Foley United 388 User manual

11

388

MANUAL

REEL MOWER

GRINDER

ASSEMBLY

and

SERVICE

MANUAL

WARNING

You must thoroughly read and understand this manual

before maintaining the equipment, paying particular

attention to the Warning & Safety instructions.

3887954 (7-95)

2

SAFETY INSTRUCTIONS

13. MAINTAIN GRINDER WITH CARE. Follow

instructions in Service Manual for lubrication and

preventive maintenance.

14. DISCONNECT POWER BEFORE SERVICING, or

when changing the grinding wheel.

15. REDUCE THE RISK OF UNINTENTIONAL

STARTING. Make sure the switch is OFF before

plugging in the Grinder.

16. USE RECOMMENDED ACCESSORIES. Consult

the manual for recommended accessories. Using

improper accessories may cause risk of personal

injury.

17. CHECK DAMAGED PARTS. A guard or other part

that is damaged or will not perform its intended

function should be properly repaired or replaced.

18. NEVER LEAVE GRINDER RUNNING UNATTENDED.

TURN POWER OFF. Do not leave grinder until it

comes to a complete stop.

19. KNOW YOUR EQUIPMENT. Read this manual

carefully. Learn its application and limitations as

well as specific potential hazards.

20. KEEP ALL SAFETY DECALS CLEAN AND

LEGIBLE. If safety decals become damaged or

illegible for any reason, replace immediately. Refer

to replacement parts illustrations in Service Manual

for the proper location and part numbers of safety decals.

21. DO NOT OPERATE THE GRINDER WHEN UNDER

THE INFLUENCE OF DRUGS, ALCOHOL, OR

MEDICATION.

1. KEEP GUARDS IN PLACE and in working order.

2. REMOVE WRENCHES AND OTHER

TOOLS.

3. KEEP WORK AREA CLEAN.

4. DON'T USE IN DANGEROUS ENVIRONMENT

.

Don't use Grinder in damp or wet locations, or

expose it to rain. Keep work area well lighted.

5. KEEP ALL VISITORS AWAY

.

All visitors should

be kept a safe distance from work area.

6. MAKE WORK AREA CHILD-PROOF with

padlocks or master switches.

7. DON'T FORCE THE GRINDER. It will do the job

better and safer if used as specified in this manual.

8. USE THE RIGHT TOOL. Don't force the Grinder or

an attachment to do a job for which it was not designed.

9. WEAR PROPER APPAREL.

Do not wear loose

clothing, gloves, neckties, or jewelry which may

get caught in moving parts. Nonslip footwear is

recommended. Wear protective hair covering to

contain long hair.

10. ALWAYS USE SAFETY GLASSES

.

11. SECURE YOUR WORK. Make certain that the

cutting unit is securely fastened with the clamps

provided before operating.

12. DON'T OVERREACH.

Keep proper footing and

balance at all times.

Safety Awareness Symbols

are inserted into this

manual to alert you to possible

Safety Hazards

.

Whenever you see these symbols, follow their

instructions.

The

Warning Symbol

identifies special instructions or

procedures which, if not correctly followed, could result

in personal injury.

The

Caution Symbol

identifies special instructions

or procedures which, if not strictly observed, could

result in damage to or destruction of equipment.

33

This machine is intended for manual reel mower reel blade and bed

knife grinding ONLY. Any use other than this may cause personal

injury and void the warranty.

To assure the quality and safety of your machine and to maintain the

warranty, you MUST use original equipment manufactures replacement

parts and have any repair work done by a qualified professional.

ALL operators of this equipment must be thoroughly trained BEFORE

operating the equipment.

Do not use compressed air to clean grinding dust from the machine. This

dust can cause personal injury as well as damage to the grinder.

Use care when unpacking. Double-check the packing cartons

for any miscellaneous items before discarding.

Inspectallitemsforshippingdamageastheyareremovedfrom

the shipping containers. If you find any damage, notify the

carrier’s claims agent and do not proceed further until the

damage has been inspected by the agent. Refer also to the

“Shipping and Receiving Instructions” packed with this unit.

UNCRATING

1. Remove the shipping crate sides, ends and top.

2. Cut the band and remove the grinding head assembly and

set aside.

3. Remove the elevator components and set aside.

4. Remove the overhead bar taped to the frame rail and set

aside.

5. Remove the corrugated box from the crate. Remove all

items from the box and sort out on a table.

Check all items against the exploded view drawings in the rear

of this manual to ensure that all items were shipped properly.

