Foley United 633 User manual

ORIGINAL INSTRUCTIONS

THIS BOOK CONSISTS OF TWO MANUALS:

The OPERATOR'S MANUAL, which contains all the

informaon to install, operate, and perform daily

maintenance on this equipment.

The SERVICE MANUAL, which is used by the

maintenance department to do all maintenance,

except roune daily maintenance.

633

AUTO - INDEX

SPIN / RELIEF

REEL GRINDER

ORIGINAL INSTRUCTIONS

We are commied to:

Providing superior customer support, training, and service.

Manufacturing the highest quality products at an unequaled

value.

Seng the industry standard by invesng in technological

product innovaon.

Manufacturing products specically designed to maintain

original equipment manufacturers' specicaons.

Interacng with and supporng all original equipment

manufacturers.

ORIGINAL INSTRUCTIONS

633

AUTO - INDEX

SPIN / RELIEF

REEL MOWER GRINDER

Patent No. 5,321,912

6,010,394 & 6,290,581

6,685,544 & 6,699,103

OPERATOR'S

MANUAL

6337950 (12-16)

YOU MUST THOROUGHLY READ AND UNDERSTAND ALL MANUALS BEFORE

OPERATING THE EQUIPMENT, PAYING PARTICULAR ATTENTION TO THE WARNING &

SAFETY INSTRUCTIONS.

4

ORIGINAL INSTRUCTIONS

IMPORTANT SAFETY MESSAGE

and a

READ AND FULLY UNDERSTAND ALL THE SAFETY PRACTICES DISCUSSED IN THIS

MANUAL. ALL SAFETY RULES MUST BE UNDERSTOOD AND FOLLOWED BY ANYONE

WHO WORKS WITH REEL GRINDERS.

