7-2-2004 2 of 4 F-3978

2-7414

PARTS LIST - MOUNTING KIT

ITEM PART NO. DESCRIPTION QTY.

1 52371 BRACKET, Front Mounting 1

2 51864 CROSS TIE 1

3 51861 BRACKET, Midmounting, Right 1

4 51868 BRACKET, Midmounting, Left 1

5 42787-1 SPACER TUBE .75" 2

6 42787-7 SPACER TUBE .69" 2

7 42787-6 SPACER TUBE 2.69 2

8 41838-64 SCREW, Cap, 5/8-11 x 2-1/2 1

9 41838-29 SCREW, Cap, 5/8-11 x 1-1/2 1

10 41838-7 SCREW, Cap, 3/4-10 x 2-1/2 4

11 41840-8 NUT, Lock, 3/4-10 4

12 52374 YOKE 1

13 39240 DECAL, Do not tow ... 2

14 41838-79 SCREW, Cap, 5/8-11 x 2-3/4 1

15 41838-27 SCREW, Cap, 5/8-11 x 2 10

16 41838-14 SCREW, Cap, 5/8-11 x 2-1/4 2

17 41838-32 SCREW, Cap, 5/8-11 x 1-3/4 5

18 41837-7 WASHER, Lock, 5/8 18

19 42502-12 WASHER, Flat, 5/8 8

20 41840-7 NUT, Lock, 5/8-11 4

21 41838-78 SCREW, Cap, 5/8-11 x 4-1/4 2

INSTALLING LOADER TO MOUNTING

BRACKETS

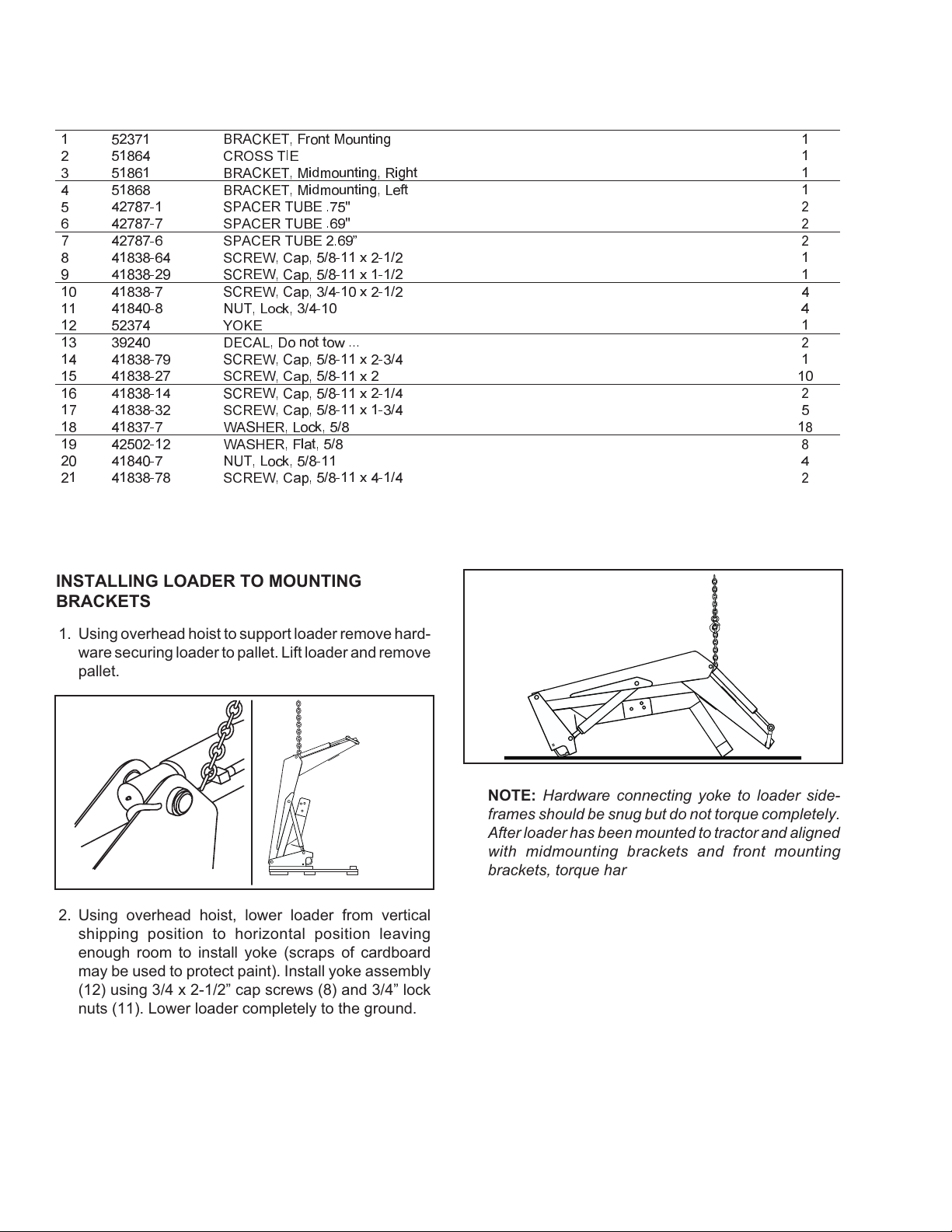

1. Using overhead hoist to support loader remove hard-

ware securing loader to pallet. Lift loader and remove

pallet.

