Foley United ACCU-Pro 670 User manual

1

ACCU-Pro

MODEL 670

SEMI-AUTOMATIC

BEDKNIFE GRINDER

ASSEMBLY

AND

SERVICE

MANUAL

WARNING

You must thoroughly read and understand this

manual before assembling or maintaining the

equipment, paying particular attention to the

Warning & Safety instructions.

6707954(8-01)

2

SAFETY INSTRUCTIONS

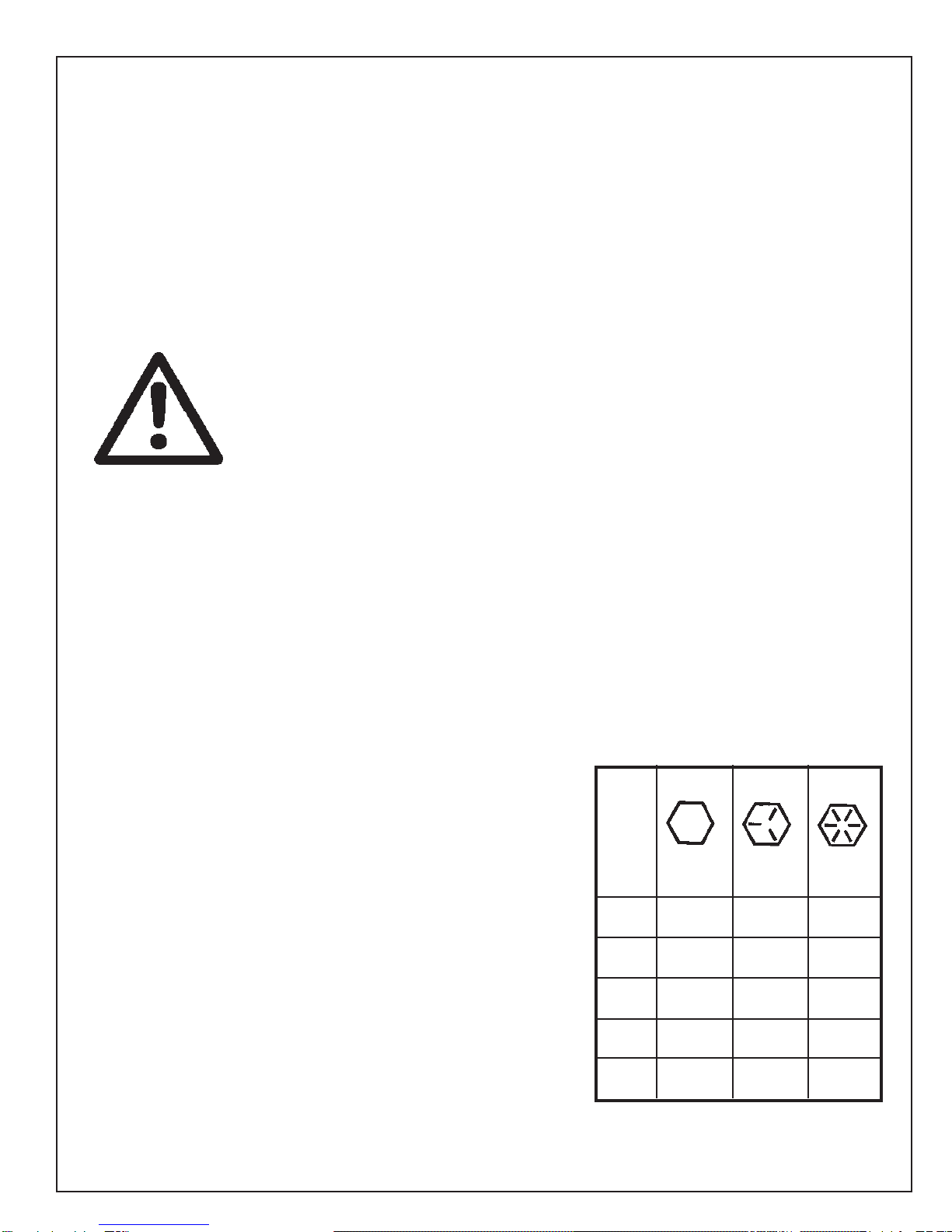

Safety Awareness Symbols

are inserted into this

manual to alert you to possible

Safety Hazards

.

Whenever you see these symbols, follow their

instructions.

The

Caution Symbol

identifies special instructions

or procedures which, if not correctly followed, could

result in damage to or destruction of equipment.

The

Warning Symbol

identifies special instructions

or procedures which, if not strictly observed, could

result in personal injury.

12. DON'T OVERREACH.

Keep proper footing and

balance at all times.

13. MAINTAIN GRINDER WITH CARE. Follow

instructions in Service Manual for lubrication and

preventive maintenance.

14. DISCONNECT POWER BEFORE SERVICING.

15. REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure the switch is OFF before

plugging in the Grinder.

16. USE RECOMMENDED ACCESSORIES. Consult

the manual for recommended accessories. Using

improper accessories may cause risk of personal

injury.

17. CHECK DAMAGED PARTS. A guard or other

part that is damaged or will not perform its

intended function should be properly repaired or

replaced.

18. KNOW YOUR EQUIPMENT. Read this manual

carefully. Learn its application and limitations as

well as specific potential hazards.

19. KEEP ALL SAFETY DECALS CLEAN AND

LEGIBLE. If safety decals become damaged or

illegible for any reason, replace immediately. Refer

to replacement parts illustrations in Service

Manual for the proper location and part numbers

of safety decals.

20. DO NOT OPERATE THE GRINDER WHEN

UNDER THE INFLUENCE OF DRUGS,

ALCOHOL, OR MEDICATION

1. KEEP GUARDS IN PLACE and in working

order.

2. REMOVE WRENCHES AND OTHER

TOOLS.

3. KEEP WORK AREA CLEAN.

4. DON'T USE IN DANGEROUS ENVIRONMENT

.

Don't use Grinder in damp or wet locations, or

expose it to rain. Keep work area well lighted.

5. KEEP ALL VISITORS AWAY

.

All visitors

should be kept a safe distance from work area.

6. MAKE WORK AREA CHILD-PROOF with

padlocks or master switches.

7. DON'T FORCE THE GRINDER. It will do the job

better and safer if used as specified in this

manual.

8. USE THE RIGHT TOOL. Don't force the Grinder

or an attachment to do a job for which it was not

designed.

9. WEAR PROPER APPAREL.

Wear no loose

clothing, gloves, neckties, or jewelry which may

get caught in moving parts. Nonslip footwear is

recommended. Wearprotectivehaircoveringto

contain long hair.

10. ALWAYS USE SAFETY GLASSES

.

11. SECURE YOUR WORK. Make certain that the

bedknife is securely fastened with the

electromagnets provided before operating.

3

SAFETY INSTRUCTIONS

DON'T

1. DON'T use a cracked wheel or one that HAS

BEEN DROPPED or has become damaged.

2. DON'T FORCE a wheel onto the machine OR

ALTER the size of the mounting hole - if

wheel won't fit the machine, get one that will.

3. DON'T ever EXCEED MAXIMUM

OPERATING SPEED established for

the wheel.

4. DON'T use mounting flanges on which the

bearing surfaces ARE NOT CLEAN, FLAT

AND FREE OF BURNS.

5. DON'T TIGHTEN the mounting nut

EXCESSIVELY.

6. DON'T grind on the SIDE OF THE WHEEL

(see Safety Code B7.2 for exception).

7. DON'T start the machine until the WHEEL

GUARD IS IN PLACE.

8. DON'T JAM work into the wheel.

9. DON'T STAND DIRECTLY IN FRONT of a

grinding wheel whenever a grinder is started.

10. DON'T FORCE GRINDING so that motor

slows noticeably or work gets hot.

AVOID INHALATION OF DUST generated by grinding and cutting operations.