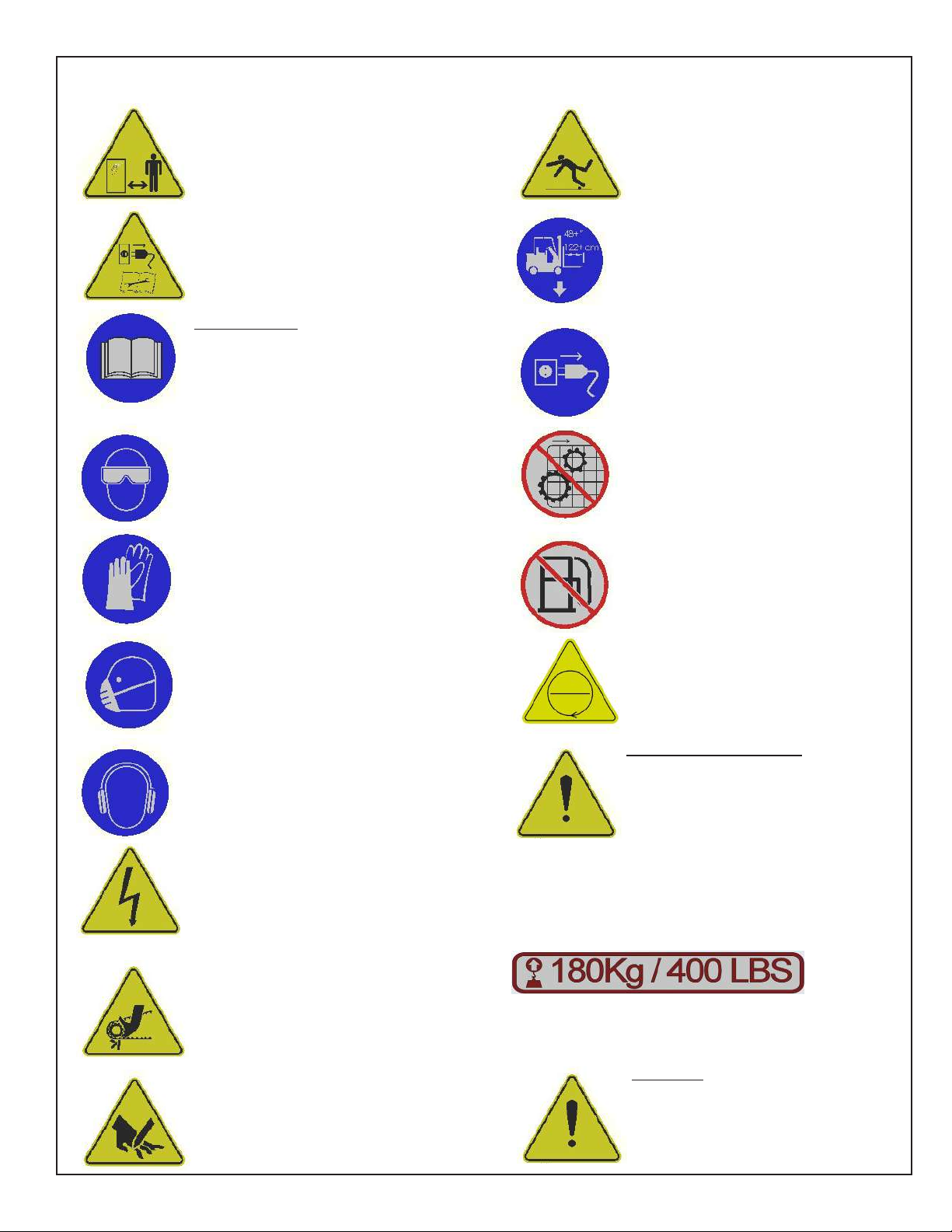

This symbol is used throughout this manual to call aenon to the safety

procedures.

The word DANGER indicates an immediate hazardous situaon, which if not

avoided, will result in death or serious injury.

The word WARNING indicates a potenal hazardous situaon, which if not

avoided, could result in death or serious injury.

The word CAUTION preceded with a safety alert symbol indicates a potenal

hazardous situaon which, if not avoided, may result in minor or moderate injury.

THROUGHOUT THIS MANUAL, THE FOLLOWING SAFETY SYMBOLS WILL BE USED TO INDICATE THE

DEGREE OF HAZARDS.

5

ORIGINAL INSTRUCTIONS

TABLE OF CONTENTS

THIS MACHINE IS DESIGNED FOR SHARPENING REEL TYPE MOWER BLADES ONLY. ANY USE OTHER

THAN THIS MAY CAUSE PERSONAL INJURY AND VOID THE WARRANTY.

TO ASSURE THE QUALITY AND SAFETY OF YOUR MACHINE AND TO MAINTAIN THE WARRANTY, YOU

MUST USE ORIGINAL EQUIPMENT MANUFACTURER'S REPLACEMENT PARTS AND HAVE ANY REPAIR

WORK DONE BY A QUALIFIED PROFESSIONAL.

ALL OPERATORS OF THIS EQUIPMENT MUST BE THOROUGHLY TRAINED BEFORE OPERATING

THE EQUIPMENT.

DO NOT USE COMPRESSED AIR TO CLEAN GRINDING DUST FROM THE MACHINE. THIS DUST CAN

CAUSE PERSONAL INJURY AS WELL AS DAMAGE TO THE GRINDER.

PREPARATION/INSTALLATION CHECK LIST

BEFORE USING THIS EQUIPMENT REFER TO THE LIST BELOW. VERIFY THAT ALL OF THE LISTED ITEMS

ARE COMPLETED BEFORE POWERING UP THE EQUIPMENT:

6

ORIGINAL INSTRUCTIONS

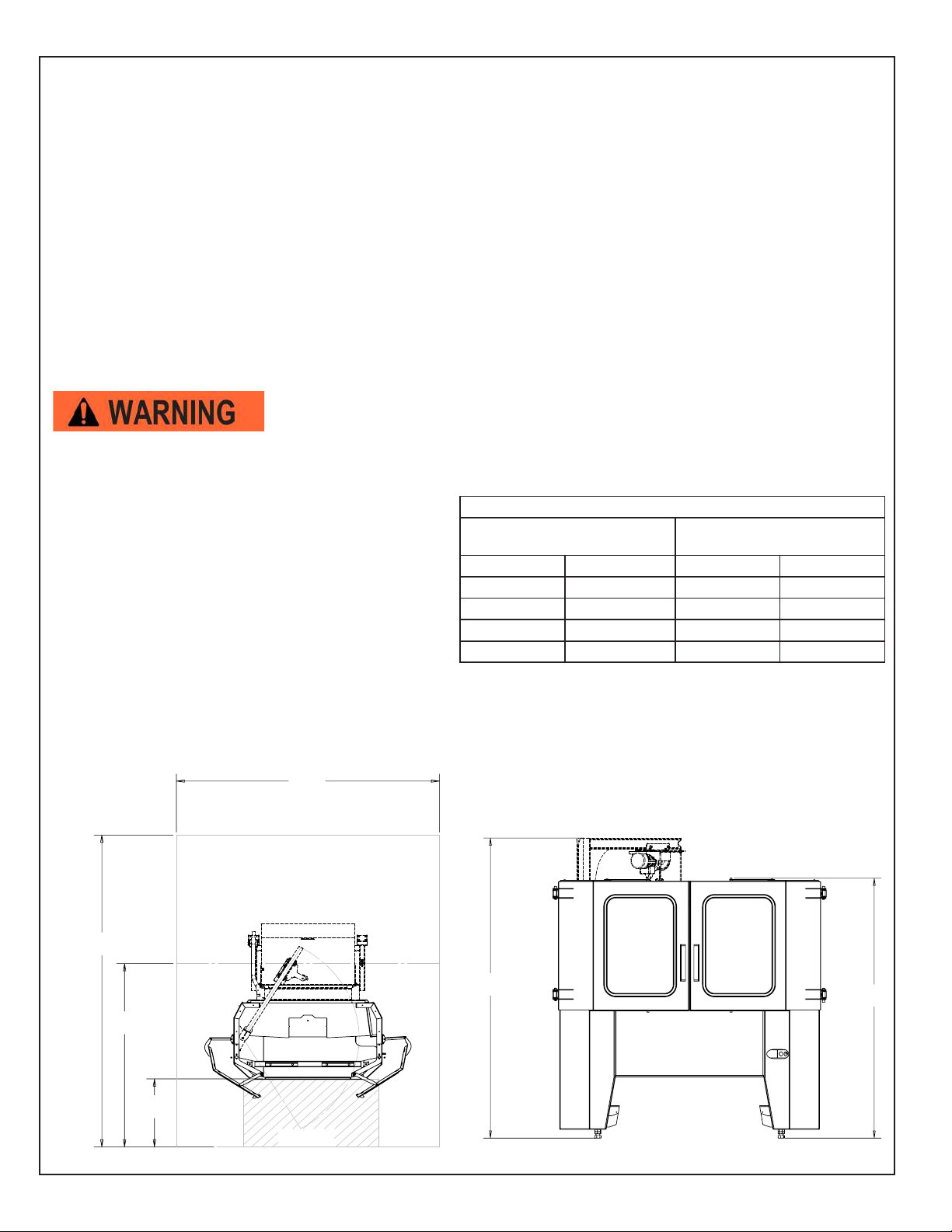

SPECIFICATIONS

OPERATING CONDITIONS: THIS MACHINE IS INTENDED FOR INDOOR USE ONLY.

AMBIENT TEMPERATURE: ................+5°C/ 40°F to +40°C/ 100°F

RELATIVE HUMIDITY: ......................

ALTITUDE: .......................................

TRANSPORTATION AND STORAGE:...-25°C/-15°F to +55°C / 130°F

SOUND LEVEL: ...............................

Means must be provided to prevent damage from humidity, vibraon and shock.

FIG. 1

7

ORIGINAL INSTRUCTIONS

DO NOT USE COMPRESSED AIR TO CLEAN GRINDING DUST FROM GRINDER.

LOW VOLTAGE RELAY

DAILY INSPECTION

INTERLOCK SYSTEM

THE DAILY INSPECTION SHOULD BE

PERFORMED ONLY WHEN THE MACHINE IS

OFF AND ALL MOTORS HAVE STOPPED.

NEVER OPERATE EQUIPMENT WITH THE INTERLOCK SYSTEM DISCONNECTED OR

MALFUNCTIONING. NEVER DISCONNECT OR BYPASS ANY SWITCH OR GUARDING.

1.

2.

3.

4.

8

ORIGINAL INSTRUCTIONS

SAFETY INSTRUCTIONS

TO AVOID INJURY, READ AND UNDERSTAND THE SAFETY ITEMS LISTED BELOW. IF YOU DO

NOT UNDERSTAND ANY PART OF THIS MANUAL AND NEED ASSISTANCE, CONTACT YOUR

LOCAL DEALER OR THE MANUFACTURER.

13. MAINTAIN GRINDER WITH CARE.

14. DISCONNECT POWER BEFORE SERVICING,

15. REDUCE THE RISK OF UNINTENTIONAL

STARTING.

16. USE RECOMMENDED ACCESSORIES.

17. CHECK FOR DAMAGED PARTS.

18. NEVER LEAVE THE GRINDER RUNNING

UNATTENDED. TURN THE POWER OFF.

19. KNOW YOUR EQUIPMENT.

20. KEEP ALL SAFETY DECALS CLEAN AND LEGIBLE.

21. DO NOT OPERATE GRINDER WHEN UNDER

THE INFLUENCE OF DRUGS, ALCOHOL, OR

MEDICATION.

1. KEEP GUARDS IN PLACE

2. REMOVE WRENCHES AND OTHER TOOLS.

3. KEEP WORK AREA CLEAN.

4. DON'T USE IN DANGEROUS ENVIRONMENT.

5. KEEP ALL VISITORS AWAY.

6. MAKE THE WORK AREA CHILD-PROOF

7. DON'T FORCE THE GRINDER.

8. USE THE RIGHT TOOL.

9. WEAR PROPER APPAREL.

10. ALWAYS USE SAFETY GLASSES.

11. SECURE YOUR WORK.

12. DON'T OVERREACH.

9

ORIGINAL INSTRUCTIONS

SAFETY INSTRUCTIONS

IMPROPER USE OF GRINDING WHEEL MAY CAUSE BREAKAGE AND SERIOUS INJURY.

