Fogazzo 755 Service manual

Model 755

Wood Fired Oven Kit

INSTALLATION INSTRUCTIONS

&

OWNER’S MANUAL

®

Manufacturing, import, export, and distribution of wood fired ovens, barbecues, fireplaces and, related accessories.

USA Headquarters

114 East Saint Joseph Street

Arcadia CA 91006

Toll Free 1- 66-FOGAZZO (364-2996) Website: www.fogazzo.com Email: [email protected]m

Model 755Wood Fired Oven Kit

Conception and industrial design: Sergio de Paula

United States Patent # USD642 55

Model 755 Installation Instructions and Owner’s Manual

Editor: Sergio de Paula

Illustrations: SDP&A and Sergio de Paula

Photography: Renata Mancini and Sergio de Paula

Recipes from: Mancini Family and De Paula Family

ote:

All information contained herein, is based on information which was available at the time of publication. Fogazzo reserves the

right to make changes as deemed necessary at any time and, without notice.

Important:

heck with the local building authority and or the fire department having jurisdiction over your project, for all construction and

permit requirements, and or use approvals, prior to the start of your installation.

Warranty:

A copy of the Fogazzo Five-Year Limited Warranty for the Model 655, is found on the last page of this manual, and is also

posted on the world wide web at: http://www.fogazzo.com/warranty.html.

EPA, UL, FPA, and SF Certification

The product listed in this installation manual, when installed in accordance to the instructions contained herein, has been fully

tested and certified to meet the

UL737 and the UL2162 standards. Additionally, it has been verified to conform to the

NSF/ANSI-4 and ANSI-Z83.11a standards

, and the NFPA lassification of a “Prefabricated Fire hamber Assembly”.

EPA certification has been applied for and granted, a copy of which will be available at the www.epa.gov website by mid 2013.

Venting:

The oven listed in this installation manual, is recommended by Fogazzo to be vented though a 5” or 6” internal diameter,

UL103HT standard listed, double wall chimney pipe system, to a minimal total length of 36 inches of pipe, and be terminated,

with a chimney cap containing a UL approved spark arrestor screen. Please check local codes, applicable to the specifics of

your particular installation.

Clearances:

The oven shall be installed to a minimum clearance of 6” (six inches) to combustible materials.

Declaration of Conformity

Fogazzo hereby declares that these products are in conformity with the following standards and directives of the EEC

Model 755

89/106 EEC

Construction Products Directive

93/68/EEC

EC Marking Directive

The construction files for this product are held by Fogazzo

(the manufacturer) and would be available for inspection

by a national authority, upon request.

Signed by 21, October, 2013

For Fogazzo Wood Fired Ovens and Barbecues, LLC

®

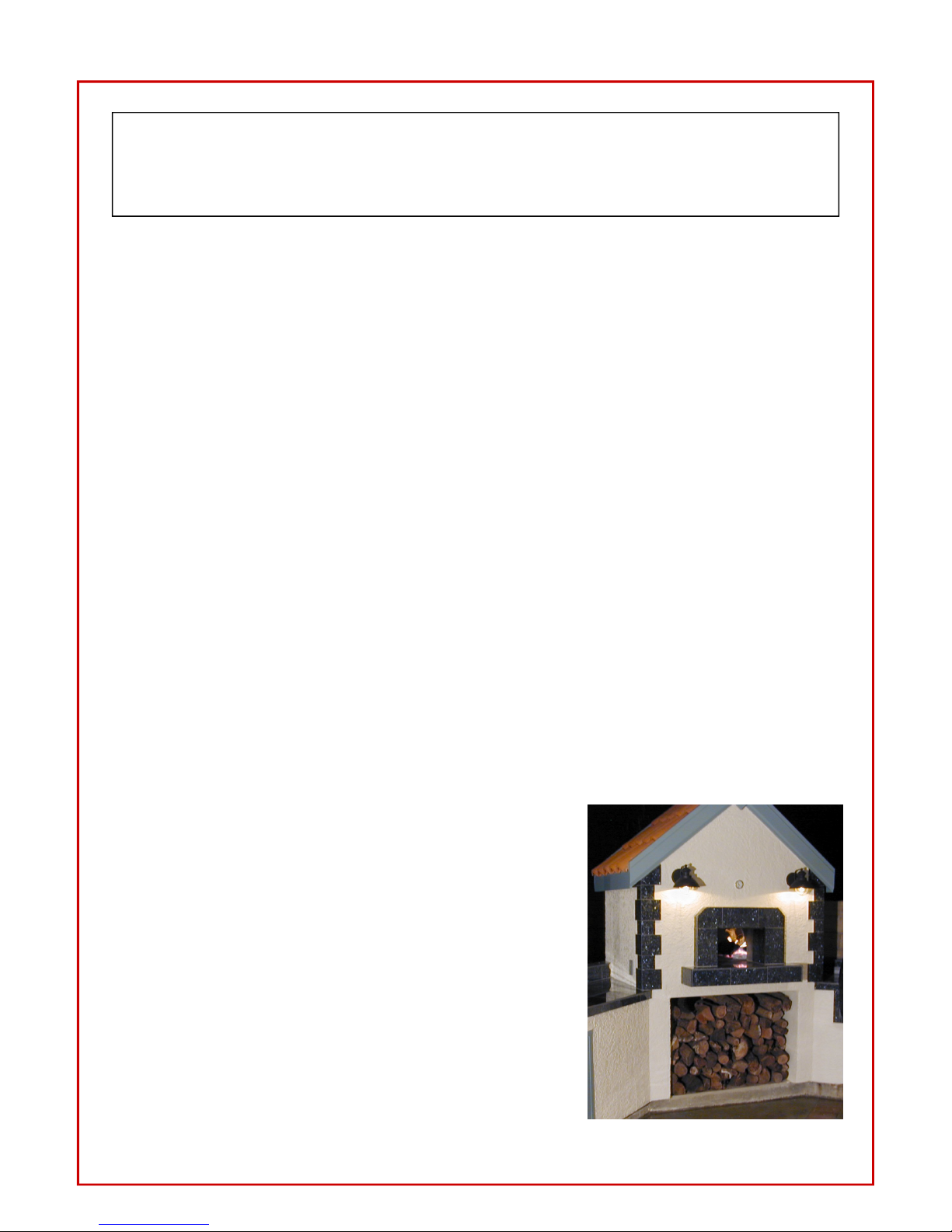

Thank you for choosing a Fogazzo Wood Fired Oven Kit.

The “Treasure Chest” series of wood fired ovens, is the result of ore than three decades of

work and study in the field of wood fired oven design, construction, and use. I used this acquired

knowledge to design a series of wood fired oven kits, that could be built quickly, at a low cost, and

with little or no chance for istakes or delays. If the directions are followed, the design is truly

foolproof and it resolves any of the flaws which I believe plague any existing oven designs.

