Model 923 Data Logger –User Manual

Focal Technologies Corporation Page iii

A Moog Inc. Company Document No: 923-0603-01, Rev. 2

TABLE OF CONTENTS

1.0 Introduction........................................................................................................................................... 1-1

2.0 Specifications....................................................................................................................................... 2-1

3.0 Product Description............................................................................................................................. 3-1

3.1 Configuration Settings and Initial User Setup............................................................................... 3-2

3.1.1 Configuration Settings ..................................................................................................... 3-2

3.1.2 Initial User Setup ............................................................................................................. 3-3

3.2 Data Logging ................................................................................................................................ 3-3

3.3 Real Time Clock (RTC) ................................................................................................................ 3-3

3.4 On-Board Sensors........................................................................................................................ 3-4

3.4.1 Temperature and Humidity Sensor ................................................................................. 3-4

3.4.2 3-Axis Accelerometer Sensor (Shock and Vibration)...................................................... 3-4

3.4.3 Ambient Light Sensor ...................................................................................................... 3-4

3.4.4 Rotation Sensor (Turns Counter and Speed).................................................................. 3-4

3.5 Interfaces...................................................................................................................................... 3-5

3.5.1 Thermocouple Inputs....................................................................................................... 3-5

3.5.2 Analog Inputs................................................................................................................... 3-5

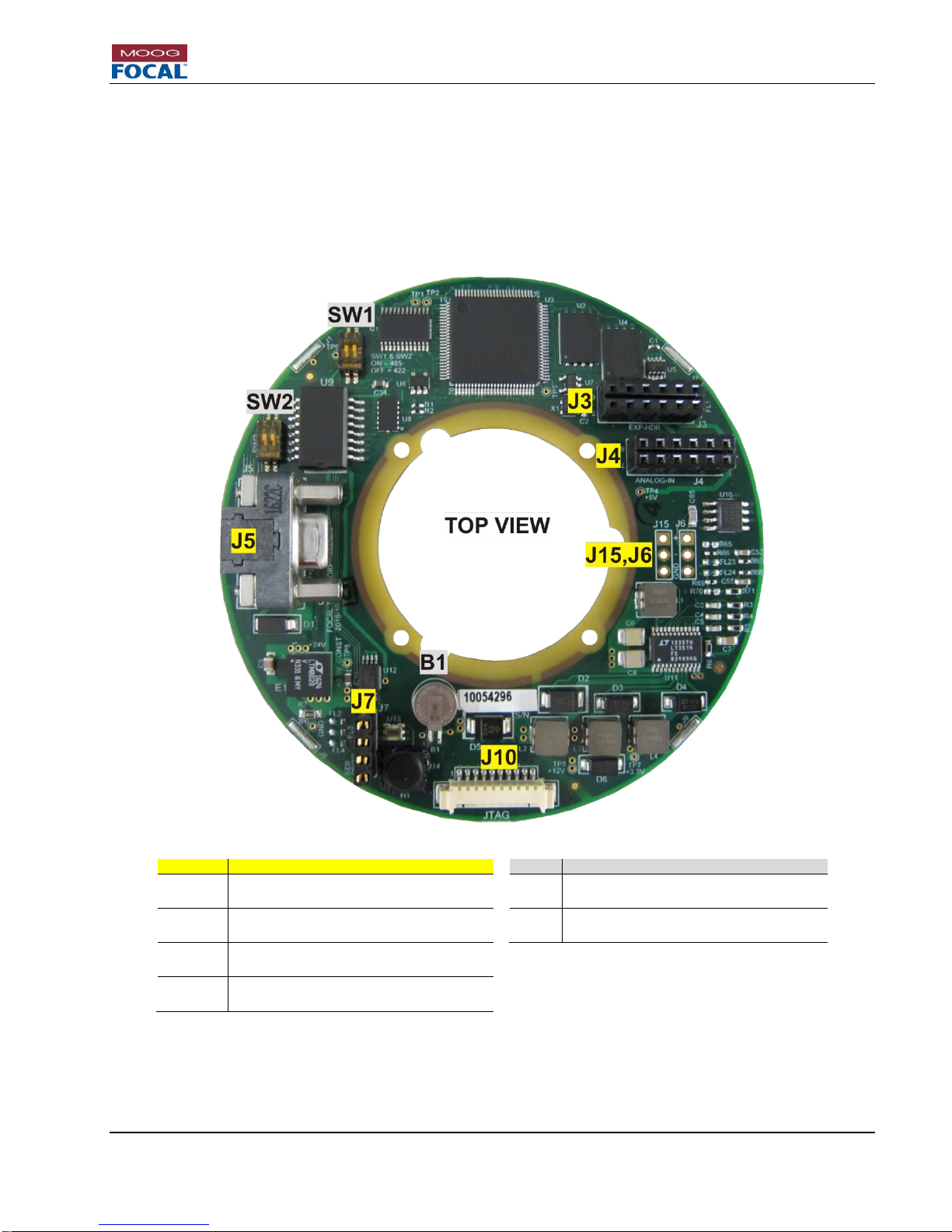

4.0 Hardware............................................................................................................................................... 4-1

4.1 General Board Handling............................................................................................................... 4-1

5.0 Electrical Connectors and Pin Descriptions ..................................................................................... 5-1

5.1 9-pin Micro-D Power and Data Connector (J5) ............................................................................ 5-1

5.2 Thermocouple Input Connectors (J6, J15)................................................................................... 5-1

5.3 12-Pin Analog Input Connector (J4)............................................................................................. 5-2

6.0 Functionality......................................................................................................................................... 6-1

6.1 Serial Diagnostic Interface............................................................................................................ 6-1

6.1.1 Modbus RTU ................................................................................................................... 6-1

6.2 Diagnostics Software.................................................................................................................... 6-2

6.2.1 Overview.......................................................................................................................... 6-2

6.2.2 Installation........................................................................................................................ 6-3

6.2.3 Application Usage............................................................................................................ 6-3

6.2.4 Special Features.............................................................................................................. 6-5

7.0 Register Maps....................................................................................................................................... 7-1

7.1 Modbus RTU Register Map.......................................................................................................... 7-1

7.1.1 On-board Sensor Registers............................................................................................. 7-4

7.1.2 Sensor Data Conversion ................................................................................................. 7-5