FMC Bolens Power-Ho Special User manual

Owner

Mama

WITH

Parts

List

/^s-o

- /9S3

DELUXE

Bolens Producis Division

_

FOODMACHINERYANDCHEMICALCORPORATION

PORT

WASHINGTON

.

WISCONSIN

To

The

Bolens

Owner

This

Owners

Manual

has

been

especiallyprepared

tobringtoyourattentionallinformation

needed

to

operateandmaintainyour

Powe

r

- Ho

tractorwith

maximumefficiency-Read

these

instructionscare-

fully

beforeassemblingoroperatingthetractor.

Through

propercareandoperation,asexplainedin

this

manual,youwillobtainlong,efficient

service

and

trouble

free

operationfromit.

Informationregardingoperationandmaintenanceof

thePower-Ho

engine

isnotincludedin

this

manual.

A

separate

engine

instructionmanualisincludedwith

eachtractorandshouldbeconsultedforallinfor-

mationconcerning

adjustments

andoperation.

REGISTERYOURTYPE

AND

SERIALNUMBER

Registeryourtractor

type

number,serialnumberand

engine

serialand

type

numberinthe

space

provided

below

and

always

refer tothemwhenwritingforin-

formationororderingparts.Completetheregistra-

tioncardreceivedwiththetractorandreturntothe

factory.Aname

plate

showing

type

andserialnumber

of

thetractorisattachedtotheframe.The

engine

type

andserialnumt)erisonthe

engine

nameplate.

TRACTOR

TYPE

NO.

TRACTOR

SERIAL

NO.

ENGINETYPE

NO

ENGINESERIAL

NO.

POWER-HODELUXE

TYPE

12BB101

IS

EQUIPPED

WITH

2H.P.

ENGINE

BOLENSPOWER-HOMODELS

POWER-HODELUXETYPE

12BB01

POWER-HOSPECIALTYPE

12BA02

The

Power-HoDeluxeispoweredbya new2-1/2

H.P,

engine

andisstreamlinedbya metalhood

which

covers

thefrontandtopofthe

engine.

The

deluxe

is completelyequippedwithBolensfamous

features

- variable

speed

sheave,

kickstand,

remote

control

stop

switchandchainguards.

Four-inch

rimscarrythenew

wide

base

5-12tires.Both

tires

are

liquid

filledwitha calciumchloride

solution.

The

Power-HoSpecialispoweredbya 2 H.P.

engine

drivingthrougha variable

speed

sheave.

Stopswitchismountedonthe

engine

cylinder head.

The

Bolenskickstand,

remote

control

stop

switch

and

chainguards, whichareavailableseparately

for

this

model,canbe

easily

installedinthefield

byyourBolensdealer.The

tires

are5 x 12

mountedonfour-inchrims,withprovisionsfor

liquid

filling.

2

Description

Attachment

Control

Lever

Main

Idler

Control

Lever

StopSwitch

Throttle

Control

Wire

and

Shut-off

Control

Wire

Variable

DriveSheave

Figure

1.

1.