This book contains valuable infor ation on how to properly install, operate, and aintain

your new oven. Please read all instructions carefully, and plan your installation well ahead of

ti e, to ensure the ti ely co pletion of your project. The installation is designed for professionals

with full knowledge of construction practices or, for well infor ed DIYers. If you are unsure of

any aspect of this installation, please consult Fogazzo toll free at 1-866-FOGAZZO or a qualified

local contractor.

Every oven installation is unique because generally, the architectural ele ents of the ho e, is

what dictates the style and types of finishes the are used. The ai of this book at a ini u is to

show proper installation of the actual kit, and where needed, to convey known practices that are

considered essential for a good installation overall.

A well-insulated oven will perfor ore efficiently and therefore better. The concrete shelf is

designed to support the oven and to aid in heat retention. Mini al cracking inside any wood fired

oven is expected and, is a characteristic of any cast refractory product. All the supplied insulation

aterials are the ini u s to aintain efficiency, any additional insulation should be ade fro

safe, non-fla able, readily available aterials. Please follow the precautions listed for each

product.

Following the guidelines contained herein, will ini ize proble s or delays and, will ensure

that your Fogazzo Treasure Chest Wood Fired Oven Kit, will last a lifeti e. Upon co pletion of

the oven kit installation, it is also critical to carefully follow all the initial firing guidelines, which

will aid in the proper curing of your new oven.

Please follow the directions carefully and be patient, your patience will surely be rewarded.

Cheers,

Sergio de Paula

President

®

Model 755 Installation Instructions and Owner’s Manual © 2013 Fogazzo Wood Fired Ovens and Barbecues, LLC All Rights Reserved

TABLE OF CONTENTS

· Precautions 1

· Kit Contents 2

· Materials List 2

· Exploded view 3

· Oven Kit Dimensions 4-5

· Before you begin / Schedule summary / Plan View 6

· Foundation & Floor Slab 7

· Masonry Construction 7

· Concrete Shelf 7

· Oven Pre-assembly/Final Assembly 8-9

· Oven Enclosure 11

· Chimney & Insulation 11

· Roofing and Exterior Finishes 11

· Curing & Initial Firing 12

· Resources 12

· Oven Basics 13

· Starting Your Oven 14

· Firewood 15

· Dough Recipes 16-17

· Pizza Making Basics 18

· Pizza Making Step By Step 19-21

· Grilling-Roasting-Baking 22

· Fogazzo Limited Warranty 23

Model 755 Installation Instructions and Owner’s Manual © 2013 Fogazzo Wood Fired Ovens and Barbecues, LLC All Rights Reserved

DO NOT THROW THIS MANUAL AWAY

PLEASE RETAIN THIS MANUAL FOR FUTURE REFERENCE!

IF YOUR OVEN IS NOT PROPERLY INSTALLED A FIRE MAY RESULT TO REDUCE

THE RISK OF FIRE, FOLLOW THESE INSTALLATION INSTRUCTIONS AND ALL

LOCAL BUILDING AND FIRE CODE REQUIREMENTS CAREFULLY

FOR YOUR SAFETY

Wood fired ovens must be vented using Class A chimney systems, installed in accordance

with all relevant Local and National Codes The installation and use of these class A chimney

components must be also be in accordance with the manufacturers installation instructions

THE USE OF WOOD FIRED OVENS, GENERATES CREOSOTE AND OTHER SUBSTANCES THAT

WILL ACCUMULATE IN IT’S CHIMNEY SYSTEM OVER TIME THE RATE OF ACCUMULATION

DEPENDS ON FACTORS SUCH AS: FREQUENCY OF USE, FIRE TEMPERATURE, THE WOOD TYPE

AND, ITS MOISTURE CONTENT THOROUGH FLUE AND CHIMNEY INSPECTION AND

CLEANING IS THE BEST WAY TO MINIMIZE THE RISK OF CHIMNEY FIRES

Chimney System Maintenance and Creosote Problems

When organic materials such as wood is burned in an oven, volatile gases and vapors are

produced These gases and vapors are carried up the chimney and, some may condense on

its surface, forming creosote Chimney creosote is combustible and, if not removed from the

inside of the chimney, may cause chimney fires Chimney fires are very hazardous because of

their high temperatures which can cause structural damage to the chimney and can ignite

nearby combustible materials

Creosote is produced when any type of wood is burned Because of their higher extractive

content, certain species have more potential than others for producing creosote, but the

amount of creosote depends more on the type of fire and the temperature of the chimney

surface A smoldering, low temperature fire will produce more creosote than a roaring, high

temperature fire, because the hotter fire burns more of the condensable gases More creo-

sote will condense on a cool chimney surface than on a warm surface More creosote is also

produced when wet wood is burned because of the lower temperature of the fire and a less

complete combustion

Creosote problems can be minimized by:

(1) Burning only well seasoned, thoroughly air-dried wood

(2) Making small hot fires instead of large smoldering fires and, keeping the oven door open

(3) Inspecting and cleaning the chimney as needed frequently

Please refer to the chimney manufacturer’s instructions for cleaning and maintenance

FOGAZZO RECOMMENDS THAT YOU SUBMIT YOUR CHIMNEY PLANS TO THE AUTHORITY HAVING

JURISDICTION BEFORE PROCEEDING WITH INSTALLATION OF ANY WOOD BURNING APPLIANCE

Information on installation and or maintenance is available from

Fogazzo, toll free at 1-866-364-2996 It is recommended that this

oven be installed, and maintained by qualified professionals

Model 755 Installation Instructions and Owner’s Manual © 2013 Fogazzo Wood Fired Ovens & BBQs, LLC All Rights Reserved 1

Model 755

Wood Fired Oven Kit

Installation Instructions

®

2

Kit Contents

24 ea Refractory floor bricks

1 ea Front wall precast

1 ea Apron precast

1 ea Hood/flue precast

2 ea Side walls, precast

1 ea Rear wall precast

3 ea Domes precast

1 ea Steel oven door

1 ea Bucket refractory mortar

Insulation Materials

24 sq ft 2” Insulation blanket

12 sq ft Rigid insulation board

Printed Materials

1 ea Installation Instructions

1 ea Warranty

Installation Instructions Toll Free Help 1-866-FOGAZZO

Order Model 755

accessories at

WWW FOGAZZO COM

Materials List

Your oven kit does not include anything not listed in the kit contents above The following materials

list is provided for your convenience only Your materials list will vary based on your particular needs

Foundation and slab

Stakes and forms

1500 psi or higher strength concrete mix

#3 or #4 steel rebar

Walls and support shelf

Forms

6x8x16” masonry blocks (CMU)

Masonry mortar (Type S)

1500 psi or higher strength concrete mix

Roof

Non-flammable roofing material

Chimney (not included in the oven Kit)

1 each Duratech® #9341

Anchor plate for 5” pipe

1 each Duratech® double wall chimney

Pipe (exact length will depend

on individual installation needs)