Exposure to dust may cause respiratory ailments. Use approved NIOSH or

MSHA respirators, safety glasses or face shields, and protective clothing.

Provide adequate ventilation to eliminate dust, or to maintain dust level

below the Threshold Limit Value for nuisance dust as classified by OSHA.

IMPROPER USE OF GRINDING WHEEL MAY CAUSE

BREAKAGE AND SERIOUS INJURY.

Grinding is a safe operation if the few basic rules listed below are followed.

These rules are based on material contained in the ANSI B7.1 Safety Code for

"Use, Care and Protection of Abrasive Wheels". For your safety, we suggest

you benefit from the experience of others and carefully follow these rules.

DO

1. DO always HANDLE AND STORE wheels in a

CAREFUL manner.

2. DO VISUALLY INSPECT all wheels before

mounting for possible damage.

3. DO CHECK MACHINE SPEED against the

established maximum safe operating speed

marked on wheel.

4. DO CHECK MOUNTING FLANGES for equal

and correct diameter.

5. DO USE MOUNTING BLOTTERS when

supplied with wheels.

6. DO be sure WORK REST is properly adjusted.

7. DO always USE A SAFETY GUARD

COVERING at least one-half of the grinding

wheel.

8. DO allow NEWLY MOUNTED WHEELS to run

at operating speed, with guard in place, for at

least one minute before grinding.

9. DO always WEAR SAFETY GLASSES or some

type of eye protection when grinding.

10.DO TURN OFF COOLANT before stopping to

avoid creating an out-of-balance condition.

4

This machine is intended for grinding the bedknife from a reel mowing

unit ONLY. Any use other than this may cause personal injury and void

the warranty.

This machine is intended for indoor use only.

To assure the quality and safety of your machine and to maintain the

warranty, you MUST use original equipment manufactures replacement

parts and have any repair work done by a qualified professional.

ALL operators of this equipment must be thoroughly trained BEFORE

operating the equipment.

Do not use compressed air to clean grinding dust from the machine. This

dust can cause personal injury as well as damage to the grinder. Do not use a

power washer to clean the machine.

CONTENTS

Assembly...................................................................................................... Page 6 - 12

Maintenance ................................................................................................ Page 13 - 15

Adjustments ................................................................................................. Page 16-23

Troubleshooting ........................................................................................... Page 24-33

Electrical Schematic..................................................................................... Page 34

Parts List. ..................................................................................................... Page 35-48

SPECIFICATIONS

Electrical Requirements ............................................................ 115V 50/60 Hz, 15-amp circuit

Net Weight ....................................................................................................... 780 lbs [354 kg]

Shipping Weight............................................................................................... 920 lbs [417 kg]

Maximum Grinding Length................................................................................34 in. [863 mm]

SoundLevel.....................................................................................................Lessthan75Dba

The grinder is equipped with a low voltage relay which

is factory preset at 100 VAC. If the power supply line

does not deliver 100 VAC power under load, the relay

will open and trip out the starter. If this occurs, your

power supply line is inadequate and must be correct

before proceeding further with the grinder.

ADJUSTMENT OF THE LOW VOLTAGE RE-

LAY MAY CAUSE ELECTRICAL COMPONENT

FAILURE. ADJUSTMENT OF THE LOW

VOLTAGE RELAY WILL VOID ALL

ELECTRICAL COMPONENT WARRANTY.

Low Voltage Relay

5

SKILL AND TRAINING REQUIRED FOR SERVICING

This Service Manual is designed for technicians who have the neces-

sary mechanical and electrical knowledge and skills to reliably test

and repair the ACCU-Pro Bedknife Grinder. For those without that

background, service can be arranged through a local distributor.

This Manual presumes that you are already familiar with the normal

operation of the Grinder. If not, you should read the Operators

Manual, or do the servicing in conjunction with someone who is

familiar with its operation.

PERSONS WITHOUT THE NECESSARY

KNOWLEDGE AND SKILLS SHOULD NOT

REMOVE THE CONTROL BOX COVER OR

ATTEMPT ANY INTERNAL

TROUBLESHOOTING, ADJUSTMENTS, OR

PARTS REPLACEMENT!

If you have questions not answered in this manual, please call your

distributor. They will contact the manufacturer if necessary.

TORQUE REQUIREMENTS

Throughout this manual we refer to torque requirements as

"firmly tighten" or the like. For more specific torque values, refer

to the information below.

Bolts Going into a Nut, or Into a Thread Hole in Steel.

Refer to table at the right.

Bolts Going into a Thread Hole in Aluminum.

Use the Grade 2 values in the table at the right.

Socket-Head Screws

Use the Grade 8 values in the table at the right.

Machine Screw

No. 6 Screws: 11in.-lbs [0.125 kg-m]

No. 8 Screws: 20 in.-lbs [0.23 kg-m]

No. 10 Screws: 32 in.-lbs [0.37kg-m]

GRADE 2 GRADE 5 GRADE 8

SMOOTH 3 MARKS 6 MARKS

HEAD on HEAD on HEAD

1/4 In. 6 ft-lbs 9 ft-lbs 13 ft-lbs

thread (0.8 kg-m) (1.25 kg-m) (1.8 kg-m)

5/16 In. 11 ft-lbs 18 ft-lbs 28 ft-lbs

thread (1.5 kg-m) (2.5 kg-m) (3.9 kg-m)

3/8 In. 19 ft-lbs 31 ft-lbs 46 ft-lbs

thread (2.6 kg-m) (4.3 kg-m) (6.4 kg-m)

7/16 In. 30 ft-lbs 50 ft-lbs 75 ft-lbs

thread (4.1 kg-m) (6.9 kg-m) (10.4 kg-m)

1/2 In. 45 ft-lbs 75 ft-lbs 115 ft-lbs

thread (6.2 kg-m) (10.4 kg-m) (15.9 kg-m)

6

ASSEMBLY INSTRUCTIONS

FIG. 2

FIG. 1

NOTE: For clarity, the Grinder is shown on the following

pages without the optional carriage bellows installed.

UNPACK THE CARTONS

NOTE: Before you install the machine, read the following

assembly procedure completely. Then study "Getting to

Know Your Bedknife Grinder" in the Operators Manual.

Use care when unpacking. Double-check the packing

cartons for any miscellaneous items before discarding.

Inspect all items for shipping damage as they are

removed from the shipping containers. If you find any

damage, notify the carrier's claims agent and do not

proceed further until the damage has been inspected by

the agent. Refer also to the "Shipping and Receiving

Instructions" packed with the unit.

Remove the Coolant Tank carton from under the machine.

Remove the control box from under the machine. Be

careful of the electrical wiring which was preconnected at

the factory.

Install the Control Box

Attach the control box to the right front end of the

machine, using the two 3/8-16 x 5/8" hex-head bolts, and

two lock washers provided. See FIG. 1. The fasteners

are shipped in an envelope inside the control box carton.

Remove the Grinder from the Pallet

To remove the Grinder from the wood pallet:

1. Unbolt the brackets that hold each end of the

Grinder legs to the bottom of the pallet.

2. The Grinder's four leveling feet (FIG. 2) are seated in

countersunk holes in the pallet. Lift one end of the

machine until both feet are out of their holes.

3. Prop this first end up with sturdy boards or other

supports so the feet remain out of their holes, then lift

the other end and remove the Grinder from the pallet.

THE GRINDER WEIGHS 780 LBS

[354 KG]. TO LIFT, USE POWER

EQUIPMENT OR GET ADEQUATE

HELP.

Remove the shipping strap that secures the grinding

head and carriage to the left end of the machine during

shipment. Reinstall the wiper plate screw which held the

right end of the strap. Discard the leg screw and the

shipping strap.