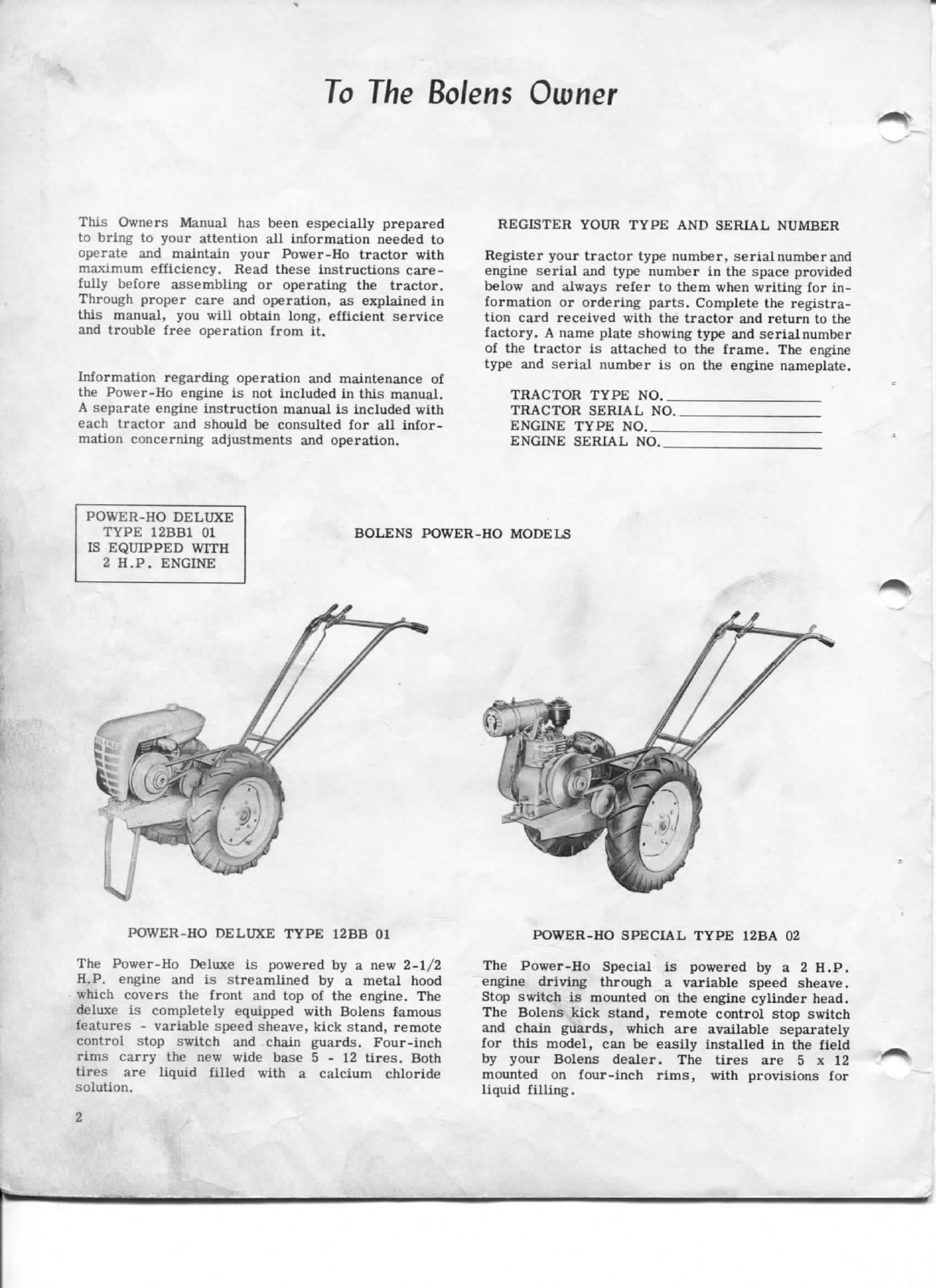

BOLENSPOWER-HO

tractorsarewalkingtype

tractorswitha ground

speed

rangeof1-1/4to

3-1/4milesperhour.A completelineofattach-

ments

areavailableforplowing,harrowing,seeding,

cultivating,lawnmowing,sicklemowing,grading,

snow

plowingandmanyotheryear-aroundopera-

tions

.

2.Thefour-cycle,single-cylinder,air-cooleden-

gine

with6 to1 gearreductiondrives thetractor

througha variablepitch

sheave

anda differential

sheave.

Speed

changes

from1-1/4to3-1/4miles-

per-hour

aremadebyvaryingthepitchofthedrive

sheave

bya simpleadjustment.Thedifferential

sheave

withratchets

allows

the

outside

wheeltoturn

fasterwhenturning.

Final

drivetothe

wheels

is

througha chainoneachwheel.

3.Allcontrolsareconvenientlylocatedonthehan-

dle.Therighthandlever

operates

maindriveidler

pulleyandthe

left

handlever

operates

front-mounted

attachments.Throttlecontrolislocatedonthe

left

handlefor

easy

accessibility.Stopswitchonthe

handleisstandardontheDeluxeandoptionalonthe

Special.

4.ThePower-Hoisequippedwithnewwide

base

tires,

size

5-12,mountedonfourinchrims.The

tiresonthedeluxearefilledwith20poundsof

calcium

chlorideforadditionaltraction.Thetires

onthespecialarenot

liquid

filledbutcanbeif

additional

tractionis desired.Twopoundsofcalcium

chloridetoonegallonofwaterwillwithstandfreez-

ing

to20°F.

5.

Front

attachments

aremountedonthefrontofthe

tractor

withBolensSnap

Hitch.

Rearmounted

attachments

areattachedbya pinintheframe.