1 each Duratech® #9384 chimney cap

with spark arrestor

1 each Tube high temperature calking

Order your Duratech® components by calling toll free

1-(866) FOGAZZO or online at www fogazzo com

Duratech

®

#9341

Anchor plate for 5” pipe

Model 755 Installation Instructions and Owner’s Manual © 2013 Fogazzo Wood Fired Ovens & BBQs, LLC All Rights Reserved

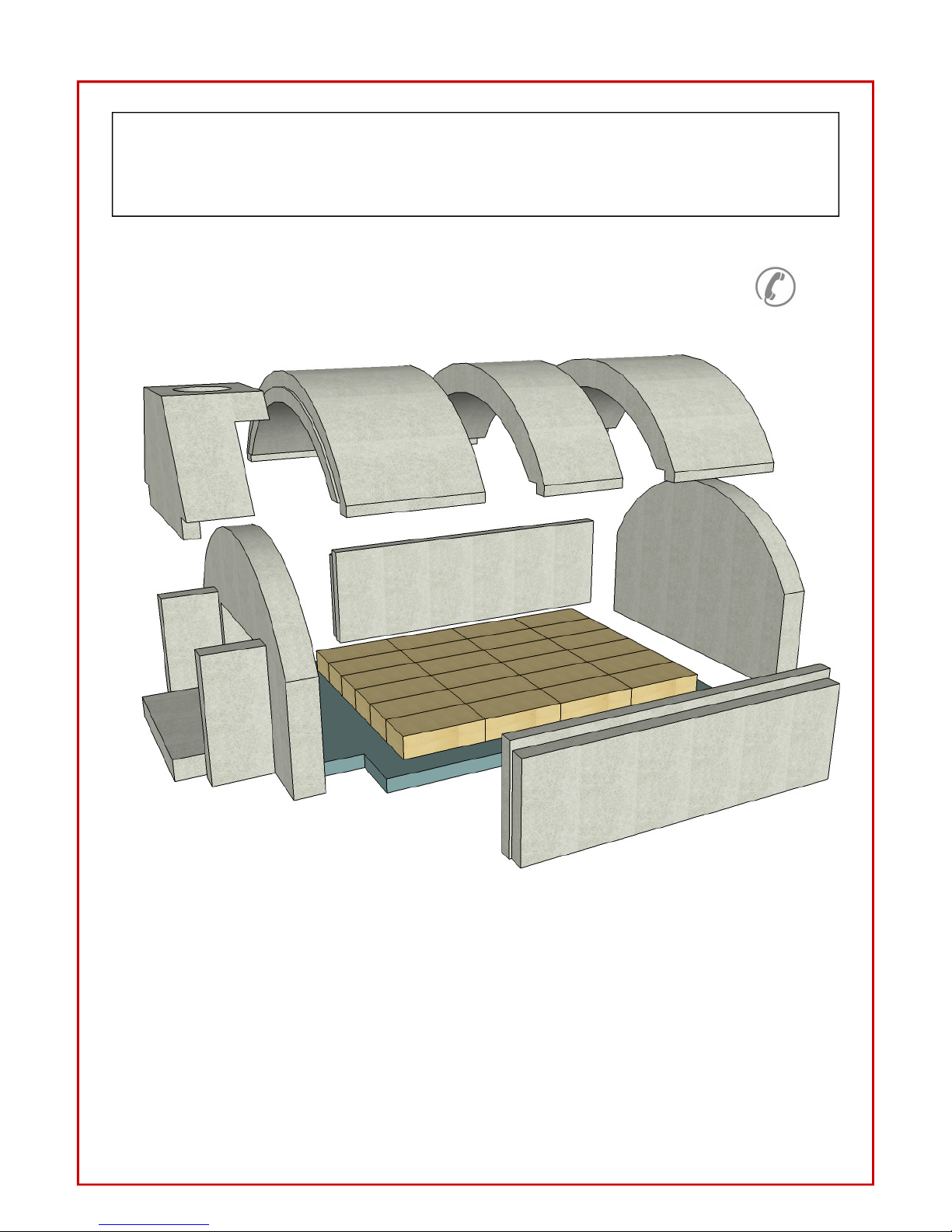

Exploded View

3

Flue Hood

Apron

Side Wall

Front Wall

Dome Front Dome Rear

Back Wall

Side Wall

Floor Bricks

Under Oven Insulation

The Fogazzo Model 755 wood fired oven kit is made up of 24 refractory bricks for the oven floor,

a front wall, an apron, two side walls, a rear wall, three hood pieces and a smoke chimney

hood All of the precast parts are made using a proprietary mix of heavy duty, made in USA

refractory materials, with a high content of alumina Our mix is designed to withstand a working

temperature of 2300 degrees Fahrenheit which is much higher than temperatures the oven will

ever encounter, of around 1000 degrees Fahrenheit

Installation Instructions Toll Free Help 1-866-FOGAZZO

Model 755 Installation Instructions and Owner’s Manual © 2013 Fogazzo Wood Fired Ovens & BBQs, LLC All Rights Reserved

Dome Front

42” Model 755

Kit Dimensions

11 5”

10”

9” 9”

23 5”

12”

17”

9”

21”

6”

6”

11 5”

10”

9”

23 5”

17”

9”

21 5”

33”

4 Model 755 Installation Instructions and Owner’s Manual © 2013 Fogazzo Wood Fired Ovens & BBQs, LLC All Rights Reserved

Before you begin

Schedule summary

Plan View

Before you begin

Review your plans carefully Be sure to order

any items which may hold up your schedule

well ahead of the start of construction Allow

for sufficient time for each concrete pour to

cure

Schedule summary:

Pre-construction:

Order oven kit

Order chimney system

Order construction materials

Order finish materials

Construction

Build foundation and base

Form and pour shelf

Assemble and grout oven

Install ceramic fiber blanket

Build surround

Fill oven cavity with vermiculite

Roof enclosure

Install finish on walls

Install finish around door

Post-Construction

Allow 72 hours after installation for curing

Initial firing of oven Follow the initial firing and

curing instructions

5

Installation Instructions Toll Free Help 1-866-FOGAZZO

Model 755 Installation Instructions and Owner’s Manual © 2013 Fogazzo Wood Fired Ovens & BBQs, LLC All Rights Reserved

Foundation and floor slab

Masonry Construction

Concrete Shelf

Foundation and floor slab

(Please follow local code if different)

Dig a 48” wide by 62” front to back, to a depth

of 12 inches Set forms around the perimeter

using 2x4 or 2x6 material held in place by

stakes Place a rebar grid using #4 rebar at 12”

on center in both directions Place rebar dow-

els for masonry at 12 to 16” on center to a

height of 24 to 36”

Pour foundation and floor slab (minimal 4

inches) as a monolith, using 1500lbs psi or

higher concrete mix with 3/8” or greater rock

Concrete can be transit mix and pumped from

truck or mixed on site Varieties of pre-mixed

concrete are readily available at local home

centers with cured strength ratings as high as

55 lbs psi Follow mixing instructions and pre-

cautions on bag

Walls (first lift)

