Foley 308 User manual

OPERATINGINSTRUCTIONS

308

FOLEYSAWCHAINGRINDER

SERVICEMANUALNO.R001088

/iV,

FOLEYMANUFACTURINGCOMPANY

3300FIFTHSTREETNORTHEAST

MINNEAPOLIS,MINNESOTA55418

ONEYEARGUARANTEE

AllFoleyequipmentisguaranteedtobesturdily

constructedandfreeofdefectsinworkmanshipor

material.

Ifwithinoneyearfromdateofshipment,any

partsshouldprovedefective,replacementpartswill

befurnishedfreeofchargewhendefectivepartis

returnedpostpaidforinspection.

Guaranteedoesnotcoverdamagesustainedin

transitorcausedbymisuse.

Wereservetherighttomakechangesindesign,

construction,ormaterialsonallFoleymachines

withoutnotice.

FOLEYMANUFACTURINGCOMPANY

ServiceDepartment3300FifthSt.N.E.

MINNEAPOLIS,MINNESOTA55418

Telephone612—789-8831

PrintedinU.S.A.

GENERALINSTRUCTIONSFORUSEANDOPERATION

OFMODEL308FOLEYSAWCHAINGRINDER

IMPORTANT

ItisverysimpletooperatetheFoleyGrinder.Allyouneeddoislearntheadjustmentsbefore

startingtogrindyourfirstchain.Thiswillsaveyoutimeandtrouble.Firstreadallthegen-

eralinstructionsgiveninthemanual.HaveChainGrinderinfrontofyouasyoureadthe

manual.Thenatthestartofyourfirstpracticesession,referagaintothesectioncovering

theparticulartypeofchainyouwishtogrind.

CHECKINGSHIPMENTOFMACHINEFOR

DAMAGEANDCOMPLETENESS

ExamineShipment:Carefullyinspectthemachinefor

intransitdamage.Lookparticularlyforcrackedcast-

ings,bentorbrokenparts.Anylossof,ordamaged

partsshouldbereportedtothefreightagentimmedi-

ately.Securethefreightagent'snotationoflossor

damageonthefreightbill.Trafficregulationsrequire

thetransportationcompanytostandcostofrepairor

replacement.

REPAIRORREPLACEMENTOF

DAMAGEDMACHINE

Youmayelecttofileyourownclaimagainstthetrans-

portationcompany.Incaseofdamagetoeasily

replacedparts,orderandpayforthenewpartsneeded;

enteryourclaimfortheirvalueagainstthedelivering

carrier.ReturnentiremachinetoMinneapolisforcom-

pleterebuildingonlyincaseofseriousdamage.

Alternatively,youmayaskthefactorytorepairor

replacewithoutcosttoyou.Inthiscase,thefollowing

papersmustbesenttoMinneapolissopartsreplace-

mentmaybeassessedagainsithetransportationcom-

pany:

(a)Itemizedreportshowingnatureandextentof

damage.

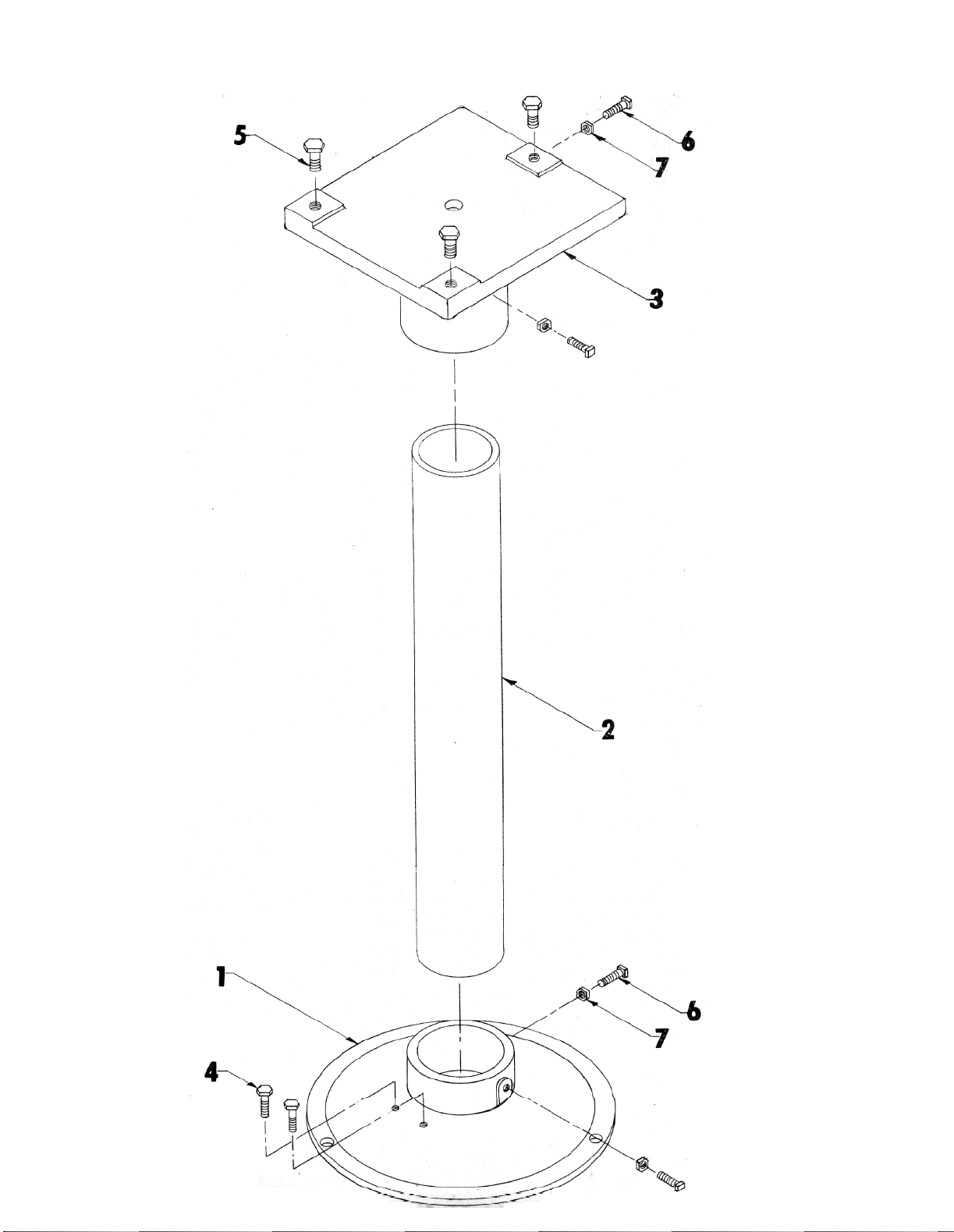

Seeexplodedviewdrawingforpartsindentifica-

tion.