7

ASSEMBLY INSTRUCTIONS (Continued)

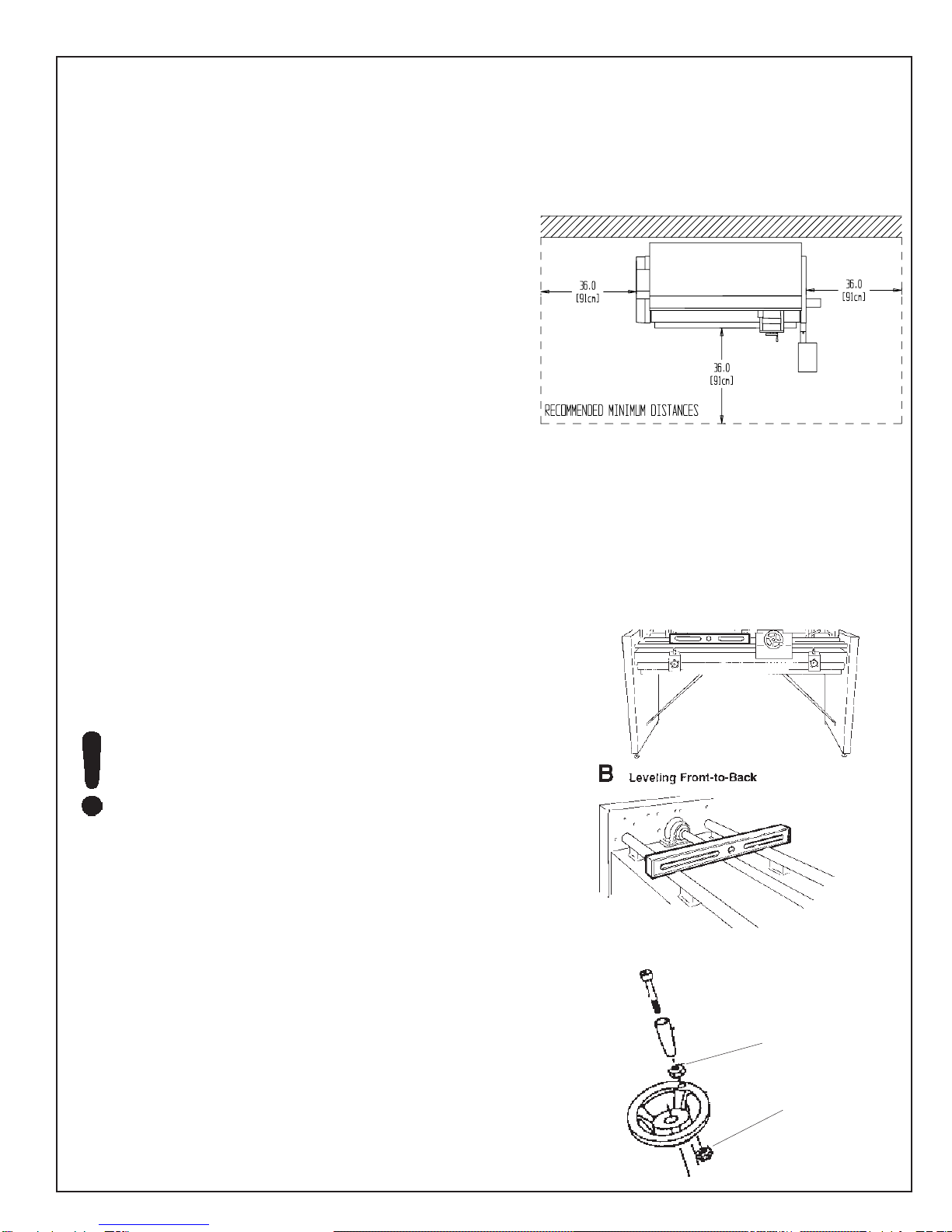

LOCATE AND LEVEL THE GRINDER

Set the Grinder on a level concrete floor, on a single

uncracked slab of concrete.

If the unit must be located near a wall, allow adequate

space for operating and servicing. Refer to FIG. 3 for

recommended and alternate locations near a wall.

Place a level on the front carriage rail near the center of

the machine and check the level from left to right. See

FIG. 4A. Adjust the leveling feet until the machine is level.

Place the level across the front and rear carriage rails near

the left end of the machine. See FIG. 4B. Adjust the two

leveling feet on the left end until the rear rail (the one

closest to the coolant tray) is slightly lower than the front

rail--so any coolant on the carriage, main base, or optional

bellows will drain back into the coolant tray.

Place the level across the front and rear carriage rails near

the right end of the carriage bed. Level the right end in

the same way as the left end. For grinding accuracy, the

two ends must have the identical backward slant within +/-

.01" [.25 mm] so the frame is not twisted.

Recheck the level in both directions. When satisfactory,

tighten the hex jam nuts on the leveling feet securely

against the nuts welded to the bottom of the base. See

FIG. 2. Don't turn the leveling feet when tightening.

Again recheck the level after the nuts are firmly tightened.

FOR GRINDING ACCURACY, THE MACHINE

DOES NOT HAVE TO BE PERFECTLY LEVEL.

HOWEVER, IT IS CRITICAL THAT FRONT-TO-

BACK LEVELING BE IDENTICAL AT BOTH

ENDS OF THE MACHINE.

INSTALL THE SPINNING HANDLES

Install the spinning handle on the horizontal handwheels.

See FIG. 5. Handle parts are packed in an envelope

taped to the wheel.

FIG. 4

FIG. 5

Regular Hex Nut

Lock Nut

ALeveling Side-to-Side

FIG. 3

8

ASSEMBLY INSTRUCTIONS (Continued)

FIG. 7

APPLY POWER

BEFORE YOU APPLY POWER TO THE

GRINDER, REFER TO THE "IMPORTANT

GROUNDING INSTRUCTIONS" ON PAGE 9.

115 Volt Model Only. Plug the control box power cord into a

standard 115V AC 15-amp grounded receptacle. See FIG. 7.

220 Volt Model Only. For 220 Volt Applications order Part

No. 6700951, which includes a 220 to 110 Volt Step Down

Transformer. See Details on page 9.

IT IS RECOMMENDED THAT THIS ACCU-

PRO BEDKNIFE GRINDER HAS ITS OWN

PERMANENT POWER CONNECTION FROM

THE POWER DISTRIBUTION PANEL, WITH

NO OTHER MAJOR POWER DRAW

EQUIPMENT ON THE SAME LINE.

IT IS REQUIRED THAT THE POWER

DELIVERED TO THIS GRINDER IS 115 VAC -

15 AMPS. THE TOLERANCE ON THIS

POWER REQUIREMENT IS +/- 5%.

THEREFORE THE MINIMUM VOLTAGE

REQUIREMENT IS 109VAC WITH 15 AMPS.

VOLTAGE MUST BE CHECKED WITH ALL

EQUIPMENT UNDER LOAD (OPERATING) ON

THE CIRCUIT.

DO NOT OPERATE THIS GRINDER WITH

AN EXTENSION CORD.

The grinder is equipped with a low voltage relay

which is factory preset at 100 VAC. If the power

supply line does not deliver 100 VAC power under

load, the relay will open and trip out the starter. If

this occurs, your power supply line is inadequate

and must be correct before proceeding further with

the grinder.

ADJUSTMENT OF THE LOW

VOLTAGE RELAY MAY CAUSE

ELECTRICAL COMPONENT

FAILURE. ADJUSTMENT OF

THE LOW VOLTAGE RELAY

WILL VOID ALL ELECTRICAL

COMPONENT WARRANTY.

PROPER GROUNDING OF THE RECEP-

TACLE GROUND IN YOUR BUILDING MUST

BE VERIFIED. IMPROPER GROUNDING IN

YOUR BUILDING MAY CAUSE THE GRINDER

TO MALFUNCTION.

FOR 15 AMP RATED LARGE MACHINES

For 0 to 30 Feet from panel to receptacle = Use 14 Ga. Wire.

For 30 to 50 Feet from panel to receptacle = Use 12 Ga. Wire.

