Dickert Electronic DCM31 User manual

Motor control unit DCM31

24.04.2006 JT D:\FILES\MOTORST UND ZUB\DCM31\28505401_DCM31_EN.DOC

DCM31

1 or 2-leaf gate control for 24VDC drive units each 11A

Installation & operating instructions for electricians & (electrically) skilled

persons

Please keep these instructions in a safe place to ensure they are available should you

have any questions at a later date.

Not intended for issuing to end customers (users)!

- An instruction manual / instruction for use must be prepared for the user for “their

application”.

- A handover declaration and/or acceptance inspection certificate must be prepared.

- Any possible hazards must be pointed out to the user.

- Operation and servicing/maintenance of the unit must be explained.

Important! Please read these instructions before putting into service!

Motor control unit DCM31

2 / 35

Contents:

1) Intended Purpose .................................................................................................3

a) Requirements.................................................................................................3

b) Legal requirements ........................................................................................3

c) Technical qualification requirements..............................................................4

d) Important safety instructions..........................................................................4

2) Installation.............................................................................................................5

a) Suitable installation site..................................................................................5

b) Installation......................................................................................................5

3) Brief Explanation of Terms Used..........................................................................5

a) Abbreviations used in the instructions............................................................6

4) Connections..........................................................................................................7

a) Terminals.......................................................................................................7

b) Radio............................................................................................................10

5) Controls / Displays..............................................................................................11

a) LEDs next to the display ..............................................................................11

b) LEDs behind terminals.................................................................................11

c) Jumper [J1]..................................................................................................11

d) 2 x 7-Segment: Display menus and states...................................................12

e) Function of the keys.....................................................................................13

6) Putting into Service / Programming ....................................................................14

a) Using menu function ....................................................................................14

b) Gate type default setting..............................................................................14

c) Programming ...............................................................................................14

d) Deleting the force values and travel paths...................................................14

e) Teaching runs / learn force values...............................................................14

f) Reset the control unit (factory setting)..........................................................15

7) Menu Table.........................................................................................................16

8) Functional Description ........................................................................................20

a) Radio module...............................................................................................20

b) Input A and B and radio receiver..................................................................20

c) Automatic closing.........................................................................................21

d) Partial opening (TÖ).....................................................................................21

e) Active leaf (GF)............................................................................................22

f) Closing delay: (in 2-motor mode).................................................................22

g) Opening delay: (in 2 motor mode)................................................................22

h) Smooth start.................................................................................................22

i) Smooth travel-out length and motor voltage ................................................22

j) Motor voltage over travel path......................................................................23

k) Smooth stop.................................................................................................23

l) Light / warning light......................................................................................23

m) Emergency stop...........................................................................................23

n) Electricity stop / obstruction detection..........................................................24

o) Force values ................................................................................................24

p) Closing edge safety device (SE)..................................................................24

q) Photoelectric barrier input (LS) ....................................................................25

r) Release........................................................................................................25

s) Close after leaving the photoelectric barrier.................................................25

t) 1 /2 leaf mode..............................................................................................25

u) Relay output OUT ........................................................................................26

Motor control unit DCM31

3 / 35

v) Running time limit.........................................................................................26

w) Type of limit switch.......................................................................................26

x) Service mode...............................................................................................27

y) Trip counter..................................................................................................27

9) Error Messages ..................................................................................................28

10) Technical Specifications .....................................................................................31

11) Notes ..................................................................................................................33

12) Images/Diagrams................................................................................................34

1) Intended Purpose

This motor control unit is intended for the following 24V/DC drive units:

- On one or two-leaf garage or courtyard gate systems (e.g. hinged, sliding, tilting

and up-and-over gates)

- In industrial, residential, business and commercial areas and in small businesses

- According to the stipulations in these instructions.

These instructions are intended for the fitter of the control unit and the processing

industry, however not for issue to the owner/operator of the gate system. The end

product manufacturer is responsible for preparing suitable instructions for the complete

gate system.

a) Requirements

The motor control unit is not operational until it is installed in the ready for use gate

system.

This requires external components such as e.g. ...

- command input devices,

- signalling devices,

- sensors and

- the drive unit,

but which are not supplied with this motor control unit.

This control unit is therefore a "non ready for use component" from a legal point of

view. It therefore does not fall within the scope of various EC Directives until it is

integrated in the end product (gate system).

b) Legal requirements

The end product manufacturer is thus responsible for compliance and declaration of

CE conformity. The control unit complies with the requirements in

- DIN EN 60204. This makes it easier for you to carry out the conformity assessment

according to the Machinery Directive.

- DIN EN 50081 T1/2 and EN 55011 and EN 55014. This makes it easier for you to

carry out the conformity assessment according to the EMC Directive.

- VDE 0700 Part 95 (Draft 02/98; IEC 60335-2-95) and EN 12445 and EN 12453

concerning requirements for motor control units for "power-driven doors and gates"

(formerly ZH 1/494).

- DIN EN 60335-1. This makes it easier for you to prepare the declaration of

conformity according to the so-called "Low Voltage Directive".

- EN 61 508, SIL2, Functional Safety.

Motor control unit DCM31

4 / 35

c) Technical qualification requirements

These instructions require technical knowledge, which corresponds to completed

vocational training in at least one of the following job profiles:

- Electrical fitter,

- Electrical installation fitter,

- Electrical machine fitter,

- Electro-mechanic,

- Industrial electronics technician ...

or knowledge as an (electrically) skilled person according to the German accident

prevention regulation BGV A2 (VBG 4).

The product is supplied as a component in "especially EMC-expert firms" in

accordance with EMC law.

d) Important safety instructions

- Reliable operation is only possible if the unit is carefully installed according to these

instructions. We do not provide any guarantee or accept liability for any damage

caused by failure to comply with these instructions.

- During the learning runs / putting into service of 2-leaf gate systems with closing

edge, check setting of the correct door closing delay of the motors and if necessary

correct, so that the closing edge does not travel at a flat horizontal angle to the

other leaf, which could cause damage to the gate system and to risks for objects

and people!

- After installation, the customer of fitter of the gate drive unit must check for

compliance of the maximum closing forces according to the standards EN 12445

(Safety in use of power operated doors, test methods) and EN 12453 (Safety in use

of power operated doors, requirements) or the applicable standards and regulations

at the respective installation location!