(b)Paidfreightbill,bearingagent'snotationofdam-

age.

(c)Orginalbilloflading,andinvoice(ifavailable).

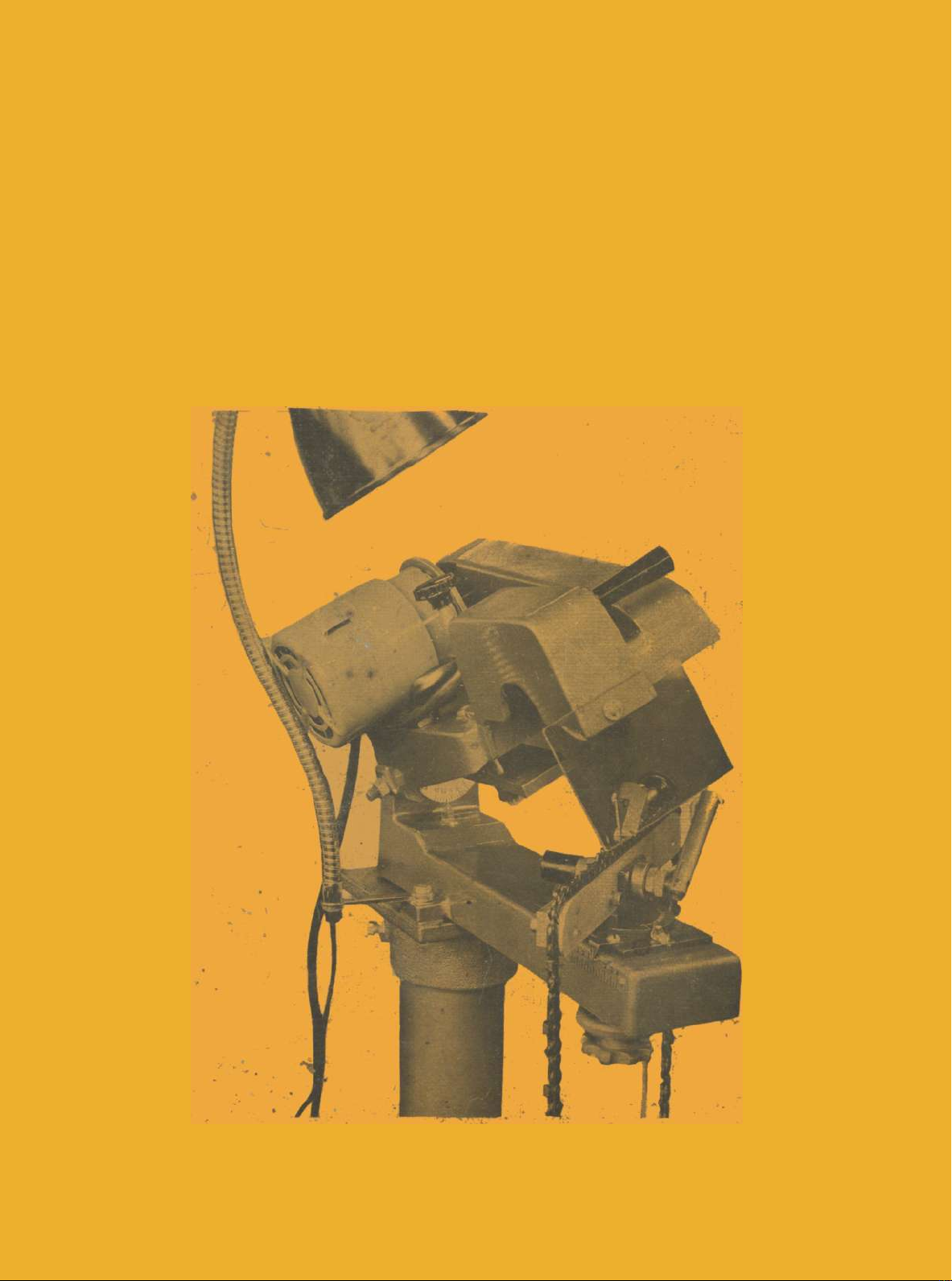

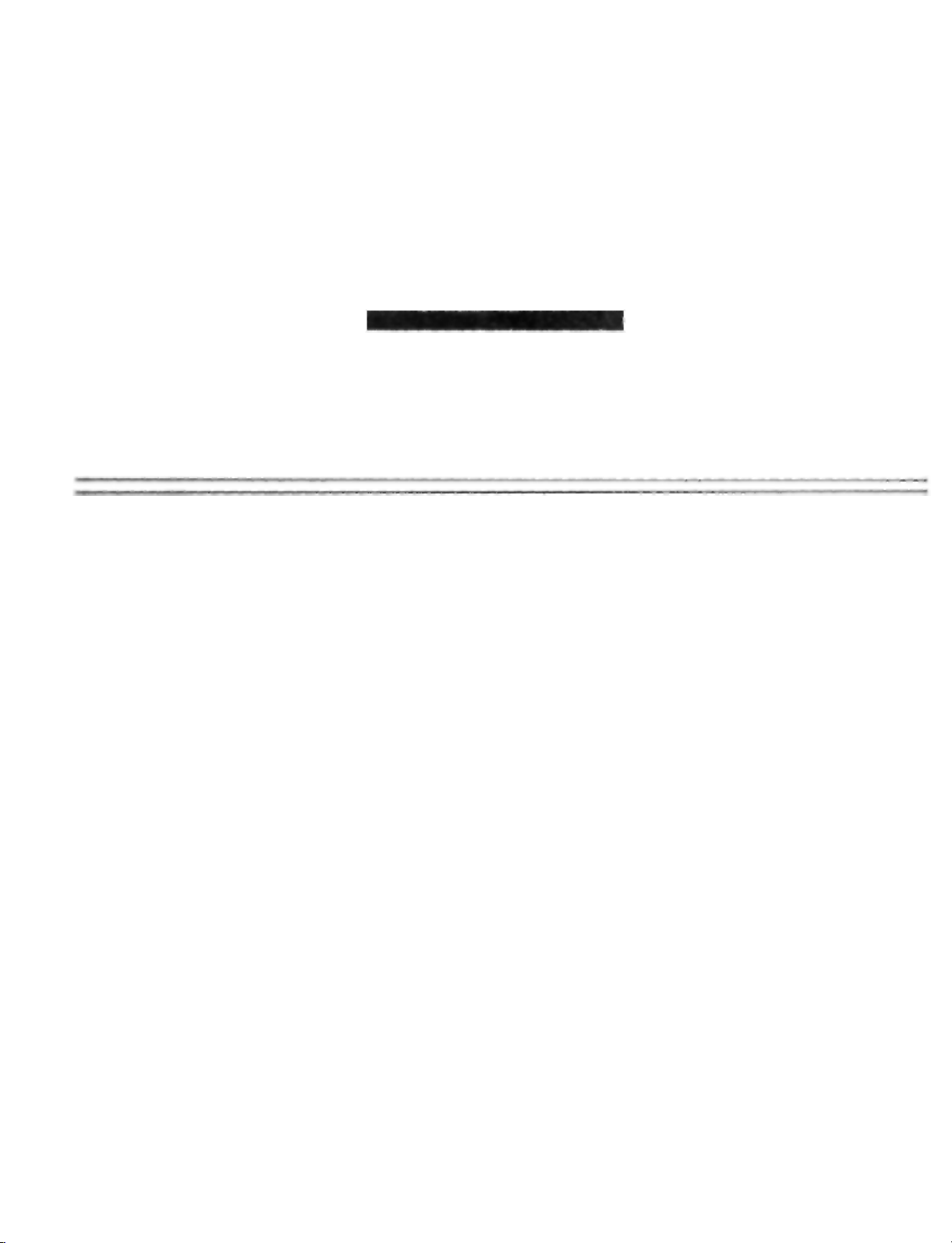

SETTINGUPTHEGRINDER

Thegrindershouldbesecurelymountedtothefloor

standoroverhangingona bench.SeeIllustrationNo.I.

Ifyouprefertooperatethechainvisemanuallyyou

mayremovethelockrodfromtheviselever.(Seeex-

plodeddiagram.)

ASSEMBLYOFFOOTOPERATEDCLAMP

Sliptheendlinkofthechainoverthelowerendofthe

lockrod.Attachthespringtotherodandhookthetop

endofthespringtotheholeinthelockrodbracket.

MOUNTFOOTPEDAL

Mountthefootpedalbracketthefloorstandorattach

ittoa legoftheworkbench(approximatelyfour

inchesfromthefloor).Attachthechaintothefoot

pedalsothattheheightofthepedaliscomfortableand

yetwillgivefullclampingtravel.

Page1

illustrationNo.1

SAFETYFIRST

Allgrindingwheelsarebreakableandthefollowing

safetyprecautionsshouldbeobserved:

1. Handleandstoregrindingwheelscarefully.

2.Discardgrindingwheelsthatarebadlychipped.

3.Alwaysmounta grindingwheelusingblottersbe-

tweenthegrindingwheelandtheflanges.

4.Donotover-tightentheflangenut.

5.Donotruna grindingwheelfasterthanthatspecified

onthewheelblotters.

6. Do notstandin linewitha grindingwheelthefirst

minuteitisrun.

7.Neverjama grindingwheelintotheworkpiece.

8.Alwaysweareyeprotectionwhenoperatingany

grindingmachine.

GENERALCHAINTYPES

Thereareseveralgeneralchaintypesthatyoumust

recognizetosharpenproperly.

TheOregon80chainisonethatisusedonsawsthat

have"builtin"sharpeners.Thecuttershavea distinc-

tiveshape(seeillustrationon page6 ) andwillnot

bemistakenforeitheroftheothertypes.

Themostcommontypesofchainareeitherthechipper

orthechisel.