For 50 to 80 Feet from panel to receptacle = Use 10 Ga. Wire.

For 80 to 140 Feet from panel to receptacle = Use 8 Ga. Wire.

For 0 to 9 Meters from panel to receptacle = Use 2.5mm Wire.

For 9 to 15 Meters from panel to receptacle = Use 4.0mm Wire.

For 15 to 24 Meters from panel to receptacle = Use 6.0mm Wire.

For 24 to 42 Meters from panel to receptacle = Use 10.0mm Wire.

9

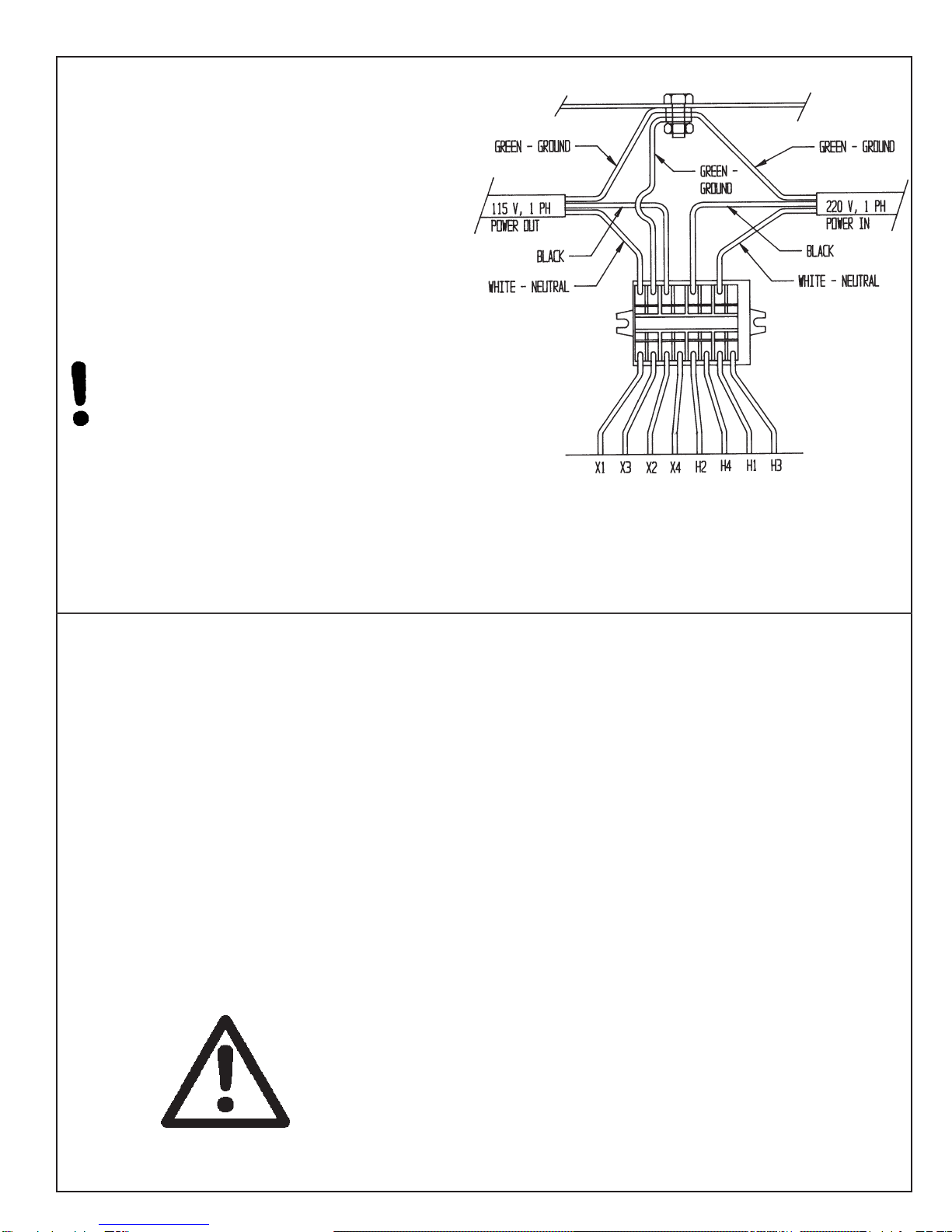

FOR 220 V 50 or 60Hz applications Product No.

6700951 should be ordered.

6700951 includes a 2 KVA 220 Volt Step Down

to 110 volt 50/60 Hz transformer which is

prewired.

The wiring diagram is shown in FIG. 8.

The power cord has no connector. A connector

which is appropriate for your locality and 220 volt,

8 amp application should be installed.

ASSEMBLY INSTRUCTIONS (Continued)

FIG. 8

IMPORTANT GROUNDING INSTRUCTIONS

In case of a malfunction of breakdown, grounding reduces the risk of electrical shock by providing a path

of least resistance for electrical current.

This Grinder has an electrical cord with an equipment grounding conductor and a grounding plug. The

plug must be plugged into a matching outlet that is properly installed and grounded according to all local

or other appropriate electrical codes and ordinances.

Before plugging in the Grinder, make sure it will be connected to a supply circuit protected by a properly-

sized circuit breaker or fuse.

Never modify the plug provided with the machine--if it won't fit the outlet, have a proper outlet and circuit

installed by a qualified electrician.

ALWAYS PROVIDE A PROPER ELECTRICAL GROUND FOR

YOUR MACHINE. AN IMPROPER CONNECTION CAN CAUSE A

DANGEROUS ELECTRICAL SHOCK. IF YOU ARE UNSURE OF

THE PROPER ELECTRICAL GROUNDING PROCEDURE,

CONTACT A QUALIFIED ELECTRICIAN.

Use only a qualified electrician to

complete the installation.

10

ASSEMBLY INSTRUCTIONS (Continued)