DO

1. DOHANDLE AND STORE

CAREFUL

2. DO VISUALLY INSPECT

3. DO CHECK MACHINE SPEED

4. DO CHECK MOUNTING FLANGES

5. DO USE MOUNTING BLOTTERS

6. DOWORK REST

7. DOUSE A SAFETY GUARD

COVERING

8. DONEWLY MOUNTED WHEELS

9. DOWEAR SAFETY GLASSES

DON'T

1. DON'THAS

BEEN DROPPED

2. DON'T FORCEOR

ALTER

3. DON'TEXCEED THE MAXIMUM

OPERATING SPEED

4. DON'T

ARE NOT CLEAN, FLAT

AND FREE OF BURRS.

5. DON'T TIGHTEN

6. DON'TSIDE OF THE WHEEL

7. DON'TWHEEL

GUARD IS IN PLACE.

8. DON'T JAM

9. DON'T STAND DIRECTLY IN FRONT

10. DON'T FORCE THE GRINDING

AVOID INHALATION OF DUST

Grinding is a safe operaon if the few basic rules listed below are followed. These rules are based on

material contained in the ANSI B7.1 Safety Code for "Use, Care and Protecon of Abrasive Wheels". For

your safety, we suggest you benet from the experience of others and carefully follow these rules.

10

ORIGINAL INSTRUCTIONS

SAFETY INSTRUCTIONS

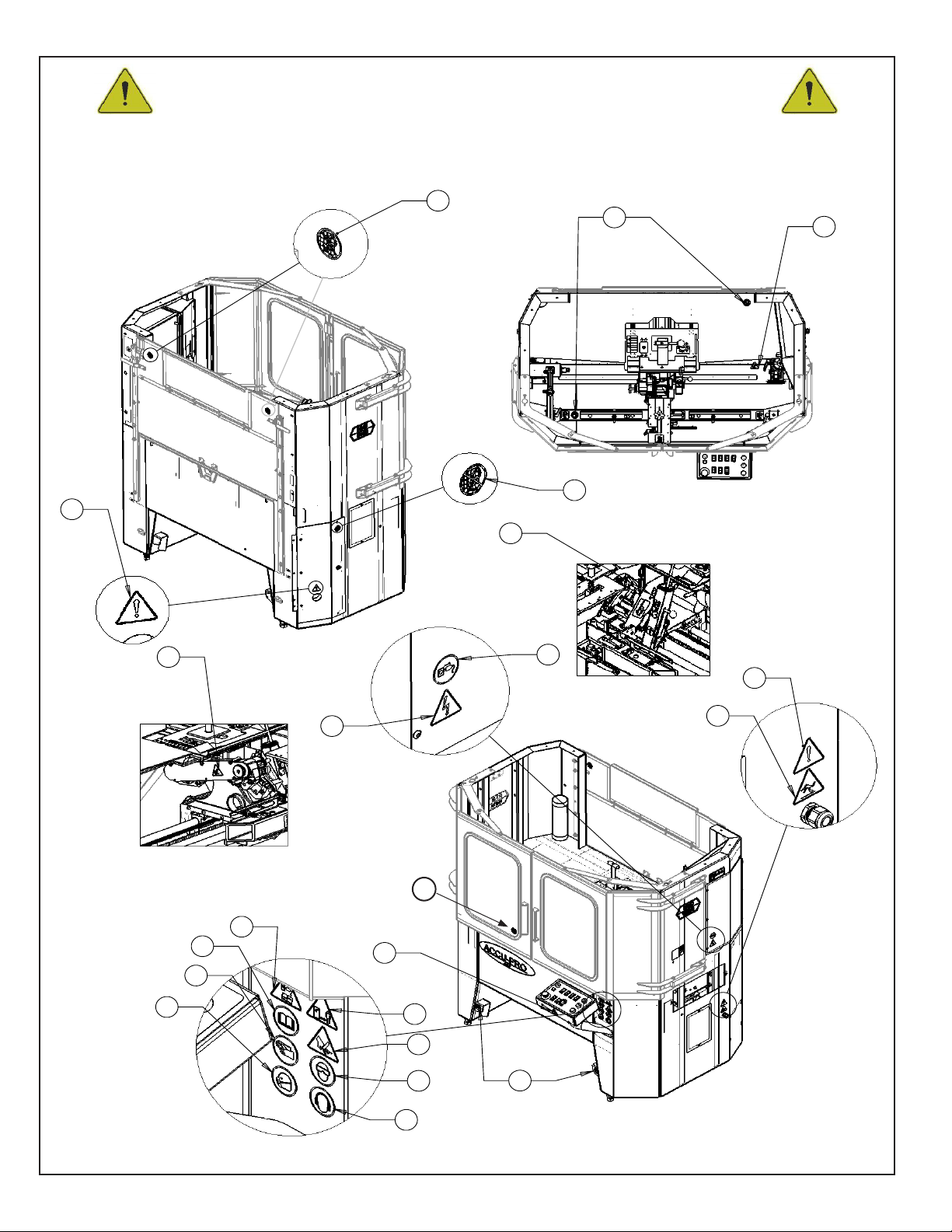

SAFETY DECALS - LOCATION.