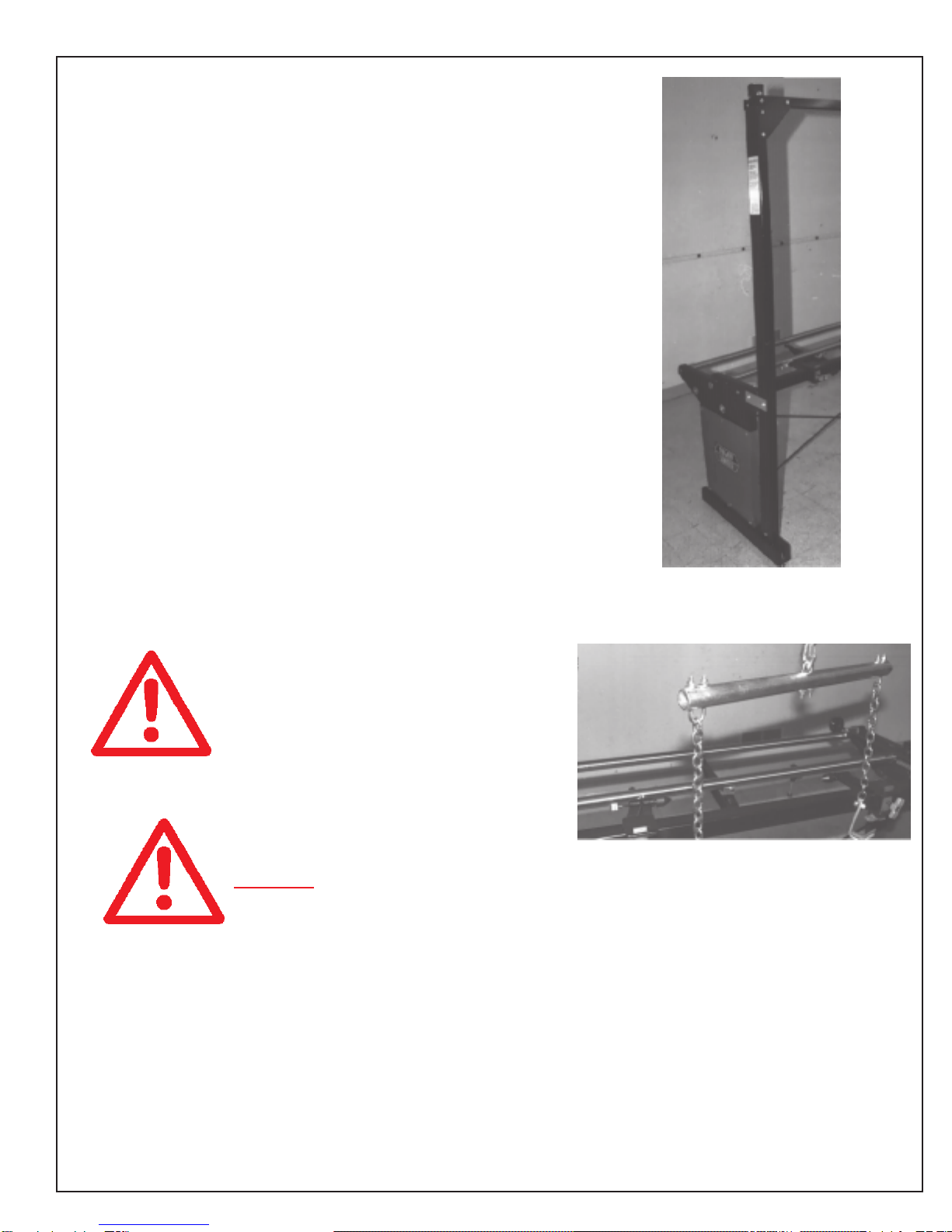

Remove Main Base Assembly from wood pallet.

The Main Base Assembly weighs

215 lbs (100 kg). To lift, use power

equipment or get adequate help.

To remove the Main Base Assembly from the wood pallet:

1. Unbolt the four lag bolts that hold each end of the

Main Base Assembly to the pallet.

NOTE: A number symbol and number in parenthesis (#__)

refers to the item number in the parts list section of this

manual.

UNCRATING AND ASSEMBLY INSTRUCTIONS

4

ASSEMBLE LEG LEVELERS TO

BASE ASSEMBLY

Place leg leveler foot (#43) and 1/2" nut (#60) into tapped

holes in cast leg base (#5), see FIG. 1, and adjust to a uni-

form 1" [25 mm] leaving the nut loose.

LOCATE AND LEVEL THE GRINDER

Set the Grinder on a level concrete floor, on a single

uncracked slab of concrete.

Placing the grinder on a floor that is

badly out of level or broken will

affect grinding quality.

If the unit must be located near a wall, allow adequate space

for operating and servicing. The clearance required around

the grinder is a 36" [90 cm] minimum on the two sides and the

frontand 48" [120 cm]minimum to the rear as shown in FIG. 2.

Place a level on the front carriage rail near the center of the

machine and check the level from left to right. See FIG. 3.

Adjust the leveling feet until the machine is level.

Place the level across the front and rear carriage rails

near the left end of the machine. See FIG. 4. Adjust the

two leveling feet on the left end until the rails are level.

Place the level across the front and rear carriage rails

near the right end of the machine. Level the right end in

the same way as the left end. See FIG. 5. For grinding

accuracy, the two ends must be level within +/- .015 in.

(.4 mm) so the frame is not twisted.

Recheckthelevelinboth directions. Whensatisfactory,tighten

the hex jam nuts (#60) on the leveling feet securely against

the bottom of the base. See FIG. 1. Do not turn the leveling

feet when tightening.

Again recheck the level after the nuts are firmly tightened.

For grinding accuracy, the machine

does not have to be perfectly level.

However, IT IS CRITICAL that

front-to-back leveling be the same at

both ends of the machine.

INSTALLATION

FIG. 5

FIG. 1

FIG. 2

FIG. 3

FIG. 4

55

INSTALL REEL ELEVATOR

Bolt the left and right end frames to the top and bottom mounting

brackets already attached to the end panels using four 3/8-16 x

3/4" hex head cap screws (#14), two flatwashers over the top

bracket slots (#19), four lock washers (#21) and four nuts (#16).

The mounting bracket might have to be loosened and adjusted to

line up with the end frames. Bolt the end frame with the decal on

the winch end (right end of unit as viewed from the operator’s

position) See FIG. 6. Bolt gussets loosely to the overhead channel,

which is installed with the pulleys on top, using eight 3/8-16 x 3/4"

long hex head screws (#14), eight lock washers (#21) and eight

nuts (#16). Lift overhead channel into position (Note the position

of the bracket in FIG. 6) and bolt to end frames using eight 3/8-16

x 3/4" long hex head screws (#14), lock washers (#21) and nuts

(#16). Align and securely tighten all nuts.

Attach the winch to the right side of unit as viewed from the

operator’s position with the crank handle facing to the rear. In-

stall two 3/8-16 x 3/4" long hex head cap screws (#14) and one

flatwasher(#19), two lock washers (#21) and two nuts (#16). The

flatwashergoesover the winch housing slot. Assemble the winch

according to the instructions provided in the manual packet.

Thread the cable through the top middle hole in the channel

and over both pulleys. Attach the cable to the winch following

the procedure described in the winch instructions.

The cable is reeled up by rotating handle in a clockwise direction,

as it is reeled up it makes a clicking sound. The spring loaded

handle actuates a brake when handle is released.

Read separate directions on winch

operation and maintenance that is

included in the manual packet.

Placespreaderbarwith chains and hooks onto cable hook (which

has safety latch feature built in). See FIG. 7.

Do not overload the winch capacity.

Winch capacity is a maximum of

400 lbs. (180 kg)

INSTALLATION (Continued)

FIG. 6

FIG. 7

6

INSTALLATION (Continued)