Erect three walls (two sides and back) using

CMU (concrete blocks), these are available in

most home centers or construction yards Build

to a height of 40” to 42” above finished floor

Allow sufficient time to dry and grout when fea-

sible Place dowels into grout to re-enforce the

concrete shelf as shown on Fig 2

Concrete shelf

Form for concrete shelf using 2x4 material and

plywood The bottom of the shelf should be at

38” up from the finished floor Install #4 rebar

grid 12” on center in both directions and dow-

els for oven enclosure (as needed) shown on

Fig 2 Pour shelf (3 5 to 6”) using 1500 lbs psi or

higher concrete mix with 3/8” to 3/4” aggre-

gate Allow this to dry at least 24 hours Do not

remove the forms for 3 to 14 days as they

should not otherwise impede progress of the

job

Fig 2

First

lift

#4 Rebar dowels

Slab on grade 4” min.

#4 rebar

Footing 12x12” min.

Fig 1

Fig 2

Concrete Shelf

#4 rebar

re-enforcing tying

walls to and shelf

to enclos re

6

Installation Instructions Toll Free Help 1-866-FOGAZZO

Model 755 Installation Instructions and Owner’s Manual © 2013 Fogazzo Wood Fired Ovens & BBQs, LLC All Rights Reserved

Oven Pre-assembly

Oven Final Assembly

Notes

Oven Pre-assembly

All our products are hand-made, as such, small

imperfections are a known characteristic In order to

achieve the best overall fit, care must be taken in

the assembly of the kit

Always check the fit during oven assembly!

Choose the best side of each floor bricks based

on it’s location in the oven Chipped sides, corners,

edges, etc, should always go where the blemish will

not be seen Chips on the oven floor can be placed

face down or where the side wall will cover it

Check the fit for each piece, to ensure the best fit

for each part Make any necessary adjustments to

the pieces to provide the best fit

Note: Small differences on the exterior of the oven,

can be made up with the finish materials

Oven Final Assembly

The mortar for setting the oven parts is in the small

white bucket

Mix mortar using clean water to the consistency of

peanut butter Do not use any add-mixes Mix only

what can be used in 15 minutes at a time

Notes:

- Front of oven should be 2 inches back from the

front edge of the support shelf

- Ensure the best fit on walls and dome, so that little

or no mortar shows through the oven interior

- DO NOT RETEMPER THE MORTAR, AFTER 15 MINUTES

DISCARD ANY UNSUSED MORTAR AND MIX A NEW

BATCH AS NEEDED

Fig 3

7

Installation Instructions Toll Free Help 1-866-FOGAZZO

Model 755 Installation Instructions and Owner’s Manual © 2013 Fogazzo Wood Fired Ovens & BBQs, LLC All Rights Reserved

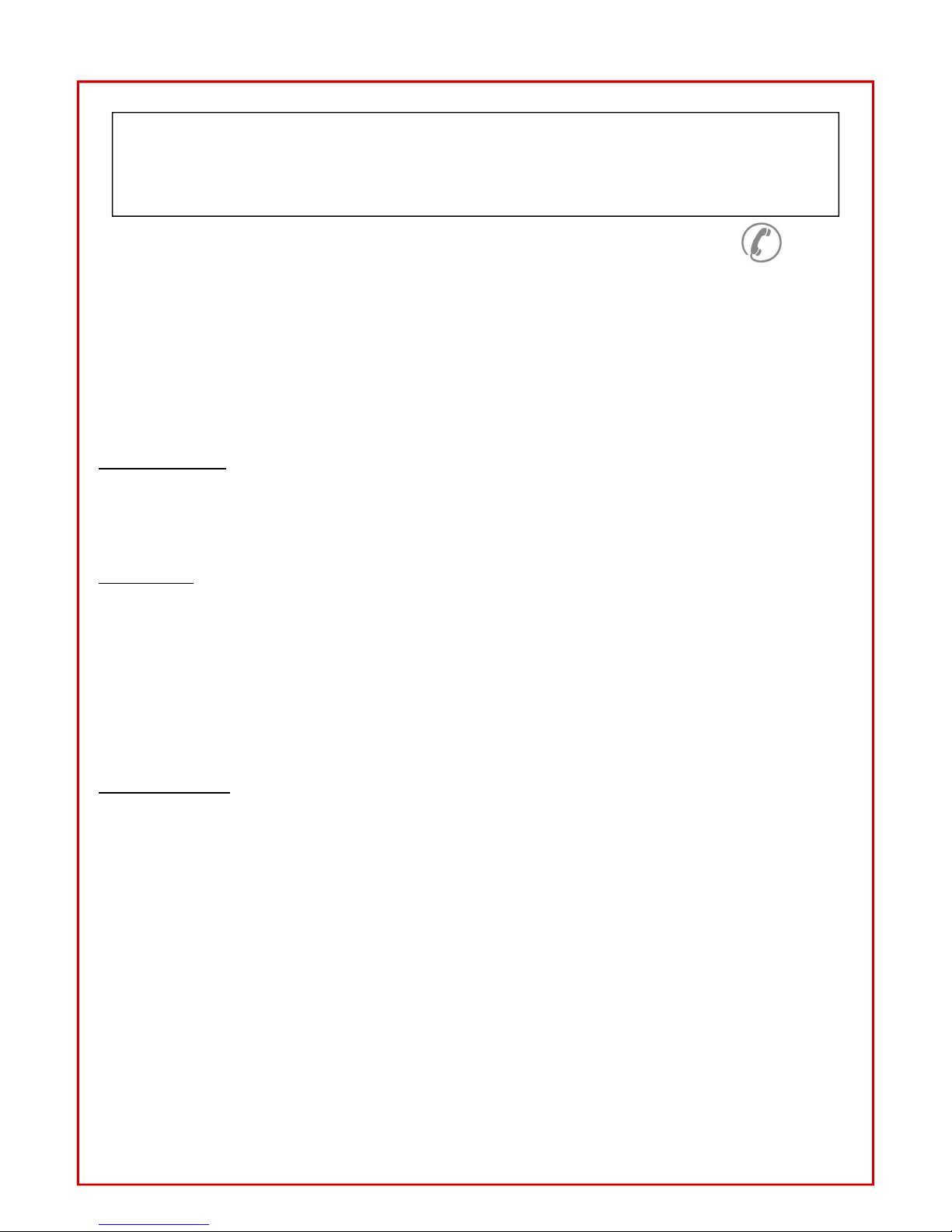

1 Place the short side of your insulation boards to

the front, centered on the support shelf You may

trim the board as shown above at the beginning or

later Measure 11” back from the front edge and

draw a line Install your floor bricks starting at this line

Be sure to look for the best side of the brick to be

facing up and put any chipped edges facing down

or along the left or right edges where the walls will

cover them All floor bricks are laid dry, without the

need to use mortar, at all

2 Next set your back wall, side walls and front wall

using mortar to set the pieces Do not mortar under

the front or back walls, only where the side walls sit

over the bricks for the oven floor and, on the joints

between the pieces, i e side walls to front and back

walls, etc The front apron will need tall globs of mor-

tar in order to level it to the height of the oven floor

3 Clean the mortar from all the inside joints of the

oven using a sponge

4 Clean the mortar from all the outside joints of the

oven using a sponge

Oven Final Assembly

8

Installation Instructions Toll Free Help 1-866-FOGAZZO

Model 755 Installation Instructions and Owner’s Manual © 2013 Fogazzo Wood Fired Ovens & BBQs, LLC All Rights Reserved