IF ANY DECALS ARE DAMAGED, REPLACE THEM IMMEDIATELY!

See next page for explanaon of symbols and decals.

12

8

DETAIL A

SCALE 1 : 5

13

3

5

61

10

4

7

2

8

17

11

15 9

16

9

14

19

14

14

11

ORIGINAL INSTRUCTIONS

SAFETY INSTRUCTIONS

READ AND UNDERSTAND AND LOCATE ALL DECALS ON THIS MACHINE BEFORE OPERATING

THIS EQUIPMENT.

1

2

11

10

9

8

7

6

5

4

3

17

15

14

13

12

Keep hands clear of sharp

edges!

DANGEROUS

HIGH VOLTAGES PRESENT

REFER SERVICING TO

QUALIFIED SERVICE PERSONNEL ONLY.

must wear respirators or have

adequate venlaon systems.

WARNING! Hearing protecon required

Refer to manual

POWER CORD PROTECTION

hand

protecon is required

16

MIN

3600

18

19 VACUUM -

12

ORIGINAL INSTRUCTIONS

36"

[91CM]

165" [419 CM]

WORKSTATION

125

[318CM]

97"

[245CM]

OPERATOR &

LOAD AREA

AREA REQUIRED IF USING

THE OPTIONAL WORKSTATION

INSTALLATION INSTRUCTIONS

FIG. 2

70

[178 CM]

81

[206 CM]

REMOVE GRINDER FROM WOOD PALLET

THE UNIT WEIGHS 1450 LBS. [658 KG]. USE POWER EQUIPMENT

TO LIFT THE UNIT.

POSITION THE BASE

PLACING THE GRINDER ON FLOORING THAT IS NOT LEVEL OR BROKEN WILL AFFECT GRINDING

QUALITY.

MACHINE MUST BE POSITIONED TO ALLOW EASY ACCESS TO THE MAIN POWER CORD PLUG FOR USE

AS THE MAIN DISCONNECT. SEE POWER INSTALLATION SECTION FOR ADDITIONAL INFORMATION.

ELECTRICAL REQUIREMENTS:

• ALWAYS USE A PROPERLY GROUNDED OUTLET!