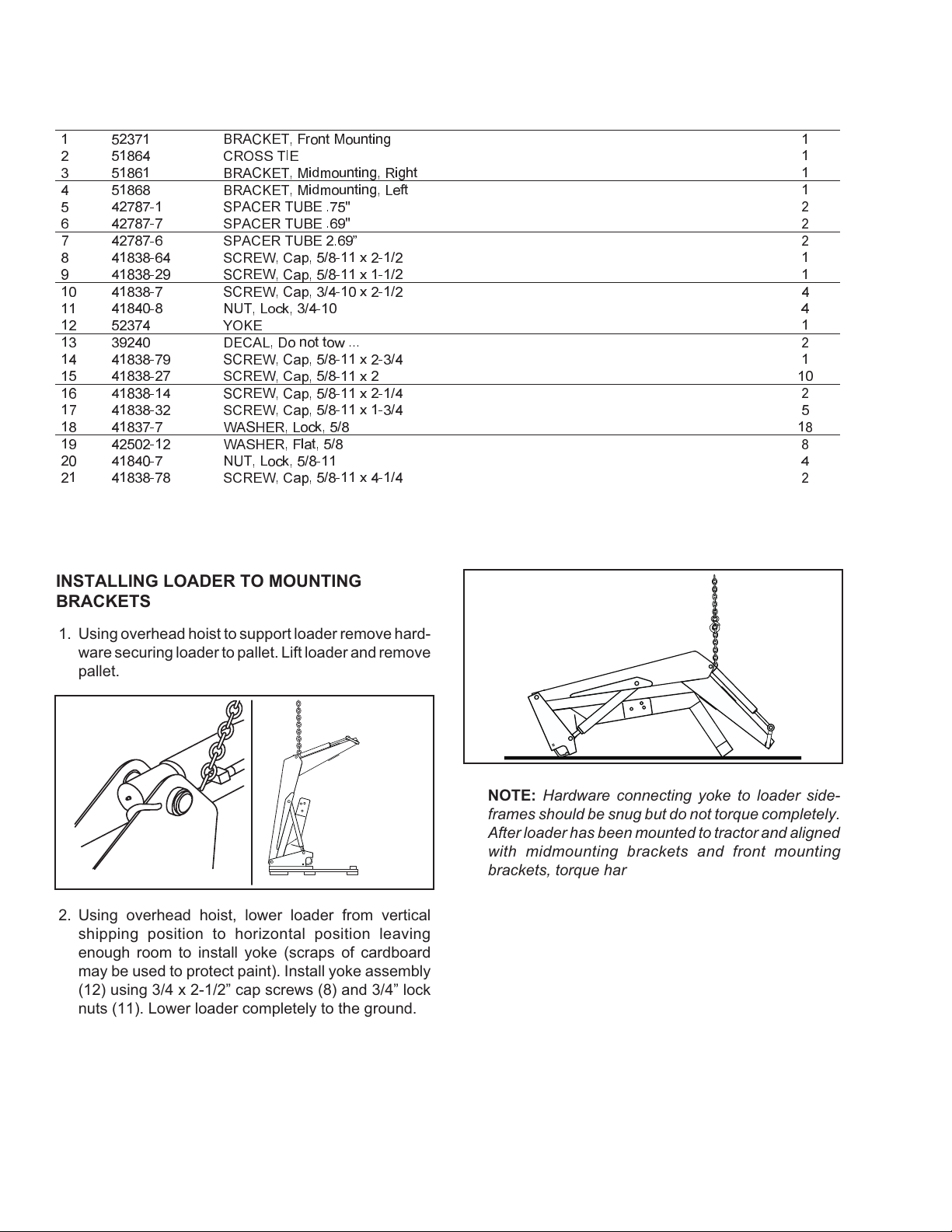

2. Using overhead hoist, lower loader from vertical

shipping position to horizontal position leaving

enough room to install yoke (scraps of cardboard

may be used to protect paint). Install yoke assembly

(12) using 3/4 x 2-1/2” cap screws (8) and 3/4” lock

nuts (11). Lower loader completely to the ground.

NOTE: Hardware connecting yoke to loader side-

frames should be snug but do not torque completely.

After loader has been mounted to tractor and aligned

with midmounting brackets and front mounting

brackets, torque hardware to 239-262 ft. lb.

3. Install hose or valve kit to tractor and loader. Refer to

assembly manual provided for installation instruc-