FOM scalarSC Manual

FOM scalarSC

OPERATION & MAINTENANCE MANUAL

Revised January 2023

i

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

Contents

1. Introduction ..............................................................................................................1

1.1. Equipment specifications ...................................................................................1

1.2. Safety: disclaimers & equipment hazards ..........................................................2

2. Description of equipment .........................................................................................5

2.1. Relevant standards............................................................................................8

2.1.1. Machine standards ......................................................................................8

2.1.2. Electrical panel standards............................................................................8

2.2. System requirements.........................................................................................9

3. Setup instructions...................................................................................................10

3.1. Safe startup......................................................................................................10

3.2. Installation........................................................................................................11

4. Software interface..................................................................................................17

4.1. Home screen & Quick Access Ribbon .............................................................17

4.2. Coating screen.................................................................................................20

4.3. Settings screen ................................................................................................22

4.4. Alarms screen..................................................................................................24

5. Slot-die, syringe, the substrate mounting...............................................................26

5.1. Slot-die assembly, syringe & tubing connection...............................................26

5.2. Slot-die mounting.............................................................................................28

5.3. Mounting syringe into the pump.......................................................................32

5.4. Substrate mounting..........................................................................................33

6. Getting started with coating....................................................................................34

7. Service & maintenance ..........................................................................................37

ii

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

7.1. Standard maintenance.....................................................................................37

8. Appendices ............................................................................................................39

8.1. Appendix 1: Background calculations for film thickness, pump rate, and coating

width 39

1

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

1. Introduction

This document is the operation and maintenance manual for the FOM Technologies

scalarSC. The FOM scalarSC is a benchtop slot-die coating tool with rigid and flexible

substrates.

