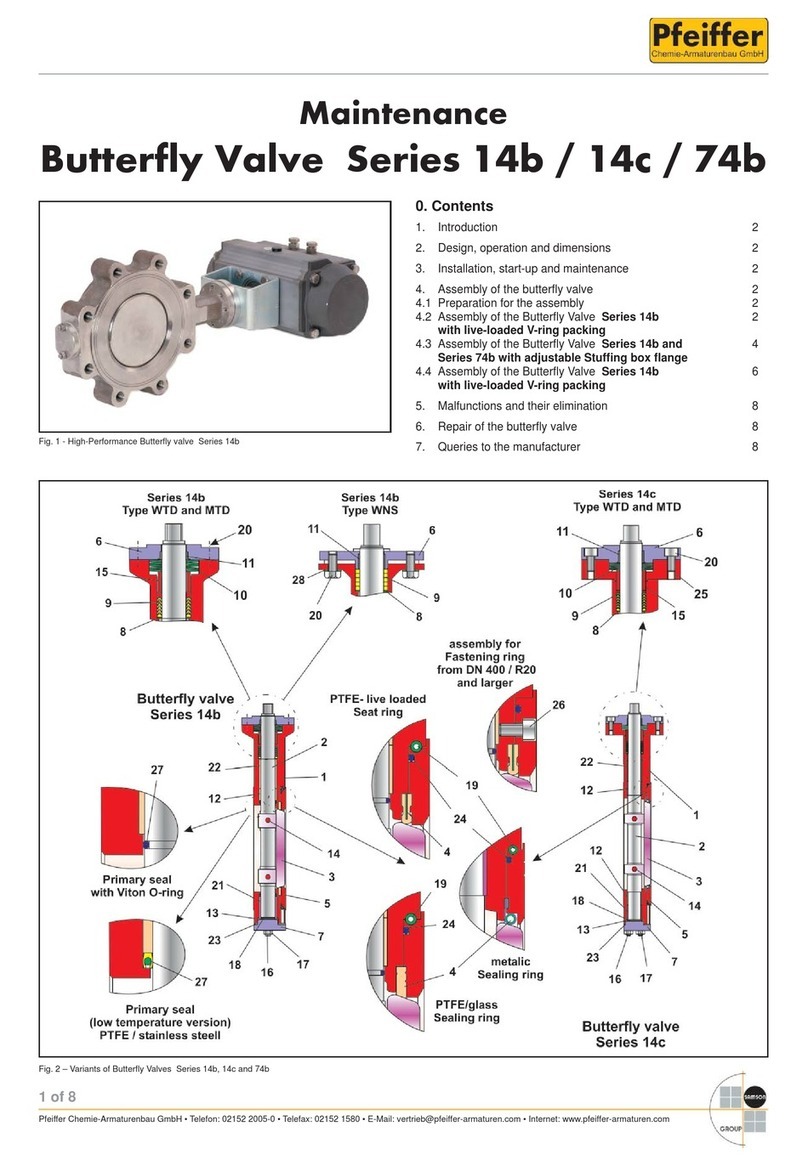

Item # Component Qty.

10 Body 1

20 Bracket 1

40 Ball 1

50 Seat 1

60 Stem 1

70 Pusher Seat 1

80 Transition Sleeve 1

Item # Component Qty.

90 Seat Spring 1

100 Retainer Ring 1

110 Gland Flange 1

120 Gland Follower 1

130 Belleville Spring 2

140 Packing Set 1

150 Metal Anti-Extrusion Ring 1

Item # Component Qty.

160 Stem Bearing 1

170 Stud, Gland 4

180 Nut, Gland 4

190 Roller Pin 2

200 Non-removable Screw

(Hidden from view)

4

2. BILL OF MATERIALS

10

70

190

20

80

100

40

50

60

200

170

180 110

120

140

150

130

160

90

JamiesonEquipmentCompany

www.jamiesonequipment.com

tollfree800.875.0280

Installation and Maintenance Manual

Series M4 - Severe Service Ball Valves

Date: May 2016/ Page 4 of 12

®

Subsidiary of BRAY INTERNATIONAL, Inc.