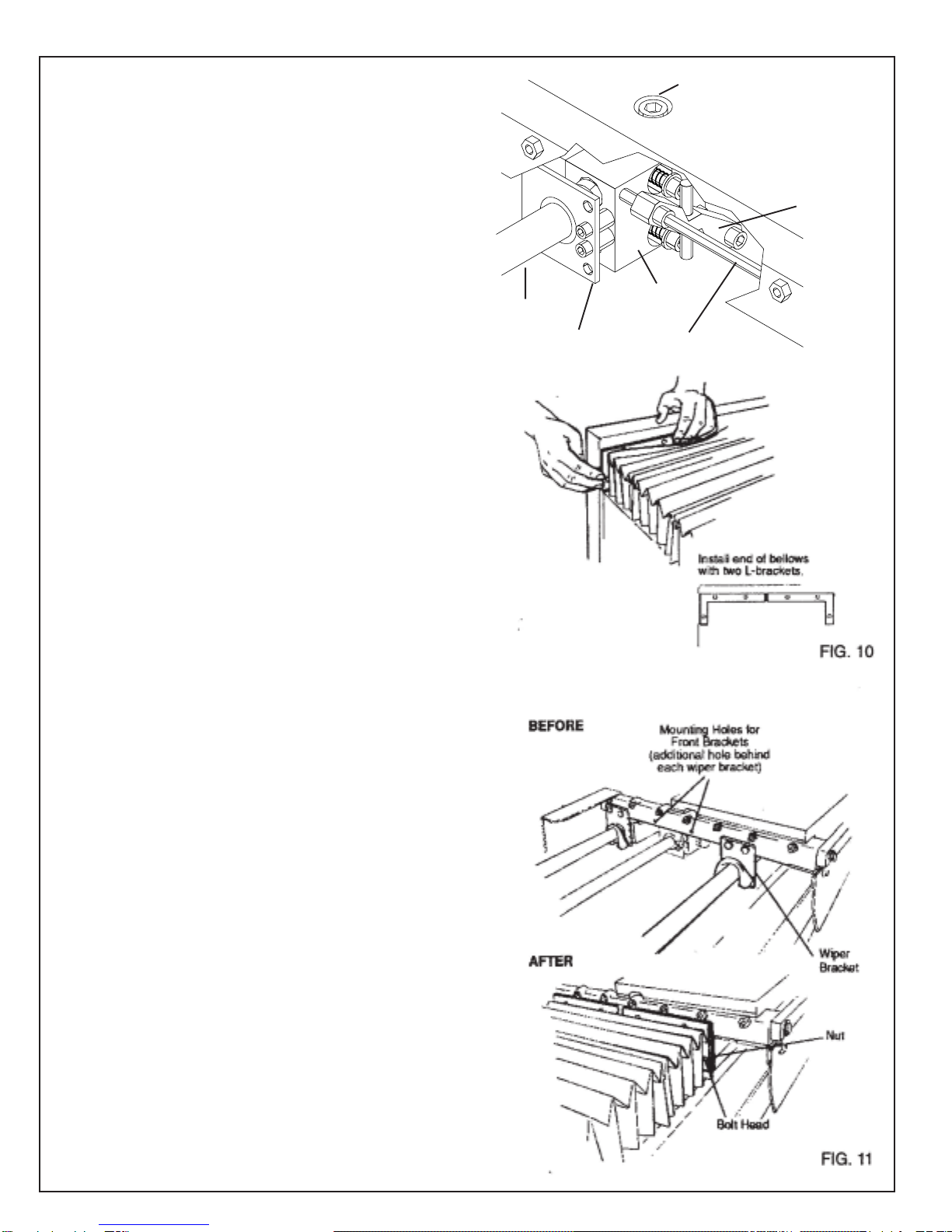

INSTALL THE OPTIONAL

CARRIAGE BELLOWS (if ordered)

Optional carriage bellows are available to keep excess

grindings, dirt, etc. out of the carriage assembly. To

install the two bellows:

1. Remove the left and right outside leg panels.

2. Remove the shaft seal on each side of the linear

actuator. See FIG. 9. NOTE: When the bellows are

used, the shafts don't get lubricated and the seals

would run dry. They would then become noisy and

not operate properly.

To remove the seals:

a. Crank the carriage all the way toward the

front (that is, toward the operator's position).

b. Remove the actuator mounting screw on top

of the carriage. See FIG. 9. Then push the

carriage toward the right end of the Grinder.

c. Loosen the two set screws in the bearing

pillow block at each end of the drive shaft.

Loosen the two set screws in the drive

coupling at the right end of the carriage.

d. Turn the actuator release lever clockwise 1/2

turn until the actuator is released from the

shaft. See FIG. 9.

e. Slide the drive shaft out the left end of the

machine.

f. Remove the shaft seals from the actuator -

two screws each.

g. Reinstall the drive shaft. The right end of

the shaft (inside the coupling) should be

1/8 - 1/4" [3 to 6.5 mm] from the end of the

motor shaft. Retighten all set screws.

h. Push the carriage back to the left, and

reattach the actuator with the mounting

screw. See FIG. 9. Turn the actuator

release lever, 1/2 turn.

3. Remove the two rail wiper brackets from each side

of the carriage - two screws each. See FIG. 11.

4. Attach the outer end of each bellows to the Grinder

leg panel. See FIG. 10. Use six bolts, and hex

nuts, at each end. The bolt heads go on the bellows

side of the brackets.

5. Attach the inner end of each bellows to the carriage.

See FIG. 11. Use four L-brackets, (two on each

side of the last bellows fold), six bolts, and two hex

nuts at each end. Nuts are required only for the

lower holes of the L-brackets.

6. Press the bellows down until it snaps onto the

carriage rails.

7. Reattach the left and right outside leg panels.

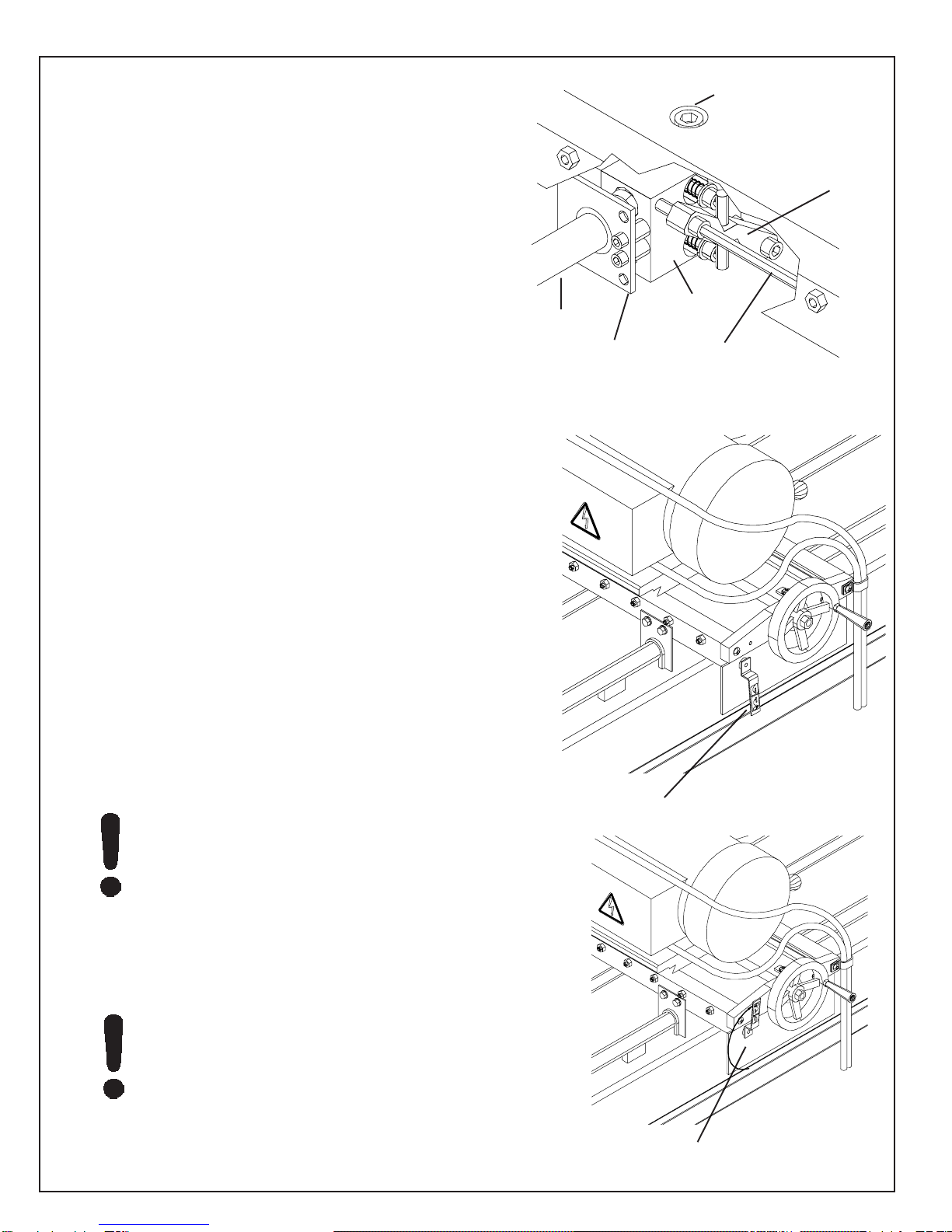

FIG. 9

Actuator Mounting

Screw (under the rubber

splash guard)

Drive Shaft

Actuator Bar Assembly

Linear Actuator

Seal Plate Actuator Release Lever

11

ASSEMBLY INSTRUCTIONS (Continued)

FIG. 12

FIG. 13

INSTALL THE COOLANT TANK

Assemble the Coolant Tank as outlined in the instructions

(Part No. 7467909) in the coolant tank carton.

