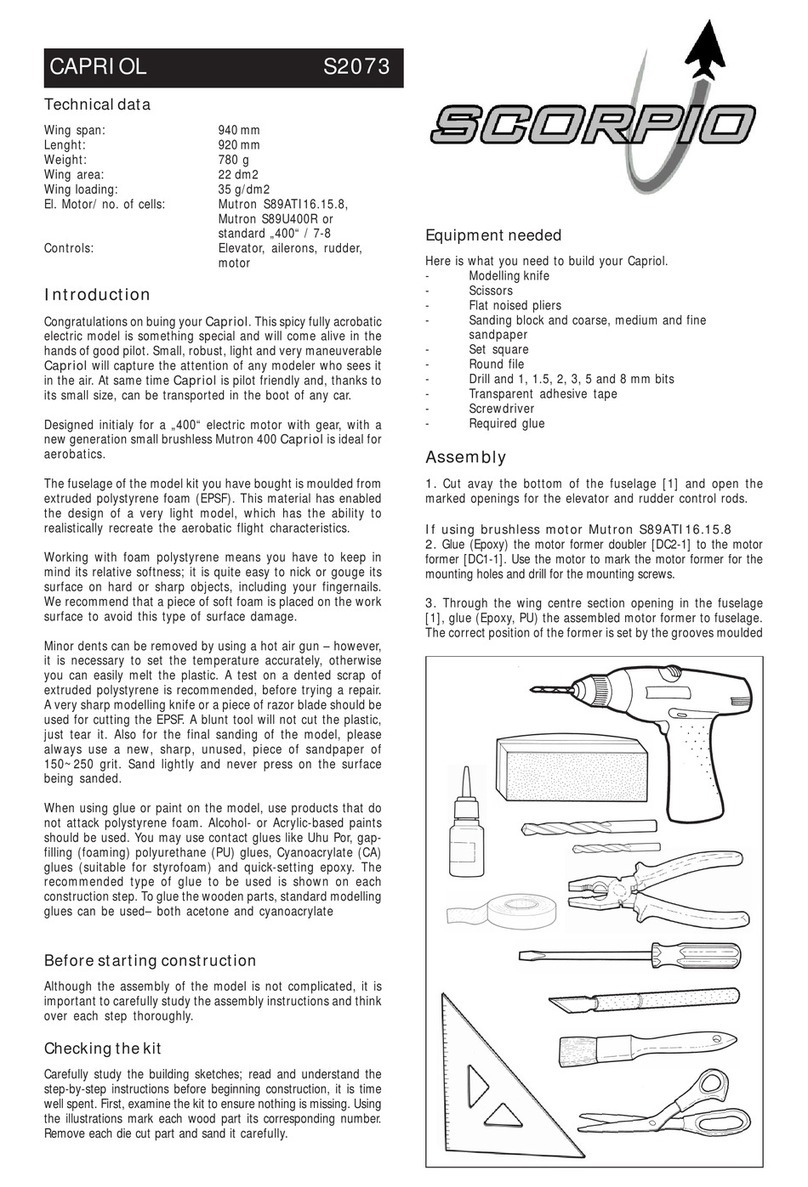

FlyingDutchmanPlans Goose V2 User manual

Introduction

Thank you for choosing the GooseV2 as your project, I hope you have much fun building and flying this model.

Before you start with the build I recommend to read through this manual and watch all the GooseV2 build videos on

my YouTube channel. Also, the build thread on RcGroups contains many pictures from the prototype build and is a

useful course of information. This book covers the build step by step but I did not make instructions for scale details

etcetera, these will have to be scratch build to your own desire. Also, obvious things such as trimming sheeting and

sanding ribs and former edges to follow the model’s curvature are not mentioned as I assume you will understand

that needs to be done.

The build is divided in several chapters, each begins with a hardware list for that build stage. Some parts will have to

be cut to size from a supplied length of material, the wing tubes and pushrods for example. The exact dimensions

can be found in the hardware list. Also, which type of glue needs to be used is not mentioned. I recommend medium

CA for balsa to balsa, waterproof wood glue for ply to balsa and ply to ply joints. Use epoxy or CA with filling powder

on high stress joints.

Waterproof wood glue is also used for balsa to balsa large area joints such as gluing the wing spars. The CF and brass

tubes can be glued in place using medium CA, I found that this works very well. Thin CA is used for hardening the

wood surrounding a screw hole, the servo cover screw holes for example.

To build the Goose a 100% flat building board 120x60cm fits the job, use waxed paper to cover it and preventing you

from gluing the model to the building board.

If you take a close look at a laser cut part you will see that the cutline is not 90 degrees. The cut is wider where it

enters the wood. Use this to your benefit when deciding in which direction to orient the parts.

The book has instructions for flaps, however if the model is built light, they are not necessary. If you choose to use a

glass cloth finish instead of covering film and the AUW is around 6kg it is recommended to equip the Goose with

flaps.

Make sure you completely understand each build stage before gluing any parts together.

When the build is ready finish the model with covering film and for the area below the waterline use glass cloth and

resin. Then setup the radio system and your ready to go. It is probably best to do some sea trials before attempting

maiden flight. I found that is a good way to get used to a flying boat before actually flying it. This helps you relax for

the maiden itself. When flying off water you will experience that the goose gets on step very easy. Landing without

bounce is bit trickier, a very slow rate of decent is demanded for a nice landing. Try to have the center of the step hit

the water first with a high angle of attack and some power on. It takes practice to get it right.