Instructionsforinstalling

attachments

areincluded

witheachattachment.

6.A kickstandisprovidedontheDeluxemodel

whichautomatically

latches

whenkickedback.A

thumblatch

releases

thestandwhichsupportsthe

tractor

withoutattachments.

7.

TYPE

AND

SERIALNUMBER.

Thenameplate

isattachedtothetopofthetransmissionbracket,

figure1.Whenwritingforserviceinformationor

ordering

partsforyourPower-Ho,alwaysfurnish

the

TYPE

NO.and

SERIALNO.

stamped

on

this

plate.

3

Installation

StopSwitch

Throttle

Control

Clip

Spring

Clip

Throttle

Control

Wire

Shut-off

Control

Wire

Figure

2,

Transmission

BracketBolt-

Handle

Bolts

Lower

RodEnd

Idler

Control

Arm

ASSEMBLY

INSTRUCTIONS

1.Thetractor,asshipped

from

thefactory,is

crated

withthe

wheels

removedandthehandleas-

semblypackedina separatepackage.

This

handle

assemblypackageincludestwoupperidlercontrol

rodsandmainidlerlowerrodassemblywhichare

standard

equipmentonbothPower-Hotractors.

2.Installwheelassembliestotractorsothey

will

rotateindirectionindicatedbyarrowontire.Hub

boltsareshippedinaccessorybagattachedto

tractor.

3.Removethefourhandleboltsatbottomofhandle.

Position

tractorhandleandinsertbottomhandle

boltsoneachsideofframe.

Then

inserttophandle

bolts.Adjusthandletodesiredoperatingpositionand

tightenallfournuts.A handleadjustmentof7 inches

is provided

between

lowandhighhandleposition.

4.Installthemainidlercontrolassembly,which

includesthelowerspringloadedrodassembly,on

therightsideofhandleassemblyasfollows.Posi-

tion

lowerrodassemblyundertransmissionbracket

and

attachrodendtoidlercontrolarm.Insert

bottomendofmainidlercontrolrodthroughidler

rod

link

from

theinside,thenthroughcenterhole

in

springretainerandsecurewithspring

clip,

see

inset

offigure2.Usethecenterholeofspring

retainer

fortemporaryinstallation.

Then

assemble

idler

controlhandletotherightweldedbracketon

handlecrossbarwithboltsandnutsprovided.

5.Adjustidlercontrolassemblyforproperbelt

tension.

With

leverengaged,thecompressionspring

should

becompressedapproximately1/4inchto1/2

inch

forproperbelttension.Usetheproperoneof

five

holes

in springretainerforthisadjustment.

6.Insertbottomendofattachmentcontrol

rod

through

leftsideidlerrod

link

from

theinsideandsecure

withspring

clip.

Attachcontrolhandletotheleft

weldedbracketonhandlecrossbarwithnutsand

bollsprovided.

This

controlassemblyis usedfor

front

mountedattachments,suchaslawnmower

and

sicklemower.

7.Thethrottlecontrolassemblyand

stop

switchwire

havebeenproperlyassembledatthefactorythrough

thetransmissionbracket.(Stopswitchisoptionalon

Special.)

Bring

throttlecontrolwireabovelower

crossbarofhandleassemblyandattachthrottle

control

leverattop

INSIDE

positionofhandle,see

figure

2,Holes,throughthehandle,havebeen

provided

forthisinstallation.

8.

Bring

stop

switchcontrolwirewith

stop

switch

attachedoverlowercrossbarofhandleassembly

in

thesamepositionasthethrottlewire.Install

stop

switchcontroltotopendofhandlethrough

holeprovidedandattach

stop

controlwire,see

figure

2,

When

installing

stop

switchhe sureto

insertoneshoulderbushingontopandoneonbottom

of

handlesothatthemachinescrew

does

notcontact

handleandshortoutengine.

9.Threeclipsareprovidedinaccessorybagfor

holding

throttlewireandshutoffwiretogetheron

handleassembly.

4

Operation

1.

IMPORTANT:

Nooilisinthecrankcaseofthe

engine

whenshippedfromthefactory.Beforestarting

the

engine

BE

SURE

TO

FILLTHECRANKCASE

TO

THE

LEVEL

INDICATEDWITH

THE

RECOM-

MENDEDLUBRICANTSPECIFIED

IN

THEENGINE

MANUAL.

