Flying Legends P-51D Mustang User manual

The Flying Legends P-51D is a model designed for experienced pilots only. If you are not an experienced pilot that is

comfortable with flying larger high-performance aircraft, do not continue.

These instructions are written with the experienced modeller in mind. They are not intended to be a step-by-step guide, but

highlight a few of the areas of construction to supplement your own modelling experience.

Instruction Manual

Congratulations on your purchase of the

Flying Legends P-51 Mustang!

Wingspan: 99” (2515mm)

Length: 85” (2159mm)

Radio: 6-8 Ch. (8/9 Servos)

Weight: 37 - 39lbs (17 - 18Kgs)

Engine: 75-85cc Petrol Required

Flying Legends P-51 Mustang Specification

FLYING

LEGENDS

241 Green Street,

Enfield,

Middlesex,

EN3 7SJ,

United Kingdom.

Part Number:

Q-FL100

1

2

Introduction

The Flying Legends P-51D Mustang comprises a fully moulded airframe, which has been completely finished at the

factory. Due to this it is vitally important that the components parts are protected during the assembly process to

avoid cosmetic damage to the surface finish. Ensure that your assembly area is of adequate size for a model of this

size and cover your work bench with protective foam to avoid marking of the paint finish.

Ensure that only the highest quality components are fitted to your Mustang, as a high performance scale model

such as this requires matching capability from the engine and radio equipment to ensure safe, enjoyable and

reliable flying. If you have not previously flown a large warbird such as the Mustang we strongly recommend that

an experienced warbird pilot carry out a comprehensive check of the model and then make the initial test flights –

although the Mustang is easy to fly and particularly easy to land, it is a large model with a great deal of inertia, and

this can take a little getting used to for a pilot inexperienced with such large warbirds.

Optional Parts

(Note that some of these parts may already be included depending on the Mustang version selected :

Q-FL100/RE - Retracts with Struts and Air System

Q-FL100/SC - Scale Cockpit

Q-FL100/SP - Alloy Machined Spinner

Q-FL100/MW - Main Wheels/Tyres (Pr)

Q-FL100/RW - Rear Wheel/Tyre

L-IRVSIL/85IL - Silencer In-Line 85cc (DA/BH)

Items Recommended

Engine: 85cc Petrol engine recommended, either DA85 or BH85 are ideal, the prototypes were flown

using a DA85 with a Menz 26 x 10” propeller.

Servos: Ailerons: 2 x 10 Kg.cm min torque req

(Futaba BLS351 used in prototypes)

Elevator: 2 x 10 Kg.cm min torque req

(Futaba BLS351 used in prototypes)

Rudder: 1 x 12 Kg.cm min torque req

(Futaba S9155 used in prototypes)

Flaps: 2 x 15 Kg.cm min torque req

(Futaba S9156 used in prototypes)

Radio Battery: Due to the weight of the Mustang and the flight loads on the servos the current consumption is

much higher than on smaller models - due to this we strongly recommend the use of a battery

pack of at least 3000mAh, ideally of 6.0v to enable the optimum servo response.

Fuel tank: A tank of 950cc was used in the prototypes, this gave plenty of flight time with the DA85 engine

installed.

1

Step 1

Step 2

Step 3

Step 4

Assembly begins with the fitting of your choice of elevator

servo in its pre-fitted mount in the first tailplane half. Note

the orientation of the servo. Use the mounting screws,

grommets and brass ferrules supplied with your servo

and ensure that the lead is drawn out of the tailplane

through the opening in the mount. Temporarily fit a servo

control horn as shown.

Measure the distance from the root face of the tailplane to

the control horn fitted in the previous step.

Transfer this measurement onto a piece of masking

tape on the underside of the tailplane. Develop the

measurement for the thickness of the control horn, then

viewing from the opening in the tailplane, mark the length

of the slot required for free movement of the control horn

over the full range of servo travel.

Using a rotary cutting disc or hand tools, cut a slot wide

enough for clearance on the servo control horn.

Section: Elevator Linkage

As the linkage for each control surface is completed in a similar manner, the elevator linkage is detailed in full here.

A Futaba BLS351 Servo was used on our prototype model.

Step 5

Step 6

Step 7

Step 8

The elevator horn’s position can now be marked out on

the elevator. Use a strip of masking tape to make marking

the elevator easier. Ensure that the slot you mark is offset

slightly outboard when compared to the servo output horn

to allow for the balljoint width and is positioned to ensure

the control horn aligns with the hinge centreline.