- The safety equipment requirements e.g. depend on whether the gate is used in a

private or commercial area, whether it is in a public street or the controls are

generally accessible

- Information is available from electric power suppliers, VDE and the employers’

professional insurance association.

- ESD-compatible earthing must be ensured for all work on the control unit.

Otherwise there is a risk of damage or even destruction of the control unit.

Motor control unit DCM31

5 / 35

2) Installation

This requires 4 screws with a shank diameter of 4mm.

a) Suitable installation site

The motor control unit is supplied as a module in a simple plastic housing. You should

therefore choose an installation site with the following conditions:

- The ambient temperature may not be lower than -20°C and not higher than

+50°C.

- The air humidity must lie within 30...90% RH.

- Electromagnetic fields at the installation site must be reliably shielded.

- Preferably protected against direct sunlight and driving rain

b) Installation

The internal temperature rating is designed for vertical installation.

[X1], [X5] show the installation, whereby the cables must be brought out at the bottom

and sealed with the enclosed threaded joints to prevent penetrating moisture.

When choosing the type of fixing, you must take into account the weight of the control

unit (see technical specifications).

Properly fit the control unit housing in the suitable installation site.

3) Brief Explanation of Terms Used

You will come across the following terms in these instructions, not in everyday use:

Release / release time

In various safety functions you can choose how the gate is to behave in a given

situation. In the event of “release” the gate only moves for the set release time in

“opposite direction”, in order to release the obstruction.

Active leaf

In 2-leaf gate systems, one leaf can be chosen as the “active leaf”. This can then be

opened separately (e.g. as a doorway for people).

OSE

Self-monitoring Optical Safety Equipment as photoelectric barrier or as contact

strip.

Panic function

In the panic function an open/close command during a gate travel always results in the

stopping of the gate travel. The gate only starts to move in the required direction if

actuated again.

Reversing

If various safety functions you can choose how the gate is to behave in a given

situation. In “reversing” the gate moves in the opposite direction to the end position.

Smooth travel-out

Motor control unit DCM31

6 / 35

The motor output / motor speed can be reduced over the last part of the travel path so

that the gate does not hit the end stop at full speed.

Electricity stop

The control unit monitors the motor current for obstacle detection. You can choose

how the control unit reacts if the set value is exceeded.

Partial opening

The gate can be specifically moved to a previously selected position between the limit

switches (e.g. to allow people through).

a) Abbreviations used in the instructions

[Bl.1] = 15 pin slot for the radio module

[Bl.2] = 2x10 pin slot for 1 or 4 channel radio receiver

[J1] = Jumper for safety equipment (SE)

[Kl.1]..[Kl.33] = Reference to terminals

M1, M2 = Motor 1 or Motor 2

[M.A0]..[M.A9]

[M.b0]..[M.b9]

[M.C0]..[M.C9]

[M.d0]..[M.d9] = Menu items A0 to d9

[Ta.+] = “+” pushbutton in the control panel under the 7 segment display

[Ta.-] = “-” pushbutton in the control panel under the 7 segment display

[Ta.F] = “Radio” pushbutton in the control panel under the 7 segment display

[Ta.M] = “Menu” pushbutton in the control panel under the 7 segment display

[X1]..[X10] = Reference to figure in the separate graphic overview

{F0}..{F9} = Radio module function, shown in the display

{Er.00}..{Er.29} = Error/fault message, shown in the display

Motor control unit DCM31

7 / 35

4) Connections

a) Terminals

[X2], [X6]

Only work on the controls after it has been disconnected from the power

supply and has been ESD-compatibly earthed!

- 230 volt mains voltage can be applied to [Kl.1]..[Kl.4] and [Kl.30], [Kl.31]. Potentially

fatal danger!

- Never connect mains voltage to [Kl.5].. [Kl.29].

- Failure to comply causes immediate destruction of the controls and the guarantee

expires!

- Signal and motor cables (e.g. pulse, open, stop, close...) must not exceed a length

of max 30 m! This does not apply to the mains supply cable.

[Kl.1]+[Kl.2] mains voltage 230V / AC

Terminal 1 = N conductor

Terminal 2 = L conductor

- Comply with the local safety regulations and applicable VDE regulations.

- We recommend installation of a motor protecting switch in the mains supply cable.

[Kl.3]+[Kl.4] light / warning light 230 V / AC output, max. 500W

Terminal 3 = N conductor

Terminal 4 = L conductor (L= connected)

- The light/warning light function is set via [M.b2].

- The switched status is displayed by the yellow “Light” LED [X7].

[Kl.5]+[Kl.6] Motor M1, 24V / DC output

Terminal 5 = “-“ for opening

Terminal 6 = “+“ for opening

- Motor 1 is the main motor and is also used as the active leaf motor.

- If the control unit is run with one motor only [M.C1], this must be connected to M1.

- In 2 motor mode, for opening motor 1 starts at the same time or before motor 2

[M.C3] and for closing motor 1 starts at the same time or after motor 2 [M.C2].

- After the control unit has been installed and the first pulse command is given, the

direction of travel must be “OPEN”.

- If the drive unit, despite bar running upwards in the 7 segment display, starts up in

the “CLOSE” direction the connection wires [Kl.5]+[Kl.6] must be switched over.

- The control unit learns the maximum motor current for each direction of travel.

- Motor adjustments are made in [M.A1]..[M.A8].

[Kl.7]+[Kl.8] Motor M2, 24V / DC output

Terminal 7 = “-“ for opening

Terminal 8 = “+“for opening

- After the control unit has been installed and the first pulse command is given the

direction of travel must be “OPEN”.

- If the control unit is operated with one motor only [M.C1], it must be connected to

M1.

- In 2 motor mode motor 2 starts in opening at the same time or after motor 1 [M.C3]

and in closing motor 2 closes at the same time or before motor 2 [M.C2].

Motor control unit DCM31

8 / 35

- If the drive unit, despite the bar moving upwards in the 7 segment display, start up

in the “CLOSE” direction, the connection wires [Kl.7]+[Kl.8] must be switched over.

- The control unit learns the maximum motor current for each direction of travel.