Nameplate Info Stamp Nameplate Info Stamp Nameplate Info Stamp

MODEL: Valve Series Model BALL: Ball Material MAX P: Maximum Pressure

SIZE: Nominal Pipe Size x Bore SEAT: Seat Material MAX T: Maximum Temperature

B16.34: Pressure Class STEM: Stem Material S/N: Valve Serial Number

BODY: Body Material B/S CTG: Ball/Seat Coating Code P/N: Valve Part Number

3. NAMEPLATE INFORMATION

4. DESIGN

Our Series M4 valve is designed as a “free floating” ball

with uni-directional sealing seat. These valves are typically

used in the power industry. It is important and critical to

install the valve correctly in the pipeline to assure the valve

will isolate the proper side of the piping system.

This product is designed for long life and economic initial

investment. Repair of the valve internals is not recommended

or approved by Flow-Tek.

Low emission, live loaded packing material and energized

gasket rings eliminate atmospheric leaks in the most severe

applications. Outerstem bushingprevents sideloading onstem.

LOW

PRESSURE

SIDE

HIGH

PRESSURE

SIDE

5. USE

The valve should be maintained as part of an overall

preventative maintenance program and in accordance with

Flow-Tek’s recommended pressure, temperature and corrosion

limits to ensure a long service life.

During shipment, storage, and in operation, the valve should

be fully open or fully closed. A valve left in the partially open

position during service will suffer premature wear to the ball

and seat sealing surfaces.

!

WARNING

Before installing this

equipment, confirm

that it is suitable for the

intended service. Refer

to the nameplate for

maximum allowable

service conditions for this

product.

JamiesonEquipmentCompany

www.jamiesonequipment.com

tollfree800.875.0280

Installation and Maintenance Manual

Series M4 - Severe Service Ball Valves

Date: May 2016/ Page 5 of 12

®

Subsidiary of BRAY INTERNATIONAL, Inc.

6. OPERATION

The M4 ball valve is a 1⁄4turn (90°) operation valve. The

valve is opened by a 1⁄4 turn counterclockwise and closed

by a 1⁄4turn clockwise.

Visual Indicators

If valve handle is in-line with pipeline, valve is in the open

position; if handle is perpendicular to pipeline, then valve

is in the closed position.

The scribe line can be used to set operator open/close stops

if the operator cannot be removed from valve. Valve shown

in closed position.

NOTICE

Misalignment will result in high operational torque and

may damage valve stem and seals.

Avoid 180° rotation of the ball and/or stem as this could

cause premature wear to the ball/seat lapping surface

thus reducing effective sealing/isolation which may lead

to void of warranty..

When cycling the valve open or close, make sure that the

valve is fully opened and fully closed to wipe away any

accumulation of debris on the ball and seat sealing surfaces.

This ensures optimal performance and long valve life.

The actuator must not be re-oriented without removal from

the valve. This prevents 180° rotation of the ball and

assures the mate-lapped ball and seat surfaces to match.

Seat leakage may occur when the ball and seat surfaces

are not matched.

Fully Closed Fully Open

JamiesonEquipmentCompany

www.jamiesonequipment.com

tollfree800.875.0280

Installation and Maintenance Manual

Series M4 - Severe Service Ball Valves

Date: May 2016/ Page 6 of 12

®

Subsidiary of BRAY INTERNATIONAL, Inc.

Handle

Lock-out devices may be used in this hole.

Lever can be secured in any of three positions

The stop screw is placed in the threaded hole of the

bracket and tightened.

Place the set screw in the adaptor and adjust so that

when the valve is in closed position, the set screw touches

the stop screw.

Set

Screw

Stop Screw

JamiesonEquipmentCompany

www.jamiesonequipment.com

tollfree800.875.0280

Installation and Maintenance Manual

Series M4 - Severe Service Ball Valves

Date: May 2016/ Page 7 of 12

®

Subsidiary of BRAY INTERNATIONAL, Inc.

7. INSTALLATION

The valve may be oriented in any position on the pipeline.

Before installing the valve, the valve should be placed in

the open position.

NOTICE

Before installing the valve the pipes must be flushed clean

of dirt, burrs, and welding residues, or the seats and ball

surface will be damaged.

Large valves and actuators may need external support to

prevent excess piping loads from affecting valve operation.

1. Clean the pipeline, connecting socket, and the weld

area on the pipe.

NOTICE

Identify the preferred sealing direction of the valve by

positioning the valve in piping where the ‘High Pressure

End’ is positioned toward the highest pressure against

the valve when the valve is closed. Valve should be

installed so that the primary sealing occurs at the low

pressure end.