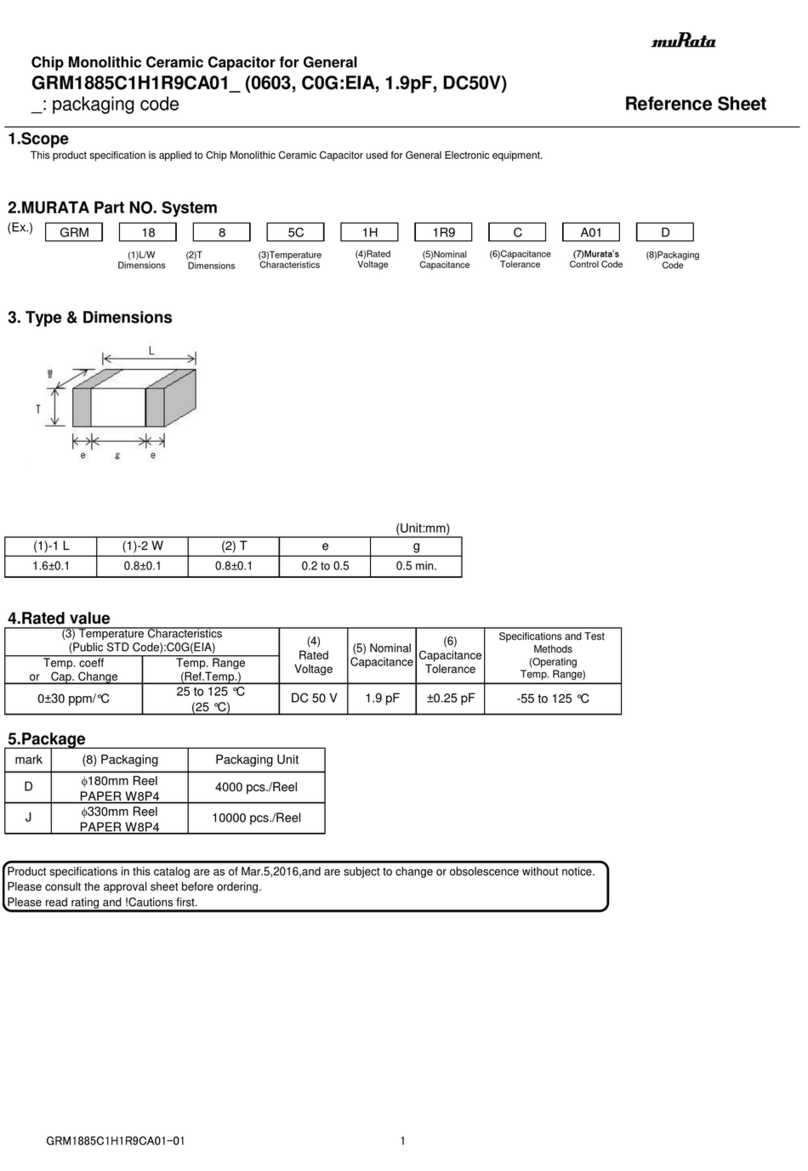

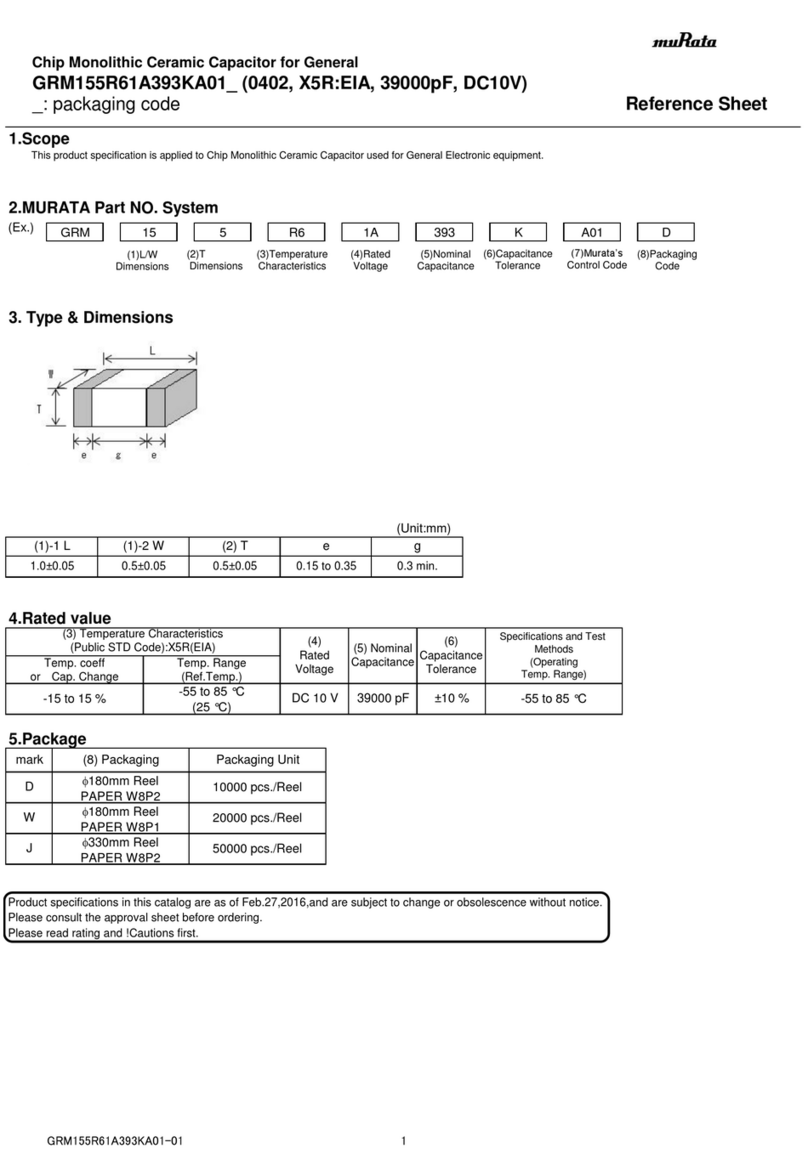

1.1. Equipment specifications

Several key specifications of the FOM scalarSC are outlined below:

Table 1 Key equipment specifications of the FOM scalarSC.