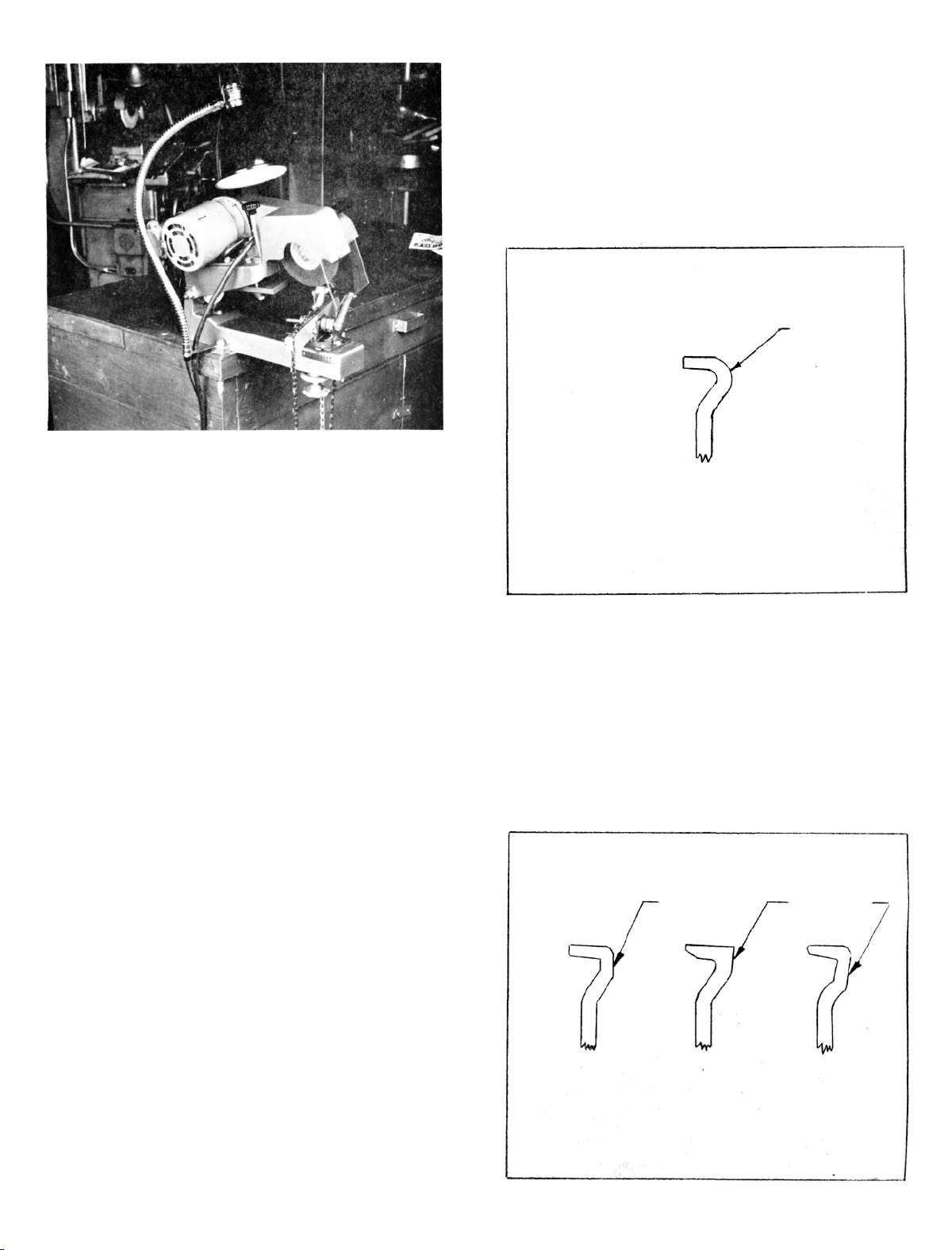

CHIPPERCHAINS

Thegeneralshapeofthechippertoothisasshownin

thissketchandinIllustration6.Notetheradiusonthe

sideofthecutter.Chippersareusuallygroundwitha

90°hookangleasshowninIllustration6.

CHISELCHAINS

Chiselteethhavea generalshapesuchas:

Page2

RADIUS

CHIPPERCHAIN

FLAT

FLAT

CHISELCHAINS

Theyappearmoreangularandhavedefiniteflatsec-

tionsonthesidesofthecutters.

Chiselcuttersaregroundwitha slighthooksuchas

showninIllustration2.

CHAINPARTS

Itwillhelpyoutofollowtheinstructionsifyoulearnthenamesofthechainparts

andtheirpropersequenceasshownhere.

IllustrationNo.2

TOFINDCHAINPITCH

Asshownabove— measurethedistancebetweenany

threerivetsnexttoeachotheranddividebytwo.

GRINDINGSUGGESTIONS

Stop Fingershouldbesetbehindthechaintoothbeing

ground.

1.Keepnewfactory-sharpenedchainsonhandto

checksideplateangleswhensharpeningchains.

2.A commonerroristogrindtoodeep.SeeIllustration

No.6 andnoticethatthecuttersarenotgroundto

thebottomofthegullets.Donotgrindintotie

strapsordrivelinks.

3.Beforegrindingthechain:

a.Removeoilandpitchfromthechaintoprevent

grindingwheelglazingandgumming.

b.Examinethechainforbentorcrackedlinks.

c.Checkforwornorbrokendrivelinks.

d.Checkfortightpinjoints. Page3

CORRECTLYGROUNDCHISELCUTTER

SEESTANDARDCHAINCHART

FORHEIGHTOFDEPTHGAUGE

30°

SIDE

END

85°SIDEPLATEANGLE

TOP

80°- SIDEPLATEANGLEONOREGON

SUPERCHISEL

RIVET

HUB

FLANGE

PRESET

TIESTRAP

PRESET

LEFTHAND

CUTTER

TIESTRAP

RIGHTHAND

CUTTER

DRIVELINK

GUARDLINKREPLACESDRIVE

LINKONALLGUARDLINK

CHAINS

PITCH:

THISDISTANCE

DIVIDEDBYTWO

GAUGE:

DRIVELINK

THICKNESS

CUTTER

PART

NAMES

HEEL

TOE

RIVET

HOLE

DEPTH

GAUGE

GULLET

TOP

PLATE

SIDE

PLATE

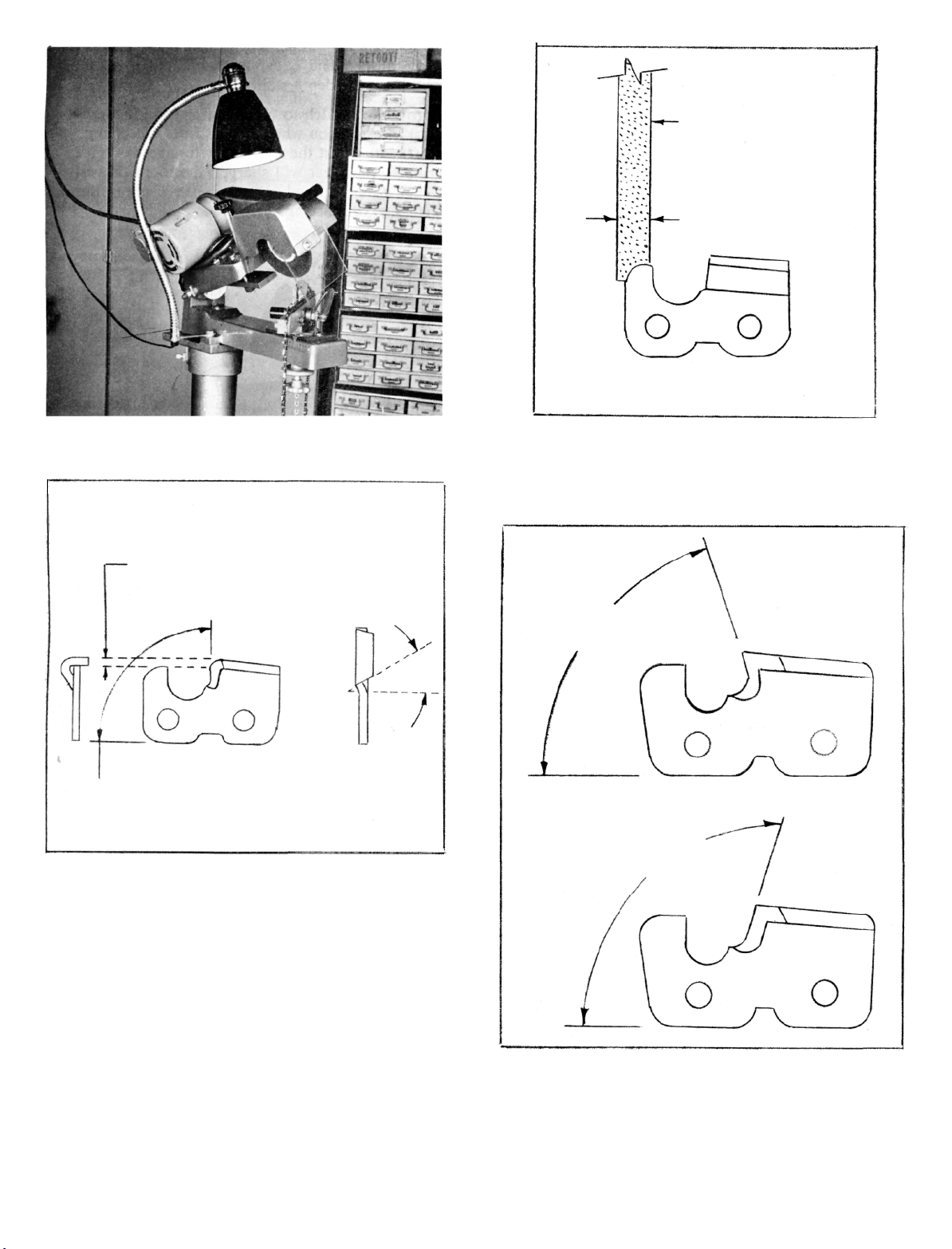

DRESSINGTHEGRINDINGWHEEL

1.Shapethewheel"freehand"byholdingthedresser

againstthewheelwhileitisrunning.Usea circular

motiontoproducethedesiredcurvatureonthe

wheel.

2.Stopthemotorandcheckthewheelshapewiththe

radiusgauge.

3.Thechartonpage7 showstherecommended

wheelthicknessfordifferentchains.

Anarrowerwheelmaybeusedinsteadoftheone

recommendedinthechart,ifitisdressedasshown

inFig.No.3.Forexample,ifthechartcallsfora

1/4"thickwheel,a 3/16"thickwheelcanbedressed

tofitonesideofthe1/4" gauge.Thiswillbehelpful

oncertainchainswherethethickerwheelmayin-

terferewiththedepthgauges.

IllustrationNo.3

GRINDINGCHIPPERCHAIN

1.Chooseanddressthegrindingwheelasexplained

above.RefertoFig.No.6 forcorrectlygroundchip-

percutter.

2.Laythechaininthevisewiththecuttingedgesfac-

ingtotheleft.

3.Tiltthegrindingheadto30°andlock.

4.Setandlockthechainviseat35°totheleft(rotat-

ingclockwisefrom0°).SeeIllustrationNo.4.

5.Setchainviseto0°onthehorizontalscaleandlock

inplace.

6.Positionthestopfingerbehindtherighthandcutter

tobegroundandalignthetoothtothegrinding

wheel.Setthedepthstop.

7.Turnmotorswitchto"Forward"position(counter-

clockwiserotationwhenviewedfromwheelendof

shaft)andadjustthestopfingertogivethelightest

grindingpassthatwillsharpenthetoothproperly.

Grindallrighthandcuttersinthechainwithout

changingyoursetup.

IllustrationNo.4

Page4

8.Swingchainvisetotherightandlockat35°.See

IllustrationNo.5.

9.Positionstopfingerbehinda lefthandcutterand

alignthetoothtothegrindingwheel.Changeonly

stopfingerpositionifnecessary.

10.Grindalllefthandcutterswiththemotorswitchin

the"Reverse"position.

11.Aftersharpeningthechainandbeforeremoving

itfromthegrindercheckthedepthgaugebylay-

inga shortstraightedgeacrossthetopoftwo

cuttersthenusinga feelergaugetomeasurethe

distancebetweentopofdepthgaugeandbottom

ofstraightedge.Properdepthgaugesettingis

shownonchartpage7...Depthgaugescanalso

becheckedbyusing#370362OregonAdjustable

DepthGauge.

Ifdepthgaugesneedtobelowered,usea 5/16"thick

grindingwheel.Dress thewheeltomatchthecontour

ofthedepthgauges(SeeIllustrationNo.7).Setthe

grindingheadto0°andto0°onboththechainvise

scaleandthehorizontalscale.Setthedepthcontrolto

giveproperheightandgrindalldepthgauges.

3/16WHEEL

1/4GAUGE

IllustrationNo.5 IllustrationNo.7

IllustrationNo.6

IllustrationNo.8 showstwocommongrindingerrors.

Excessivehookonthecutterswilltendtomakethe

chaingrabandrequireexcessivepowertodriveit.If

youaregettingtoomuchhook,checkradiusofwheel

withradiusgaugeastoosmalla radiuswillcauseex-

cesshook.Anotherpossiblecauseofexcesshookis

grindingtoodeep.