The

engine

isshippedwithoilinthe

gear

case,

however,

this

shouldbecheckedbefore

startingtobesureitisfilledtotheproperlevel.

Further

instructionspertainingtothe

engine,

its

careandlubricationarecontainedin the

engine

manual;

these

shouldbestudiedverycarefully.

2.

LUBRICATION,

Beforeoperatingyourtractor,

lubricateasfollows:

There

arefourhighpressure

grease

fittingsonthe

tractor;

oneontheidlerpulley,oneatcenterof

transmissionbracketandoneoneachwheelhub.

Lubricate

each

grease

fittingapproximatelyevery8

to10hoursofoperation.A

grease

gunis provided

withthetractor.Cleanallfittingscarefullybefore

applying

lubricant.UseMobileNo.4 (orequivalent)

and

applynewlubricantuntiloldlubricantis forced

out.Periodicallylubricateworkingpartsoftractor

withlightoiltorsmoothoperation.

3.

KICKSTAND.

Thefrontkickstandisoperated

bythumblatchatcenterofmainframedirectly

behind

the

engine.

Itautomatically

latches

tobottom

of

mainframewhenswungbackward.

4.

WHEELSETTINGS.

Twowheel

settings

areavail-

ableonthePower-Ho.Thetractorisshownin

figure1 withthe

wheels

dishedinward.This

setting

is17

inches

center-to-centuroftires.Fora wider

22-3/4

inchcenter-to-centertread,removehub

bolts

andreverse

wheels

so

they

aredishedout.

5.

TIREPRESSURE

Keeptiresinflatedto6 pounds

pressureatalltimes.Tiresfilledwithanti-freeze

calcium

chloridesolutionshouldalwaysbechecked

for

pressurewithvalveinuprightposition.

6.

OPERATION.

Start

engine

withbothidlercontrol

levers

inforwardposition.Afterthe

engine

is

run-

ning,

tostarttractor,movemaincontrolleverback.

To

stop

engine,

holddown

stop

switchuntil

engine

stops.

7.

TRACTOR

CARE.

Keepthetractor shelteredfrom

the

weather

whennotinuse.Attheendofeach

season

itisadvisabletohaveyourdealer

give

your

Power-Ho

a thoroughcheck-upforlongertractor

lifeand

better

performance.Beforestoring,

lubri-

cate

as

suggested

and

coat

any

exposed

metalparts

witha rustpreventitive.

8.

VARIABLESHEAVE.

Thevariable

sheave

pro-

vides

a ground

speed

rangeof1-1/4to3-1/4miles

perhourthroughadjustmentofpitch.Tochange

speed,liftupspringcliponadjustingnutuntil

disengagedfromchannelin

sheave

hub.Thenturn

adjustingnuttodesired

speed

position,figure3.

Four

and

one

-halfturnsofadjustingnutisthe

rangefromlowpositiontohighpositionofthe

sheave.

Thelow,or

outside

setting,

isfor

slow

forward

ground

speed

whilethehigh,orfurthest

Turn

Clockwise

To

Increase

Speed

Spring

Clip-

Adjusting

Nut

Variable

Sheave

Turn

Counterclock-

wise

toDecreaseSpeed

Figure

3

inward

setting

isforhighforwardgroundspeed.

WTien

adjustingthe

sheave

fordifferenttractor

speeds,

checkbelttensionand,if

necessary,

adjust

theidlercontrolassembly,paragraph9.

9.

DRIVEBELTADJUSTMENT.

Toinsurelongbelt

life,theidlercontrolshouldnotbesetto

cause

excessive

tensiononthebelt.Properbelttension

is obtainedwhenthecompressionspringinthespring

retaineris compressed1/4inchto1/2inch. Ad-

justmentis madebyremovingthespringcliponthe

idler

controlrod,changingthepositionofthespring

retaineratthepointofassemblytotheidlerrod

link

andcontrolrod,toanotheroneofthefive

holes

provided,

figure2.K beltadjustmentcannotbe

properly

madeby

this

procedure,

loosen

the

engine

mountingbolts,movethe

engine

forward

in

the

slotted

holes

andre-tightenbolts.Thenfinalcorrectbelt

tensioncanbemadebytheidlercontroladjustments.

10.

CHAINADJUSTMENT.

Thetransmissionbracket

is attachedtomainframewithfour

bolts

andnuts,

figures1 and2.Loosen

these

four

nuts

undermain

frame,

pull

backwardontransmissionbracketuntil

chainsare

firm

andtightennuts.Chainsshouldbe

tightenedtothepointwherethereis verylittle

slackbutcautionshouldbeusedsothatchaiRsare

nottootight.