- Motor adjustments are made in [M.A2]..[M.b0].

[Kl.9]+[Kl.10] output 12 V DC / stable

Terminal 9 = 12 V/DC stable, max. 40 mA

Terminal 10 = 0 V/earth

- e.g. for OSE connection

[Kl.10]+[Kl.11] output 24 V / DC unstable

Terminal 11 = 24 V/DC unstable, max. 200 mA

Terminal 10 = 0 V/earth

- e.g. for connecting the supply voltage for a photoelectric barrier

[Kl.12]+[Kl.13] relay output (floating)

- For connecting electric lock or other options, max. 24 Volt, 4 ampere.

- The function is set via [M.C4].

- The switched status is displayed via the yellow “OUT“ LED [X7].

[Kl.14]+[Kl.15] emergency stop

- Controls with floating contact can be connected to the emergency stop input.

- The behaviour of the control unit following an emergency stop is set via [M.b8].

- The contact must be closed in the idle condition (break contact).

- Several controls can be connected in series.

- An unused emergency stop input must be jumpered!

- The switched status of the emergency stop input is displayed by the red LED

behind the [Kl.14]+[Kl.15].

- The emergency stop input directly switches off the motor relay for safety reasons

and therefore is still active even if the electronics fail!

- In the event of an emergency stop command the motor stops immediately.

- If the emergency stop command while the motor is running, with the next pulse

command the gate travels in the “opposite direction” (away from the danger spot).

- If an emergency stop command is given while the gate is at a standstill, the gate

generally travels in the OPEN direction when the next pulse command is given.

[Kl.16]+[Kl.17]+[Kl.18] limit switch M1

Terminal 16 + 17 = limit switch M1 OPEN

Terminal 18 + 17 = limit switch M1 CLOSE

[Kl.19]+[Kl.20]+[Kl.21] limit switch M2

Terminal 19 + 20 = limit switch M2 OPEN

Terminal 21 + 20 = limit switch M2 CLOSE

- Controls with floating contact (break contact) can be connected at the limit switch

inputs.

- The contact must be closed in the idle condition (opened in the end position).

- The switched status is displayed via the LEDs behind the terminals. (LEDs lit in

end position, i.e. if limit switch pressed/opened)

- If [M.C6] = 00 or = 02, the limit switch inputs function and the LEDs are always off.

- Alternatively, drive units with integrated limit switches can be used [M.C6], which

interrupt the motor current in the relevant direction. The control unit then interprets

Motor control unit DCM31

9 / 35

this as an external limit switch. The limit switch behind the terminals is not

displayed.

[Kl.22]+[Kl.23] photoelectric barrier (LS)

Terminal 22 = LS signal input

Terminal 23 = connected earth

- A photoelectric barrier or an electrical safety contact strip with a floating break-

contact element can be connected.

- The function of the input is determined via [M.b4].

- If the input is not used, it must be jumpered with a wire jumper (delivered

condition).

- The switched status is displayed by the yellow LED behind [Kl.22]+[Kl.23].

- During the control unit self-test, the LED briefly flashes.

- The input has a safety function and is monitored by self-tests of the electronics.

- The “close after leaving the photoelectric barrier” function [M.b5] can be triggered

via the photoelectric barrier input.

[Kl.23]+[Kl.24] safety input (SE) for closing edge safety device 8K2 or OSE

Terminal 23 = connected earth

Terminal 24 = SE signal input

- Optional use of a 8K2 safety strip or OSE is possible as a closing edge safety

device.

- The type of strip connected and function of the input are set via [M.b6].

- OSE connection: Kl.9=+12V, Kl.10=earth, Kl.24=signal

- The switched status is displayed via the yellow LED behind [Kl.24].

- If the SE input is not used, the [J1] must be connected to NC [X4] (8k2-resistor is

switched on internally) and [M.B6] set to 8k2 (10) or the SE input deactivated

[M.B6] = 00.

- If a closing edge safety device is connected, [J1] must be connected to SE [X4].

- This input has a safety function and is monitored by self-tests of the electronics.

[Kl.25]+[Kl.26] input A (pulse / open)

- Input for pushbutton, key-operated switch, external radio, etc.

- The controls must have a floating contact, which is open in the idle condition (make

contact).

- Several pushbuttons, etc. can be connected in parallel.

- The input is connected internally parallel to the slot of the radio receiver ([Bl.2]

channel 1).

- The switched status is displayed by the green LED behind [KL.25]+[Kl.26].

- The function of the input is set via [M.b9].

- Simultaneous actuation of input A and input B has an emergency stop function.

[Kl.26]+[Kl.27] input B (partial opening/ active leaf / close)

- Input for pushbuttons, key-operated switch, external radio, etc.

- The controls must have a floating contact, which is open in the idle condition (make

contact).

- Several pushbuttons, etc. can be connected in parallel.

- The input is connected internally parallel to the slot of the radio receiver ([Bl.2]

channel 2).

- The switched status is displayed via the green LED behind [Kl.26]+[Kl.27].

- The function of the input is set via [M.b9].

Motor control unit DCM31

10 / 35

- Simultaneous actuation of input A and input B has an emergency stop function.

[Kl.28]+[Kl.29] antenna

- An antenna litz wire must be connected to [Kl.29] and must be stretched parallel to

the main reception direction along its whole length.

- The antenna litz wire can be fed out through the small hole next to the self-sealing

plugs.

- The largest range is achieved by laying the cable at a large distance from the metal

parts (concrete ceilings, cables, ...).

- If a rod antenna is used, the shielding of the coax cable is connected to the

adjacent earth terminal [Kl.28].

[Kl.30]+[Kl.31] transformer connection (primary 230V/AC)

[Kl.32]+[Kl.33] transformer connection (secondary 24V/AC)

- An external power transformer (usually installed in the factory) must be connected

to [Kl.30] and [Kl.31] (primary) and [Kl.32] and [Kl.33] (secondary).

- For safety and EMC reasons, a short-circuit proof toroidal transformer to EN60742

(VDE0551) must be used.

b) Radio

[X8], [X10]

- The control unit can be remotely controlled, either via the radio module (evaluation

and storage of the radio code in the controller of the control unit) or via a radio

receiver with integrated logic for evaluation and storage of the radio code. The

radio receiver and radio module work independent of each other.