Using a small file or rotary cutting disc prepare a suitable

close-fitting slot for the control horn. The slot should be

the full depth of the elevator to the underside of the top

elevator skin, but not through the skin. Take great care not

to cut too deeply and mark the top surface of the elevator.

Roughen the base of the elevator horn with coarse

sandpaper. Glue the horn in place using Hysol or 30

minute epoxy ensuring it is firmly seated in its slot and at

90° to the elevator. Ensure that the horn is vertical - not

leaning to one side - and that the balljoint hole is directly

above the pivot rod of the elevator. Allow glue to fully cure.

Centre the elevator and the elevator servo and make up

the supplied linkage using the 3mm steel elevator pushrod

with an aluminium ball link at the elevator and steel clevis

with a locknut at the servo control horn. Don’t omit the

fitting of a fuel tubing retainer to the clevis.

Repeat all the above steps for the second elevator taking

care to ensure that you work on the underside of the

tailplane.

2

3

Step 9

Step 10

Step 11

Step 12

Prepare your flap servos by fitting their rubber grommets

and ferrules, then screw them to the moulded right-angled

mounting brackets as shown. Note that M3 screws are

used to screw the servos to these brackets. Some servo

ferrules may be too small to accept these screws, so will

have to be changed to a suitable type. Due to the size

of the flaps, we recommend using heavy duty aluminium

servo horns. Make up the flap linkage as shown and

screw to the servo horn.

Remove the flap servo cover and screw the flap servo

in position with the output horn towards the flap. Note

the orientation of the servo’s control horn when the flap

is extended / lowered. When the flap is up / retracted,

the servo should be as far forward as possible without

touching the wing joiner tube.

Using the balljointed end of the flap pushrod as a guide,

mark the flap control horn’s position on the flap. Now

remove the flap from the wing and slot the flap for the

control horn as shown. Note that the slot is towards the

top of the flap.

Temporarily fit the control horn into the slot in the flap and

check for clearance as the flap is lowered and raised.

Roughen the control horn and glue it into the flap using

Hysol or 30 minute epoxy. Refit the flap and adjust the

linkage accordingly. Repeat this procedure for the second

flap. Ensure the horn positions are identical on both flaps.

Section: Aileron/Flap Linkage

A Futaba S9156 Servo was used on our prototype model.

4

Step 13

Step 14

Step 15

Step 16

Prepare your aileron servos by fitting their rubber

grommets and ferrules, then screw them to the moulded

right-angled mounting brackets as you did with the flaps.

Fit a heavy duty nylon control horn. Remove the aileron

servo cover and screw the aileron servo in position with

the output horn towards the leading edge of the wing.

As was done with the elevators, prepare a slot and glue

the aileron control horn into the aileron in line with the

servo output arm using Hysol or 30 minute epoxy. Once

cured, make up your aileron linkage, re-fit the servo cover

and link up the aileron. Test that it moves freely throughout

the entire range of movement. Note that the pre-cut slot in

the servo cover will require enlarging to suit the ouput arm

being used. Repeat for the second aileron.

Note that depending on which version of the P-51D

Mustang you have purchased, some of the following

steps concerning the installation of the retracts and

gear doors will not be applicable as they are factory

installed.

Installing the retracts is a simple task. Simply mount each

unit to the factory fitted plate in the wing using the four

screws supplied for each.

Fit each oleo leg and wheel assembly and tighten the

retaining socket head screw in the retract unit. Ensure

that both legs retract and extend without fouling the wing

and that both wheels track straight ahead.

Section: Retracts

A Futaba BLS351 Servo was used on our prototype model.

5

Step 17

Once you have installed the inner gear doors, fit your air

rams as shown. Ensure that all air lines are fixed to the

airframe to reduce the risk of them being caught by a

retracting undercarriage unit.

Step 18

Step 19

Unless they are factory fitted, the outer doors must be

hinged then attached to the undercarriage leg as shown.

Prepare your rudder servo by fitting its rubber grommets

and ferrules, then screw it to the moulded right-angled

mounting brackets as shown.