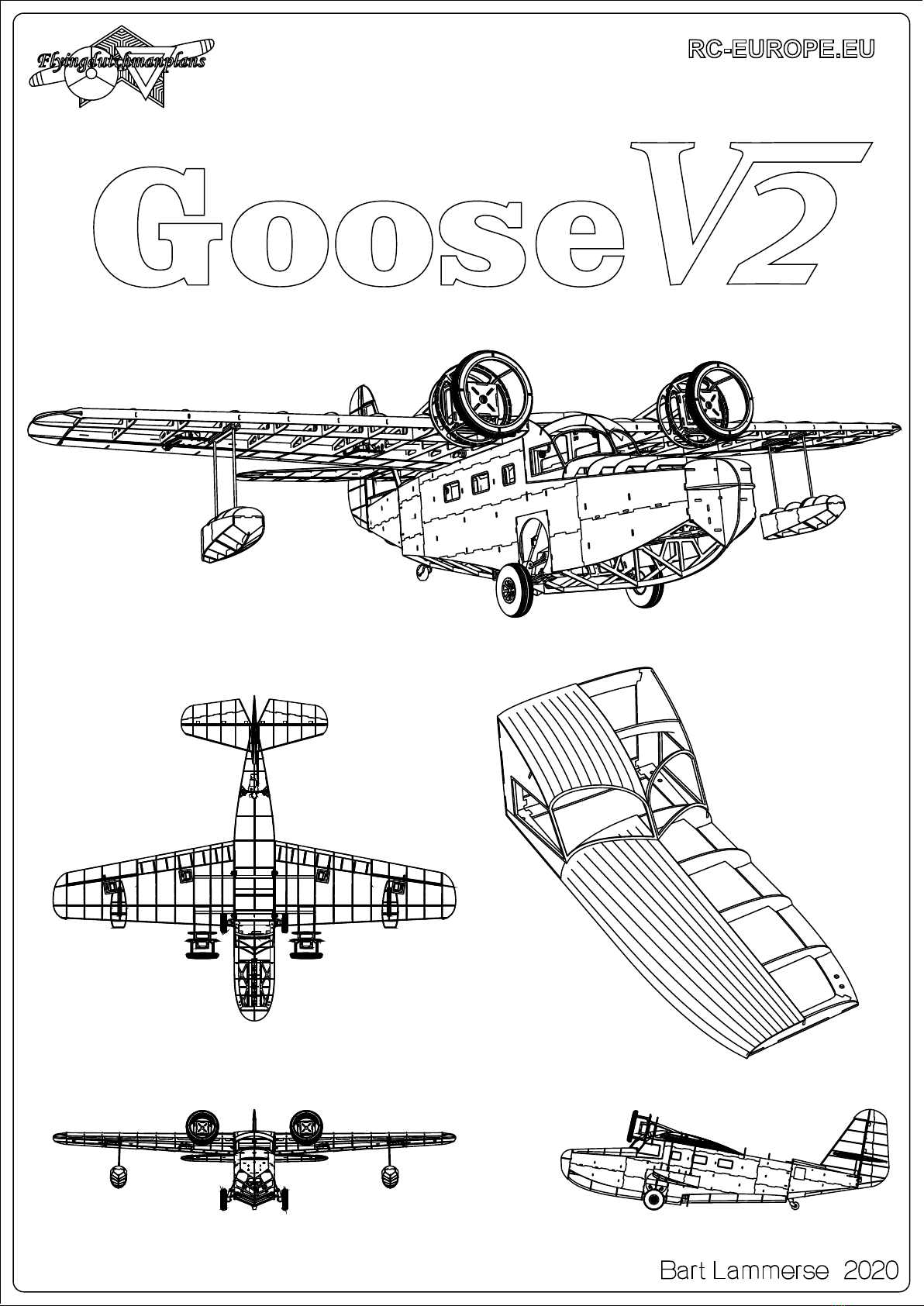

After each season the landing gear need maintenance. The brass tubes all need to be cleaned and lubricated. Also

give all the metal parts a coat of CorrosionX every now and then to prevent them from rusting.

But all this is many building hours away so let’s get started . . . . .

On YouTube look for GooseV2 and you’ll find the video series on my channel (Bart83)

Link to GooseV2 playlist:

https://www.youtube.com/playlist?list=PLkpKj72K3uYmgntGXOHDq5Y_r17no_eFl

Link to prototype build thread :

https://www.rcgroups.com/forums/showthread.php?3515473-GooseV2-new-lasercut-kit

If you have any question about the GooseV2 feel free to email me at [email protected]

For questions about the kit contact Sebastiaan (owner RC-Europe.eu) at [email protected]

Enjoy the build,

Bart Lammerse Bart83 ( RcGroups user name)