Center the Tank under the Grinder.

Install the 1" I.D. drain tubing over the barbed end of the

plastic adapter on the coolant tray drain. Cut the tubing to

the proper length to reach about 1-1/2" [40 mm] into the

large opening on top of the Coolant Tank. See FIG. 12.

A pre-filter sock is shipped with the Tank. Install it onto the

tubing, using the plastic tie provided. Drop the other end of

the sock into the opening on top of the Tank.

Read the coolant mixing directions and the electrical

warnings in the Coolant Tank instructions.

THE COOLANT RATIO AS SPECIFIED MUST BE

USED. TO HIGH A CONCENTRATION OR LOW A

CONCENTRATION WILL CAUSE CORROSION

AND PERFORMANCE PROBLEMS.

1. Be sure the COOLANT PUMP switch is OFF. Mix (Part

No. 3708620) coolant in the coolant tank, at a ratio

of 50 parts water to 1 part concentrate. This will take

about 6 gallons of water and 1 pint of concentrate (24

liters of water and 0.5 liter of concentrate).

Refer also to the label on the coolant container, and the

instructions packed with the CoolantTank.

CHECK THE COOLANT PUMP

Plug the pump motor cord (from the top of the Tank) to the

female connector from the control box.

RISK OF ELECTRICAL SHOCK!

MAKE CERTAIN THAT THE ABOVE

ELECTRICAL CONNECTION IS

SECURED ABOVE AND AWAY FROM

POSSIBLE CONTACT WITH THE

COOLANT.

Turn all control panel switches OFF. Close the guard door

and press START. Press Coolant Pump Switch to ON.

Check that the Coolant System functions properly. Be

prepared to press STOP if there is any problem.

NOTE: If the unit doesn't begin to pump coolant, press the

reset button on the motor contactor inside the control box.

See FIG. 13.

Secure any excess electrical cord to a crossbar on the

underside of the machine.

12

ASSEMBLY INSTRUCTIONS (Continued)

CHECK THE CARRIAGE TRAVERSE

Move the proximity switch assemblies to about 12" [300 mm]

from the ends of the machine, and tighten their knobs.

Visually check that the grinding head will be able to traverse

to both sides of the machine without contacting any

components.

Turn all control panel switches OFF. Set the TRAVERSE FT/

MIN knob to zero. Close the guard door and press START.

Press CARRIAGE TRAVERSE to ON. Set TRAVERSE FT/

MIN to a low speed, and check that the grinding head runs

through a complete traverse cycle. Be prepared to press

STOP if there is any interference. Watch carefully for

obstructions to the head travel, and check that the grinding

motor cord and proximity switch cords are not stretched.

NOTE: If the unit doesn't begin a traverse cycle, press the

reset button on the motor contactor inside the control box.

See FIG. 13.

CHECK THE GRINDING MOTOR

Turn all control panel switches OFF. Close the guard door to

connect the interlock. Press START. Press Grinding Motor

Switch to ON. Check that the grinding head runs properly.

Be prepared to press STOP if there is any problem.

NOTE: If the grinding head doesn't begin properly, press the

reset button on the motor contactor inside the control box.

See FIG. 13.

CHARGING TO SUPPLEMENTARY POWER SUPPLY

The Supplementary Power Supply (SPS) comes from the

supplier with no charge. When the machine is ready for

operation, plug it in and turn on the SPS. The battery will

charge in six hours. For SPS functions, refer to the separate

manual supplied with the grinder.

MAKE FINAL PREPARATIONS FOR OPERATION

Carefully read the operating instructions in the Operators

Manual.

First, study the pages titled "Getting to Know Your Grinder"

and "General Operating Information" for important

background explanations about the machine and about

bedknife grinding. Then, read the "Operating Instructions"

pages for step-by-step procedures on mounting the

bedknife and grinding its top and front faces.

13

MAINTENANCE

FIG. 14

FIG. 15

DAILY MAINTENANCE IS SPECIFIED ON PAGE 4

OF THE OPERATOR'S MANUAL, AND IS TO BE

PERFORMED BY THE OPERATOR. LISTED

BELOW ARE PERIODIC MAINTENANCE ITEMS

TO BE PERFORMED BY YOUR COMPANY'S

MAINTENANCEDEPARTMENT:

1. Lift the bellows, (See FIG. 14) if used, and wipe off

the traverse driveshaft and the bearing rails monthly.

When a squeaking noise is coming from the actuator

bearings, follow the lubrication procedure for actuator

and linear bearings. Generally, this will be every

6 months to a year.

2. Check the gib plate adjustment in the carriage base

every 3 months. See Page 21.

3. Replace the four foam rail wipers (FIG. 15) every 6

months of operation. Note: Wipers are removed if

optional bellows are installed.

4. Clean the interior and the top cover of the Coolant

Tank as necessary and at least every 6 months.

5. Check the brushes on the auto traverse drive motor

once every 24 months. Replace as necessary.

Carriage

Rails

THE UNINTERUPTABLE POWER SUPPLY (UPS)

WHICH IS USED AS A BACKUP TO HOLD THE

BEDKNIFE TO THE ELECTROMAGNETS DURING

A POWER INTERUPTION HAS A BATTERY.

THIS BATTERY HAS A THREE YEAR LIFE AND

MUST BE REPLACED AFTER THREE YEARS OF

SERVICE LIFE. SEE THE PARTS LIST FOR

REPLACEMENT BATTERY PART NUMBER.

14

MAINTENANCE (Continued)

LUBRICATION

Actuator and Linear Bearings

Do the following every six months (or more often if the linear

actuator seals are squeaking):

1. Thoroughly clean the carriage rails, drive shaft, and

shaft seals. Wipe the shafts and seals thoroughly with

a clean rag.

While cleaning, traverse the carriage several times to

clean the full length of the drive shaft and rails.

2. Flood-spray all three shafts with WD-40 or an equivalent

lubricant (do not use a Teflon-based lubricant) until

lubricant drips off the shafts. Then run the carriage back

and forth through its range of travel, to carry lubricant

onto the outer surface of the actuator bearings and the

inner surface of the seals.

NOTE: Because of the flood of lubricant, you may find

that the actuator slips and traversing is erratic or stalls.

This is not a problem, as it will be corrected in Step 3.

3. With a clean rag, wipe the excess lubricant from the

shafts. Run the carriage back and forth through its

range of travel, and wipe the shafts after each

traverse. Repeat until the shafts feel dry.

IMPORTANT: If the machine will be shut down for more than

one month, flood the shafts and other appropriate parts with

lubricant as outlined above, and leave the lubricant in place

until the unit will be used again. Then repeat the above

lubrication procedure before operating.

15

CLEANING AND MAINTENANCE GUIDELINES FOR POLYCARBONATE WINDOWS

Cleaning Instructions

DO NOT USE GASOLINE

Adherence to regular and proper

cleaning procedures is recommended

to preserve appearance and performance.

Washing to Minimize Scratching

Wash polycarbonate windows with a mild dish washing liquid detergent and lukewarm water, using a

clean soft sponge or a soft cloth. Rinse well with clean water. Dry thoroughly with a moist

cellulose sponge to prevent water spots. Do not scrub or use brushes on these windows. Also,

do not use butyl cellosolve in direct sunlight.

Fresh paint splashes and grease can be removed easily before drying by rubbing lightly with a

good grade of VM&P naphtha or isopropyl alcohol. Afterward, a warm final wash should be made,

using a mild dish washing liquid detergent solution and ending with a thorough rinsing with clean

water.

Minimizing Hairline Scratches

Scratches and minor abrasions can be minimized by using a mild automobile polish. Three such

products that tend to polish and fill scratches are Johnson paste Wax, Novus Plastic Polish #1 and

#2, and Mirror Glaze plastic polish (M.G. M10). It is suggested that a test be made on a corner of

the polycarbonate window with the product selected following the polish manufacturer's instruc-

tions.