Step 20

The retractable tailwheel is steered from the rudder via

an internal closed loop linkage. Begin by removing the

rudder from the fin by withdrawing the hinge pin. Attach

the factory made closed loop cables to the retractable

tailwheel unit as shown. The tailwheel unit can then be

installed in the fuselage. Push it back towards the rudder

to allow the closed loop cables to exit through the rear of

the fuselage.

Section: Rudder

A Futaba S9155 Servo was used on our prototype model.

6

Step 21

Step 22

Step 23

Proceed to the next page for the Full Size Mount Diagram

Connect the closed loop cables to the rudder as shown.

Now the rudder can be re-fitted by installing the hinge

pin and the tailwheel unit can be installed in its mount.

Adjusting the tension of the closed loop is done before

the tailwheel unit is permanently installed, so secure the

tailwheel unit with only a couple of screws to check, then

undo these screws and slide the rudder back to allow the

clevis adaptors to be screwed in or out as required.

Remove the rudder servo cover from the rear of the

fuselage and screw the rudder servo in position and

re-fit the servo cover. Install the prepared pushrod.

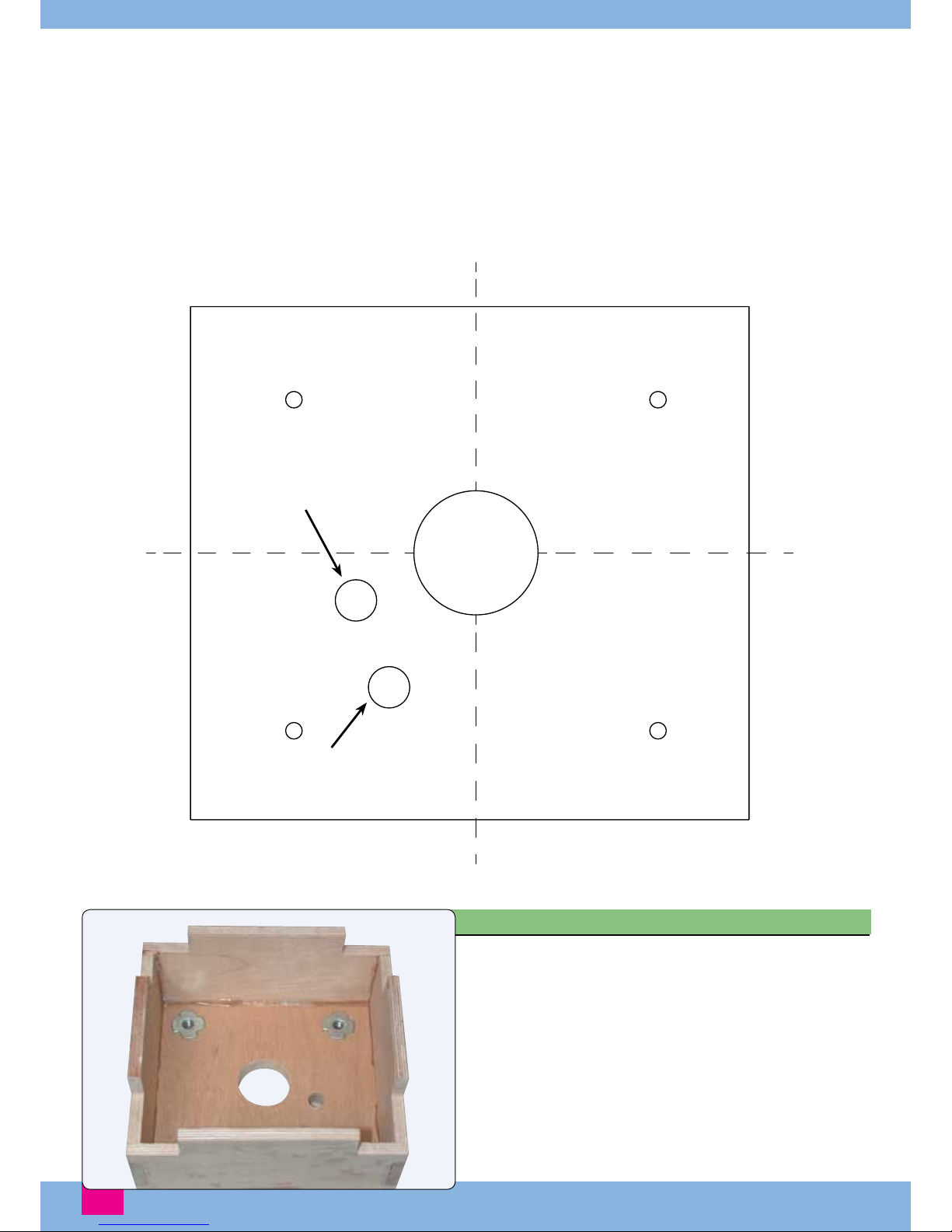

The DA-85 is one of the most commonly available and

suitable petrol engines for the P-51D Mustang. Use the

following template to mark the positions of the holes

required in the factory built engine-mounting box. Other

engines are suitable for this model - simply adjust the

positions of the mounting holes accordingly.