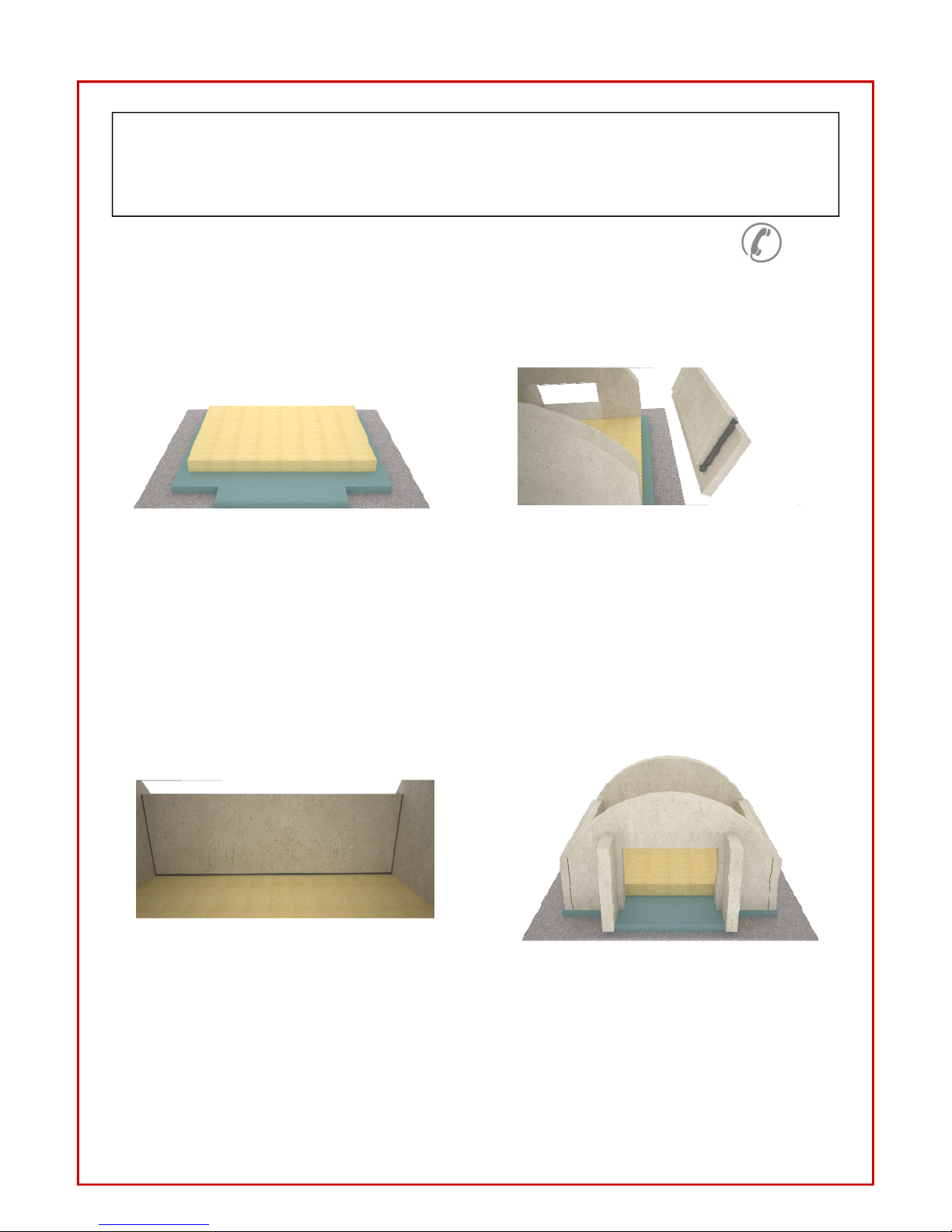

Oven Final Assembly

5 Clean the mortar from all the outside joints of the

oven using a sponge

6 Next place your rear and front dome pieces

Place mortar over the rear wall, set rear dome piece,

clean mortar from the inside at the top of the rear

wall joint, and any mortar that falls on the floor Next

place mortar over the front wall and set the dome

front, again cleaning the joint and oven floor as

needed Last, fill the gap between rear and front

domes from the outside of the oven only This joint is

meant to be filled after the dome pieces are in

place and from the outside only

7 Lastly, set your flue/hood by placing a bead of

mortar at either side of the door and over the front

wall Level the flue/hood and clean any of the excess

mortar as needed for a clean joint Fill around where

the flue/hood meets the dome as needed for a solid

finish

8 Clean the mortar from all the outside joints of the

oven using a sponge

9

Installation Instructions Toll Free Help 1-866-FOGAZZO

Model 755 Installation Instructions and Owner’s Manual © 2013 Fogazzo Wood Fired Ovens & BBQs, LLC All Rights Reserved

Oven Enclosure

Chimney & Insulation

Oven Enclosure

Enclose oven using CMU block masonry or light

gauge metal studs and track with cement

backer board

Chimney

Set your chimney anchor plate, Duratech

#9441 using high temperature caulking You

can also use concrete screws Drill for fasteners

following the manufacturers directions You

must be very careful not to damage the flue

You must use high temperature (550˚F) caulk or

other suitable sealer between anchor plate

and flue to seal it tight against air leaks Next

set a section of Duratech pipe The chimney

length dictates airflow in the oven We recom-

mend a minimal of 36” of pipe to ensure proper

air flow Set your cap with spark arrestor Du-

ratech # 9484 to complete the chimney

Insulation

After oven has dried a minimal of 48 hours,

cover it with the 2” ceramic blanket You can

use wire or metal lath to hold it in place After

exterior walls are built, place vermiculite gran-

ules 6” above the dome of the oven or to

within 3 inches of the top of the enclosure

Additional Mass

The Model 755 is a well balanced oven that

was designed for everyday use, and it should

satisfy the needs of 90+% of our customers For

those who are heavy bread bakers, and we

mean baking a lot of bread, they may want to

consider adding additional mass Although this

may give them additional cooking time, they

will take longer to heat up, (3 hours or 4 hours

or more)

