FMC Technologies Syntron DL-1-A Owner's manual

Syntron®

DL-1-A Dental Vibrator

■Installation ■Operation ■Maintenance

©2002 FMC Technologies, Inc. All rights reserved SM1115- 071703

2

Thank you for buying your equipment from FMC. This manual will help you to understand how your

equipment operates and what is required to maintain peak performance. Please read it thoroughly and

keep it on file for reference.

Your satisfaction is important to us, so pease direct any comments to our Marketing Communications

Department.

TABLE OF CONTENTS

Safety Instructions ............................2

Inspection and Storage.....................2

Introduction.......................................3

Installation.........................................3

Maintenance .....................................3

Air Gap..............................................4

Operating Specifications...................5

Field Repairs.....................................5

Troubleshooting................................5

Parts List...........................................6

Wiring diagram..................................8

The DL-1-A Dental Vibrator is ”classsifed by Underwriters Laboratories Inc.® with respect to

electric shock, fire and mechanical hazards only in accordance with UL2601-1, (UL2601-1-XX, if

applicable), (UL2601-1-2-XX, if applicable)”.

The DL-1-A Dental Vibrator is also CSA certified per file #LR 53131.

SAFETY INFORMATION

WARNING: These instructions and safety precautions must be followed. There is a hazard of electrical

shock to the operator.

NOTE: Local safety codes and regulations must be considered when operating this equipment.

WARNING: Failure to follow these instructions and procedures could result in personal

injury, unsatisfactory performance, and /or damage or shortened service life.

WARNING: Unauthorized modifications to the equipment may present a safety hazard to the

operator and void the warranty.

Modifications or additions to the equipment should not be made without first cosulting FMC Corporation.

WARNING: Power supply voltage and frequency must be the same as that designated on the

nameplate.

Power supply voltage and frequency other than that designated on the nameplate may damage the unit.

Product safety labels must be highly visible. Check their visibility regularly. Do not remove or

paint over safety labels. Contact FMC Corporation for an additional supply, free of charge, if labels

3

need replaced,

INSPECTION AND LONG TERM STORAGE

Upon receipt, carefully unpack and inspect the DL-1-A Dental Vibrator for any damage that may have

occurred during shipment. If damage is found, notify the shipping carrier and FMC immediately.

If the DL-1-A Dental Vibrator is to be stored for an extended period of time, store the unit indoors in its

original shipping carton. Ambient temperature should not exceed 100°F (40°C). Outdoor storage or storage

under extreme conditions is not recommended.

INTRODUCTION

The Syntron® DL-1-A Dental Vibrator is designed for the processing of dental molds. A magnet assembly

produces a vibrating action which is transmitted to the deck through a system of leaf springs. The control

assembly includes an ON/OFF switch, a rheostat to control the amplitude of vibration, and rectifier to

convert from AC to DC current. The DL-1-A vibrator weighs approximately 25 pounds and must be lifted by

the base only.

The DL-1-A vibrator is rated at 115V or 230V, as specified at the time of manufacture. It can operate at

either 50 or 60 Hz, with no adjustments required. At 60 Hz operation, the vibrator produces an operating

frequency of 3600 vpm. 50 Hz operation produces an operating freqency of 3000 vpm. If a different

vibration output is desired, then the air gap must be changed (refer to Air Gap, page 4).

WARNING: Power supply voltage and freqency must be the same as that designated on the

nameplate.

INSTALLATION

Place the DL-1-A vibrator on a solid support that does not vibrate while the vibrator is operating. The deck

should not touch any rigid object or adjacent surface; it must be able to vibrate freely.

CAUTION: Lift the vibrator by the base only. Lifting it by the top deck may cause damage.

OPERATION

Once the dental vibrator is in its operating location, plug it into a self-grounding receptacle. Turn the switch

to the ON position and place a dental mold on the deck. The strips on top of the deck will keep the mold in

position while the investment is poured.

Turn the rheostat knob clockwise to increase vibration amplitude. Turn the switch to the OFF position to

stop the vibrator.

MAINTENANCE

WARNING: Disconnect and lock out the power supply before performing any maintenance on this

equipment.

Use a mild household cleaner and water to clean the dental vibrator. Do not use excessive water; a damp

cloth is sufficient. Wipe the unit dry. DO NOT use acids for cleaning. To remove dental cement from the

neoprene deck, remove the deck and simply flex it. Do not twist it tightly or crease the deck.

4

If an apparent problem exists, do not operate the dental vibrator. If parts are found to be defective, they

must be replaced immediately.

AIR GAP

The air gap is the space between the pole faces of the armature and the core. Low current draw indicates

that the air gap is too narrow, resulting in a striking condition.

WARNING: A striking condition can cause damage to the vibrator. If a striking condition exists,

immediately shut off power to the vibrator.

Excessive current draw indicates that the air gap (the gap between the core and the armature pole faces)

is too wide. An excessive current draw can result in heat buildup. The dental vibrator should run warm, but

not too hot to touch.

WARNING: Do not operate the vibrator if there is excessive current draw.

If either condition exists, an adjustment of the air gap is required. The air gap must be adjusted while the

vibrator is in operation.

WARNING: When adjusting the air gap, exercise caution to prevent electrical shock to personnel or

damge to the vibrator.

To adjust the air gap, perform the following steps:

Place the dental vibrator in a position to gain access to the

adjustment screw on the bottom of the vibrator. FMC

recommends placing the unit between two tables (sse

Figure 1). Supporting the vibrator by the deck, or hand-

holding the unit will adversely affect the air gap adjustment

since the unit must be supported by its rubber feet.