Remove the cowl from the model and test fit the engine

mounting box. Mark the top of the box and remove.

Cut out the engine mounting drill template below and

temporarily paste it to the mounting box as shown.

Section: Engine

7

Step 24

Once the mounting holes have been drilled, remove the

template and fit the supplied captive nuts for your aluminium

engine mounting stand-offs.

Choke Linkage

Throttle Linkage

TOP

DA85 Engine

Mounting Template

8

Step 25

Step 26

Step 27

Step 28

Now screw your engine mounting stand-offs in place.

Offer up the engine mounting box to the fuselage and

mark its position on the firewall. Remove the paint from the

firewall where the mounting box will be glued. Thoroughly

roughen the firewall.

Now glue the mounting box in place using plenty of 1 hour

epoxy or Hysol and leave to cure.

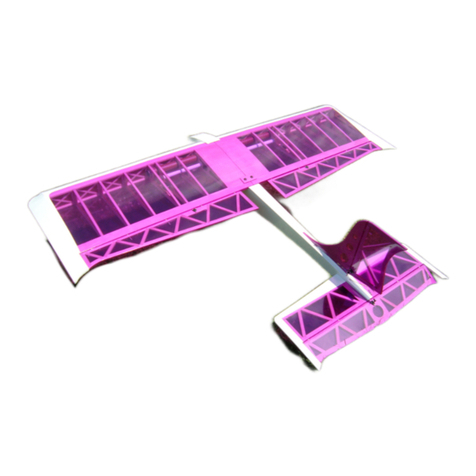

Mounting your throttle and choke servo (if used) will

depend on the engine you are fitting. On our prototypes,

we screwed the throttle and choke servos to a plywood

mount as shown.