Note: Any additional mass is only necessary if

you intend to use your oven primarily for bread

baking You can bake bread in the Model 855

ovens with the same results, you will just have

less total time for baking, since it is a lighter

oven, balanced for everyday use, including

baking bread

Roofing and Exterior Finishes

Roof using non-flammable roofing materials

that conform to local building codes

10

Installation Instructions Toll Free Help 1-866-FOGAZZO

Model 755 Installation Instructions and Owner’s Manual © 2013 Fogazzo Wood Fired Ovens & BBQs, LLC All Rights Reserved

Oven Finishes

Cut-Away View

*Typical cut away view of oven installation using masonry construction

11

Installation Instructions Toll Free Help 1-866-FOGAZZO

Model 755 Installation Instructions and Owner’s Manual © 2013 Fogazzo Wood Fired Ovens & BBQs, LLC All Rights Reserved

Curing & Initial Firing

Oven Resources

Installation Instructions Toll Free Help Line 1-866-FOGAZZO

Curing

Allow the oven to cure a minimum of 3 days prior to

the initial firing (72 hours), so sufficient moisture can

evaporate from mortar etc

Initial Firing Procedures

Initial firing is the single most critical component in

completing a good installation Please follow these

instructions carefully to ensure proper operation of

your oven for many years to come

First firing - 4 to 9 hours

NOT TO EXCEED 225˚ FARENGHEIT

Use three 16oz cans of alcohol gel fuel (aka chaffing

dish fuel) Placed at the center of the oven, and

light them Keep oven door partially off The first cans

will burn for 4 to 4 5 hours Once first cans are empty,

light three more cans like the first These cans will

burn for 4 to 4 5 hours When these cans run out of

fuel, close the oven door and allow the oven to cool

down overnight

Caution: THE OVEN MAY STILL BE HOT!

You may now start to cook in your oven!

Please keep in mind that the oven is still tempering

Over the next few firings the performance charac-

teristics of your oven will improve gradually During

this break in period, caution should be taken to

gradually increase the heat with each fire for the first

5 to 6 times the oven is used After these first few fir-

ings your oven will become fully ready for normal

use!

Under normal operating conditions, small cracks will

develop due to the heating and cooling process

These small cracks are normal and will not effect the

performance or durability of your oven

Resources

Chimney / Venting products:

Fogazzo Toll free at 1-866-FOGAZZO or online at:

www fogazzo com

Gel Fuel, to start the oven the first time only!

Gel fuel is available at most sporting goods or res-

taurant supplies stores You can use any of the differ-

ent styles available What’s important is the amount

of time that they burn and, the temperature they

heat the oven up to The goal is to reach and main-

tain 200 degrees Fahrenheit in 4 hours

Non-toxic fire starters:

Fatwood

Available at most home centers or from Fogazzo

Weber Fire Starters

Available nationally at most home centers

Cans of chaffing

dish fuel in an oven,

during initial firing

procedure.

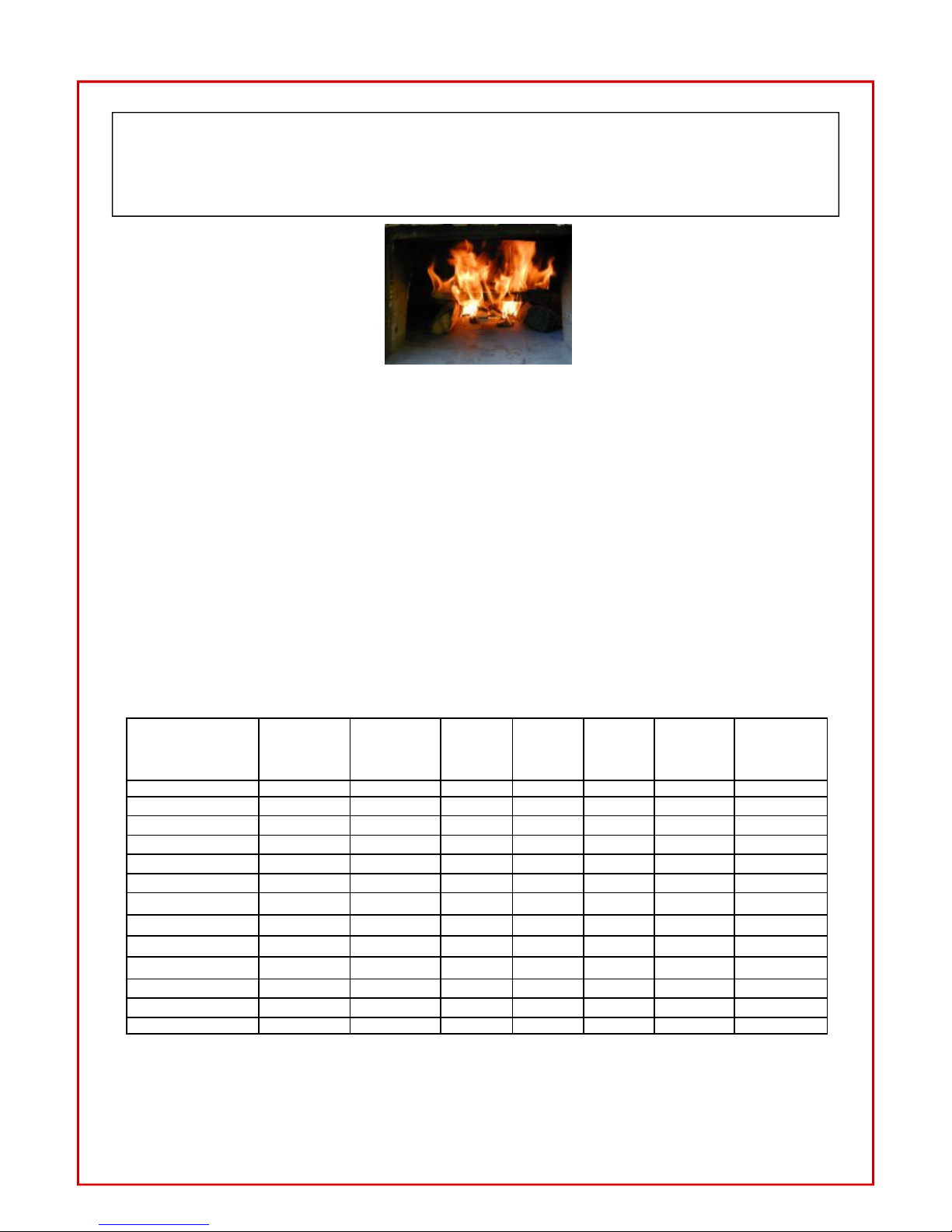

Second Firing - 5 hours

NOT TO EXCEED 500˚ FARENGHEIT

Use a non-toxic fire starter to light a small pile of fire-

wood, placed in the center of the oven Each piece

should be up to 8 inches long and 1 inch thick

Flames must not be allowed to reach the dome of

the oven Continue to maintain temperature by

adding 1 or 2 pieces of the same size of firewood

every 15 to 20 minutes for a total of 5 hours At the

end of the second firing, close the oven door, and

allow the oven to cool down overnight

Caution: THE OVEN MAY STILL BE HOT!