Some Important "DON'TS"

¨DO NOT use abrasive or highly alkaline cleaners on the polycarbonate windows.

¨Never scrape polycarbonate windows with squeegees, razor blades or other sharp

instruments.

Benzene, gasoline, acetone or carbon tetrachloride should NEVER be used on

polycarbonate windows.

¨DO NOT clean polycarbonate windows in hot sun or at elevated temperatures.

Graffiti Removal

• Butyl cellosolve, (for removal of paints, marking pen inks, lipstick, etc.)

• The use of masking tape, adhesive tape or lint removal tools works well for lifting off old

weathered paints.

• To remove labels, stickers, etc., the use of kerosene, VM&P naphtha or petroleum spirits is

generally effective. When the solvent will not penetrate sticker material, apply heat (hair

dryer) to soften the adhesive and promote removal.

GASOLINE SHOULD NOT BE USED!

MAINTENANCE (Continued)

16

TO REPLACE THE LINEAR ACTUATOR BEARINGS

NOTE: Do not remove the linear actuator from the drive

shaft. Only remove the bearings from the actuator block.

1. Crank the horizontal handwheel until the carriage is

all the way forward (toward the operator position).

2. Turn the actuator release lever 1/2 turn clockwise

to release the linear actuator bearings from the

drive shaft. Slide the actuator release lever out

of actuator bar assembly by loosening the retainer

shaft collar, which preloads the holding spring.

See FIG. 18A and 18B.

3. Remove the feed screw guide two mounting screws

and slide the grinding head assembly back. Lift the

rubber splash guard to expose the actuator mounting

screw (FIG. 17) on the top side of the carriage base.

Remove the mounting screw, to disconnect the linear

actuator from the carriage. Slide the carriage

assembly to one side.

4. Disconnect the shaft seal plate (FIG. 17) from each

side of the linear actuator. Slide the seals down the

drive shaft until they are out of the way. (If the optional

carriage bellows were installed, the shaft seals may

already have been removed).

5. Remove the shoulder bolts holding the six bearings

(three on each side) to the actuator block. Remove

the old bearings and discard them, but save the inside

washers and shoulder bolts.

Inspect the hole from which the bearing and shoulder

bolt were removed, for foreign matter. Clean

thoroughly.

6. Wipe the drive shaft clean and dry.

If oil is left on the drive shaft, the pulling

force may have to be set too high in the

following procedure. This will shorten

the bearing life.

7. Insert the shoulder bolts through the new bearings

and through the inside washers (saved in Step 6).

Then install the complete bearing assemblies into the

actuator block and tighten the shoulder bolts.

Be very careful not to cross-thread the

bearing bolts!

Reinstall the shaft seal plates if applicable. Be sure

the seal plates are mounted concentric to the drive

shaft.

ADJUSTMENTS

FIG. 17

Actuator Mounting

Screw (under the rubber

splash guard)

Drive Shaft Linear Actuator

Seal Plate Actuator Release Lever

Actuator Bar Assembly

FIG. 18A

FIG. 18B

Actuator Engaged

Actuator Released

17

TO REPLACE THE LINEAR ACTUATOR BEARINGS

8. Slide the carriage over the actuator, and line up the

hole in the carriage with the tapped hole in the top of

theactuator block. Insert the actuator mounting screw

throughthe self-adjustingbearing, andtighten thescrew.

9. Install the two feed screw guide mounting screws.

Install the actuator release lever into the actuator bar

assembly. Turn the actuator release lever

counterclockwise 1/2 turn to engage the actuator.

10.Connect a spring scale so it pulls on the carriage

parallel to the drive shaft. Hold the drive shaft from

rotating while you pull on the carriage. See FIG. 19.

To overcome the actuator, the pulling force should be

45 to 60 lbs (20-27 kg), with 50 lbs (23 kg) being ideal.

If not within those specifications, the actuator tension

must be adjusted. See "Adjusting the Pulling Force"

below.

Exceeding 60 lbs force won't greatly

improve drive performance - and it will

shorten the bearing life.

Adjusting the Pulling Force

Ifthepullingforceisnotwithinspecification(Step10above),

adjust it:

1. With the actuator bearings engaged to the drive shaft,

readjustthe twooutboard screwswith springs thathold

theactuatortogether. To reachthesescrews, youmust

remove the actuator bar assembly. See FIG. 17.

Turn each outboard screw an equal amount when

resetting. Turn clockwise for more tension.

2. Check the force again (repeat Step 10 above).

Continue adjusting and rechecking until within

specification.

NOTE: The factory-adjusted position to reach tension

specifications is to compress the spring until there is

.22 in. (5.5 mm) clearance between the underside of

thewasher and the actuator block. See FIG. 20. Use

this as a starting pointunless you are already close to the

specifiedtension.

3. When the tension adjustment is correct, reinstall the

actuator bar assembly and actuator release lever.

ADJUSTMENTS (Continued)

FIG. 19

FIG. 20

If the actuator release lever is

tightened too much, it will

contact the outboard screw

heads and override their

adjustment, which could

cause a traverse malfunction.

Make certain that you have

full engagement when you

reengage the actuator.

Hold the drive shaft from

rotating while you check

the pulling force.

18

TO REPLACE THE CARRIAGE LINEAR BEARINGS

NOTE: Set a small bench or table near the center

front of the machine for use in the following procedure.

1. Remove the optional carriage bellows (if used) from

the carriage. Remove the actuator release lever from

thelinear actuator.

2. Remove the complete carriage assembly from the

machine:

A. Removethetwo feedscrew guidemounting screws

and pull the grinding head assembly back. Lift the

rubberflapand exposetheactuator mountingscrew

(FIG. 22) on the top side of the carriage base.

Remove the screw, to disconnect the actuator from

thecarriage.

B. Remove the bolts which secure the front and rear

carriage rails to the Grinder base (six screws for

each rail, accessible from beneath the machine).

The carriage assembly weighs

about 50 lbs (23 kg). If necessary,

get help for the following steps.

C. Lift the complete assembly (carriage, carriage

shafts, andgrinding head)out ontothe tablein front

of the Grinder. Be careful you don't damage the

motor cord.

3. Lift the carriage and slide the rails out of the bearings,

one at a time.

4. Remove the three linear bearing pillow blocks (four

screws each) from the bottom of the carriage, and

discard them.

5. One at a time, slide the three new linear bearing pillow

blocks onto a carriage rail.

6. Adjust the tension screw (FIG. 23) on the side of each

bearing block so that when you radially rotate the pil

low block around the carriage (See FIG. 24) rail there

isnofree playbetween thebearingand rail. Youshould

feel a strong drag.

Repeat this adjustment to all three pillow blocks, and

then remove the pillow blocks from the carriage rail.

NOTE: The tension is too tight if you feel a cogging

action when you rotate a pillow block around the rail. This

cogging is caused by the bearing skidding on the rail.

Rocking the bearing block back and forth should be a

smooth uniform motion.

Bearings which are too tight or too loose will

cause poor grinding quality. Bearings which

are too tight will also have a much shorter life,

and could damage the rail.

ADJUSTMENT (Continued)

FIG. 22

Actuator Mounting

Screw (under the rubber

splash guard)

Drive Shaft Linear Actuator

Seal Plate Actuator Release Lever

Actuator Bar Assembly

Radial Rotation

Carriage

Tension

Adjustment

Screw

19

ADJUSTMENTS (Continued)

FIG. 25

TO REPLACE THE CARRIAGE LINEAR BEARINGS

7. Attach the three linear bearing pillow blocks loosely to

the bottom of the carriage, with their tension adjustment

screws (FIG. 23) facing outward.

8. Clean the carriage rails.

NOTE: The two rails are interchangeable and are also

reversible(end-for-end).