9

Step 29

Step 30

Step 31

Step 32

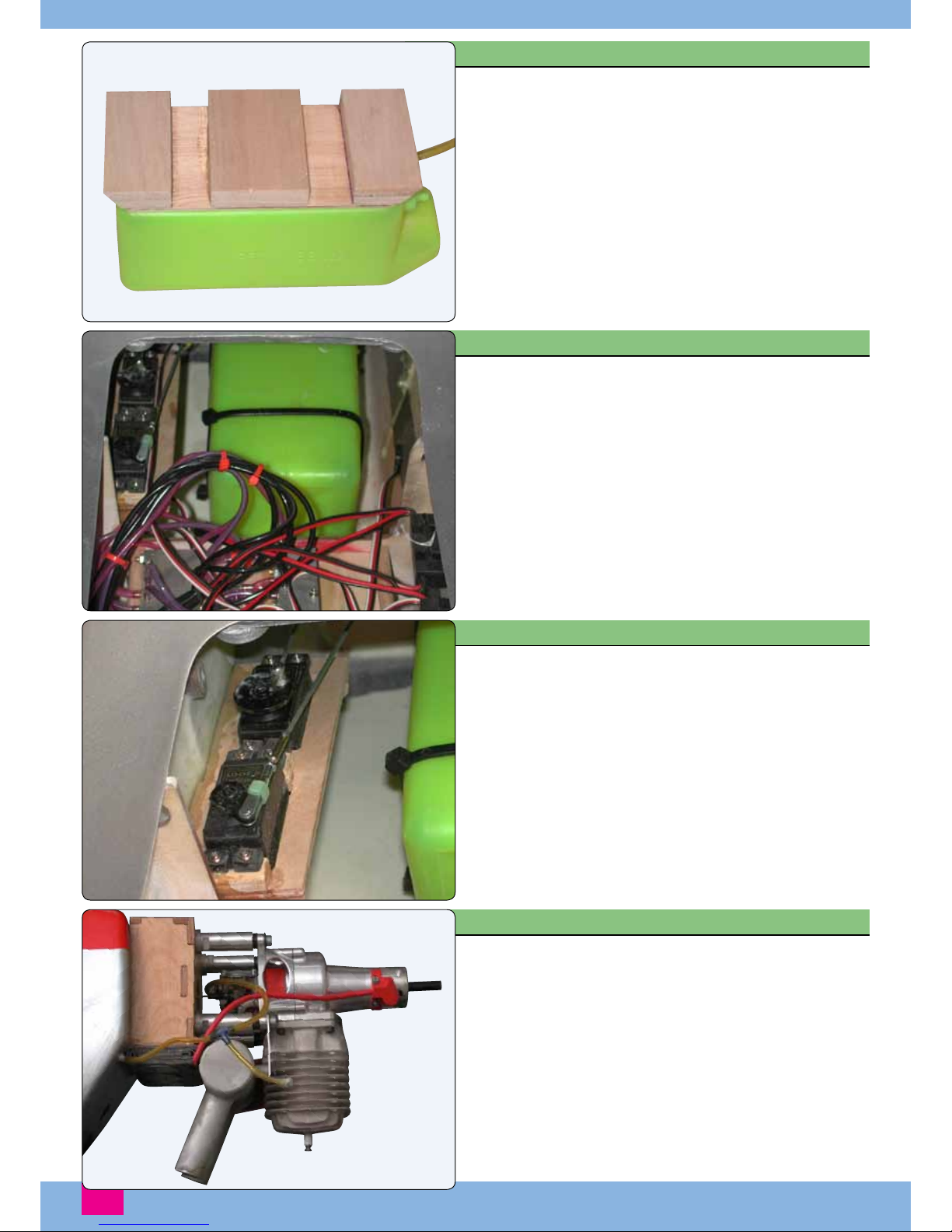

Once you have decided on your choice of fuel tank, you

need to make a simple plywood mount as shown.

The tank is then retained to its mount using two large tie

wraps and double sided tape. Once the fuel tubes have been

connected to the tank and drawn through the bulkhead, the

tank mount can be glued in place in the model’s nose.