2

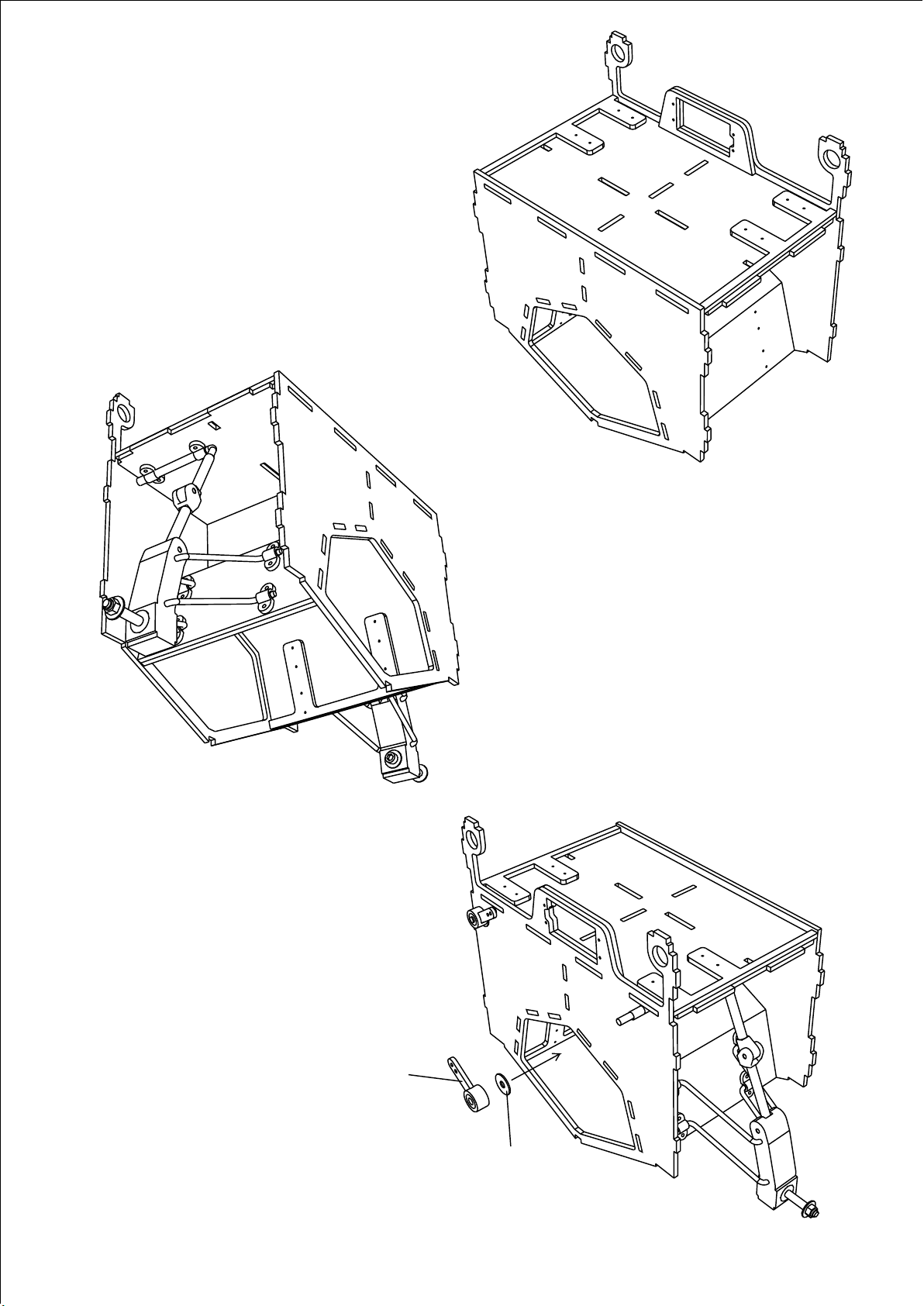

Build the model stand from parts on sheet 23

3

4mm

M4x55mm

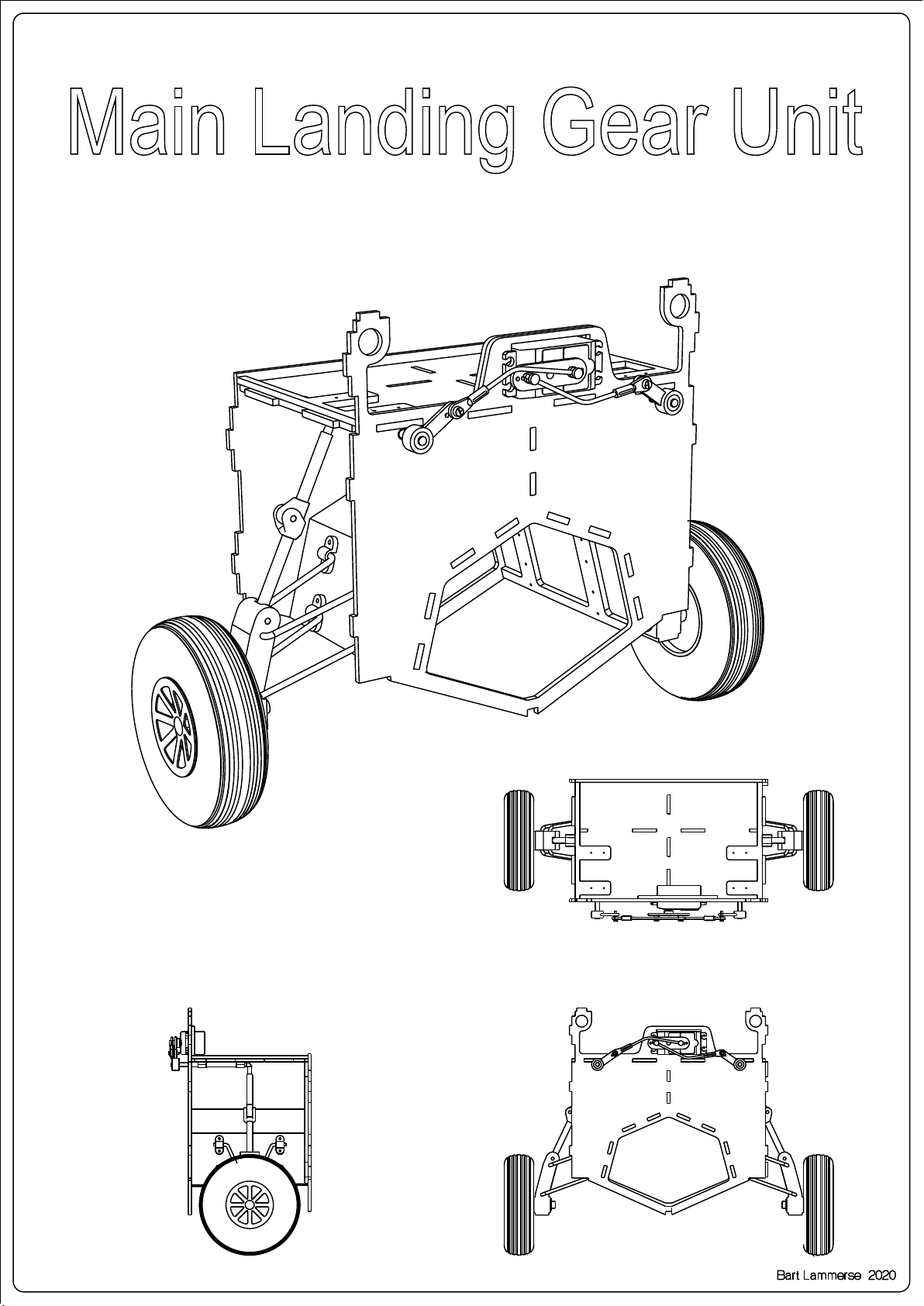

Pre-bend upper folding arm

2x

steel wire

Lower folding arm

Pre-bend suspension arm 3mm steel wire

3x12mm

Upper folding arm 3d printed part

2x

4x

3d printed part

2x Lower T-Bone 3x20mm cut to from supplied steel wire

2x Folding hinge pin

5x4.1x65mm

cut to from supplied steel wire

2x Lower folding arm inner 3x41mm cut to from supplied steel wire

2x Inner axle

2x

Stainless steel allen bolt

2x Outer axle 5x4.1x22mm Cut from supplied brass tube

2x Wheel locking nut M4 Stainless steel

10x Washer large OD M4 Stainless steel

2x Folding arm sleeve

Hardware for this build stage

Cut from supplied brass tube

8x Suspension arm tube 4x3.1mm Cut from supplied brass tube

4x Du-Bro gear strap 3/16 + screws

8x Du-Bro gear strap 5/32 + screws

2x Nylon steering arm 4mm hole

2x Threaded pushrod M2 Cut to correct size

2x Ball-link M2

2x Machine screw M2x12mm Stainless steel

2x Nut M2 Stainless steel

2x Washer M2 Stainless steel

2x Dubro EZ connector .22’’ Heavy Duty

1x Hitec HS-75BB Retract servo + mounting hardware

2x Du-Bro Lightweight wheel 4’’

5

Steel wire T-bone 3x20mm

Steel wire hinge pin 3x12mm

Lubricate the tube with grease

Brass tube 5x4.1x65mm

Slide the remaining axle member parts in place and glue assembly,

make sure to have the parts aligned correctly!

Steel wire lower folding arm reinforcement 3x41mm.