Ifthereisblackslopeontheteeththechainwillnot

feedproperlyandwillrequireexcessivedownpressure

tomakeitcut.Thiscausesunduewearonchainand

chainbar.Ifthereisbackslopeontheteeth,check

radiusofwheelwithradiusgauge,astoolargea radius

willcausebackslope.Anotherpossiblecauseofback-

slopeisnotgrindingdeepenough.

IllustrationNo.8

Page5

GRINDINGWHEEL

5/16

HOOK

BACKSLOPE

35°

SEESTANDARDCHAINCHARTFOR

HEIGHTOFDEPTHGAUGE

CORRECTLYGROUNDCHIPPERCUTTER

END

SIDE

TOP

90°SIDEPLATEANGLE

NOTE:ANGLEIS85°FOROREGONS70

GRINDINGCHISELCHAIN

1.Chooseanddressthegrindingwheelasexplained

earlier.RefertoIllustrationNo.2 forcorrectly

groundchiselcutter.

2.Placechaininchainvisewiththecuttingedges

facingtotheleft.

3.Tiltthegrindingheadto30°andlock.

4.Setandlockchainviseat30°totheleft(rotating

clockwisefrom0°).SeeIllustrationNo.4.

5.Slidethechainvisebackandlockiton1½onthe

horizontalscale.

6.Positionthestopfingerbehindtherighthandcut-

tertobegroundandalignthetoothtothewheel.

Setthedepthstop.

7.Turnthemotorswitchto"Forward"position

(counterclockwiserotationwhenviewedfrom

wheelendofshaft)andadjustthestopfingerfor

thelightestgrindingpassthatwillsharpenthe

toothproperly.Grindallrighthandcutterswith-

outchangingyoursetup.

8.Slidethechainviseforwardandlockat1½on

horizontalscale.

9.Rotatethechainviserightandlockat30°.See

IllustrationNo.4.

10.Positionthestopfingerbehindthelefthandcutter

tobegroundandalignthetoothtothegrinding

wheel.Changeonlythestopfingerpositionif

necessary.

11.Grindalllefthandcutterswiththemotorswitch

inthe"Reverse"position.

12.Checkandgrinddepthgaugesifnecessary.See

IllustrationNo.11underGrindingChipperChain.

OREGON#80SERIESCHAIN

1.Usea 5/16"thickwheelwitha straightface.Faceof

thegrindingwheelmustbe90°tothesidesofthe

wheel.

2.Placechainintochainviseandpositionstopfinger

behinda right-handcutter.

3.Thechainviseshouldbesetat0°onthescaleand

the0 positiononthehorizontalscale.Grinding

wheelshouldbesetat10°rightonthegrindinghead

scale.

Grindthetopsofallrightandleftcuttersthesame

height.

IllustrationNo.9

4.Togrinddepthgauges,setthestopfingerbehinda

righthandcutter.Setthewheelto15°leftonthe

grindingheadscale.Movethechainvisetoposi-

tionthedepthgaugedirectlyunderthewheeland

grindalloftherighthanddepthgauges.020lower

thanthetipsofthecutters.Setthestopfingerbehind

alefthandcutter.Positionthelefthanddepthgauge

underwheelandgrindalllefthandgauges.Leave

grindingheadat15°left.

5.Grindingfacesofcutters(notrequiredeverysharp-

eningunlesschainhasbeendamagedorisextremely

dull).Dress3/16"thickwheelroundtofittheradius

gauge.Chainbarsetat0°positiononthesidescale

andat22°totheleft(clockwisefrom0°)onthe

chainvisescale.

Setthegrindingheadat22°andgrindallrighthand

cutters.

6.Swingthechainvisetotherightandlockat22°.

Grindallofthelefthandcutters.

ADJUSTMENT-CHAINVISE

Theopeningandclampingrangeofthechainviseis

controlledbythetwo3/8nutsontheviseshaftand

leverassembly.

Backofftheouterlocknut.Adjusttheviseopening

withtheinnernutwhileholdingtheviseleverinthe

properpositiontoprovidefulltravel— locktounlock.

Holdtheinnernutinplaceandtightenthelocknut.