Radio module mode [Bl.1]

- A suitable radio module must be plugged with correct orientation into the 15-pin

socket connector [Bl.1] [X9] [X8].

- Replace radio module: (frequency change): If noise exists in the frequency band

used, the control unit can be converted to another frequency by replacing the radio

modules.

- Procedure:

• Switch off power supply!

• Carefully pull the radio module out of the plug-in holder.

• Plug-in the new radio module with the required frequency with the “correct

orientation”.

• Switch supply voltage back on.

• Delete radio (see p 20).

• Teach new sender (see p 20).

• The transmitters must have the same frequency as the new radio module!

Radio receiver [Bl.2]

- A suitable radio receiver must be plugged in, with the correct orientation, in the

2x10-pin socket connector [Bl.2] [X9] [X10].

- Channel 1 is internally connected parallel to input A.

- Channel 2 is internally connected parallel to input B.

- The function of channels 1 and 2 is set via [M.b9].

- Refer to the respective operating instructions for information on how to use the

radio receiver.

Motor control unit DCM31

11 / 35

5) Controls / Displays

[X7]

[Ta.+] +: value + / menu + / open function

[Ta.-] -: value - / menu - / close function

[Ta.F] Radio: key to teach / delete the radio in radio module mode

[Ta.M] Menu: menu selection/ display input status

a) LEDs next to the display

[X7]

Light (yellow)Light / warning light control display

radio (red) radio display for radio module mode (reception)

OUT (yellow)display output OUT [Kl.12]+[Kl.13]

b) LEDs behind terminals

[X6]

behind [KL.14]+[Kl.15] red emergency stop input

behind [KL.16]+[Kl.17] green limit switch M1 OPEN

behind [KL.17]+[Kl.18] green limit switch M1 CLOSE

behind [KL.19]+[Kl.20] green limit switch M2 OPEN

behind [KL.20]+[Kl.21] green limit switch M2 CLOSE

behind [KL.22]+[Kl.23] yellow photoelectric barrier (LS)

behind [KL.23]+[Kl.24] yellow closing edge safety device (SE)

behind [KL.25]+[Kl.26] green input A

behind [KL.26]+[Kl.27] green input B

c) Jumper [J1]

[X4]

- If a closing edge safety device is connected to the SE input (8K2 or OSE), the

jumper must be connected to SE.

- If no closing edge safety device is connected, the jumper must be connected to

NC.

Motor control unit DCM31

12 / 35

d) 2 x 7-Segment: Display menus and states

Gate status (horizontal bar)

[X7]

Segment Segment status Motor Gate status

A Lit 1 Standing in CLOSE end position

B Lit 1 Standing between end positions

C Lit 1 Standing in OPEN end position

D Lit 2 Standing in CLOSE end position

E Lit 2 Standing between end positions

F Lit 2 Standing in OPEN end position

Left Bars moving upwards 1 Opening

Left Bars moving downwards 1 Closing

Left Bar stopped + flashing 1 Last travel was ended with SE, LS

or forced stopping (obstruction!)

Right Bars moving upwards 2 Opening

Right Bars moving downwards 2 Shutting

Right Bar stopped + flashing 2 Last travel was ended with SE, LS

or forced stopping (obstruction!)

Left point

(0) Lit 1 + 2 Automatic closing is active, keep

open time running

Right

points (0) Flashing 1 + 2 Automatic closing is active, early

warning running

Input status (vertical bar)

[X7]

Segment Segment status Input

1 lit limit switch M1 OPEN actuated = open

2 lit limit switch M1 CLOSE actuated = open

3 lit input LS pressed = open

4 lit input SE pressed = open or short-circuited

5 lit input A actuated = closed

6 lit input B actuated = closed

7 lit limit switch M2 OPEN actuated = open

8 lit limit switch M2 CLOSE actuated = open

9 lit emergency stop actuated = open

0 lit Automatic closing is active, keep open time running

0 flashing Automatic closing is active, early warning running

Learning runs:

Brief display of the digits 1..4 = number of learning runs still to be performed

separately for M1 (left display) and M2 (right display).

Radio:

- During teaching for radio module mode the display switches between gate status

and {F0}..{F9} for the selected radio function. In addition, the “radio” LED next to

the 7-segment display flashes.

- Deletion of all codes in radio module mode is indicated by rapid flashing of {FL} in

the display and by rapid flashing of the “radio” LED.

- If a teaching radio is detected, the teaching function {F0}..{F9} is shown in the

display and the “radio” LED is lit.

Error messages:

Display switches between “ER” (error) and error number.

Motor control unit DCM31

13 / 35

Menu settings:

The menu item (A0...d9, prefixed letter) or the set menu value (00...99) is displayed.

e) Function of the keys

[X7]

“Menu” key [Ta.M]

[Ta.M] < 1sec actuated in function mode = switch the display between

gate status (horizontal bar)

and / input status (vertical bar).

“+” key [Ta.+]:

- in gate status mode and input status: opening or stop.

- in setting mode: see 6)a) Using menu function, p. 14

“-“ key [Ta.-]:

- in gate status mode and input status: closing or stop

- in Adjustment mode: see 6)a) Using menu function, p 14

Motor control unit DCM31

14 / 35

6) Putting into Service / Programming

a) Using menu function

The buttons [Ta.+], [Ta.-] and [Ta.M] next to the display [X7] can be used to

set/change the individual functions of the control unit as follows:

[Ta.M] > pressed for 1 sec = Switch between display

function (display: horizontal or vertical bar)

and setting (display: letters/digits).

[Ta.M] < pressed for 1 sec in function mode = switch between display

gate status (horizontal bar)

and / input status (vertical bar).

[Ta.M] < pressed for 1 sec in setting mode = switch between displays

Menu item (left display letter A, b, C, d)

and menu value (both displays with digits, 00-99)

- Use [Ta.+] and [Ta.-] to select the menu item to be changed [A0..d9].

- Use [Ta.M] < 1 s to select “Menu value” mode (display 00...99, digits only).

- Use [Ta.+] and [Ta.-] to set the required value.