Slide the first two axle member

parts on the suspension arms

Pre bend 4mm landing gear part

3d printed lower part

Position the previously build folding arm

3d printed upper part

6

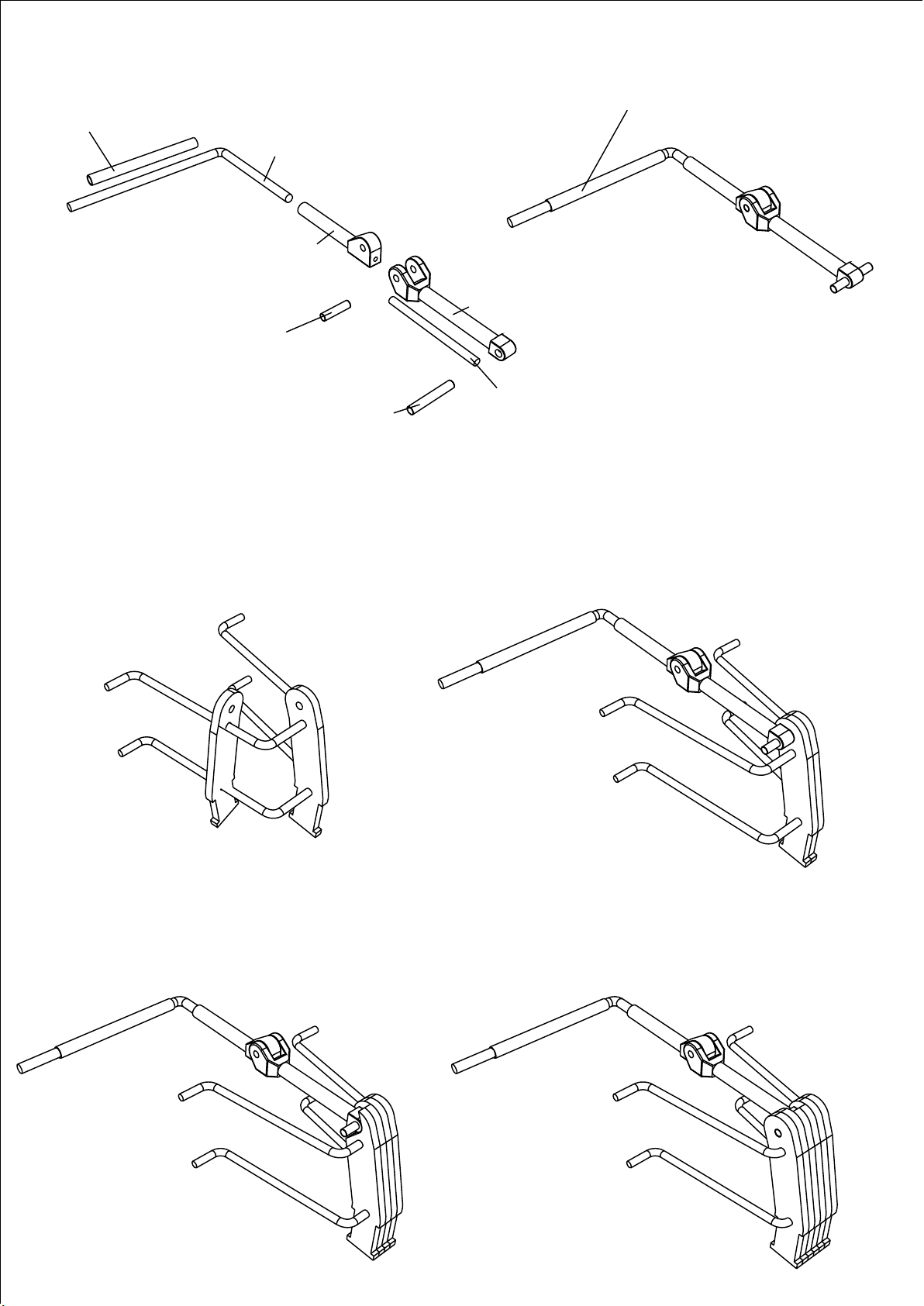

Allen bolt M4x55mm

Washer M4 large OD

Locknut M4

Brass tube 5x4.1x22mm

(lenght may be different when not using Du-Bro wheels)

Use more washers if wheel does not clear axle member

Du-Bro 5/32'' gear straps

Du-Bro 3/16'' gear straps Brass tube 4x3.1mm

Glue the two plywood plates to the axle member and drill 4mm hole

7

FF-G2

FF-G1D

FF-G1

FF-F6

8

Arrow on part points to nose

FF-F4

FF-G4

Sand beveled edge

9

Washer M4

Nylon steering arm with 4mm hole

Install previously build retracts

FF-G4D

FF-F4D

10

Hitec HS-75BB Retract servo

Nut M2

Washer M2

Du-Bro EZ connector Heavy Duty .22''

Machine screw M2x12mm

Ball link M2

Setup linkage, mount wheels and test the retract system

Threaded pushrod M2

Du-Bro Lightweight wheel 4''