0-40 0-12 12 4.0

40-60 12-18 10 6.0

60-100 18-30 8 10.0

100-160 30-48 6 16.0

13

ORIGINAL INSTRUCTIONS

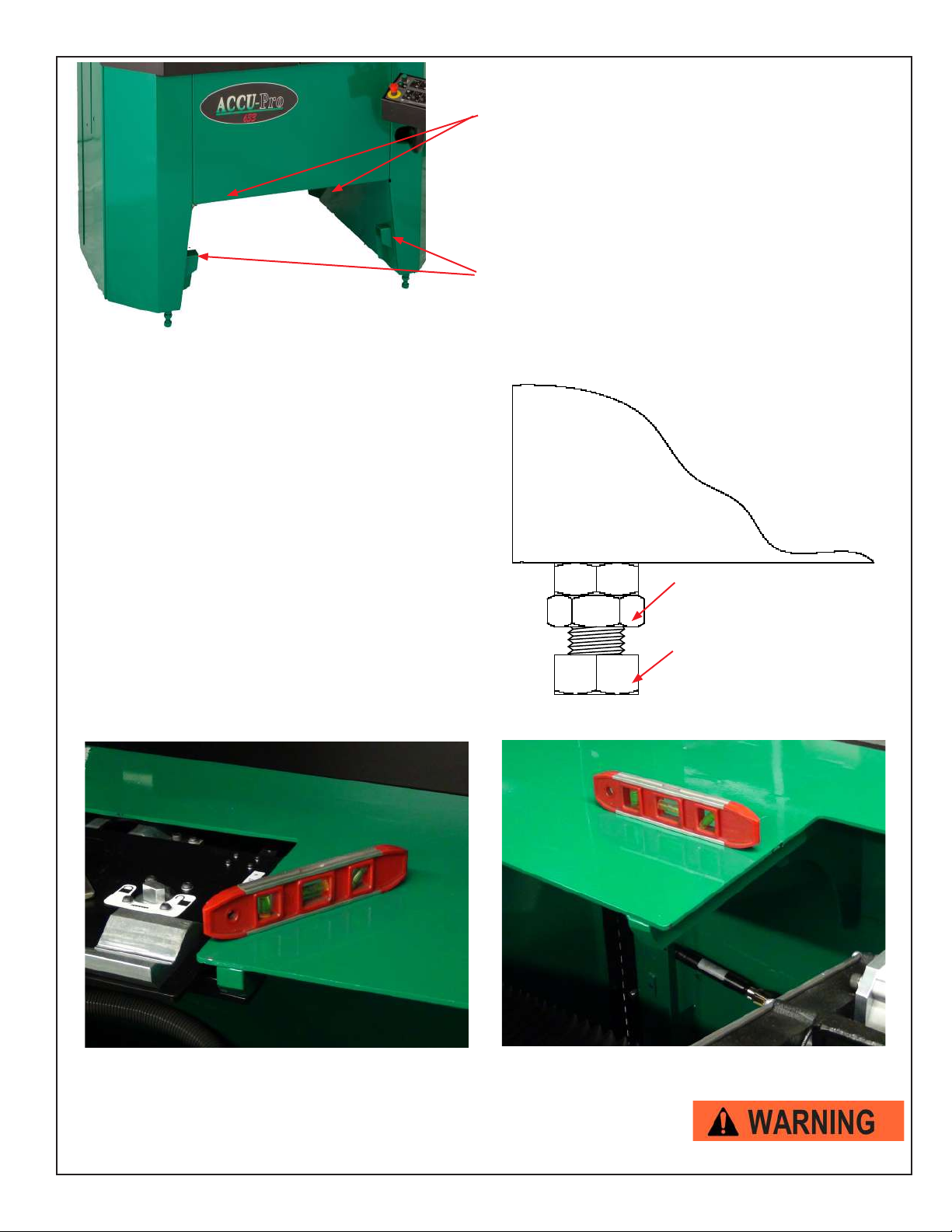

INSTALLATION INSTRUCTIONS

LEVEL BASE

See FIG. 5.

FIG. 4

FIG. 6FIG. 5

LOOSEN JAM NUT TO

ADJUST FOOT

LEVELING FEET LOCATED

THE EQUIPMENT SHOULD NEVER BE LEFT UNATTENDED WHEN RUNNING.

LIFTING LOCATION

FIG. 3

14

ORIGINAL INSTRUCTIONS

It is recommended that grinder has its own permanent power connecon from the power

distribuon panel, with no other major power draw equipment on the same line.

The grinder is equipped with a high-low voltage relay (LVR) which is factory preset at 100-140 V

ac. If the VOLTAGE INSIDE THE CONTROL PANEL FALLS OUTSIDE OF THE RANGE OF 100-140 V ac

power under load, the relay will open and trip out the starter. If this occurs, your power supply

line is INADEQUATE TO RUN THIS MACHINE and must be corrected before proceeding any further

with the grinder. If the oponal transformer is installed on the outside of the machine, the

power delivered to the machine will be 230 V ac, but the power in the machine must be 100-140

V ac under load as stated above.

DO NOT operate this grinder with an extension cord.

Do not operate this grinder on a Ground Fault interrupter (GFI) circuit. Nuisance tripping of the

(GFI) may occur.

PROPER GROUNDING OF THE RECEPTACLE GROUND IN YOUR BUILDING MUST BE VERIFIED.

IMPROPER GROUNDING IN YOUR BUILDING MAY CAUSE THE GRINDER TO MALFUNCTION.

POWER INSTALLATION

IF THE MACHINE DOES NOT HAVE A PLUG ON THE END OF THE MAIN POWER CORD, A PLUG OR

CONNECTOR THAT COMPLIES TO THE LOCAL LAWS AND REGULATIONS SHOULD BE INSTALLED BY A

QUALIFIED ELECTRICIAN. THE PLUG IS CLASSIFIED AS A CATEGORY 0 MAIN DISCONNECT. DO NOT

WIRE THIS MACHINE DIRECTLY TO A POWER SOURCE WITHOUT A PLUG OR CONNECTOR UNLESS

A DEVICE THAT MEETS THIS CATEGORY 0 MAIN DISCONNECT REQUIREMENT IS USED TO PROVIDE

POWER TO THE MACHINE.

IMPORTANT GROUNDING INSTRUCTIONS

In case of a malfuncon or breakdown, grounding reduces the risk of electrical shock by providing a path

of least resistance for electrical current.

This grinder has an electrical cord with an equipment grounding conductor and a grounding plug. The plug

must be plugged into a matching outlet that is properly installed and grounded according to all local or

other appropriate electrical codes and ordinances.

Before plugging in the grinder, make sure it will be connected to a supply circuit protected by a

properly-sized circuit breaker or fuse. SEE SERIAL NUMBER PLATE FOR FULL LOAD AMP RATING OF YOUR

MACHINE.