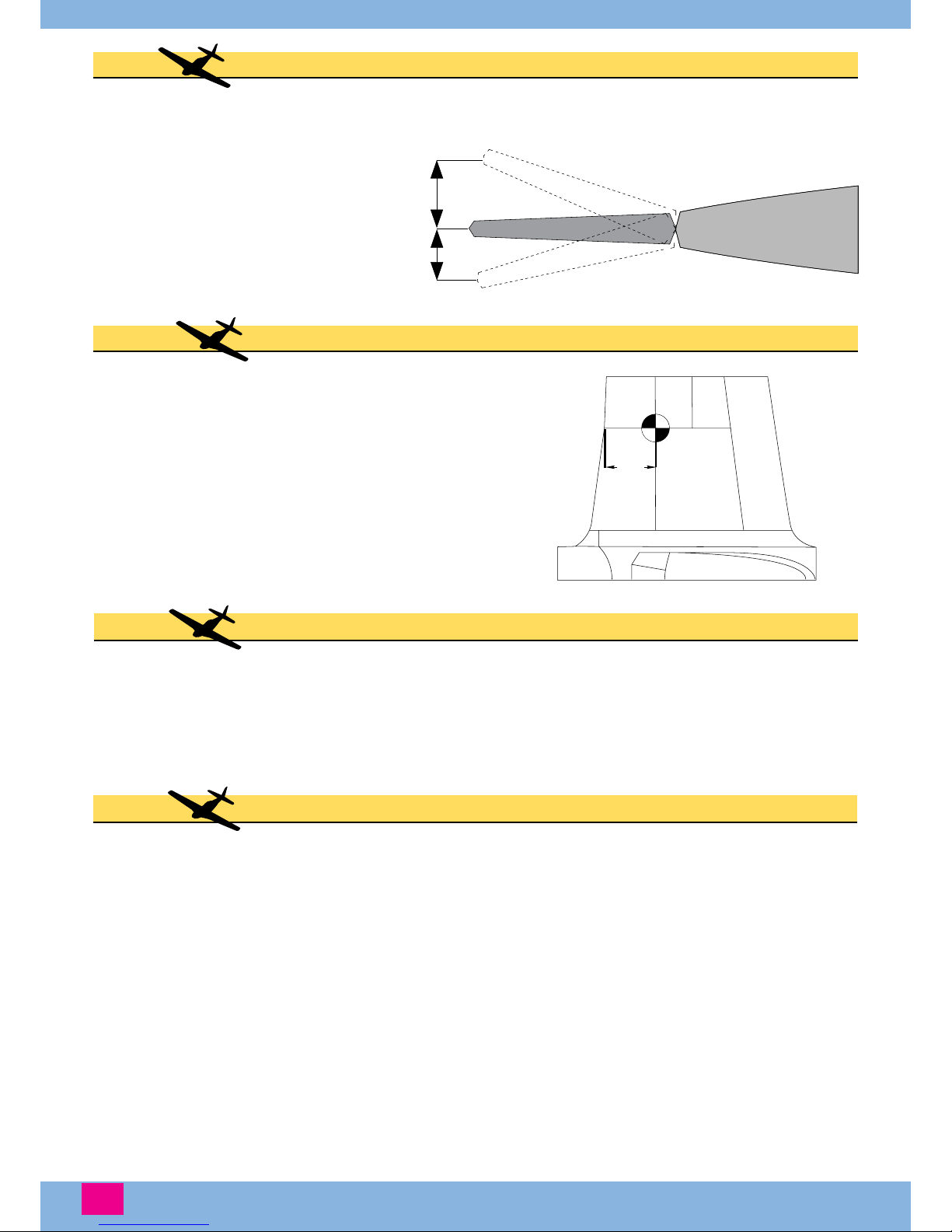

Make up suitable linkages for the throttle and choke and

then glue your servo mounting tray in place alongside the

tank in the nose of the model.

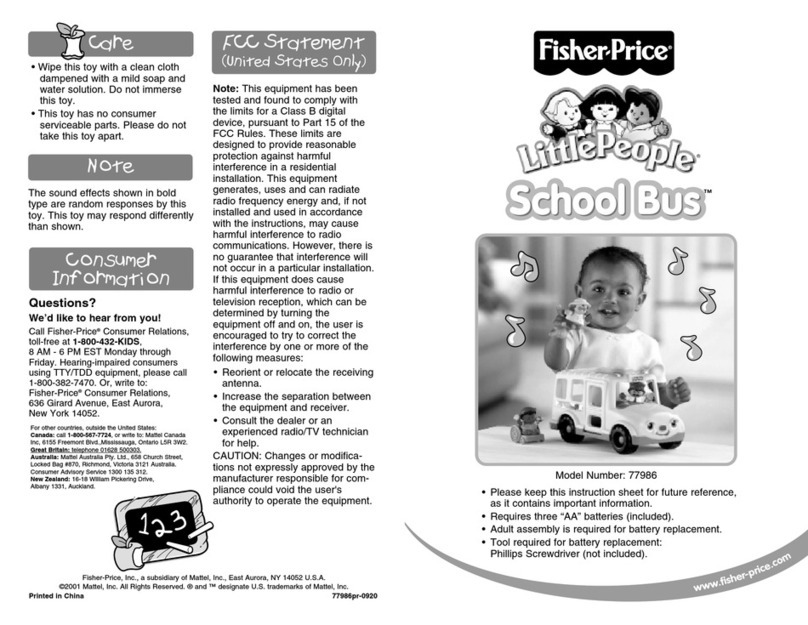

The engine can now be installed, the plumbing completed

and the ignition system wired in. Note that the silencer in

these shots is a pre-production prototype.

Step 33

Step 34

Step 35

To complete the air system, remove the rear mounting

plate from the fuselage. Drill the plate for a pair of tie

wraps, then a large volume air cylinder can be fitted to the

top of the plate as shown.

The plate can now be re-installed in the fuselage as

shown. Ensure that the tongues at the rear locate before

tightening the two retaining screws.

To complete the installation, remove the radio plate for

easy access. Mount your receiver, air control valve, retract

servo and any other equipment you require. Re-fit the

plate by locating the tongues then tightening the retaining

screws.

10

Section: Air Supply

Section: Final Installation

9

Section: Final Assembly

Step 38

Check the center of gravity to ensure the model

balances correctly 136mm back from the Leading edge

at the crank in the wing. We needed 1.7kg of nose

weight to achieve this on our prototype. Secure any

weight well to avoid it coming loose due to vibration. 136mm

Section: Center of Gravity

Step 37

The wing panels are joined with the large diameter aluminium tube supplied, and the wing is then mounted

to the fuselage using four M4 bolts. The tailplane halves mount to the fuselage using the smaller diameter

aluminium tube supplied and two countersunk M3 screws.