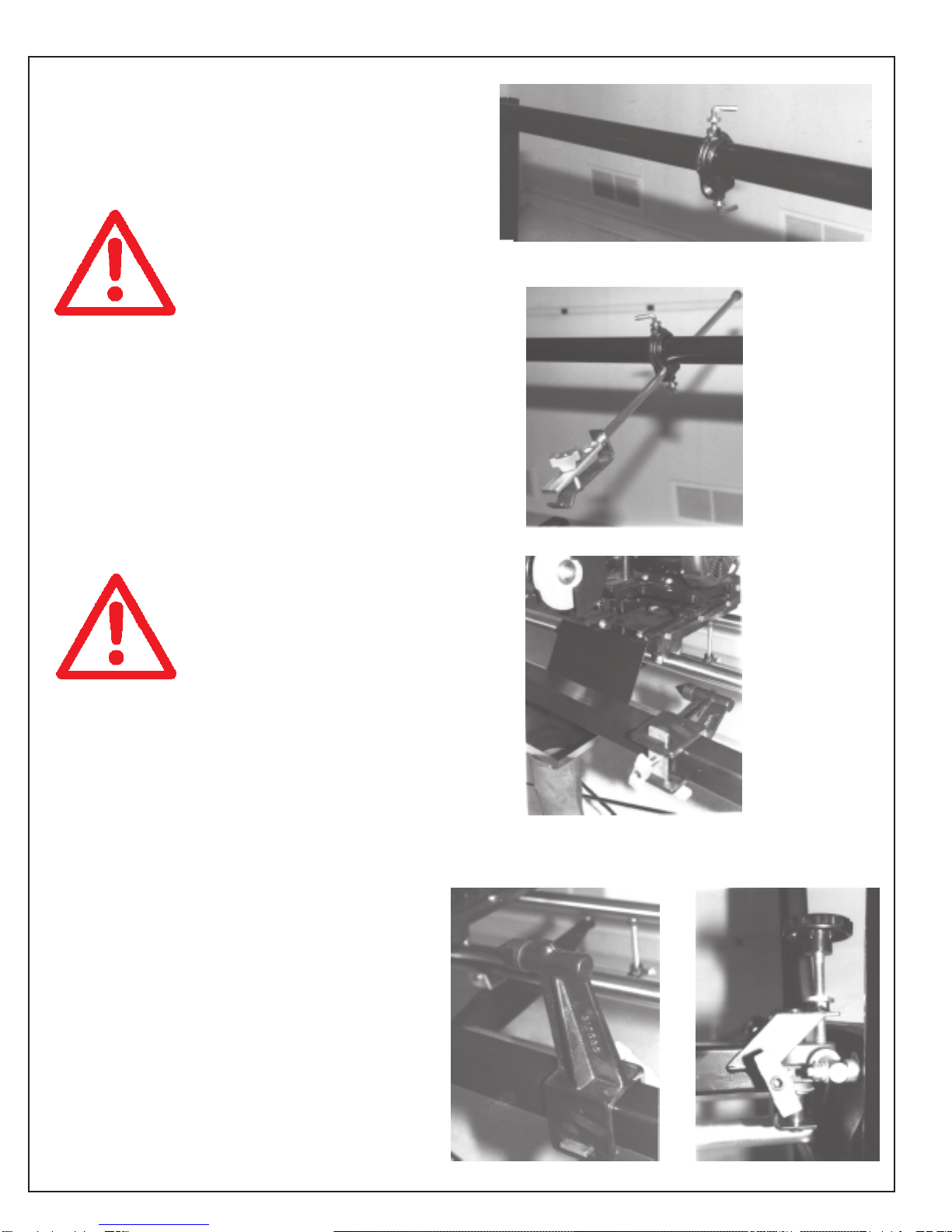

ASSEMBLE OVERHEAD SUPPORT ARM & BAR

Assemble overhead support arm (#25) and (#26) using four

3/8 x 2-1/4" cap screws (#51), four 3/8" nuts (#59), and four

lock washers (#13). Sandwich the warning panel assembly

(#70) between left hand end frame (#2) and the left side

support arm (#25).

Warning panel assembly must be

installed to protect the operator

and visitors.

Install two overhead clamp castings (#8) onto the overhead

bar (#37) as shown in FIG. 8. Assemble overhead bar

(#37) with two 3/8" x 3/4" cap screws (#48) & two lock

washers (#13) being sure to place overhead clamp castings (#8)

onto overhead bar as shown before assembling. See FIG. 8.

Assemble the overhead clamp assemblies. (#45,46,47,62)

onto the overhead clamp castings (#8). Assemble bumper (# 65)

onto mower clamp weldment (#46). See FIG. 9.

MOUNT GRINDING HEAD ASSEMBLY

The Grinding Head Assembly weighs

approximately 85 lbs (40 kg). To lift,

use power equipment or get adequate

help.

Place grinding head assembly onto machine rails. Position

the carriage travel stops (#35) and clamp into place.

Remove grinding wheel guard (#5), install the 6" diameter x 3/8"

wide grinding wheel (#30) and snugly hand tighten. Adjust

the guide finger (#13) and tighten. Then reinstall the grinding

wheel guard (#5).

INSTALL DUST DEFLECTOR SHIELD

Attach the dust deflector shield with two 3/8-16 x 3/4"

cap screws (#40) and two lock washers (#42). Install

Dust Bag (#35) and Hose Clamp (#57). See FIG. 10.

TOOLING BAR COMPONENTS

The reel support centers are mounted horizontally on

the tooling bar. Reposition them vertically on the

tooling bar at this time. See FIGS. 10 and 12.

Assemble the vertical adjusting screw (#33) and lock

(#15). Center the horizontal adjusting screw (#34).

See FIG. 13.

FIG. 13

FIG. 12

FIG. 8

FIG. 9

FIG. 10

77

INSTALLATION (Continued)

FIG. 14

FIG. 15

FIG. 16

Wiring,

as built.

To convert to wiring.