11

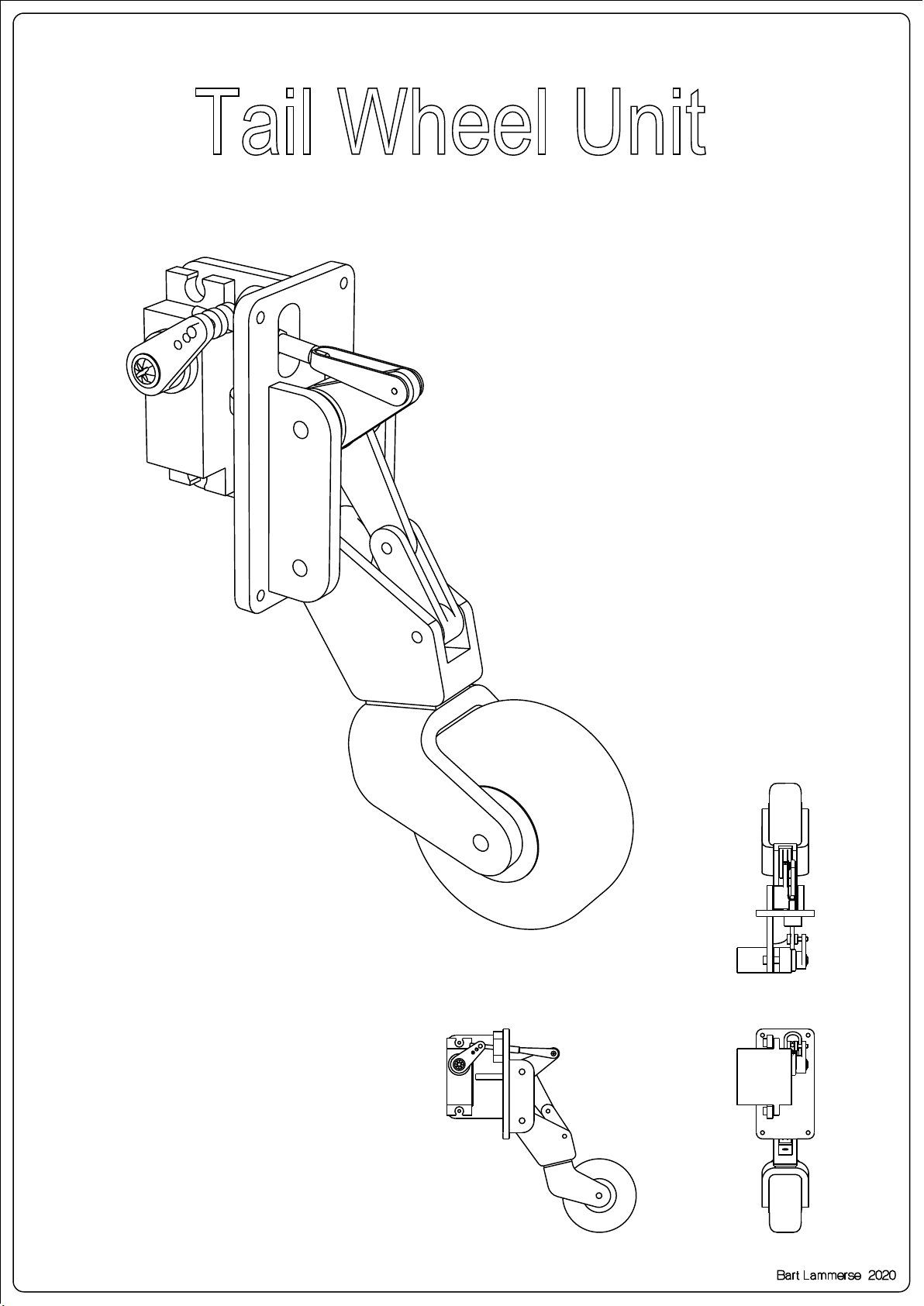

1x

M2

Balloon

4x

1.5’’Du-Bro tailwheel1x

2mmSelf tapping screw

1x

Mighty micro servo + mounting hardwareHitec HS-85BB1x

To make the watertight cuff

Metal clewis1x

Pushrod connector1x

Cut to sizeM2Pushrod

Hardware for this build stage

3mm steel wire3x25mmAxle1x

Cut from leftover m2 pushrod2x7mmHinge pin1x

Cut from leftover m2 pushrod2x12mmHinge pin1x

Steel wire3x33mmHinge pin2x

3d printed partsTailwheel unit1x

13

3d printed parts

3d printed parts

Steel wire 3x25mm

Du-Bro tailwheel 1.5''

Steel wire 2x12mm

Steel wire 3x33mm

Steel wire 3x33mm

Steel wire 2x7mm

14

Threaded pushrod M2 & metal clewis

Setup linkage and test operation.

Pushod may need to be bend to prevent binding to the 3d printed part

Flange to attach watertight cuff

Hitec HS-85BB Servo

Pushrod connector

15

Round magnet

MPX Connector female

2x Wing joiner tube 13x12.1mm

Machine screw

4x Nylon screw M6

8x Nylon nut M6

6x

Cut to from supplied brass tube

M2

2x Spring or rubber band For closing gear door

2x Gear door hinge Make from leftover pushrod & tube

2x Spring attachment Make from pushrod inner wire

1x Canopy lock

2x MPX Connector male

1x

5x3mm

2x EC3 Connector male

1x Lipo connector

1x Battery wire 12 AWG

1x Battery wire 14 AWG

-- Servo wiring See YouTube channel for reference

1x Receiver Min. 5 channel

1x Ubec Min. 6A

1x Flight battery

6x

Hardware for this build stage

17

3s5500 to 4s6500 mAh Lipo

IH

G

F

E

D

C

BA

Use the window frames and

parts labeled 'press' on sheet 23

to form the windows.

FF-W2

FF-W1

J

Window frames need to be flush with the outside of the fuselage.

Make sure to build one left and one right side!

Assemble fuselage sides

See video on YouTube for tips and tricks

18

Previously build landing gear box

FF-F7

FF-F8

FF-BX1

Assemble FF-BX1

Fuselage boxframe sub assembly

FF-BX1

FF-F5

19

FF-L4

FF-L3

FF-L2

FF-L1

Round magnet 5x3mm FF-L2 Round magnet 5x3mm

FF-F12D

Use tailwheel unit to position FF-F12D

6M

Canopylock determines position of support frame

Glue canopy lock in place

Nylon nuts M6

FF-LC2

FF-LC1

Split fuse former sub assembly

FF-F12

FF-TR

Locktab should move without friction

HEX

Battery lock sub assembly

20

Keep the locktab free of glue!