Plug in the electrical cord and turn on the vibrator. Turn the

dial to ”100”. Using a 5/32-inch Allen wrench, loosen the

socket head cap screw located in the core on the bottom of

the vibrator.

Use a slotted blade screwdriver to adjust the air gap using the slot in the core. Turn the core clockwise to

reduce the air gap (lower the current draw), and counterclockwise to widen the air gap (increase the

current draw). To adjust the air gap to the proper setting, turn the core clockwise until a striking condition

exists, then immediately turn the core counterclockwise, just until the striking stops. Check the current

draw.

NOTE: When using an analog tong meter to read the vibrator current, the meter reading must always be

multiplied by a factor 1.7. Due to the waveform characteristics of the vibrator, the tong meter does not

reveal the current rating designated on the nameplate. When using a true RMS meter, the current is as

indicated.

When the proper air gap has been achived (indicated by the current draw), lock the core in place by turning

the socket head cap screw in the end of the core. The dental vibrator is now ready for further operation.

5

OPERATING SPECIFICATIONS

MAXIMUM LOAD OPERATING FREQUENCY CURRENT RATING

10 lb 3600vpm 1.0 Amps – 115V

0.5Amps – 230V

FIELD REPAIRS

The following tools are required to adjust the air gap or make field repairs to the dental vibrator:

•5/32 inch Allen wrench

•1/2 inch socket wrench

•Slotted blade screwdriver

•Ammeter

TROUBLESHOOTING

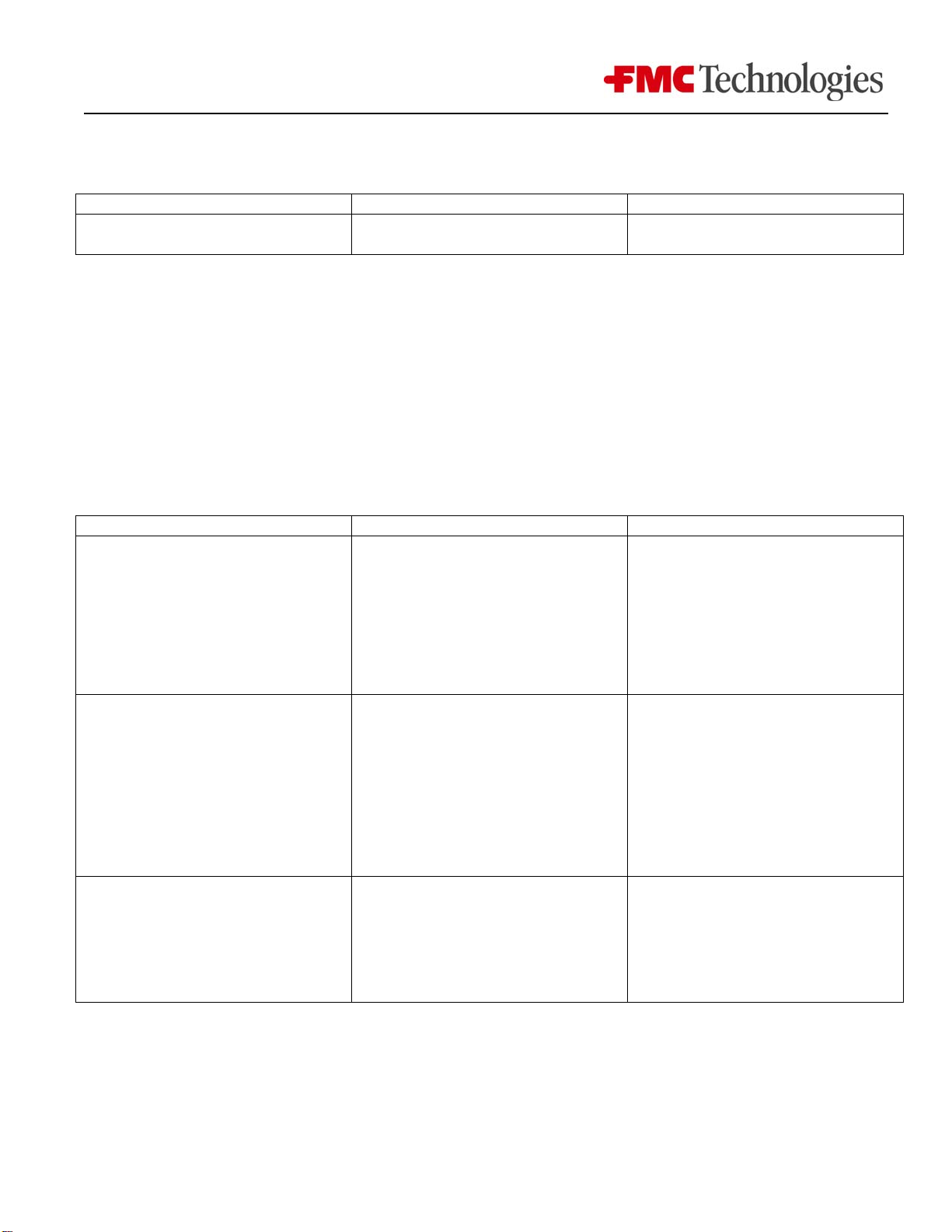

PROBLEM CAUSE CORRECTION

Unit does not Operate

Defective rheostat

Shorted wiring, loose connection,

no power to the unit

*Replace

Repair

Unit operates, but will not vibrate

Unit in contact with rigid object

Or adjacent surface

Defective rubber feet

Defective springs

Defective rectifier

Isolate unit

*Replace

*Replace

*Replace

Excessive noise

Armature and magnet

Assemblies making contact

Adjust air gap

* Replace only with parts supplied or recommended by FMC Technologies.

Table of contents