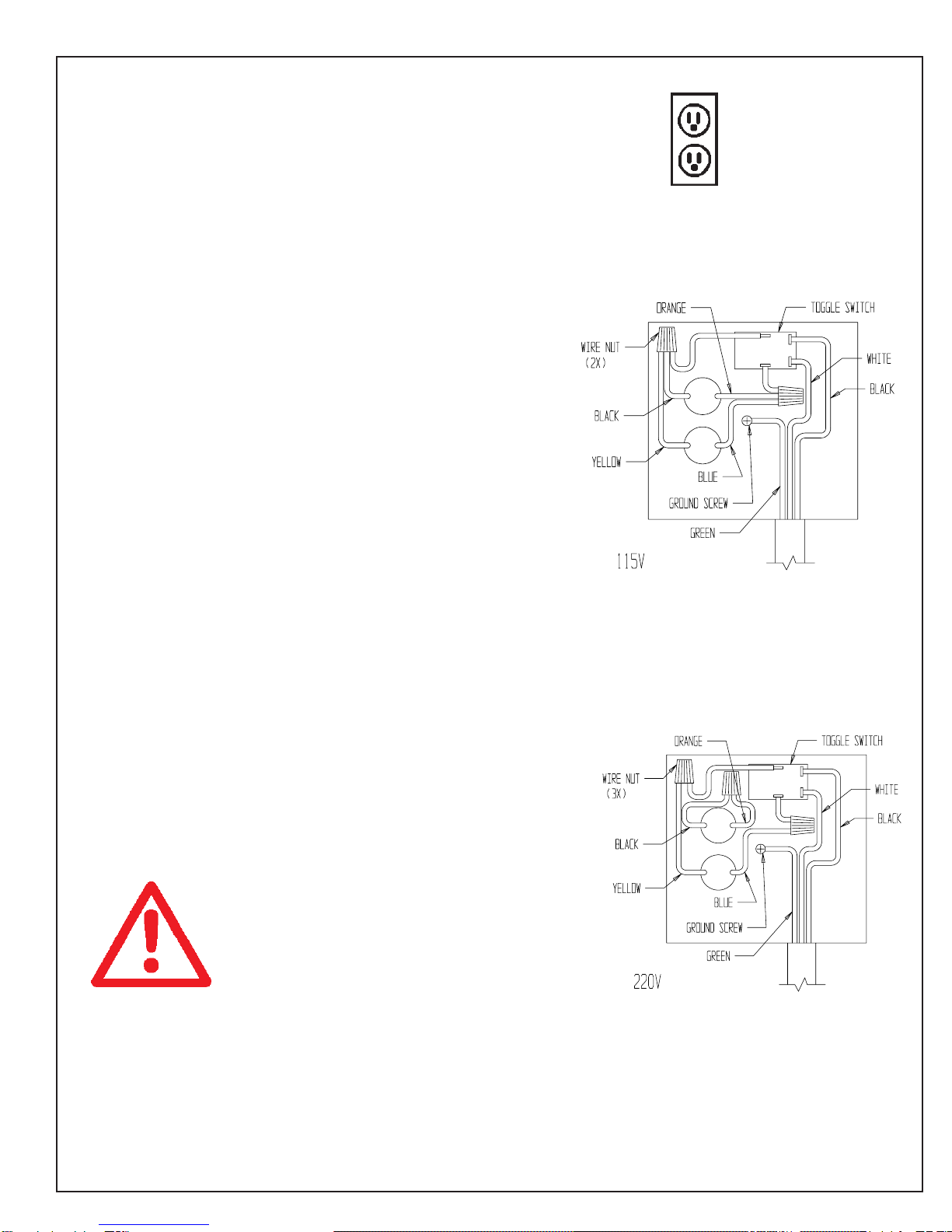

MOTOR WIRING &

GROUNDING INSTRUCTIONS

Your Model 388 Grinder has been completely prewired at

thefactory, andnoadditionalwiring is necessary. TheModel

388 is set up for a 115 VAC, 50/60 HZ 1 Phase - current.

The grinder operates on a 15 AMP circuit. The wall outlet

should be grounded and look like the outlet shown in

FIG. 14. See FIG. 15 for 115 volt motor wiring, as built.

Toconvertthis grinder tooperateon220 V 50/60HZ1phase

current, cut the plug off from the cord and replace it with the

appropriateplug for yourlocality. For plugandcircuit breaker

sizing, see motor nameplate ratings. Use only a qualified

electrician.

To convert the grinder from 115 Volt to 220 Volt, disconnect

the four wires coming from the motor internally and

reconnect them as shown in FIG. 16. One additional wire

nut will be required to complete. NOTE: This motor will

operate correctly on 60 HZ or 50 HZ power.

GROUNDING INSTRUCTIONS

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electrical current to

reduce the risk of electrical shock. This tool is equipped

with an electrical cord having an equipment grounding

conductor and a grounding plug. The plug must be plugged

into the matching outlet that is properly installed and

groundedinaccordance with all local codesandordinances.

Before plugging in your machine, make sure it will be

connected to a supply circuit protected by a properly

sized circuit breaker or fuse.

Do not modify the plug provided if it will not fit the outlet,

have the proper outlet and circuit installed by a qualified

electrician.

Always properly electrical ground

your machine. An improper

connection can cause an electrical

shock. If unsure of the proper

electrical grounding procedure,

contact a qualified electrician.

8

MAINTENANCE

PERIODIC MAINTENANCE

1. Wipe and re-oil with a spray lubricant (do not use a teflon

based lubricant) lead screws once a month or every 40

hours of operation.

2. Wipe and re-oil with never-seez horizontal and vertical

cross slide shafts on mower support bar once a month or

every 40 hours of operation.

3. Lubricate the traverse rails with a spray lubricant (do not

use a teflon based lubricant) and wipe off the excess once

a month or every 40 hours.

4. Check Gib plate adjustment in the grinder carriage base

monthly or every 40 hours. See Page 9.

5. Check ALL Fasteners once every 3 months or 100 hours..

6. Clean dust bag when 1/2 full - approximately every 3

months or 100 hours.

7. Check the belt every 3 months or 100 hours. Check the

tension and look for cracks. See Page 9.

8. Wipe and grease carriage dovetail with lithium grease

every six months or every 200 hours of operation.

9. Rail Alignment - Check every 6 months or every 200

hours. See Page 9.

10. Rotate traverse shafts once a year or every 300 hours of

operation. See Page 9.

99

MAINTENANCE ADJUSTMENTS

GIB ADJUSTMENT

The four gib set screws should be adjusted by loosening the

four lock nuts and then turning in the set screws while turning

the horizontal infeed handwheel. Adjust the gib for a snug

movement of the slide and gib. To adjust all four set screws, it

will be necessary to move the slide from front to back. NOTE:

The slide must be fully in front of the gib screw when making

adjustments. DO NOT adjust the gib screw without the slide

positioned adjacent.

BELT TENSIONING AND REPLACEMENT

To adjust belt tension loosen the two set screws on the Head

Support and push the grinding head forward to tension the belt,

making sure to hold the head square and retighten the set

screws. Headsquarenessis shown on page 7 of the Operator's

Manual. After correctly tensioning the belt, check your tension

with a

5 lbs [2 kg] load applied approximately in the center of the belt,

you should observe 1/8" [3 mm] of deflection. See FIG. 17. To

change the belt, remove the two belt guards, and loosen the set

screwsontheHeadSupport. Push the grinding head in against

the internal spring and remove the belt. Install the new belt

andreversethesequencemaking certain to reinstall the guards.

DO NOT OVERTIGHTEN OR PRY ON THE

GRINDING HEAD TO TIGHTEN. DAMAGE

COULD OCCUR TO THE MOTOR OR GRINDING

HEAD BEARING.

RAIL ALIGNMENT AND ROTATION

The front (away from the operator) carriage rail is adjustable

in horizontal and vertical planes. The rear rail (nearest the

operator) is adjustable only in the vertical plane. Using a

PRECISION straight edge adjust the rails using the set screws

(#54) and locknuts (#57) as shown on pages 16 and 17.

Afterextendeduse, the carriage bearingswillstartto wear tracks

into the carriage rails. To minimize this, it is recommended that

once a year or every 300 hours of operation the carriage rails

should be turned. Loosen the set screws holding the carriage

rails and turn the rails so the bearings run on a new track.

Retighten the set screws. After rail turning, recheck rail

straightness.

FIG. 17

10

TROUBLESHOOTING

PROBLEM

PROBLEM

No electrical power to

grinding motor.

Reel ground in a

concave, convex, or

irregular shape.

This is determined by

irregularitiesin therelief

grind, i.e.: larger on

ends than center, vice

versa, irregular relief,

not uniform

POSSIBLE CAUSE

Main power source

is off.

Nottraversed manually

with uniform travel

speed.

Not a uniform travel

speed coming off the

end of reel blade.

Overhead clamps and

fixture clamps not

holding mower unit

tight.

Squaretube toolingbar

for fixture holding is not

rigid.

REMEDY

Turn on main circuit

breaker. Plugpower in.