Never modify the plug provided with the machine--if it does not t the outlet, have a proper outlet and

circuit installed by a qualied electrician.

Always provide a proper electrical ground for your machine. An improper connecon can cause a

dangerous electrical shock. If you are unsure of the proper electrical grounding procedure, contact a

qualied electrician.

INSTALLATION INSTRUCTIONS

15

ORIGINAL INSTRUCTIONS

INSTALLATION INSTRUCTIONS

120 VOLT MODEL ONLY.

STANDARD PLUG FOR

FIG.7

230 V 50/60Hz MODEL

USE ONLY A QUALIFIED

ELECTRICIAN TO

COMPLETE THE

INSTALLATION.

FIG. 8

1. and

2. X3

A

3.

14 G. (2.5MM) GREEN

GROUNDWIRE TO BE

ADDED.

GROUND WIRE

GROUND WIRE

BROWN

NEUTRAL

BROWN

0-40 0-12 12 4.0

40-60 12-18 10 6.0

60-100 18-30 8 10.0

100-160 30-48 6 16.0

16

ORIGINAL INSTRUCTIONS

GETTING TO KNOW YOUR GRINDER

5. CONTROL

1.

2.

3.

4.

5. CONTROL

SYSTEMS

4. SPIN DRIVE

17

ORIGINAL INSTRUCTIONS

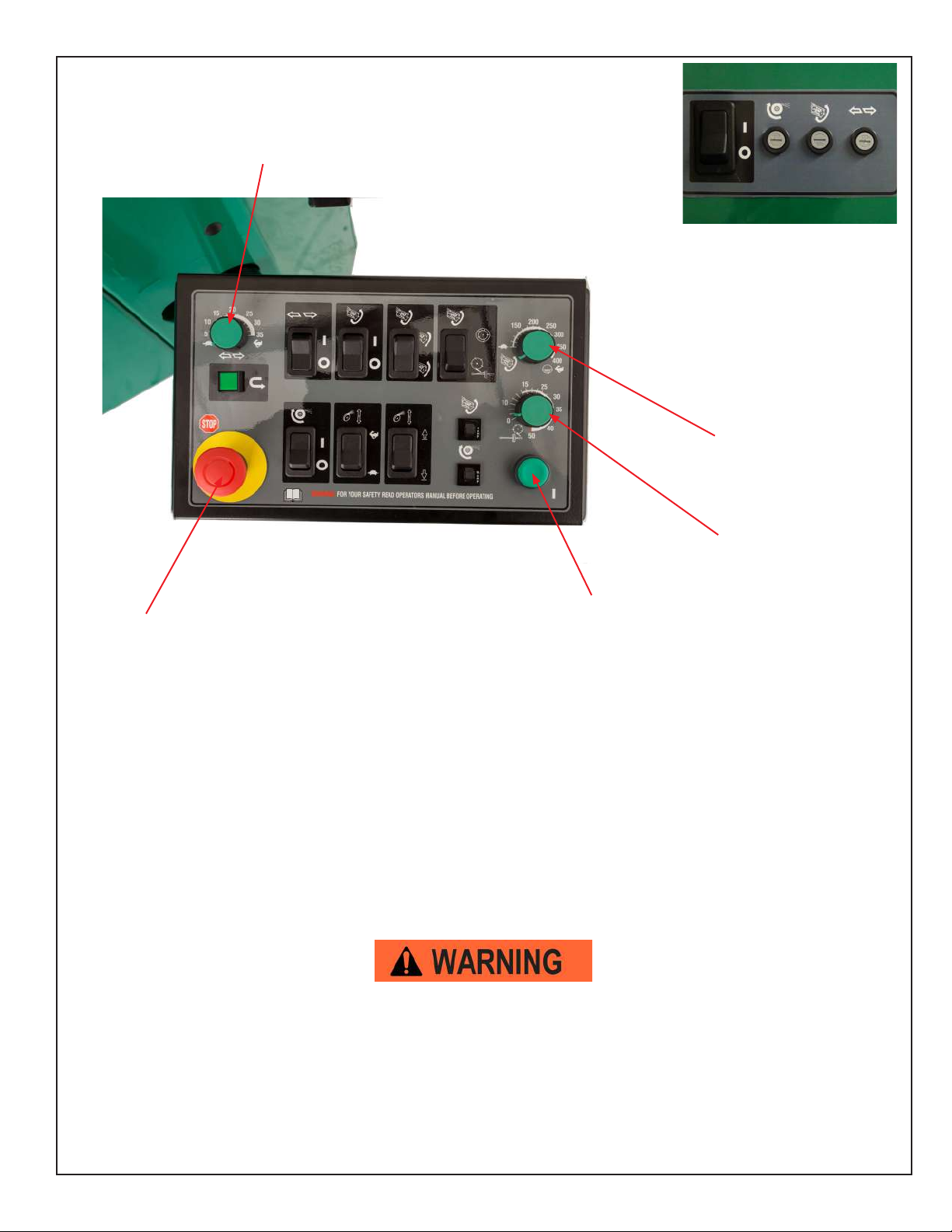

GETTING TO KNOW YOUR GRINDER

CONTROLS

2. START/RESET BUTTON

5. TORQUE

6. SPIN SPEED

1.