- Press button < 1 s to reselect “Menu item” mode

- Adjust all settings using this schema.

- If the menu value is changed, this value is automatically adopted and saved.

- If none of the buttons are pressed for longer than 15 sec, the display switches back

to gate status.

- During the setting mode it is not possible for the motor to run.

b) Gate type default setting

After all the additional equipment (SE, LS, ES...) and loads (motor, warning light, ...)

have been connected, the gate type must be set first!

- The gate type can be preset using [M.A0].

- By changing [M.A0], all menu items are preset to the typical values for this type of

gate (factory setting) and the force values and running times are deleted, so that

new teaching runs must be carried out!

- Changing [M.A0] via [Ta.+] and [Ta.-] is only possible by simultaneously actuating

[Ta.F], to prevent accidental adjustment!

c) Programming

Use the table from page 16 to set the required parameters for the individual menu

items, and enter the selected values in the “Setting” column.

d) Deleting the force values and travel paths

- - Press [Ta.-] and [Ta.+] simultaneously until “44” flashes in the display. During the

deletion the two points in the display flash rapidly.

- - Important: New teaching runs must be completed (see below).

e) Teaching runs / learn force values

- If all menu items have been set, 4 complete teaching runs from limit switch to limit

switch must be completed to learn the force values and travel paths (for operation

without limit switch [M.C6] = 02 only 2 teaching runs).

Motor control unit DCM31

15 / 35

- During the teaching runs no STOP along the path is allowed! The gate must be

able to travel unobstructed from limit switch to limit switch.

- The flashing digits in the display indicate how many teaching runs still have to be

completed for which motor.

Command Status/function

Gate is closed:

1 x pulse or “OPEN” Both leafs are moving “OPEN”

1 x pulse or “CLOSE” Motor 2 moving “CLOSE”, then motor 1 moves

“CLOSE”

1 x pulse or “OPEN” Both gate leafs are moving “OPEN”

1 x pulse or “CLOSE” Motor-2 moves "CLOSE”, motor 1 moves with delayed

“CLOSE”

- The teaching runs are completed when the digits no longer flash.

- Check the forced stopping / obstruction detection and all connected safety devices

for compliance with EN12445 and EN12453!

f) Reset the control unit (factory setting)

- The control unit can be reset by adjusting [M.A0] and then resetting to the “Original

value”.

- Procedure:

• [Ta.M] pressed until [M.A0]..[M.d9] appears.

• Use [Ta.-] to select menu item [M.A0].

• Briefly press [Ta.M], menu value (00...07) is displayed.

• Press [Ta.F] and simultaneously use [Ta.+] and [Ta.-] to adjust the menu value

and then reset again.

• Release [Ta.F].

• All menu settings are reset to their basic values (factory setting) for the relevant

gate type of [M.A0].

- Important: When the control unit is reset, the functions of the safety equipment are

changes. It is necessary to reset the whole control unit and to complete new

teaching runs.

Motor control unit DCM31

16 / 35

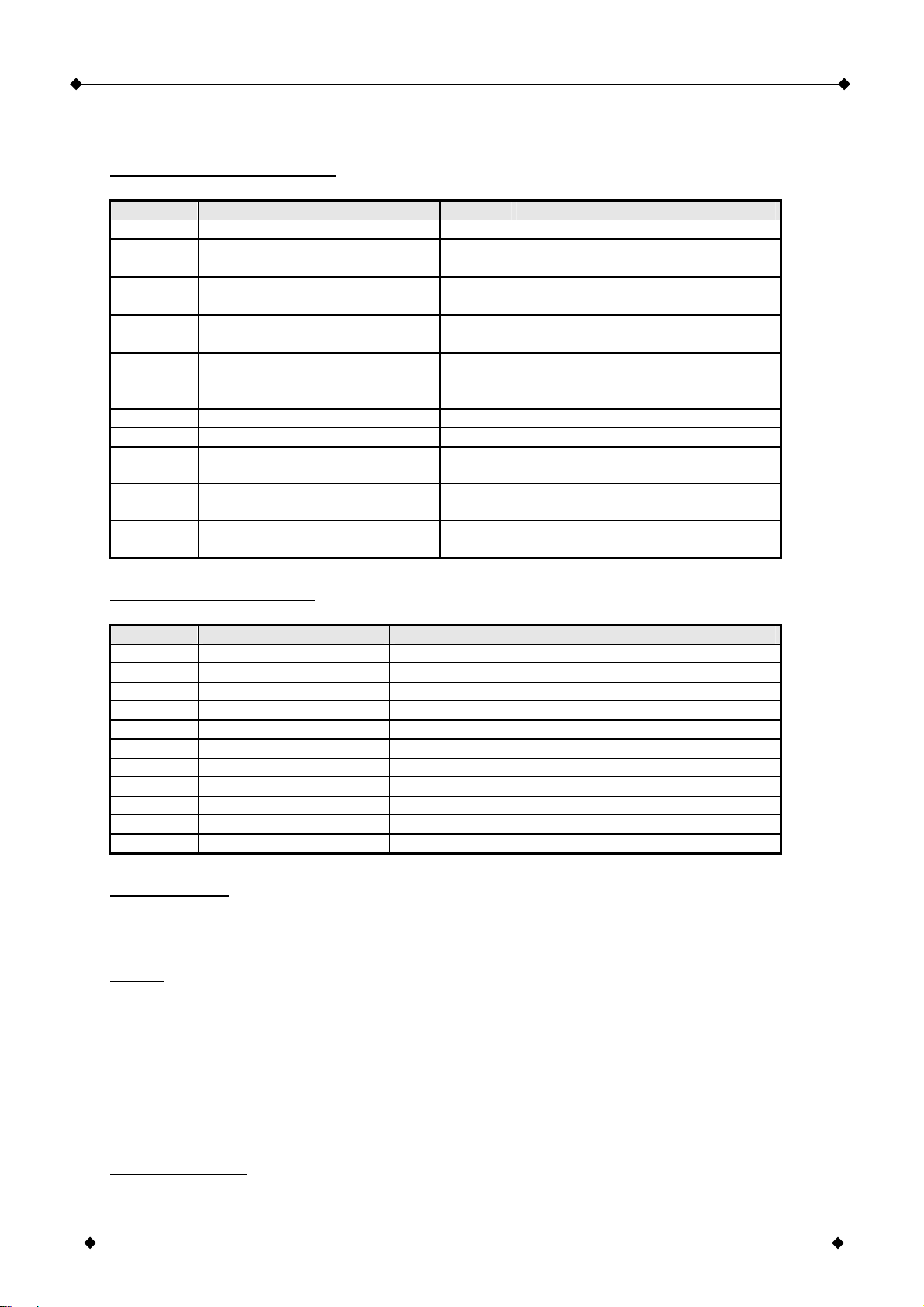

7) Menu Table

Grey background: basic values (factory setting)

Basic values

Menu Value

range Function / values

[M

.