Verify motor switch is

on.

Travel at a very steady

speed on the reel

blade.

Travel at a very steady

speed across the full

blade. Do not slow

down near the end of

the blade.

Tighten down all locking

hand knobs. Four hand

knobs for the square

tube side and bottom

clamps; two knobs for

the mower holding

clamps; and two knobs

for the mower clamp

swivel. Checkalignment

of overhead clamp so

thereisnobindingbefore

locking down of hand

knobs. Useallenwrench

for increased tightness

of appropriate knobs.

The pivot end is bolted

on rubber mounts. On

adjustable end, tighten

slide end locking

handles one for vertical

and one for horizontal

locking.

REASON

Irregular speed on the

blade will cause

irregular grind pattern.

To eliminate reel

movement during

grinding.

To eliminate reel

movement during

grinding.

1111

TROUBLESHOOTING CONT.

PROBLEM

Reel ground in a

concave, convex, or

irregular shape, cont.

POSSIBLE CAUSE

Grinding wheel head

moving.

Gibs loose on carriage.

Carriage ball bearings

worn outside diameter

or internal wear.

Grinding Head Bearing

has develped free play.

REMEDY

Tighten up two set

screws that hold the

Grinding Head into the

Head Support.

There is a lock handle

to tighten. It is the lock

handlewithanylon plug

atthetiptosetthetension

against the threads for

thegrindingwheelvertical

height adjustment

screw.

The two adjustable

cone point set screws

on the pivot of the mo-

tor plate need adjust-

mentso the motor plate

has no side movement.

Tighten gib screws to

prevent movement.

Adjust the motor slide

baseforwardandadjust

the gib screws. Then

adjust the motor slide

base all the way back

and adjust the final gib

screws.

Replace bearings.

Try to move the grinding

wheel from side to side

with the power

disconnected. If there

is more than .005" [.13

mm] side movement,

replace the grinding

head assembly.

REASON

To prevent grinding

head from moving

during grinding.

To prevent grinding

head from moving.

To prevent grinding

head from moving

during grinding.

To prevent the grinding

wheelfrommovingduring

grinding.

12

TROUBLESHOOTING CONT.

PROBLEM

Reel ground in a

concave, convex, or

irregular shape, cont.

POSSIBLE CAUSE

Tooling bar support

brackets are loose.

REMEDY

All reels are mounted

with two V-support

brackets or two center

support brackets. Be

suretheyare tighttothe

square tooling support

tube in horizontal and

vertical plane. Tighten

the horizontal locking

screws. First, firmly

pulling the center

bracket over to the side

of the tooling support

tube. Then tighten the

vertical locking handle

to pull down the

supports to the tooling

supporttube. Whenus-

ing center supports,

check to see if the fixed

center is screwed in

tight to its casting using

a wrench. The

adjustable center is to

be locked tight with the

locking hand knob.

REASON

When the supports are

not held tight to the

square tube, the reel

can move during

grinding.

Loose centers effect

grinding accuracy.

1313

TROUBLESHOOTING CONT.

PROBLEM

Reel ground in a

concave, convex, or

irregular shape, cont.

POSSIBLE CAUSE

Rails not straight.

Check rail towards the

reel side for

straightness in the

horizontal plane.

Rails not straight.

Checkvertical planefor

straightness of rails.

Carriage has varying

load in either direction

from grinding grit

buildup inside the

carriagebearingsorun-

even wear on the bear-

ing outside

diameter.

Rails have grinding grit

buildup and carriage

bearings do not track

straight.

REMEDY

Using a three foot long

PRECISION straight

edge, and feeler gage,

checkforamaximum of

.002 inch [.05 mm]

straightnessat thefront

edge of the front rail.

Front rail has three ad-

justing screws. Rear

rail has one adjusting

screw.

Using a three foot long

PRECISION straight

edge, and using a

feelergage, checkfor a

maximum of .003 inch

[.08 mm] straightness

at the top edge of the

front rail and rear rail.

Replace Bearings

Clean rails of grinding

grit.

REASON

Rail straightness

directly affects grind

straightness of the

outside diameter of

the reel in the

horizontal plane.

This plane is not as

criticalforreel grinding

accuracy,butstillmust

be held to tolerance

listed to hold grind

straightness of

outside diameter of

the reel.

Bearings will fail after

many hours of use.

Rails buildup with grit

during operation and

must be cleaned

often.

14

TROUBLESHOOTING CONT.

PROBLEM

Cone shape of reel.

Relief grind on the reel

blades does not go full

length.

Blades are turning blue

during grinding.

POSSIBLE CAUSE

Reel position not

parallel to

carriage travel.

Grinding wheel is not

correctly dressed.

Removing too much

material in one pass.

REMEDY

Use reel alignment

gage procedure

touchingoff onreel hub

to zero out the reel

positionfrom eachend.

(For more information,

see reel setup gage

procedure in manual.)

See the correct

grindingwheeldressing

procedure on page 15

of the Operator's

Manual.

Adjust the horizontal

infeed to remove less

material per pass.

REASON

Reel hub has to be

parallel to carriage

traverse rails so reel is

not cone shaped.

If grinding wheel is

improperly dressed

it will not grind

approximately the

last 3/8" of the blade.

Heavy material

removal builds up

heat and turn the

blade blue.