11.

CHAINS.

Itisadvisabletorunchainsdry.

Oiling

thechains,particularlyifthetractor isbeingusedin

grittysoil,

causes

fineabrasivedirttoadheretothe

chain.

This

causes

excessive

wear.Attheendof

each

season,

removeandthoroughlywashthechains

in

kerosene;thendryand

reassemble

totractor.

12.

ENGINE.

Referto

engine

manual,

13.

TRANSMISSIONSHAFT.

Thisshaftcontains

hardenedportionswhichareatdifferentpositions

from

theend.Theseportionscannotbereadily

identifiedasboth

ends

arefinishedoffexactlyalike

witha Woodruffkeywayanda snap

ring

groove.

However,a

spot

drill

isontherighthandendof

this

shaftandwheneverchanging

this

partitis

necessary

that

this

spot

drilledendbeassembledontheright

hand

side

whenviewingthetractorfromtherear.

14.

JACKSHAFTSHEAVE.

Differentialactionwheel

ratchetsareattacheddirectlytothejackshaft

sheave.

The

unitis packedwith

grease

atthefactoryandthe

ratchetsshouldberemoved

once

a yearforrepack-

ing

witha goodfiber

grease.

Thisratchet

sheave

allows

smoothturningand

easy

operationofthe

tractor.

6

IMPORTANT

ORDERING

INSTRUCTIONS

InappointingBolens

agencies

consideration

has

been

given

to

theirability

to

provideprompt

and

efficientservice.

We

recommend

that

yourlocal

dealer

be

contacted

for

your

service

requirements.

He

wiU

furnishcorrectpartsfrom

his

stock

or

order

them

foryouif

necessary.

To

insure

getting

correctmaterialswithoutdelay

please

supply

the

followinginformation.

Please

print

to

avoiderrors.

1.

The

type

number

ofthe

Power-Hotractor

and

serialnumberstamped

onthe

nameplate.

2.

Whenordering

engine

parts

giveengine

serial

and

type

number

as

stamped

onengine

plate.

3.Quantity,partnumber,

and

description

of

each

part

wanted.

4.

Advise

asto

whether

partsshould

be

shipped

by

mail,

expressor

freight.

(All

repairorders

are

shipped

F.O.B.

factory.)

5.

Name,shippingaddress

and

mailaddress.

This

parts

list

covers

both

models

12BAand12BB.

Wheredifferences

between

models

occur

themodel

ofthe

tractor

on

which

the

part

is

used

follows

name

of

part

in

parenthesis.