9. Insert a rail through the rear two pillow blocks, and align

the rear pillow blocks to each other with a straight edge

laidalongtheirsides. SeeFIG.25. Whenaligned,tighten

the four socket-head screws which hold each rear pillow

block. Slide the other carriage shaft through the front

bearing, but do not tighten the socket head screws.

10.Lift the complete carriage assembly back onto the

Grinder main base, and secure the rear carriage rail

to its V-groove bosses with the six bolts.

11.With the front rail resting in the V-groove bosses and the

carriageapproximately centered onthe machine, tighten

thetwo outsidesocket-headscrewswhichsecure thefront

pillow block. Lift the front of the carriage, and tighten the

twoinside pillow-block screws. Securethe front carriage

rail to its V-groove bosses with the six bolts.

12.Recheck the bearing tension. The tension is correct

when you try to lift the carriage and can feel no free

carriage movement up or down.

Check for excessive carriage-traverse load by using a

spring scale to pull on the carriage parallel to the drive

shaft (as in FIG. 19). There should be only about a 3- to

5- lb. pulling force.

To double-check, manually slide the carriage assembly

from one end of its travel to the other. There should

be uniform resistance through the full range of travel.

13.Slide the linear actuator under the carriage, and line up

the hole in the carriage with the tapped hole in the top of

the actuator block. Insert the actuator mounting screw

through the self-aligning bearing, and tighten it.

Be careful not to cross-thread the screw.

14.Reinstall the feed screw guide mounting screws and then

the actuator release lever into the linear actuator.

15.If being used, reattach the two carriage bellows. Refer

to the assembly section of this manual.

Rear Pillow Blocks

Underside of

Carriage

Straightedge

20

ADJUSTMENT (Continued)

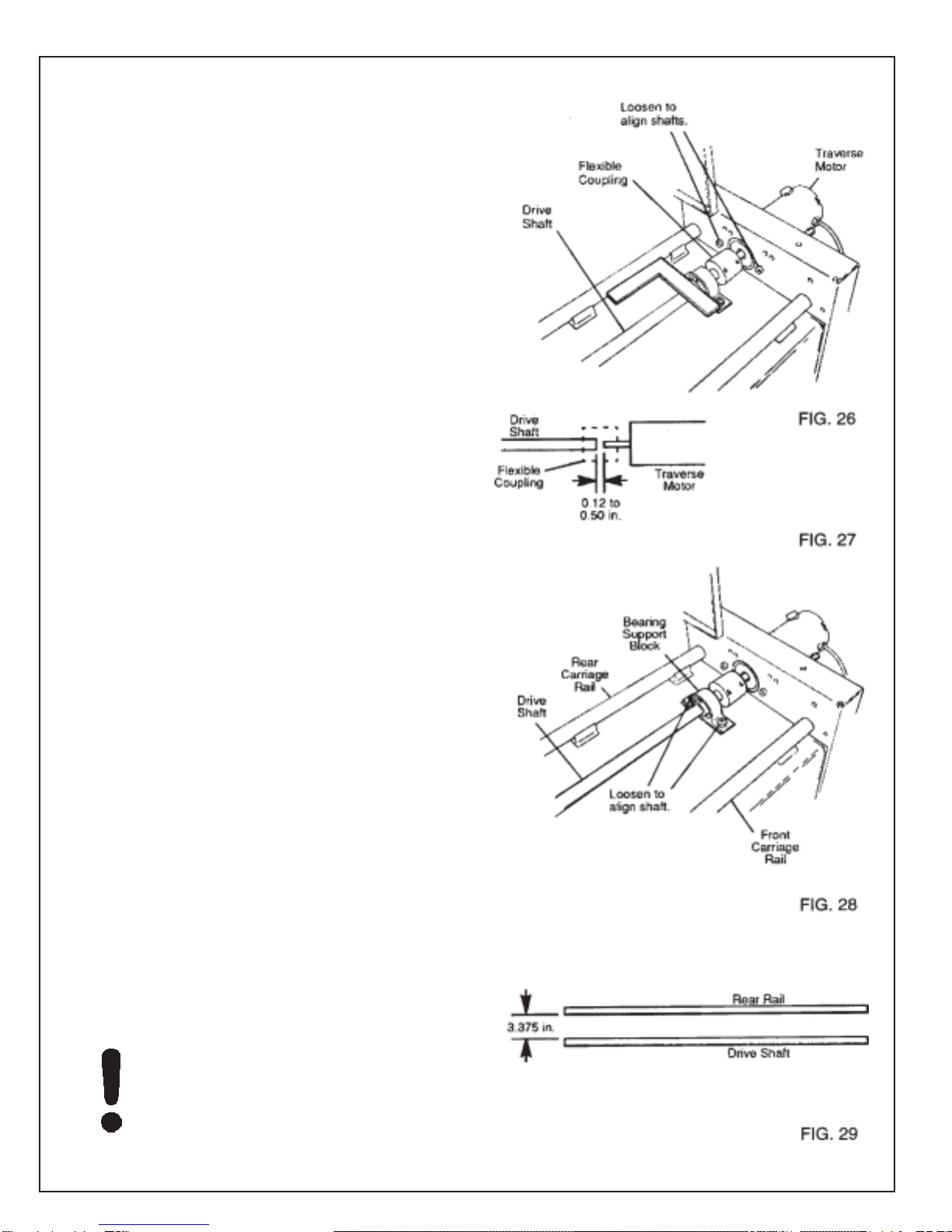

TOALIGN THE MOTOR SHAFT AND DRIVESHAFT

There must be 0.12 to 0.50 in. (3.0 to 12.7 mm) end

clearancebetweenthetraversemotoroutput shaftand

the drive shaft, inside the flexible coupling (FIG.27).

To prevent drive shaft "whipping" at higher traverse

speeds, the two shafts must be aligned so they are

concentric within .010 in. [0.25 mm]. To align:

1. Loosen the two set screw in the coupling.

2. Remove the cover on the outside of the right

leg.

3. Loosen the two bolts which secure the motor

assembly to the leg.

4. Visually align the two shafts, then tighten the

motor mounting bolts. Reinstall the leg cover.

5. Check that the spiral gaps in the flexible

couplingare equally spaced,with nocompression

orextension load on the coupling, thentighten the

coupling screws.

6. Check that the bearing load block is at 90o

to the drive shaft (within +/- 1/4 degree). Use a

precision square held against the bearing

shoulder and the rear rail, as in FIG. 26.

TO ALIGN THE REAR RAIL AND DRIVE SHAFT

The rear carriage rail and the drive shaft must be

precisely aligned:

1. Loosen the two bolts holding the bearing support

blocks at each end of the drive shaft. FIG. 28.

2. Align the drive shaft and rear carriage rail (FIG.

29) so the distance between their facing surfaces

is 3.375"+/- .010 [85.75 mm +/- 0.25]. See FIG.

29.Then tighten the support block bolts.

3. Check that the bearing support blocks are still at

90oto the drive shaft (within +/- 1/4 degree).

Use a precision square held against the bearing

shoulder and the rear rail.

4. Ifyouhavedifficultyobtaining theabovealignment,

check the straightness of the carriage rails (see

below).

NOTE: Thevertical andhorizontal straightnessof the

rails is very accurately set at the factory, so they are

unlikelyto beincorrect. Contact thefactory ifyou sus-

pect a problem after making the following tests.

If the drive shaft is adjusted, you

may have to realign the motor shaft

and drive shaft (see above).

Table of contents

Other Foley United Grinder manuals

Popular Grinder manuals by other brands

HIKOKI

HIKOKI CV 12DA Handling instructions

Sealey

Sealey SG101.V2 instruction manual

Parkside

Parkside 331789 1910 Translation of the original instructions

Northern Industrial

Northern Industrial 143388 owner's manual

COWLEY INDUSTRIES

COWLEY INDUSTRIES BSM075 Installation and operating instructions

eisenblatter

eisenblatter VARILEX WSF 900 Operating Instructions, Detail drawing, Spare part list