A0]

=

00

2-leaf.-Hinged

gate

[M

.

A0]

=

01

1-leaf.-Hinged

gate

[M.A0] = 02

Sliding gate

[M.A0] = 03

Folding gate

[M

.

A0]

=

04

Roller

shutter gate

[M.A0] = 05

Type 5

[M.A0] = 06

Type 6

[M.A0] = 07

Type 7

Setting

A0

00

01

02

03

04

05

06

07

DEFAULT SETTING for gate type

2-leaf hinged gate

1-leaf hinged gate

Sliding gate

Folding gate

Roller shutter gate

Type 5

Type 6

Type 7

(Important: Changing effects all other menu items)

Switch over only possible by simultaneously pressing the radio key

00

00

00

00

00

00

00

00

A1 00..20 Motor voltage Smooth travel-out M1 10 10 10 5 10 10 10 10

A2 00..20 Motor voltage Smooth travel-out M2 10 10 10 5 10 10 10 10

A3 00..20 Motor voltage along path M1 20 20 20 20 20 20 20 20

A4 00..20 Motor voltage along path M2 20 20 20 20 20 20 20 20

A5

00

01..20

Length smooth travel motor1 and motor2

No smooth travel-out

Travel time in 0.5 sec steps before end position, start point self-teaching

05

05

05

05

05

05

05

05

A6

00..05

START-UP TIME after motor start (start time, electric lock, electricity

fade-out)

Start up time in 0.5 sec steps, 0.5..3.0 sec

02

02

02

02

02

02

02

02

A7 00..30 Force in open M1 (electricity stop) 15 15 15 15 15 15 15 15

A8 00..30 Force in close M1 (electricity stop) 15 15 15 15 15 15 15 15

A9 00..30 Force in Open M2 (electricity stop) 15 15 15 15 15 15 15 15

b0 00..30 Force in close M2 (electricity stop) 15 15 15 15 15 15 15 15

b1

00

01..62

63..90

AUTOMATIC CLOSING

switched off

keep open time in 2sec steps, plus 5sec early warning

keep open time 63=3min, 64=4min, ... , 90=30min plus 5 sec early

warning

(Number – 60 = time in minutes)

00

00

00

00

00

00

00

00

b2

00

01

02

03

04

05

06

07

08

09

LIGHT / WARNING LIGHT function

Only while motor running

1min overrun travel after motor operation

2min overrun travel after motor operation

3min overrun travel after motor operation

4sec before motor start open and close and while motor running

4sec before motor start open and close and while motor running -

flashing (1Hz)

4sec before motor start close and while motor running

4sec before motor start close and while motor running - flashing (1Hz)

Status display: gate in OPEN end position

Status display: gate in CLOSE end position

02

02

02

00

02

02

02

02

Motor control unit DCM31

17 / 35

Basic values

Menu Value

range Function / values

[M

.

A0]

=

00

2-leaf.-Hinged

gate

[M

.

A0]

=

01

1-leaf.-Hinged

gate

[M.A0] = 02

Sliding gate

[M.A0] = 03

Folding gate

[M

.

A0]

=

04

Roller

shutter gate

[M.A0] = 05

Type 5

[M.A0] = 06

Type 6

[M.A0] = 07

Type 7

Setting

b3

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

ELECTRICITY STOP / obstruction detection

opening: no effect closing: no effect

opening: no effect closing: stop

opening: no effect closing: release

opening: no effect closing: reversing

opening: stop closing: no effect

opening: stop closing: stop

opening: stop closing: release

opening: stop closing: reversing

opening: release closing: no effect

opening: release closing: stop

opening: release closing: release

opening: release closing: reversing

opening: reversing closing: no effect

opening: reversing closing: stop

opening: reversing closing: release

opening: reversing closing: reversing

Important: If electricity stop “no effect” the control unit can be damaged

or destroyed in the event of overload!

10

10

11

05

07

10

10

10

b4

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

PHOTOELECTRIC BARRIER function

opening: no effect closing: no effect

opening: no effect closing: stop

opening: no effect closing: release

opening: no effect closing: reversing

opening: stop closing: no effect

opening: stop closing: stop

opening: stop closing: release

opening: stop closing: reversing

opening: release closing: no effect

opening: release closing: stop

opening: release closing: release

opening: release closing: reversing

opening: reversing closing: no effect

opening: reversing closing: stop

opening: reversing closing: release

opening: reversing closing: reversing

10

10

03

03

10

10

10

10

b5

00

01..20

Close after leaving the photoelectric barrier

Function switched off

Delay time in 0.5sec steps

00

00

00

00

00

00

00

00

Motor control unit DCM31

18 / 35

Basic values

Menu Value

range Function / values

[M

.

A0]

=

00

2-leaf.-Hinged

gate

[M

.

A0]

=

01

1-leaf.-Hinged

gate

[M.A0] = 02

Sliding gate

[M.A0] = 03

Folding gate

[M

.