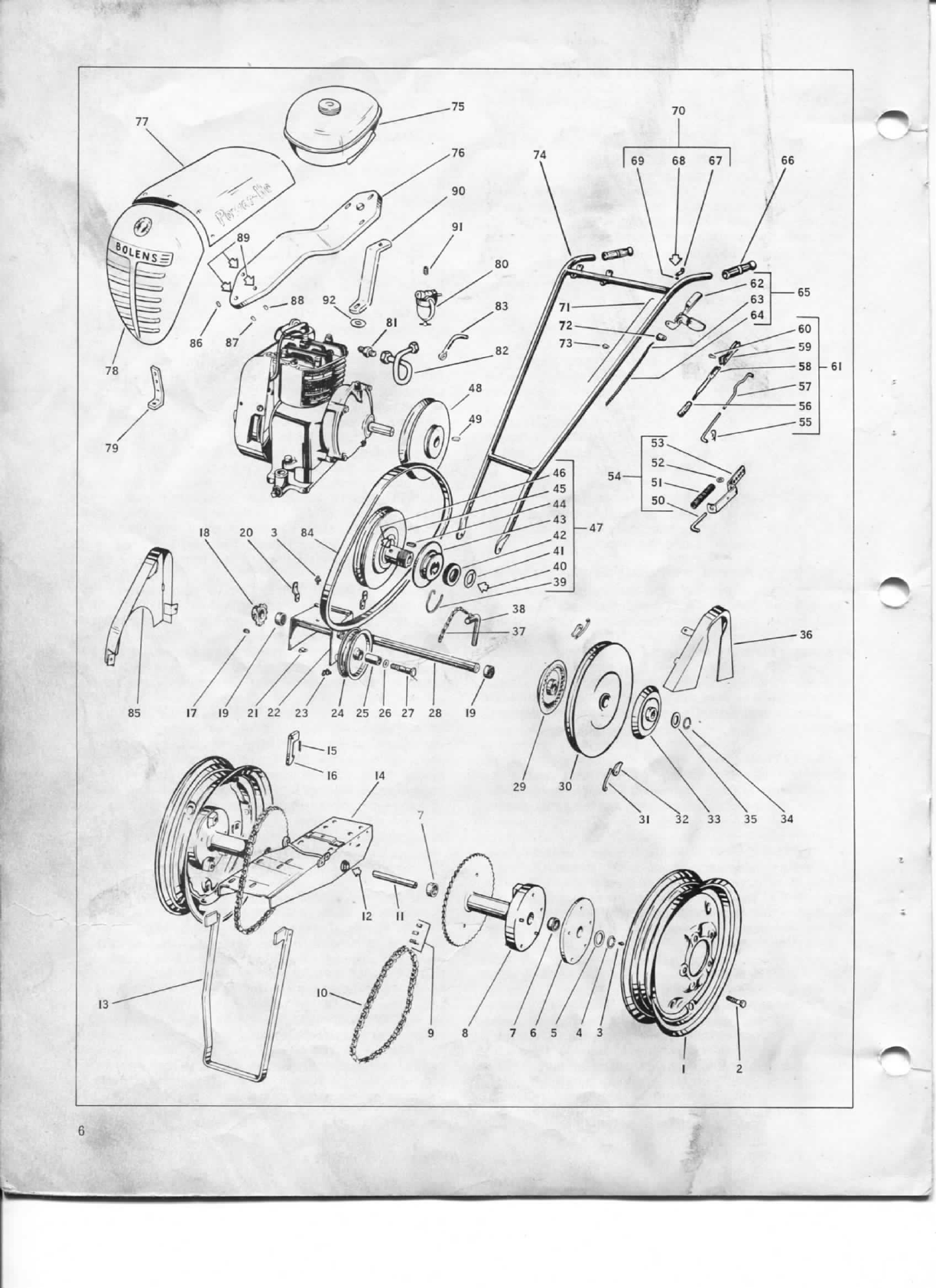

Ref.

No.

No.

Part

No.

Description

Req*d

1

181030

Wheel

- 3"*

2

1701393

Wheel

- 4"**

2

2

101085

Hub

Bolt

6

3

1104954

GreaseFitting

3

4

121896

Retainer

Ring

2

5

121895

Thrust

Washer,

7/8

2

6

308932

Spacer 2

7

1185007

Bearing

4

8

990578

Hub

&

SprocketAssy

(lessbrgs)2

9

1185013

Link

2

10

180124

Drive

Chain

2

11 119469

Spindle 2

12

1185050

KnurledSetScrew,

3/8-16x3/8

2

13

990601

Kick

Stand(12BB)

1

14 990599

Frame

1

15 149899

Latch

Spring(12BB)

1

16

308761

Stand

Latch

(12BB)

1

17

Woodruff

Key,

5/32x 5/8

2

18

211046

Drive

Sprocket

1

19

1185010

Bearing

2

20 308747

IdlerRod

Link

2

21

1700984

Clip

2

22

990581

TransmissionBracket

1

23

1110086

GreaseFitting,

45*^ 1

24

990586

IdlerPulley

1

25

190138

Pulley

Sleeve 1

26

1107372

Flat

Washer,

1/2 1

27

129042

IdlerPulleyBolt

1

28

119533

TransmissionShaft

1

29

990583

InnerRatchetw/sprocket

— 1

30 990497

Sheave

1

31 149897

Pawl

Spring 2

32 308737

Pawl

2

33

990584

Outer

Ratchet

1

34 121897

Retainer

Ring

2

35

1700880

Thrust

Washer

As

Req'd.

36

990618

Chain

Guard

L.H.

(12BB)

1

37

180173

Chain

1

38

310814

Pin

1

39

1700774

Spring**

1

40

Machine

Screw,

10-32x 3/8**

2

41 1700779

SpecialWasher**

1

42

1700773

SpecialNut**

1

43

1702386

Adjusting

Sheave**

1

44 1104335

Key,

3/16x3/16x2** 1

45

1702384

Variable

Sheave**

1

46

SetScrew,

3/8-16

x 1/4**

2

47 17

0078

0

Variable

Sheave

Assy**(Incl.