2. Position valve in piping. Verify that the valve and

actuator/handle orientation is correct.

NOTE: Support or lift as required, using lifting lugs or

nylon straps around the valve body. Do not lift or support

by the actuator alone. Refer to Section 9 – Handling and

Lifting for more information.

3. Secure valve in place.

4. Remove the plastic protective caps from the valve ends.

Do not remove the contraction rings.

Low

Pressure Side High

Pressure Side

JamiesonEquipmentCompany

www.jamiesonequipment.com

tollfree800.875.0280

Installation and Maintenance Manual

Series M4 - Severe Service Ball Valves

Date: May 2016/ Page 8 of 12

®

Subsidiary of BRAY INTERNATIONAL, Inc.

5. Inspect the valve bore and remove any debris.

6. Verify that the ball is in the open position prior to

welding to protect the ball from possible damage.

7. Follow appropriate welding procedure when welding

pipe to the valve ends.

NOTE: Figures used in this document show only SW

end connections; however, BW connections are also

available.

NOTICE

When welding, assure that the temperature of the valve

body does not exceed 1100°F.

Verify packing torque prior to placing valve in service as

packing consolidation is expected.

Post Weld Heat Treatment (PWHT)

Post weld heat treatment shall be performed localized only;

PWHT in a kiln is NOT allowed. After welding the valve in

the pipeline, follow the instructions below for PWHT:

1. Prior to heat treatment, install heating blankets, as

shown, covering the weld areas up to the valve body

socketweld.

!

WARNING

Do not allow valve body temperature to exceed 1100°F

during welding or post weld heat treating. To avoid body

temp exceeding 1100°F, perform PWHT on one end then

normalize to room temperature before proceeding to the

second end. Valve body reaching to higher temperatures

will lead to void of warranty.

2. Stress relieve the welds using appropriate procedures.

Refer to ASME B31.1 Table 132, Postweld Heat

Treatment.

3. Verify operation. After installation of the valve in the

pipeline, cycle the valve to ensure proper operation.

!

WARNING

Do not pressurize the line without an actuation device

properly installed and working on the valve.

Valve Insulation

Valve insulation should not extend above the packing gland.

Refer to the dotted line in the picture below:

Weld Weld

Insulation

Heat Blanket

Insulation

Heat Blanket

JamiesonEquipmentCompany

www.jamiesonequipment.com

tollfree800.875.0280

Installation and Maintenance Manual

Series M4 - Severe Service Ball Valves

Date: May 2016/ Page 9 of 12

®

Subsidiary of BRAY INTERNATIONAL, Inc.

8. MAINTENANCE

!

WARNING

Depressurize the line before loosening any packing

gland nuts.

!

NOTICE

Check packing gland nuts periodically, and re-torque

if necessary.

Open/Close the valve intermittently (at least once a year).

Valves should always be fully opened or fully closed to

wipe away any accumulation on the sealing surfaces.

After installation, verify bolting torque at the following

locations:

1. Gland Flange (or Stem Packing)

2. Valve Operator Mounting (if present)

Table 1 - Packing Torques lbs/in

ASME Class

1700 2500 3100 4500

MAWP (psi): 4250 6250 7750 11250

Valve Bore

0.63 35

42 max

52

63max

65

78 max

94

113 max

1.03 48

58 max

70

85 max

87

105 max

127

152 max

1.56 75

90 max

111

133 max

137

165 max

199

239 max

Check the bolting at these locations periodically. If bolting

torque is lower than the specified values, re-torque bolting

as necessary. Test certification available upon request.

1.

2.

JamiesonEquipmentCompany

www.jamiesonequipment.com

tollfree800.875.0280

Installation and Maintenance Manual

Series M4 - Severe Service Ball Valves

Date: May 2016/ Page 10 of 12

®

Subsidiary of BRAY INTERNATIONAL, Inc.

Repacking Procedure

1. Loosen and remove gland nuts and/or gland studs

holding gland flange in place.

2. Slide the gland flange, live load springs (X2), and the

gland follower upwards.

3. Using a small pick or scribe, carefully remove stem

packing set. Make sure that all of the packing is removed.

Do not remove the metal anti-extrusion ring at the bottom

of the packing box.

4. Clean packing box with an air hose before installing

the new packing set.

NOTICE

Do not scratch the stem or the packing bore in the body.

Scratches could cause a leak.

Before installing the new packing, make sure the packing

box is clean. Use of an air hose to clean debris from

packing box is permitted.