A0]

=

04

Roller

shutter gate

[M.A0] = 05

Type 5

[M.A0] = 06

Type 6

[M.A0] = 07

Type 7

Setting

b6

00

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

CLOSING EDGE SAFETY DEVICE function

8k2 opening: no effect closing: no effect

8k2 opening: no effect closing: stop

8k2 opening: no effect closing: release

8k2 opening: no effect closing: reversing

8k2 opening: stop closing: no effect

8k2 opening: stop closing: stop

8k2 opening: stop closing: release

8k2 opening: stop closing: reversing

8k2 opening: release closing: no effect

8k2 opening: release closing: stop

8k2 opening: release closing: release

8k2 opening: release closing: reversing

8k2 opening: reversing closing: no effect

8k2 opening: reversing closing: stop

8k2 opening: reversing closing: release

8k2 opening: reversing closing: reversing

OSE opening: no effect closing: no effect

OSE opening: no effect closing: stop

OSE opening: no effect closing: release

OSE opening: no effect closing: reversing

OSE opening: stop closing: no effect

OSE opening: stop closing: stop

OSE opening: stop closing: release

OSE opening: stop closing: reversing

OSE opening: release closing: no effect

OSE opening: release closing: stop

OSE opening: release closing: release

OSE opening: release closing: reversing

OSE opening: reversing closing: no effect

OSE opening: reversing closing: stop

OSE opening: reversing closing: release

OSE opening: reversing closing: reversing

10

10

10

02

02

02

02

02

b7

00..15

Release time

Release time in 0.25 sec steps, 0.25..4.00 sec

07

07

01

07

07

07

07

07

b8

00

01

02

EMERGENCY STOP input function

Automatic closing blocked after emergency stop

Closing time runs again after emergency stop release

After emergency stop next run in start travel, automatic closing blocked

00

00

00

00

00

00

00

00

b9

00

01

02

03

04

05

06

07

08

09

Function of inputs A/B and radio receiver

A: Open pulse + panic B: Close pulse + panic

A: Open pulse + panic B: Close pulse

A: Open pulse + panic B: Close dead man

A: Open pulse B: Close pulse + panic

A: Open pulse B: Close pulse

A: Open pulse B: Close dead man

A: Open dead man B: Close pulse + panic

A: Open dead man B: Close pulse

A: Open dead man B: Close dead man

A: Pulse (open-stop-close-...) B: Active leaf / partial opening

00

00

00

00

00

00

00

00

C0

00

01..99

Duration of the PARTIAL OPENING

Active leaf mode (only in 2-leaf mode)

Running time until partial opening/ventilation position in 0.5 sec steps

00

10

10

00

02

00

00

00

Motor control unit DCM31

19 / 35

Basic values

Menu Value

range Function / values

[M

.

A0]

=

00

2-leaf.-Hinged

gate

[M

.

A0]

=

01

1-leaf.-Hinged

gate

[M.A0] = 02

Sliding gate

[M.A0] = 03

Folding gate

[M

.

A0]

=

04

Roller

shutter gate

[M.A0] = 05

Type 5

[M.A0] = 06

Type 6

[M.A0] = 07

Type 7

Setting

C1

00

01

1- / 2- LEAF MODE

2- leaf mode

1- leaf mode

00

01

01

00

01

00

00

00

C2

00

01..19

20

Closing delay in 2-leaf mode

No closing delay

Closing delay in 0.5sec steps

Closing delay is automatically learnt

20

00

00

03

00

20

20

20

C3

00

01..19

Open delay in 2-leaf mode

No opening delay

Opening delay in 0.5sec steps

04

00

00

03

00

04

04

04

C4

00

01

02

03

04

05

Relay output OUT function

Electric lock (during startup time, see menu A6)

Photoelectric barrier test

Status display: gate in OPEN end position

Status display: gate in CLOSE end position

Radio module function 8 and 9 (if current surge drop after 10min)

Forward Open command

00

00

02

03

00

00

00

00

C5

00..99

Running time limit

in 1 sec steps, 1 sec..100sec

99

99

99

15

99

99

99

99

C6

00

01

02

Type of LIMIT SWITCH

Internal limit switch (in the motor cable)

External limit switch (connected to terminals 16-21)

No limit switch (electricity stop only) only permissible with safety strips!

01

01

01

02

01

01

01

01

C7 00 -

C8 00 -

C9 00 -

d0 00 -

d1 00 -

d2 00 -

d3 00 -

d4 00 -

d5 00 -

d6 00 -

d7 00 -

d8

00

01

Service mode

control panel free, menu items adjustable

control panel blocked, menu items not adjustable

Switchover: emergency stop, Simultaneously press + key

and – key ,

Switchover with menu key

00

00

00

00

00

00

00

00

d9

00

01

02

03

04

05

Trip counter (read only, cannot be changed)

100,000 digit

10,000 digit

1,000 digit

100 digit

10 digit

1 digit

Motor control unit DCM31

20 / 35

8) Functional Description

a) Radio module

- The radio frequency and modulation type is determined by the plug-in radio module

in [Bl.1].

- The transmitter coding is teaching. Up to 40 codes (transmit keys) can be teaching

with different functions.

- The motor control unit can either learn the 12 bit dual coding schema, the 18 bit

tristate coding schema or Keeloq coding. Further coding types by arrangement.

- The type of coding schema is specified during teaching of the first transmitter –

after deleting all codes. The first learning process can take up to 10s!

- If an already teaching transmitter is re-teaching, the control unit recognises this and

does not allocate any more of the 40 memory locations.

Teaching a transmitter:

• Briefly press [Ta.F] once. Radio LED flashes.

• The 7 segment display shows which function is being learnt.

• Press [Ta.F] until the required function is displayed (F0..F9).

• Press the transmit key to be teaching until the “Radio” LED is permanently lit.

The transmitter has now been teaching.

• If a transmitter is not teaching, learn mode is automatically quit after 15 s.

Functions for operation with radio module

• {F0} Pulse (open-stop-close-..) (not for dead man)

• {F1} Open pulse with panic function, i.e. stop while motor running

• {F2} Close pulse with panic function, i.e. stop while motor running

• {F3} Stop

• {F4} Partial opening / active leaf *

• {F5} Light

• {F6} Open pulse (without panic function)

• {F7} Close pulse (without panic function)

• {F8} OUT relay (active if [M.C4] = 04) pulse function

• {F9} OUT relay (active if [M.C4] = 04) current surge function

* Note: If dead man function is set via [M.b9], the relevant direction of travel cannot be

controlled by radio!

Delete all transmitters:

• Keep [Ta.F] pressed for approx 6 s.

• Radio LED flashes fast and in {FL} flashes in the display.

• If the flashing stops, all coding is deleted.

b) Input A and B and radio receiver

- The inputs A and B and channels 1 and 2 of the radio receiver slot are connected

in parallel.