During the second

firing, small pieces of

firewood are used, to

take the oven to

higher temperatures

than in the first firing

The small fire is kept

at the center of the

oven floor, and the

flames should not

reach the top of the

dome’s interior

12 Model 755 Installation Instructions and Owner’s Manual © 2013 Fogazzo Wood Fired Ovens & BBQs, LLC All Rights Reserved

Oven Basics

“Even if you own the worlds greatest coffee maker, it cannot guarantee

that you will get the best cup of coffee in the world, on your first try”.

Cooking with real fire takes some getting used to, but don’t be afraid to experiment

Many recipes need adjustments, but will work well As a general rule, anything that a

conventional oven can do, a wood fired oven will do better

Most splattering from baking or roasting will burn off To avoid excessive splattering use

cookware that is suitable for the food you are cooking Wood fired ovens are very

low-maintenance If you spill something on the floor of the oven, just wait for it to burn

off If you want to expedite this process, move some coals over the spill Wait for it to

burn off and sweep with an oven safe brush

When you are through cooking Close oven door to help extinguish any coals that are

still burning Allow oven to cool down slowly or overnight Remove ashes using an ash

vacuum or oven safe brush

Always

• Allow 2 hours or more to bring your oven to temperature slowly

• Add wood in 15 to 30 minute intervals

• Add wood of similar size

• Keep oven closed when not in use

• Use safety gear to avoid injuries or burns

Never

• Leave a burning fire unattended

• Allow cold water to hit a hot oven

• Use tools that can chip or scrape your oven walls or floor

• Drag heavy cookware on the oven floor

• Add too much wood at once

• Throw wood against walls or floor

• Build a large fire inside your oven

• Dispose of hot coals in the trash

• Use liquid fuels such as gasoline to start an oven

13 Model 755 Installation Instructions and Owner’s Manual © 2013 Fogazzo Wood Fired Ovens & BBQs, LLC All Rights Reserved

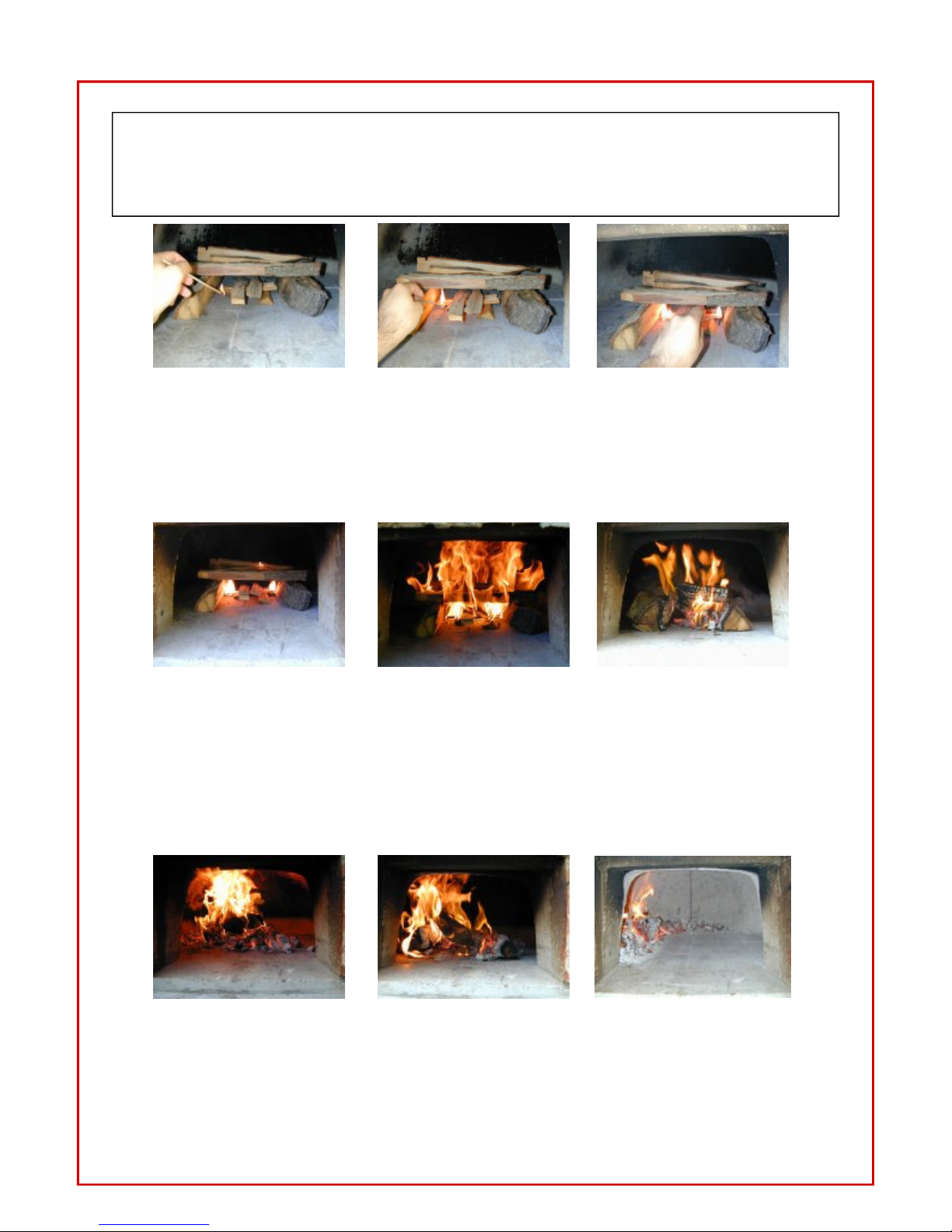

Use two medium size logs, one on the left and one on the right as props to hold up

smaller pieces of kindling across them Place a few pieces of kindling below per-

pendicular to the pieces above Add one or two pieces of “Fatwood” or other

nontoxic fire starter to this kindling Using fireplace matches or a fireplace lighter,

light the two pieces of “Fatwood”

After these pieces burn for about fifteen minutes, add a piece 3 to 4 inches thick

and 12 to 16 inches long over the top of the kindling parallel to the larger pieces

Add a similar size piece every 15 to 20 minutes for the next 90 to 120 minutes

After 90 to 120 minutes, the oven will have a nice size pile of coals right in the mid-

dle Move them to either the left or the right, sweep the smaller pieces straight

back and add a medium size piece of wood over the coals You are now ready to

cook Always keep a small piece of wood burning to provide a source of light in-

side the oven

Lighting your oven

14 Model 755 Installation Instructions and Owner’s Manual © 2013 Fogazzo Wood Fired Ovens & BBQs, LLC All Rights Reserved