2. START/RESET BUTTON

3.

4.

THIS IS NOT A MAIN DISCONNECT!

5.

6.

18

ORIGINAL INSTRUCTIONS

OPERATION

the E-STOP BUTTON

RESET BUTTON.

RELIEF ANGLE DECAL

RELIEF ANGLE

ADJUSTER

REEL POSITIONER

RELIEF ANGLE ADJUSTER. NOTE: The pre-posioned sengs

do not work for walking greens mowers with a rear drum only. SEE PAGE 38.

RELIEF ANGLE.

STEP 1: PLACING THE CUTTING UNIT

PREPARE CUTTING UNIT

1.

2.

3.

4.

12° angle

Example: If your reel is a 7" Jacobsen reel you will set the ACCU-REEL POSITIONER as shown above and

the relief will be set to the corresponding 12° angle as shown in the picture to the right. If the reel you are

grinding does not t these parameters see Page 38.

19

ORIGINAL INSTRUCTIONS

OPERATION-WINCH

FRONT ELECTRIC BOOM LOADING

REAR ELECTRIC BOOM OPTION

LIFTING OPTIONS

LIFTING A REEL INTO POSITION

OPTIONAL BOOM WITH ELECTRIC WINCH

1.

2.

OPTIONAL ELECTRIC WINCH

OPTIONAL WORKSTATION - Can be used to load from the

rear on both the ACCU-Master and the ACCU-Pro Grinders.

20

ORIGINAL INSTRUCTIONS

OPERATION

Read carefully before aempng to operate or service your oponal electric winch or oponal

Workstaon! Failure to comply with instrucons could result in personal injury and/or property damage!

FOR YOUR OWN SAFETY AND THAT OF OTHERS, THIS EQUIPMENT MUST BE USED AS RECOMMENDED BY

THE MANUFACTURER. FAILURE TO HEED THE FOLLOWING RECOMMENDATIONS COULD ENDANGER YOUR

LIFE.

DO NOT ATTEMPT TO

MOVE LOADS GREATER THAN THIS RATINGS.

2. NEVER CARRY

3. NEVER MOVE A LOAD

4. DO NOT ALLOW

5. KEEP CLEAR OF RAMP OR WINCH WIRE ROPE AND

HOOK WHEN OPERATING. DO NOT ATTEMPT to

6. AVOID

7. BE SURE

8. DO NOT OPERATE

9. KEEP WORKSTATION/WINCHING AREA CLEAR.

11. ALLOW WORKSTATION/WINCH TO COOL

DOWN FREQUENTLY

12. DO NOT OPERATE WORKSTATION/WINCH WHEN

UNDER THE INFLUENCE OF DRUGS, ALCOHOL, OR

MEDICATION.

13. DO NOT USE WORKSTATION/WINCH TO HOLD

LOADS IN PLACE

14. USE ONLY FACTORY APPROVED SWITCHES,

REMOTE CONTROLS AND ACCESSORIES.

15. DO NOT MACHINE OR WELD ANY PART OF THE

WORKSTATION/WINCH

16. DO NOT OPERATE THIS WORKSTATION/WINCH

OUT DOORS OR IN A CORROSIVE OR EXPLOSIVE

ENVIRONMENT.

NOTE: THE FOLLOWING APPLY TO OPERATION OF

THE WINCH ONLY.

1. MAINTAIN A MINIMUM OF 4 TURNS OF WIRE

ROPE

2. WHEN SPREADER BAR ASSEMBLY IS USED

3. NEVER HOOK THE WIRE ROPE BACK ON ITSELF.

USE THE SPREADER BAR ASSEMBLY.

4. DO NOT

5. NEVER TOUCH

6. INSPECT WIRE ROPE FREQUENTLY

7. USE HEAVY LEATHER GLOVES

Table of contents

Other Foley United Grinder manuals

Popular Grinder manuals by other brands

Meterk

Meterk S1M-GW20-115 Translation of the original instructions

U.S.SAWS

U.S.SAWS SX65000C operating manual

Parkside

Parkside PWS 230 C3 Translation of the original instructions

SUHNER ABRASIVE

SUHNER ABRASIVE ASC 9 Technical document

PTA

PTA P1322 Operation manual

Craftsman

Craftsman CMCG400 instruction manual