Section: Flying the P-51D Mustang

Step 39

For first flights we recommend the use of a large and open flying site with a good length of runway, not

because the model is hard to fly, but in the event of a minor problem or an engine cut, having plenty of

runway available can make the difference between a safe landing and a wrecked model. If there is going

to be a problem it is most likely to occur during the first few flights, so any extra time required to travel to a

good open site can prove to be well worth the effort.

Do carry out thorough range checks before flying, both with the engine off and running, and check for any

radio interference caused by the engine, throughout the rpm range. Also check all the controls, ensuring

that they operate in the correct direction and with the correct movements, and that there is no slop or lost

motion in any of the linkages and that all clevises and balljoints are secure. Any clevises being used must

have keepers fitted for added security. Finally check the retracts and doors to make sure they are operating

correctly and that no air leaks have developed.

Once happy, refill the fuel and air tanks, and once the engine is running and warmed up check that it will

Check that the controls move in the correct direction and that

their throws correspond to the following when measured at

their widest points.

Ailerons - 25mm up/20mm down

Elevator - 35mm up/30mm down

Rudder - 60mm each way

Flap - 20 Degrees (Take Off)

- 45 Degrees (Landing)

Section: Control Movements

Step 36

10

hold full throttle without sagging. Taxi the model out to the runway being used – although flap can be used

for take off we suggest that this is not done for first flights. Right rudder will be required during the early

stages of the take off run, and some up elevator should be held at first to avoid the model nosing over,

although this must be reduced to nothing as the model accelerates. Once at flying speed a small amount

of up elevator is all that is required to allow the model to lift off, and at full power with an 85cc engine

a comfortable height will quickly be gained, at which point the throttle can be brought back to obtain a

suitable cruise speed.

Fine trimming can now be carried out, and once the model is correctly trimmed we suggest that a few

handling manoeuvres are performed at a safe height, for example turns in both directions, slow flight,

a clean stall, etc, etc. When happy with the handling of the model it is recommended that the model be

slowed down, the undercarriage lowered and flaps applied into landing configuration and a simulated

landing approach is flown at a safe height, so that descent rates and flight attitudes at various throttle setting

can be observed. With this completed the model can be flown through basic and advanced aerobatics until

it is time to land.

The Mustang is a fairly simple model to land, a normal approach should be flown to stabilise the model

and slow it enough to lower the undercarriage, once aligned with the runway the flaps can be lowered in

stages until full flap is applied – note that more throttle will be required due to the increased drag of the

flaps. You will find that the Mustang is very stable in the landing configuration and it should be relatively

simple to position the model for an accurate touchdown, the stability once on the ground being excellent

due to the wide track of the main wheels.

Happy and safe flying!

11

Distributed to all good model shops by

Ripmax Ltd.,

241 Green Street,

Enfield, EN3 7SJ

www.ripmax.com

Ripmax Ltd. guarantees this product to be free from manufacturer’s defects in both material and workmanship at the

date of purchase. This guarantee does not cover faults arising from misuse or accident and the guarantee does not

cover damage or malfunction caused by negligence, misuse, accident, unauthorised repair or modification. In no case

shall Ripmax’s liability exceed the original cost of the purchased kit. In that Ripmax has no control over the final use,

no liability shall be assumed or accepted for any damage resulting from the use of the product by the user. By the

act of using the product, the user accepts all the resulting liability. If the purchaser of this product is not prepared to

accept the liability associated with the use of this product, they are advised to return this product immediately in new

and unused condition to the place of purchase.

The above guarantee in no way affects your statutory rights as a consumer.

Made in China

Table of contents

Popular Toy manuals by other brands

Evolution

Evolution MEGA FUSION instruction manual

Hasbro

Hasbro ForrestFox 6504 Assembly manual

Fisher-Price

Fisher-Price N3193 manual

Fisher-Price

Fisher-Price SCHOOL BUS 77986 instruction sheet

REVELL

REVELL Dassault Rafale M Assembly instructions

Nickelodeon

Nickelodeon Paw Patrol Marshall RC Fire Truck User instruction guide