- The function of the inputs A, B [Kl.25]+[Kl.26]+[Kl.27] and the radio receiver in

[Bl.2] can be selected via [M.b9] between open, close, pulse and partial opening.

- If dead man’s mode is set, radio mode via the radio module is blocked for the

relevant direction of travel. Operation with radio receiver in [Bl.2] is not permitted in

this direction of travel.

Table of contents

Popular Control Unit manuals by other brands

Logic Controls

Logic Controls LS6000 installation guide

Pickering

Pickering 40-170 user manual

Clack

Clack Water Specialist WS1CS Operation and instruction manual

Lunos

Lunos Touch Air Comfort Technical Information Sheet

Jorc

Jorc TEC-44 Installation & maintenance instructions

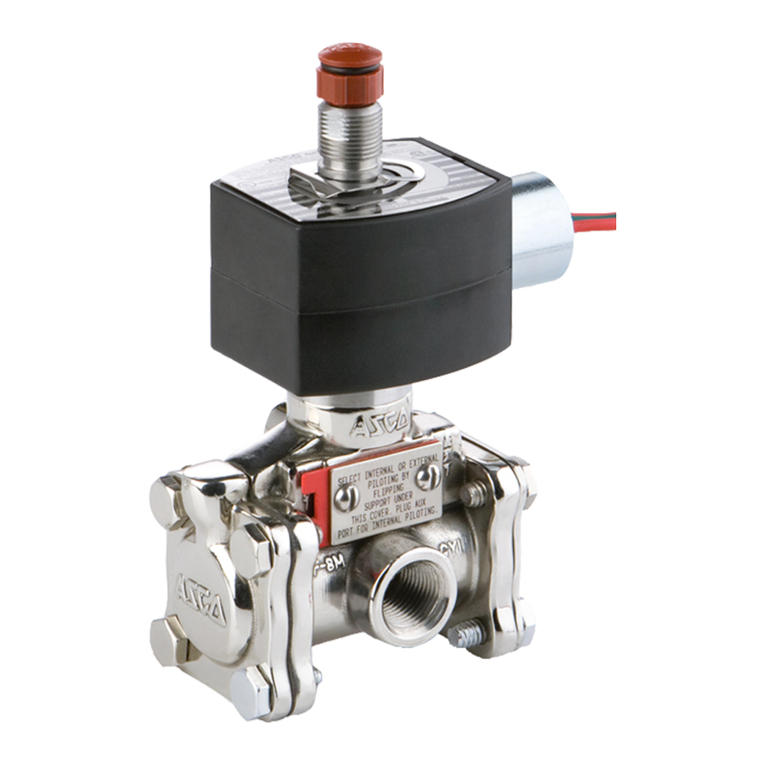

Asco

Asco 8316 Series Installation & maintenance instructions

Panasonic

Panasonic VBHN330SA17E General installation manual

Monmouth Scientific

Monmouth Scientific CAM-F 1500 operating & maintenance manual

Cisco

Cisco Catalyst 9400 Series Installation note

ViewSat

ViewSat VPC25 quick start guide

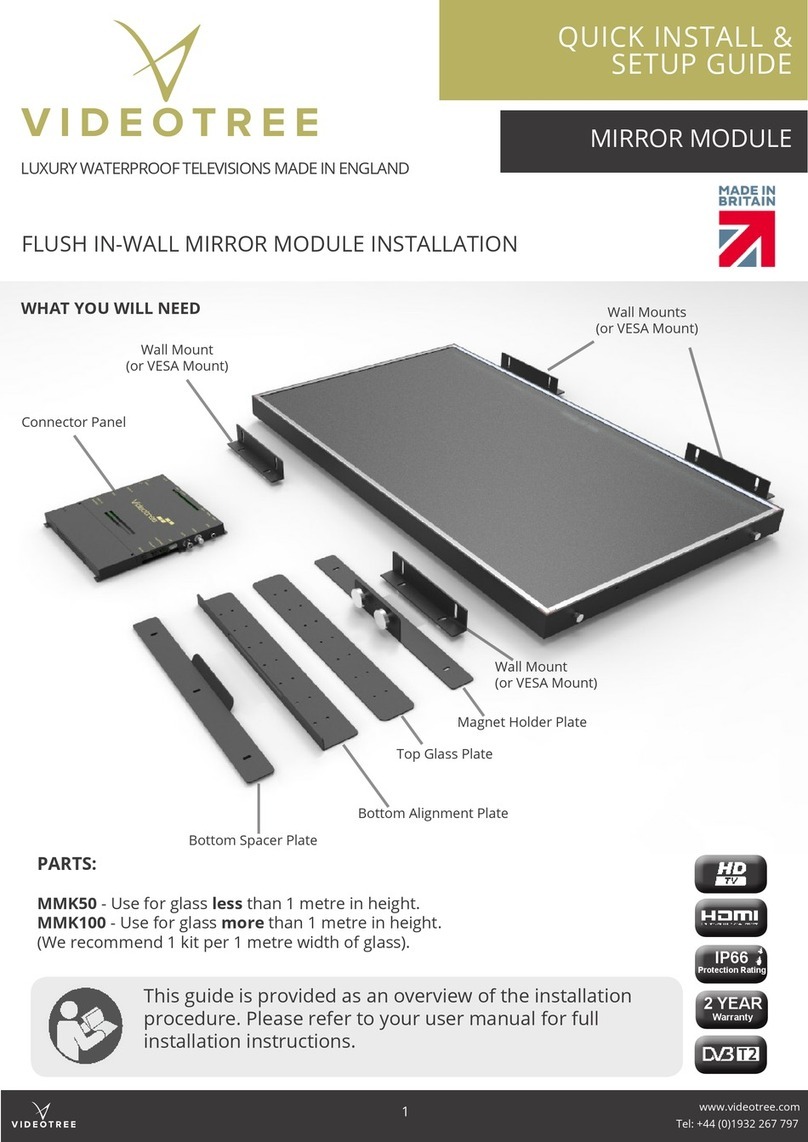

Videotree

Videotree MMK50 Quick Install & Setup Guide

Watts

Watts AMES 910GD Installation, operation and maintenance