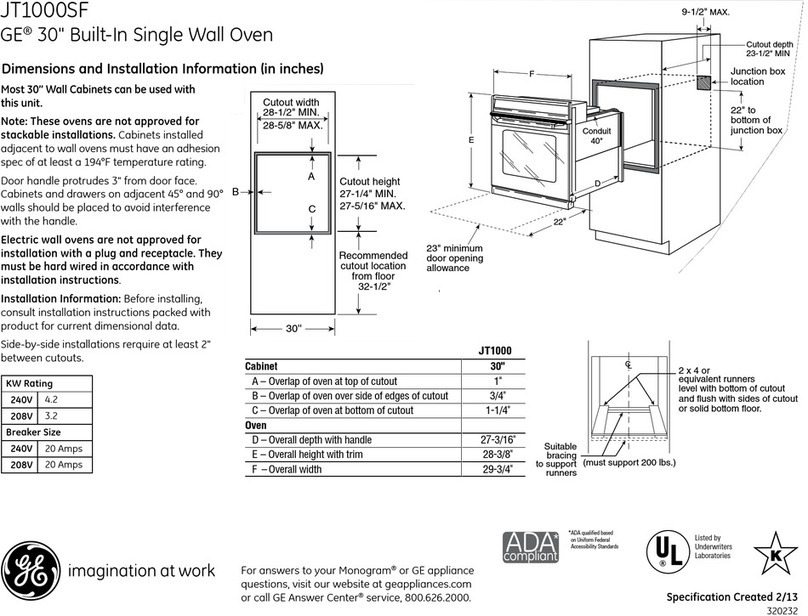

Firewood

Quality firewood is essential for the operation of your wood fired oven When buying fire-

wood it is important to get your money’s worth Cord sizes are regulated and so firewood

quantities must comply with industry standards The best way to be sure you are getting

what you are paying for is to measure your delivered firewood, which should be neatly

stacked

Quantities are as follows:

Full cord = 4’ x 4’ x 8’ = 128 cu ft

½ cord = 4’ x 4’ x 4’ =64 cu ft

¼ cord = 4’ x 4’ x 2’ =32 cu ft

Firewood should be split, seasoned, and ready to burn, cut to approximately 12 to 16 inches

in length and 2 to 4 inches in diameter The following table contains a list of firewood rec-

ommended for use in wood fired ovens and the qualities associated with each species The

Firewood BTU (British Thermal Units) is the amount of heat energy produced by different

types of wood when burned

Species Heat/ Cord

(1,000,000

BTU'S)

Ease of

Splitting

Smoke Sparks Coals Fragrance Overall

Quality

Almond 23 5 Medium Low Few Good Good Good

Apple 27 Medium Low Few Good Excellent Excellent

Ash, Green 20 Easy Low Few Good Slight Excellent

Ash, White 24 2 Medium Low Few Good Slight Excellent

Avocado 17 5 Medium Low Few Good Slight Good

Birch, Paper 20 8 Medium Medium Few Good Slight Fair

Cherry, Black 20 4 Easy Low Few Excellent Excellent Good

Hickory, Shagbark 27 5 Difficult Low Few Excellent Excellent Excellent

Maple, Other 25 5 Easy Low Few Excellent Good Excellent

Maple, Silver 19 Medium Low Few Excellent Good Fair

Oak, Bur 26 2 Easy Low Few Excellent Good Excellent

Oak, Red 24 6 Medium Low Few Excellent Good Excellent

Oak, White 29 1 Medium Low Few Excellent Good Excellent

15 Model 755 Installation Instructions and Owner’s Manual © 2013 Fogazzo Wood Fired Ovens & BBQs, LLC All Rights Reserved

Table of contents

Other Fogazzo Oven manuals

Popular Oven manuals by other brands

Zanussi

Zanussi ZBM973 Instruction booklet

GE

GE JT1000DFBB Dimensions and installation information

Fisher & Paykel

Fisher & Paykel Aerotech OB30SD installation instructions

Klugmann

Klugmann KO608TCP instruction manual

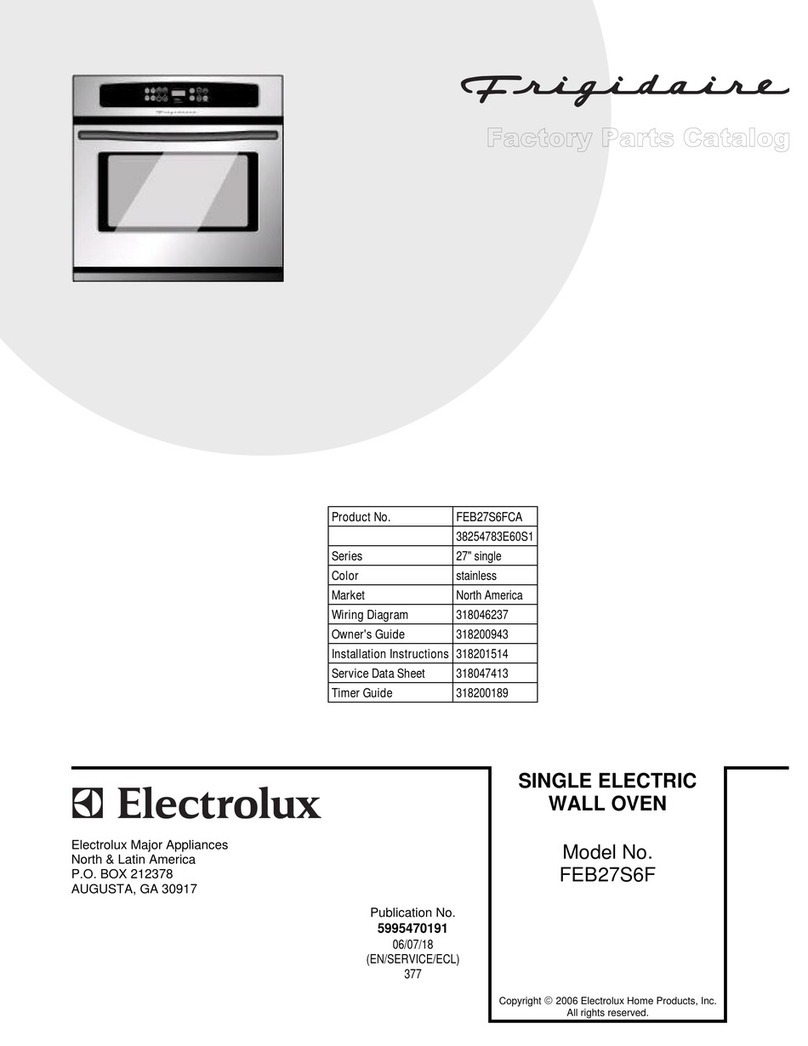

Frigidaire

Frigidaire FEB27S6F Factory parts catalog

Bosch

Bosch 8 Series installation instructions