1515

--This page left blank intentionally, for note taking purposes--

16

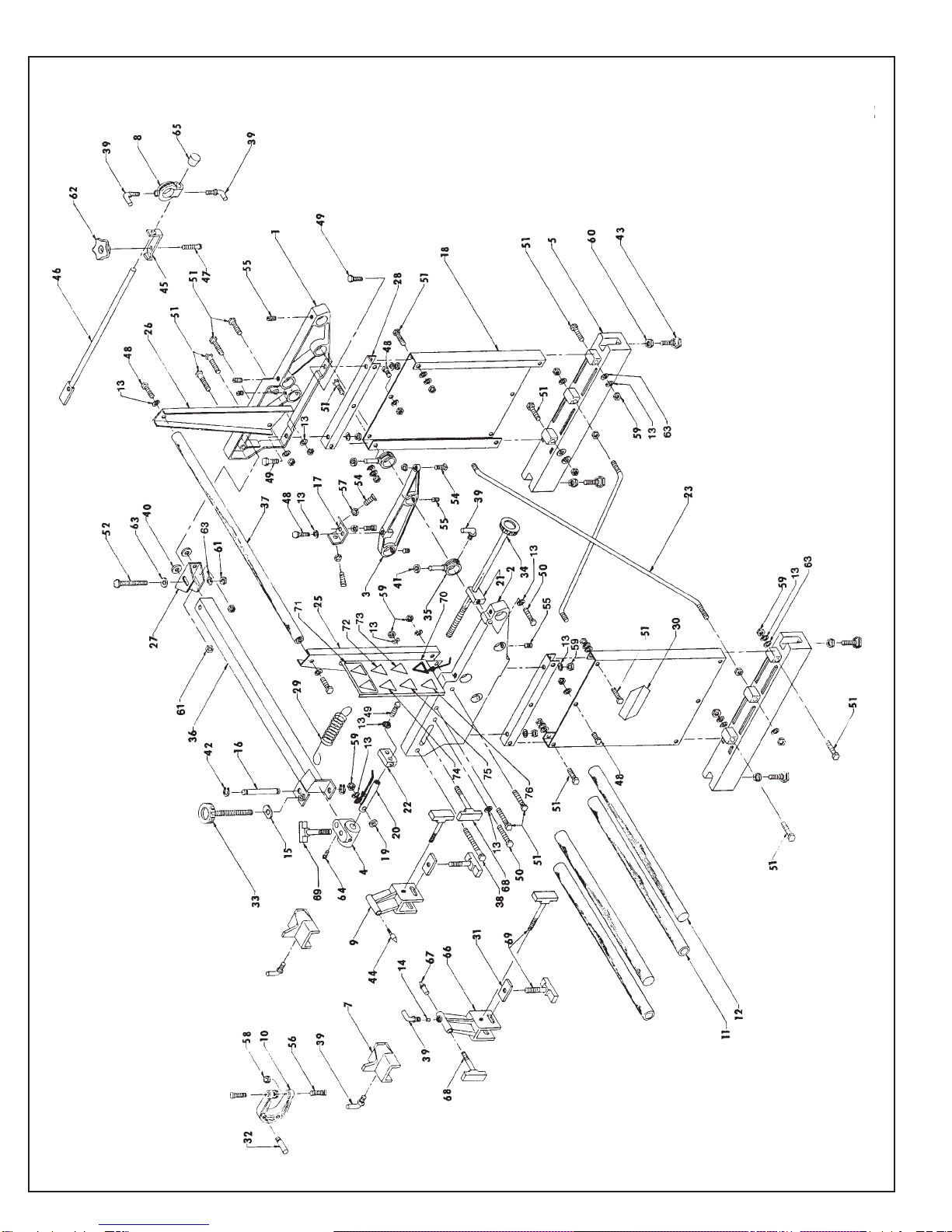

EXPLODED VIEW: 388 MAIN BASE ASSEMBLY

77

78

1717

PART NO.

3889001

3889002

3889003

3969012

3889009

3889014

3889015

3889016

3889017

3889031

3889032

K371501

3579109

3889035

3889039

3889041

3889043

3889045

3889046

3889047

3889048

3889049

3889051

3889052

3889053

3889054

3889055

3709990

3889066

3889067

3889510

3889511

3889514

3889521

3889522

B375601

3709253

3709254

3709255

3709331

PART NO.

3709563

6009517

3649078

3969547

A313202

B371201

B371601

B373201

B373601

B374801

C251602

C370820

C374000

J251000

J372000

J371000

J501000

J377100

3708262

K370001

R601018

3709258

3889022

6009020

6009577

6009555

3889112

3708524

3708461

3708526

3707458

3708525

3708527

3708528

K310101

DIAGRAM NO.

1

2

3

4

5

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

PART NAME

Right-Hand End Frame

Left-Hand End Frame

Strut

Cross Slide

Base

Roller Bracket

Overhead Clamp

Center Stand - Fixed

"C" Clamp

Frame Tie Bar

Carriage Rail

Lockwasher 3/8

Nylon Plug

Lock

Clevis Pivot Pin

Adjusting Bracket

End Frame Panel

Spacer

Cross Slide Shaft

Guide Block

Support Block

Tie Rod

Left-Hand Overhead Support Arm

Right-Hand Overhead Support Arm

"L" Bracket

End Cap

Spring - Support Bar

Decal

Center Stand Lock

Shoulder Pin

Vertical Adjust. Screw Assembly

Horizontal Adjust. Screw Assembly

Carriage Stop Assembly

Tube Weldment

Overhead Bar

Hex Cap Screw 3/8-16 x 3-1/2 Long

Lock Handle

Rubber Washer

Rubber Washer

Retaining Ring

DIAGRAM NO.

43

44

45

46

47

48

49

50

51

52

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

PART NAME

Adjust Leveling Bolt

Center - Fixed

Clamp Lip

Mower Clamp Weldment

Round Head Machine Screw 5/16-18 x 2" Long

Hex Cap Screw 3/8-16 x 3/4" Long

Hex Cap Screw 3/8-16 x 1" Long

Hex Cap Screw 3/8-16 x 2" Long

Hex Cap Screw 3/8-16 x 2-1/4 " Long

Hex Cap Screw 3/8-16 x 3" Long

Square Hd Set Screw Oval Point 1/4-20 x 1" Long

Sock Set Screw 3/8-16 x 2-1/2" Long

Square Hd Set Screw 3/8-16 x 2-1/2" Long

Hex Nut 1/4-20

Hex Jam Nut 3/8-16

Hex Nut 3/8-16

Hex Nut 1/2-13

Hex Nut Nylok 3/8-16

Knob 5/16-18 x 1.50 Wide

Plain Washer 3/8

Drive Screws No. 2 Round Head

Bumper

Center Stand - Adjustable

Center - Adjustable

Knob Assy

Knob Assy

Warning Panel

Warning Decal - Glasses

Warning Decal - 3600 RPM

Warning Decal - No Fuel

Warning Decal - Sharp

Warning Decal - Stay Clear

Warning Decal - Respirator

Warning Decal - Hearing Protection

Flat Washer - Heavy

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

. . . . .

PARTS LIST: 388 MAIN BASE ASSEMBLY

. . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . .

