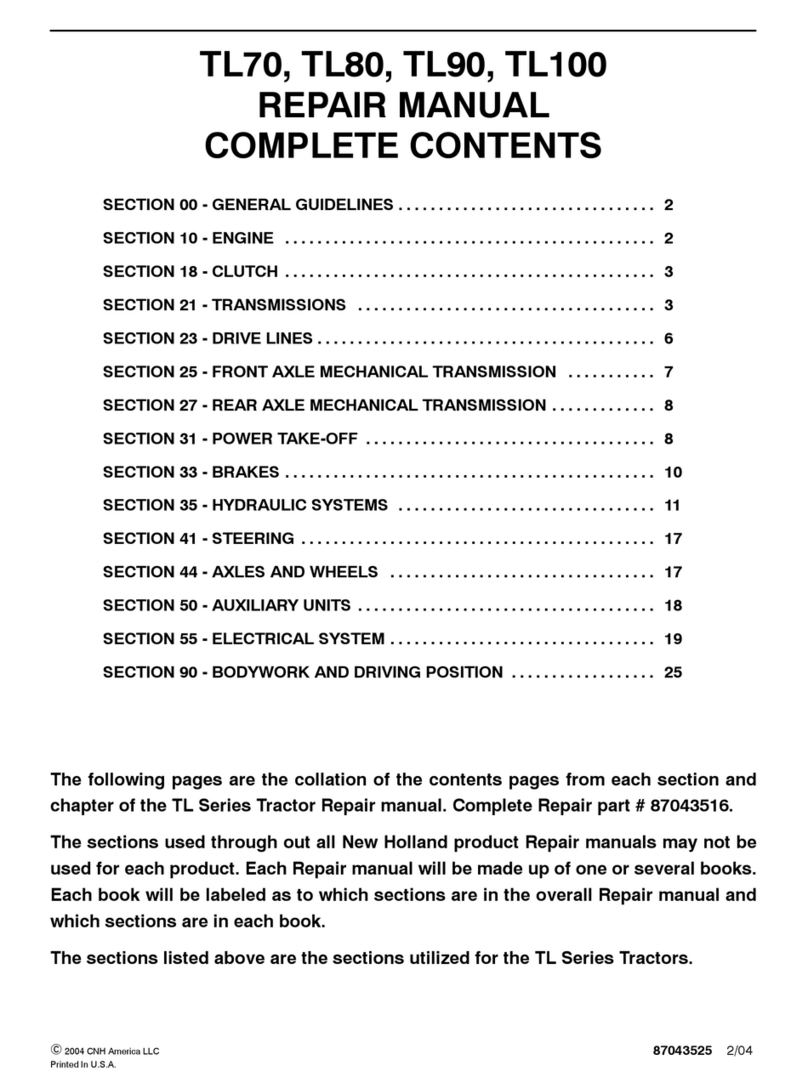

[35.000]Hydraulicsystems..................................................................35.1

[35.104]Fixeddisplacementpump..........................................................35.2

[35.204]Remotecontrolvalves.............................................................35.3

[35.300]Reservoir,cooler,andlters........................................................35.4

Steering.....................................................................................41

[41.200]Hydrauliccontrolcomponents......................................................41.1

[41.206]Pump...............................................................................41.2

[41.216]Cylinders...........................................................................41.3

Cabclimatecontrol.....................................................................50

[50.100]Heating.............................................................................50.1

[50.104]Ventilation..........................................................................50.2

[50.200]Airconditioning.....................................................................50.3

Electricalsystems.......................................................................55

[55.000]Electricalsystem...................................................................55.1

[55.024]Transmissioncontrolsystem.......................................................55.2

[55.100]Harnessesandconnectors.........................................................55.3

[55.201]Enginestartingsystem.............................................................55.4

[55.301]Alternator...........................................................................55.5

[55.302]Battery..............................................................................55.6

[55.404]Externallighting....................................................................55.7

[55.408]Warningindicators,alarms,andinstruments......................................55.8

[55.518]Wiperandwashersystem..........................................................55.9

[55.640]Electronicmodules...............................................................55.10

[55.DTC]FAULTCODES..................................................................55.11

Platform,cab,bodywork,anddecals.............................................90

[90.100]Enginehoodandpanels...........................................................90.1

[90.116]Fendersandguards................................................................90.2

[90.124]Pneumatically-adjustedoperatorseat..............................................90.3

4785194303/02/2016