39

thru

46) 1

Ref.

No.

No.

Part

No.

Description

Req'd.

48

1700398

Drive

Sheave*

1

49

Sq.

Key,3/16x 3/16x 1* 1

50

310830

Lower

Control

Rod

1

51

149896

Spring

1

52 1107369

Washer,

5/16 1

53

308788

Spring

Retainer

1

54 1700989

Lower

Control

Assy(Incl.

50

thru

53) 1

55 135037

Spring

Clip

2

56

180886

Rubber

Handle

Grip

2

57 310827

Idler

Control

Rod 2

58

308878

•

Throwout

Lever 2

59 308879.

Throwout

Clamp 2

60 130147

Bearing

Pin

2

61

990625

Lever

Assy

{Incl.

55

thru

60)

2

62

290568

Throttle

Lever

1

63 1701079

Throttle

Wire,

66" 1

64

1701080

Throttle

Casing,

63" 1

65

1700806

Throttle

Assy(Incl.

62,63,64)

1

66

180885

Handle

Grip

67

1700213

Ground

Switchfl2BB)

1

68

Mach

Screw,

8-32x 1-1/2(12BB)1

69

1701051

ShoulderBushing(12BB)

70

1701361

Ground

SwitchAssy(12BB)(Incl.

67,

68,

69.

washers

&

nuts) 1

71

1701288

Ground

Wire

(12BB)

1

72

149925

Cable

Clip

73 1700799

Wire

Clip

(12BB)

74

990595

Welded

Handle(Only)

1

75

1701520

Gasoline

Tank

(12BB)

1

76 1701529

Tank

Support(12BB)

1

77

1701528

Hood

(12BB)

1

78

1701522

Grille

(12BB)

See

Note

1 1

78

1703010

Grille

(12BB)

See

Note

2 1

79 1701525

Grille

Mounting

Clip

(12BB)

1

80

1700141

Fuel

Strainer(12BB)

1

81 1701575

Connector(12BB)

1

82 66489

Gasoline

Line

(12BB)

1

83

1701513

BeltStop

1

84

1108566

Belt,

57" 1

85

990611

Chain

Guard,

R.H.(12BB)

1

86

1700321

Spacer(12BB)

See

Note

1 1

87

1701531

Spacer(12BB)

See

Note

1 1

88

1701530

Spacer(12BB)

See

Note

1 1

89

1103201J

SpecialScrew,

5/16-18

x 1-3/^

(12BB)

See

Note

1

90

1701536

Brace

(12BB)

1

91 1701675

Nipple

(12BB)

1

92 1701997

Seal(12BB)

I

NOTE:

All

bolts,

nuts

and

washers

are

standard

ImplementDealer.

*

Used

on12BAupto

Serial

No.

A18710

**

Used

on12BA

afterSerial

No.

A18710

and

all12BB

Models

can

be

obtainedfromyour

Local

Hardware

or

1-

Used

on

12BBwith

engine

type

No.

702814

sizes

and

NOTE

NOTE

2 -

Used

on

12BBwith

engine

type

No.107829

NATIONWIDE

SERVICE....

GENUINE

FACTORY

REPAIR

PARTS

The

BolensDivision

of

FoodMachinery

Cor-

poration

has

established

a

nationwidereputa-

tion

for

qualityproducts.Thisreputation,

gainedthroughadvancedengineering

and

effi-

cientmanufacturing

methods

is

important

to

rememberwhenbuyingreplacementparts.

Genuine

Bolenspartsassure

the

continued

highperformance originallybuiltintoyour

equipment.Bolensdealers

are

appointed

on

theirabilitytoprovidepromptefficientservice,

and

are

backed

bythe

Bolensserviceorgani-

zation.Whenreplacingpartsconsultyour

nearest

Bolensdealer

for

GENUINEBOLENS

SERVICE

PARTS

When

buying

new

equipment,remember

the

protectiveserviceofferedthrough

the

Bolens

dealer

in

yourcommunity.

PIONEERMANUFACTURERS

OF

GARDENTRACTORS

ANDEQUIPMENT

FOODM A C H I

Form

No.550338-4

PORT

I

R

Y ANDCHE

WASHINGTON,

IC A L

CORPORATION

WISCONSIN

Ken

Cook Milwaukee

LHtw

U.S.A.

This manual suits for next models

3

Table of contents