Popular Toy manuals by other brands

Bengtson Company

Bengtson Company Albatros DVa 54" instructions

Dancing Wings Hobby

Dancing Wings Hobby S21 Fieseler Fi 156 Storch V2.0 instruction manual

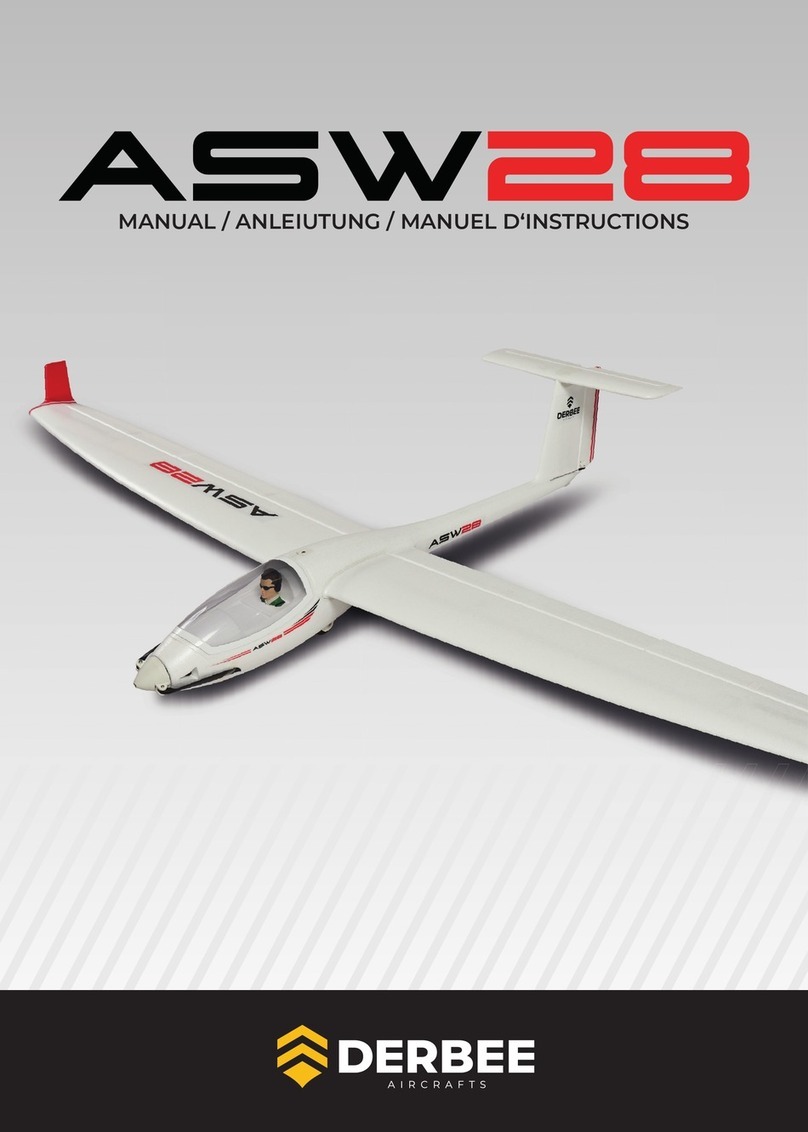

DERBEE

DERBEE ASW28 manual

BNF

BNF Blade 300 X instruction manual

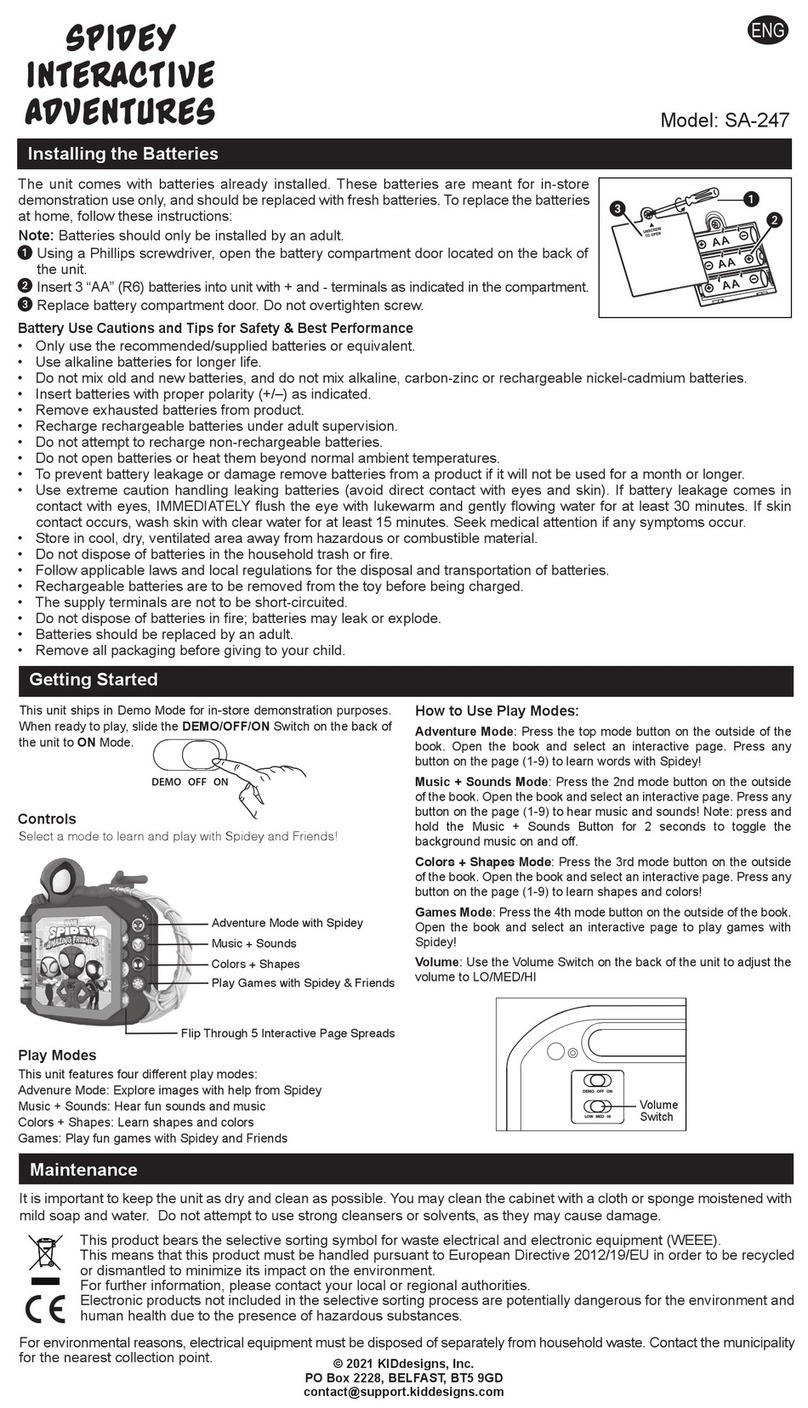

KIDdesigns

KIDdesigns SPIDEY INTERACTIVE ADVENTURES quick start guide

Trix