Page6

.020 22°BEVEL

22°HOOK

15°

10°

OREGON80CHAIN

STANDARDCHAINCHART

CHAINPITCH

1/4

.354

3/8

.404

7/16

1/2

9/16

5/8

3/4

WHEELTHICKNESS

1/8*

1/8*

1/8OR3/16*

1/8OR3/16*

3/16OR1/4*

3/16OR1/4*

3/16OR1/4*

3/16OR1/4*

1/4OR5/16*

USE

GAUGE

1/8

1/8

3/16

3/16

1/4

1/4

1/4

1/4

5/16

DEPTHGAUGESETTING

.020

.025

.025

.030

.030

.030

.040

.060

.060

*RECOMMENDEDWHEELTHICKNESS

Page7

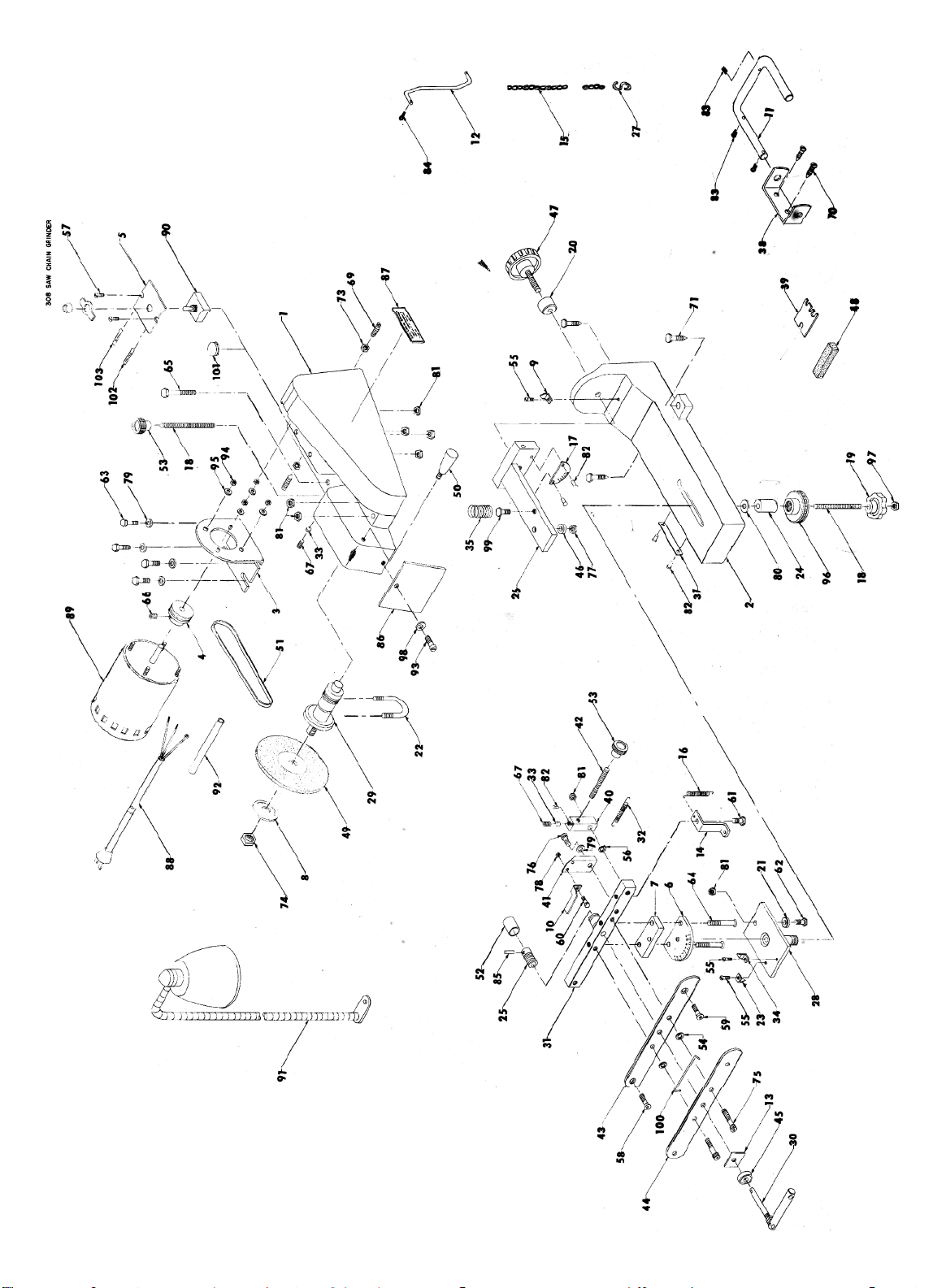

PARTSLISTFOR308SAWCHAINGRINDER

DIA.NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

37

38

39

40

41

42

43

44

45

46

47

48

49

50

PARTNO.

308001

308002

308020

308025

308027

308028

308030

308032

308038

308042

394027

308066

308045

308065

308068

308069

308049

314039

314038

308052

3O8053

308054

308055

308056

308057

308501

370789

308503

308504

308505

308506

352050

357109

357121

358055

394036

394044

394056

394070

394075

394076

394077

394078

370042

370255

370341

370508

370587

370634

PARTNAME

Overarm

Base

MotorMount

MotorSheave

SwitchCover

PivotPlate

SpacerBar

OuterFlange

Pointer

StopFinger

FootPedal

TopRod

VisePlate

LockRodBracket

Chain

Spring

QuadrantScale

LockStud

Handwheel

OverarmLockingKnobSpacer

SlidePlateSpacer

U-Bolt

HorizontalPointer

Spacer

AnvilLockScrew

PivotBarWeldment

"S"Hook

SlidePlateWeldment

MandrelBearingAss'y.

ViseShaft& LeverAss'y.

Bar& FeedSpacingNutWeldment

SawRestSpring

NylonPlug

Pointer

VerticalShaftSpring

HorizontalScale

FootPedalBracket

RadiusGage

BarFeedScrew

StopFingerPivotPlate

FeedScrew

ChainGuidePlate

FrontChainGuidePlate

ThrustBearing

PlainRubberWasher

Knob

DressingStick

GrindingWheel5 x 3/16x 1/2

LeverHandle

8

DIA.NO.

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

69

70

71

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

PARTNO.

370714

370715

370788

370873

A190302

R000481

A160602

A250803

A252403

B190601

B250801

B251001

B251201

B251603

B254801

C190620

C250406

C372013

E192011

E251603

J371000

J502100

R000368

R000369

R000380

R000497

R000524

R000528

R000552

R601018

R764100

R772050

R841050

308041

308058

360066

370879

370901

370026

370148

A190404

J161000

R000531

361273

J312000

R000522

B250601

308062

370101

340005

340004

PARTNAME

V-Belt

EndCap

Knob

SpringWasher

Rd.Hd.Mach.Sc10-24UNCx 3/16Long

LockwasherExt.Teeth1/4I.D.x 1/2O.D.

Rd.Hd.Mach.Sc.8-32UNCx 3/8Long

FlatHd.Mach.Sc.1-4-20UNCx 1/2Long

FlatHd.Mach.Sc.1/4-20UNCx 1-1/2Long

HexCapSc.10-24UNCx 3/8Long

HexCapSc.1/4-20NCx 1/2Long

HexCapSc.1/4-20UNCx 5/8Long

HexCapSc.1/4-20UNCx 3/4Long

FlatHd.CapSc.1/4-20UNCx 1 Long

HexCapSc.1/4-20UNCx 3"Long

SockSetSc.10-24UNCx 3/8"Long

SockSetSc.1/4-20UNCx 1/4Long

SlottedSetSc.ConePoint3/8-16UNCx 1-1/4Long

WoodSc.#10x 1-1/4Long

LagSc.1/4-20x 1"Long

HexNut3/8-16UNC

HexJamNut1/2-20NF

SockHd.CapSc.1/4-20UNCx 3/4Long

SockHd.Sc.Nylok1/4-20UNCx 1/2Long

HexLocknutNylok1/4-20UNC

HexLocknut10-24UNC

PlainWasher1/4SAE

PlainWasher5/8SAE

KepNut1/4-20UNC

DriveScrew#2x 3/16

CotterKey1/8x 1 Long

CotterKey1/16x 1/2Long

Rollpin1/8x 1/2Long

SafetyShield

Nameplate

CordSet

Motor1/8H.P.115V50HZPerm.SplitCap

ReversingSwitch

MachineLight

InsulatingTube

Fill.Hd.Mach.Sc.10-24UNC

HexNut8-32UNC

PlainWasher#8Med.