5. When installing the new packing set install the rings

one at a time. Packing set should have an anti-extrusion

ring on each end. Use the gland follower as a packing

tool to stuff each packing ring all the way down against

the previous ring.

6. Slide the gland follower, the live load Belleville springs,

and the gland flange down the stem so that the scribe

lines are matched. If necessary rotate the gland flange

so that the two scribe lines are aligned.

NOTICE

The gland flange must be pulled down evenly to prevent

cocking or side loading, as this could cause damage to

the packing and prevent the valve from operating properly.

Make sure that the gland flange remains perpendicular to

the stem, and the gap around the stem remains concentric

during tightening process.

Refer to Table 1 - Packing Torques.

7. In some cases the studs may unscrew from the body at

the same time the nuts are removed. This is acceptable.

Assure during replacement that studs are reassembled

to the full thread depth.

8. Apply anti-seize to stud threads and bottom face of

hex nuts.

9. Insert studs into threaded holes. Install nuts onto each

stud and torque to specified value. Be sure to torque

in a cross pattern to avoid uneven loading. Packing

assembly torques are given in Table-1.

10. Cycle the valve a few times to ensure proper

re-packing. Verify packing torque after cycling and

re-torque if necessary.

Gland

Nuts

Gland

Studs

Gland

Flange

Gland

Follower

Live Load

Springs

Anti-Extrusion Ring

3X Seal Rings

Anti-Extrusion Ring

Metal Anti-Extrusion Ring

JamiesonEquipmentCompany

www.jamiesonequipment.com

tollfree800.875.0280

Installation and Maintenance Manual

Series M4 - Severe Service Ball Valves

Date: May 2016/ Page 11 of 12

®

Subsidiary of BRAY INTERNATIONAL, Inc.

9. REMOVING VALVE FROM SERVICE

Before the valve is removed from service it should be placed

in the open position to prevent internal damage to valve

components.

Fully Closed Fully Open

!

WARNING

Depressurize the line and close the valve before removing

the valve from the pipeline.

10. HANDLING AND LIFTING

1. The valve should be lifted in such a way that the body

supports the load.

2. The end protector covers should be kept in place on

the end connections during all handling. Remove only

during final installation of the valve.

3. The ball should be fully open during the installation

of the valve. Failure to keep the ball fully open during

installation could cause damage to the valve.

4. Do not leave the valve in the partially open position

for an extended period of time.

5. Do not lift the valve from the actuator, positioner, or limit

switch.

!

CAUTION

The end connection necks are suitable places to attach

lifting slings/straps. Never use hand wheels or other

protruding parts of the gearbox or actuator not designated

for this purpose.

NOTICE

During handling, protect the end connection faces and

fittings against damage from the lifting devices. Failure to

cover faces and fittings could cause damage to the valve.

JamiesonEquipmentCompany

www.jamiesonequipment.com

tollfree800.875.0280

Installation and Maintenance Manual

Series M4 - Severe Service Ball Valves

Date: May 2016/ Page 12 of 12

®

Subsidiary of BRAY INTERNATIONAL, Inc.

11. TRANSPORT AND STORAGE

Transport

Valves will be shipped in wooden crates that are plastic lined.

Upon arrival at the site, valves general condition should be

inspected right away for any potential shipping damage.

Any damage should be reported to Flow-Tek.

Short Term Storage (Up to 3 Months)

1. Ball valves should remain in the original shipping

containers and be placed on pallets of wood or other

suitable materials. End protectors should remain on the

valve ends until the valves are installed to prevent the

entrance of dirt.

2. Valves should be stored in the open position to protect

the ball and seat.

3. Storage of ball valves can be in an open uncovered area

provided provisions are made for inclement weather

such as tarps or sheeting. Valves with actuators shall be

stored under cover until ready for installation.

Long Term Storage (Over 3 Months)

1. Valves should be stored in the open position to protect

the ball and seats.

2. Ball valves should remain in the original shipping

containers and be placed on pallets of wood or other

suitable materials and stored indoors. End protectors

should remain on the valve ends until the valves are

installed to prevent the entrance of dirt

3. The storage environment should be dry and not have

severe swings in temperature and humidity.

Fully Closed Fully Open

JamiesonEquipmentCompany

www.jamiesonequipment.com

tollfree800.875.0280

Table of contents

Other Flow-Tek Control Unit manuals