Trix 22243 manual

Mega Bloks

Mega Bloks Collector Series instructions

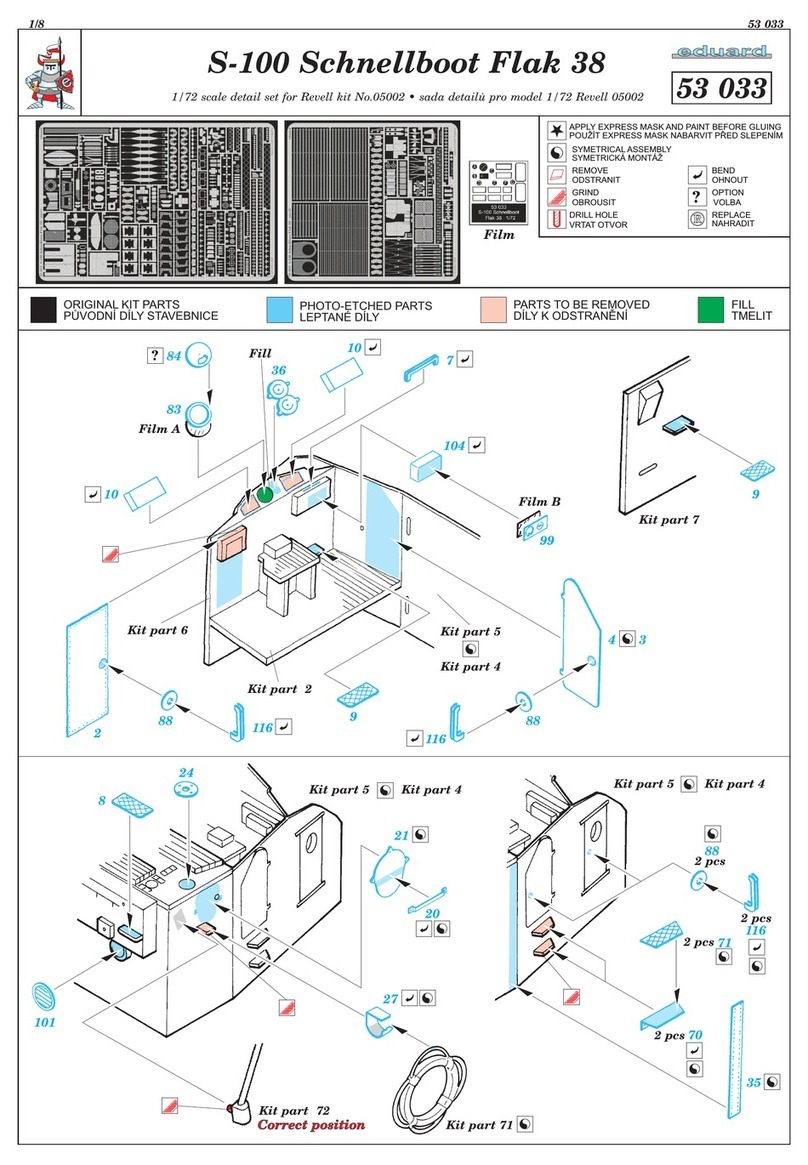

Eduard

Eduard S-100 Schnellboot Flak 38 quick start guide

Eduard

Eduard F-15E Strike Eagle seat manual

GRAUPNER

GRAUPNER MAXIE SPORT 490 Building instructions

POLA G

POLA G Madulain Station quick start guide

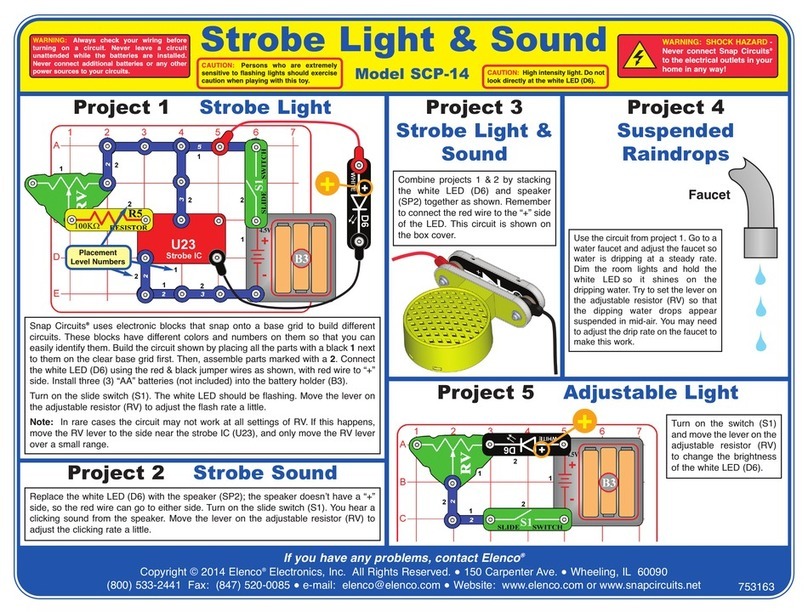

SNAP CIRCUITS

SNAP CIRCUITS SCP-14 quick start guide