18

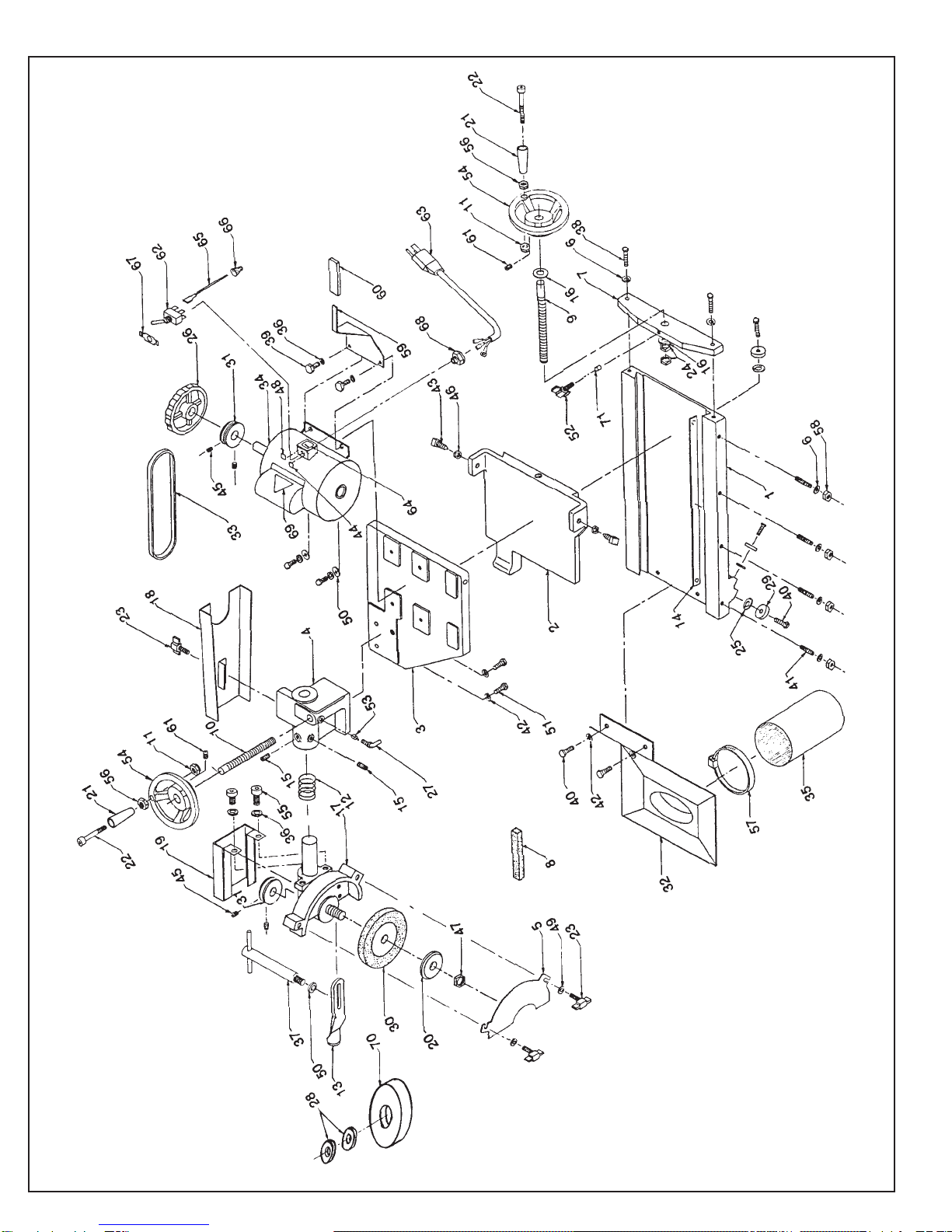

EXPLODED VIEW: 388 GRINDING HEAD ASSEMBLY

1919

DIAGRAM NO. PART NO. PART NAME

41 . . . . .C252420 . . . . . . Socket Setscrew 1/4-20x1-1/2" Long

42 . . . . .K371501 . . . . . . 3/8" Lockwasher

43 . . . . .C372000 . . . . . . Square Head Setscrew 3/8-16x1-1/4" Long

44 . . . . .3708460 . . . . . . Start Decal

45 . . . . .C250620 . . . . . . Socket Setscrew 1/4-20x3/8" Long

46 . . . . .J372000 . . . . . . 3/8-16 Hex Jam Nut

47 . . . . .J502100 . . . . . . 1/2-20 Hex Jam Nut

48 . . . . .3708459 . . . . . . Emergency Stop Decal

49 . . . . .K250001 . . . . . . 1/4" Flat Washer

50 . . . . .K310001. . . . . . .5/16" Flat Washer

51 . . . . .B371601 . . . . . . Hex Head Cap Screw 3/8-16x1" Long

52 . . . . .6109597 . . . . . . Tee Knob Assembly

53 . . . . .3579109 . . . . . . Nylon Plug 3/16"

54 . . . . .3708155 . . . . . . Hand Wheel

55 . . . . .B310811. . . . . . Socket Head Cap Screw 5/16-18x1/2" Long

56 . . . . .J252000 . . . . . . 1/4-20 Hex Jam Nut

57 . . . . .3709804 . . . . . . Hose Clamp

58 . . . . .J251000 . . . . . . 1/4-20 Hex Nut

59 . . . . .3889110 . . . . . . Carriage Handle Bracket

60 . . . . .3709624 . . . . . . Plastic Handle

61 . . . . .C310420. . . . . . Socket Setscrew 5/16-18x1/4" Long

62 . . . . .3707070 . . . . . . Toggle Switch

63 . . . . .3707034 . . . . . . Cord Set

64 . . . . .3707130 . . . . . . Warning Decal

65 . . . . .3707188 . . . . . . Wire Assembly

66 . . . . .3707264 . . . . . . Wire Nut

67 . . . . .3707316 . . . . . . On-Off Switch Plate

68 . . . . .3707976 . . . . . . Conduit Connector

69 . . . . .3708448 . . . . . . Warning Decal - Electrical

70 . . . . .3700265 . . . . . . Grinding Wheel 6x1x1.25 Bore 60 Grit

Straight Cupped Vitrified Ruby

71 . . . . .3579284 . . . . . . Nylon Plug 1/8"

** . . . . . 3700067 . . . . . . Grinding Wheel 6-4x1x1.25 Bore 60 Grit

Flared Cupped Vitrified Ruby

** . . . . . 3700266 . . . . . . Grinding Wheel 6x1x1.25 Bore 46 Grit

Straight Cupped Vitrified Grey

** OPTIONAL

DIAGRAM NO. PART NO. PART NAME

1 . . . . . .3889005 . . . . . . Carriage Base

2 . . . . . .3889006 . . . . . . Slide

3 . . . . . .3889007 . . . . . . Motor Plate

4 . . . . . .3889008 . . . . . . Head Support

5 . . . . . .6009037 . . . . . . Grinding Wheel Guard

6 . . . . . .K251501 . . . . . . 1/4" Lockwasher

7 . . . . . .3889136 . . . . . . Feed Screw Guide

8 . . . . . .3702508 . . . . . . Dressing Stick .75x.75x3"

9 . . . . . .3889056 . . . . . . Feed Screw

10 . . . . .3889057 . . . . . . Elevating Screw

11 . . . . .J257000 . . . . . . 1/4-20 Locknut - Thin

12 . . . . .3889059 . . . . . . Compression Spring

13 . . . . .6009133 . . . . . . Reel Guide Finger

14 . . . . .6009025 . . . . . . Gib Plate

15 . . . . .C310826 . . . . . . 5/16-18x1/2 Long Dog Point Setscrew

16 . . . . .3709027 . . . . . . Thrust Washer

17 . . . . .3889502 . . . . . . Grinding Head Assembly

18 . . . . .3889523 . . . . . . Motor Belt Guard

19 . . . . .3889509 . . . . . . Grinding Head Belt Guard

20 . . . . .3649018 . . . . . . Outer Flange

21 . . . . .3709370 . . . . . . Spinning Handle

22 . . . . .B255011 . . . . . . 1/4-20x3-1/8 Long Socket Head Cap Screw

23 . . . . .6009598 . . . . . . Tee Knob Assembly

24 . . . . .3709214 . . . . . . Hex Jam Nut 1/2-13 LH

25 . . . . .3709216 . . . . . . Retaining Washer

26 . . . . .3889098 . . . . . . Handwheel

27 . . . . .3709253 . . . . . . Lock Handle

28 . . . . .3700408 . . . . . . Reducer Bushing

29 . . . . .3709257 . . . . . . Ball Bearing

30 . . . . .3700363 . . . . . . Grinding Wheel 6x3/8x1/2 Bore 46 Grit Vitrified Ruby