InnerHandwheel

HexJamNut5/16-18UNC

PlainWasher#10SAE

HexCapSc.1/4-20x 3/8Long

WireSpacer

SnapinBlank

ForwardDecal

ReverseDecal

PARTSLISTFOR308SAWCHAINGRINDER

10

394930PEDESTAL

DIA.NO.PARTNO.PARTNAME

1308061Foot

2358012Leg

3394009PedestalBase

4B250801HexCapScrew1/4- 20NCx 1/2Long

5B311201HexCapScrew5/16- 18NCx 3/4Long

6C371600Sq.Hd.SetScrew3/8- 16NCx 1 LongCupPoint

7J372000HexJamNut3/8- 16NC

PARTSLISTFOR394930- PEDESTAL- SAWCHAINGRINDER

OPTIONALEQUIPMENT

This manual suits for next models

1

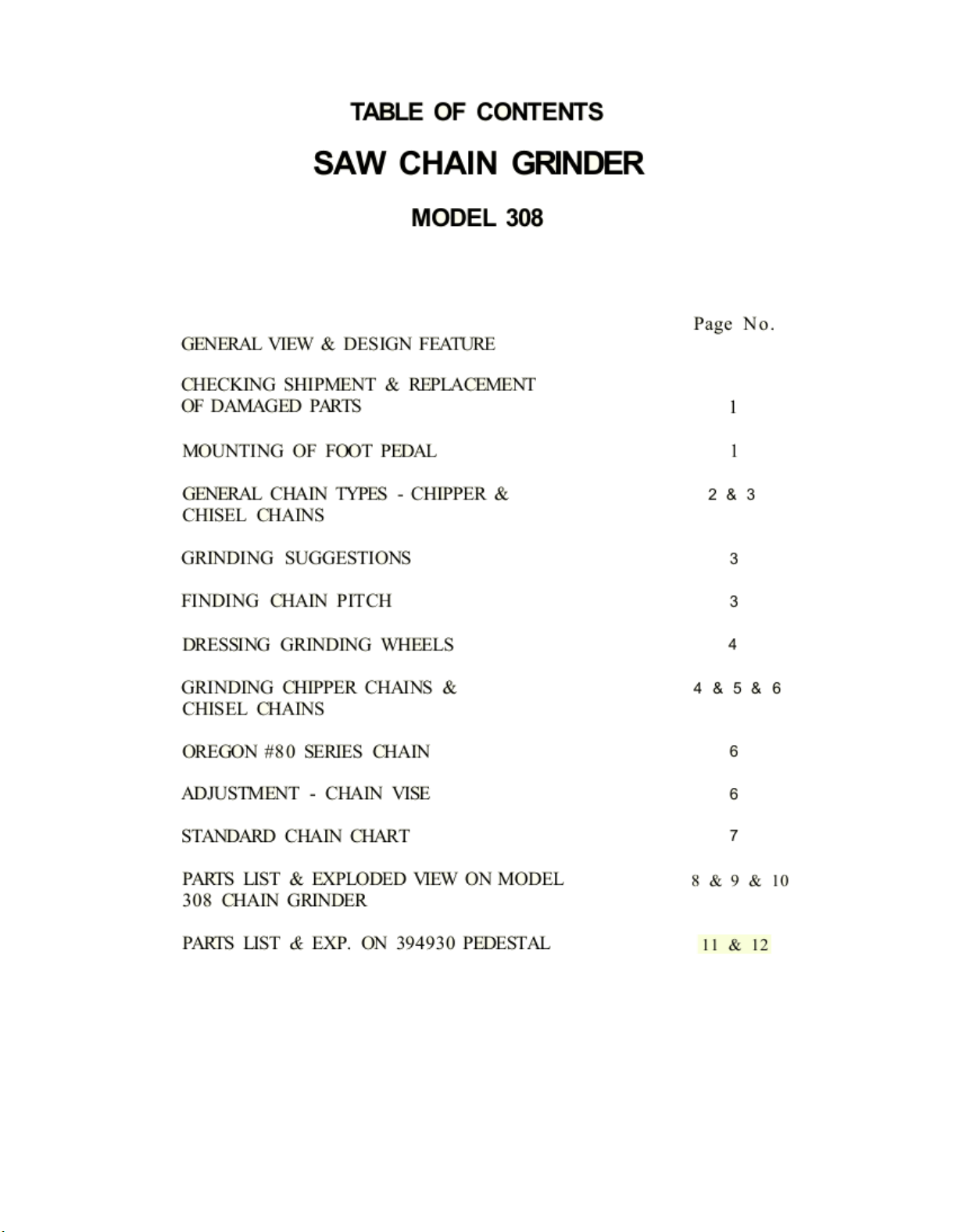

Table of contents

Other Foley Grinder manuals

Popular Grinder manuals by other brands

HIKOKI

HIKOKI CM 12Y Handling instructions

Bosch

Bosch GWS 20-230 Professional Original instructions

Worx

Worx WX701 Safety and operating manual

Makita

Makita GA042G instruction manual

Campbell Hausfeld

Campbell Hausfeld DG470800CK Operating instructions and parts manual

Milwaukee

Milwaukee M18 FLAG230XPDB Operator's manual

Ingersoll-Rand

Ingersoll-Rand CD Product information

Ingersoll-Rand

Ingersoll-Rand TA Series Operation and maintenance manual

Axminster

Axminster AW8SRG2 user manual

Chicago Pneumatic

Chicago Pneumatic CP9113G Operator's manual

RIDGID

RIDGID R10201 Operator's manual

REENTEL

REENTEL Cabking-6v3 instruction manual