31 . . . . .3889088 . . . . . . Pulley

32 . . . . .3889501 . . . . . . Dust Collector

33 . . . . .3709764 . . . . . . V - Belt

34 . . . . .3707991 . . . . . . Motor 115/220V 60/50HZ 1 Phase

35 . . . . .3708146 . . . . . . Dust Bag

36 . . . . .K311501 . . . . . . 5/16 Lockwasher

37 . . . . .6009535 . . . . . . Tee Handle Assembly

38 . . . . .B251601 . . . . . . Hex Head Cap Screw 1/4-20x1" Long

39 . . . . .B311401 . . . . . . Hex Head Cap Screw 5/16-18x7/8" Long

40 . . . . .B371201 . . . . . . Hex Head Cap Screw 3/8-16x3/4" Long

MODEL 388 GRINDING HEAD ASSEMBLY

20

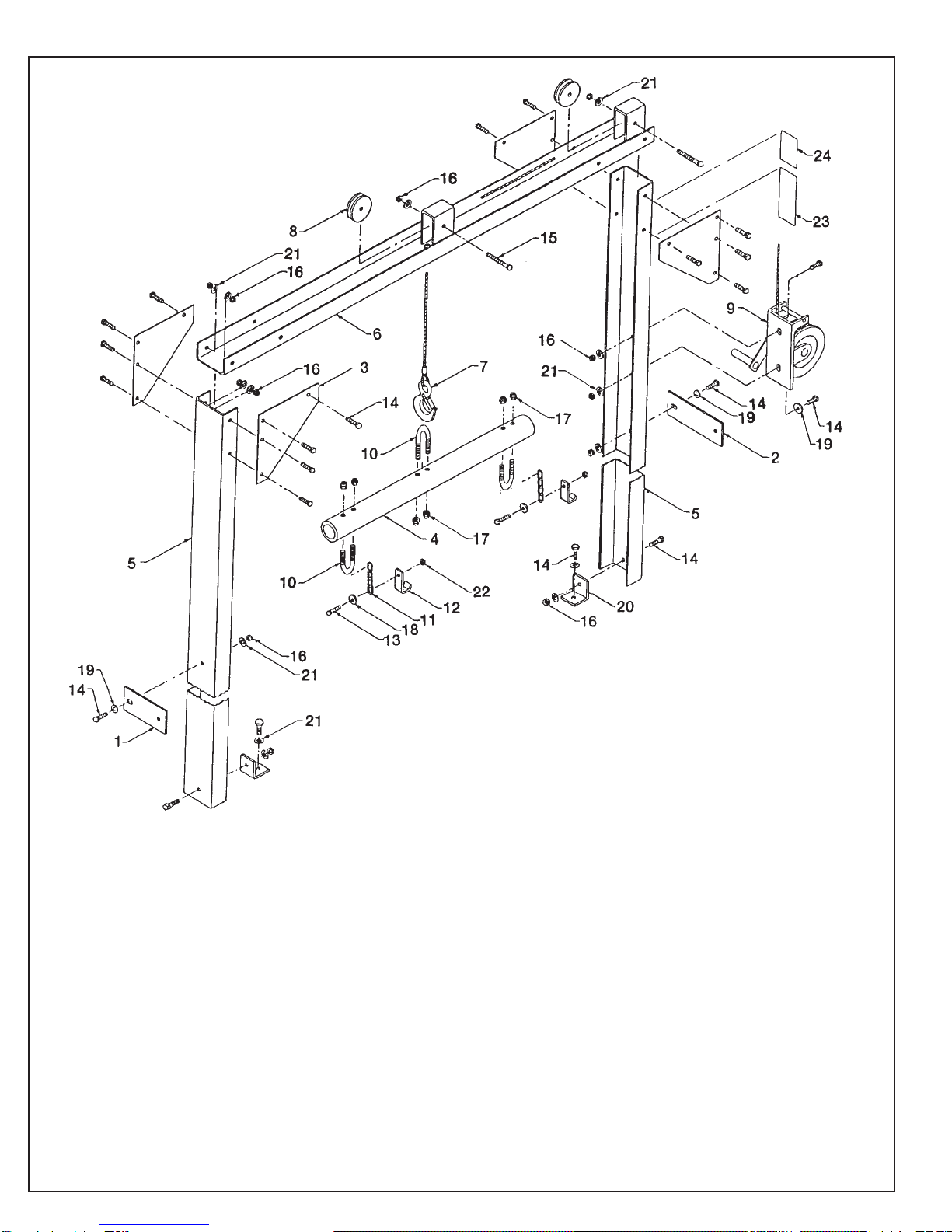

DIAGRAM NUMBER

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

PARTS LIST: 388 ELEVATOR ASSEMBLY

PART NAME

Anchor Strap

Anchor Strap

Gusset

Spreader

End Frame

OverheadChannelWeldment

Hook and Cable Assembly

Pulley

Winch

"U" Bolt

Chain

Grab Hook

Hex Cap Screw 3/8-16 x 1.00 Long

Hex Cap Screw 3/8-16 x 3/4" Long

Hex Cap Screw 3/8-16 x 1-3/4" Long

Hex Nut 3/8-16

Hex Nut Nylok 5/16-18

Plain Washer

Plain Washer 3/8

AngleTab

Lock Washer 3/8

Hex Nut Nylok 3/8-16

Winch Warning Decal

Winch Warning Decal - Symbol

PART NUMBER

3889068

3889069

3889071

6009011

6009166

3889526

3709407

3709795

3709796

3709316

3649005

6009102

B371601

B371201

B372801

J371000

J317100

R000453

K370001

3889074

K371501

J377100

6009099

3708449

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

Table of contents

Other Foley United Grinder manuals

Popular Grinder manuals by other brands

Napa/Evercraft

Napa/Evercraft 775-0232 Instruction manual & parts breakdown

Desoutter

Desoutter KA309-9 manual

Speedaire

Speedaire 10D235 Operating instructions & parts manual

Bosch

Bosch Professional GWS 12-125 CIP Original instructions

Bluerock Tools

Bluerock Tools 120D Operational manual

Bluebird

Bluebird SG1314A Operator's manual