Specification

Value

Coating width

≤ 200 mm

Substrate compatibility

Rigid and flexible

Substrate throughput

≤ 5.0 m min-1

Syringe pump

External

Substrate heating

≤ 200 °C

Slot-die heating

≤ 80 °C (optional)

Slot-die height repeatability

± 12.5 μm

Protocol control

Yes

Dimensions

87 x 63 x 500 cm3

Weight

71 kg

Intended lifetime of equipment and safety components

20 years

Site workspace requirement

Suitable fumes extraction

2

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

The FOM scalarSC has been designed and dimensioned for convenient glovebox

compatibility. In addition, the stated temperature rating and coating speed are ideally

suited to achieve stable coating of a wide range of materials with thicknesses of a few

nanometers to several tens of microns.

1.2. Safety: disclaimers & equipment hazards

IMPORTANT

To ensure the successful operation of the FOM scalarSC and the safety of all lab users,

operators, trainees, and maintenance personnel should read and understand this manual

before beginning any coating experiments or tool maintenance. Operators must be of

sound mind and body before operating this equipment. Operators under the age of 18

should not attempt to operate this equipment. The general public should not be permitted

to use this equipment.

It is recommended that new users are trained in the use of this equipment by experienced

operators, any deviation from the instructions provided in this manual may lead to

personal and material damage for which FOM Technologies A/S cannot be held

responsible.

The FOM scalarSC is equipped with an emergency stop button, which immediately halts

all ongoing operations in case of an emergency. Thisbutton must be tested once per year

to guarantee its function.

Further information on the risks and hazards associated with the operation of the FOM

scalarSC is provided below.

3

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

Table 2 Risks and hazards associated with the use of the FOM scalarSC.

Risk

Comment

Burn risk

Operators should avoid touching the heating parts when they are hot, as

temperature can reach 200 °C. It should be noted that heated parts will

remain hot for some time even after the equipment has been shut down,

representing a burn risk for operators even when power is not supplied to

the tool. In the case of FOM scalarSC units fitted with an oven module,

operators should additionally avoid touching or opening the oven while it

is heating due to high temperatures and significant IR output. To prevent

the risk of burn, the FOM scalarSC is equipped with a warning LED red

light which will be activated when either the chuck or the slot die head

temperatures are higher than 50 °C. Burn risk areas are depicted in Figure

1.

Crushing/pinching

People can be struck and injured by moving parts of machinery. Parts of

the body can also be drawn in or trapped between, belts drivers and

other components of the tool. Operators should avoid placing their

fingers or any other body parts in the path of any moving part. Damage to

items and persons may occur if they become caught between the slot-die

and chuck, the chuck and the scalarSC housing case, or the shaft and

plates of the syringe pump as they are moving. In the case of FOM

scalarSC units fitted with an oven module, operators should additionally

avoid placing objects or body parts in the path of the oven lid while it is

opening or closing. Crushing/pinching parts are depicted in Figure 1.

Electric shock

Operators should avoid contact with cables and plugs at the rear of the

tool while the main power is being supplied. Operators should avoid

contact with wiring for the chuck energy chain and heated slot-die while

mains power is being supplied. Operators should avoid contact with

electrical cabinet wiring while main power is being supplied. Operators

should take care to only touch the physical power switch on the exterior

of the electrical cabinet when switching on the main power supply for the

tool.

4

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

Chemical exposure

Open coating of heated, solution-processed chemical mixtures may lead

to the evaporation of solvents and other hazardous materials. Operators

should ensure that the tool is installed in a suitably ventilated location to

avoid unintended exposure to these chemical hazards. Operators should

be fully aware of the material risks associated with their work.

Misc.

To avoid damage to persons and equipment, repairs, and servicing of the

FOM scalarSC and its accompanying electrical components should only be

carried out by authorized, trained technicians. If on-site servicing is

required, please contact FOM Technologies directly.

Figure 1: Hot surface and crushing/pinching hazards are present on the FOM scalarSC. (1) Hazard due to

heated vacuum chuck surface, (2) crushing/pinching hazard between moving chuck and right-hand-side

tool structure, (3) crushing/pinching hazard between moving chuck and left-hand-side tool structure, (4)

crushing/pinching hazard between fixed slot-die head and moving chuck platform.

1

2

34

Stop button

5

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

2. Description of equipment

The FOM scalarSC is a compact slot-die coating tool with a simple, user-friendly design.

The exterior of the tool consists of several simple components, as seen below:

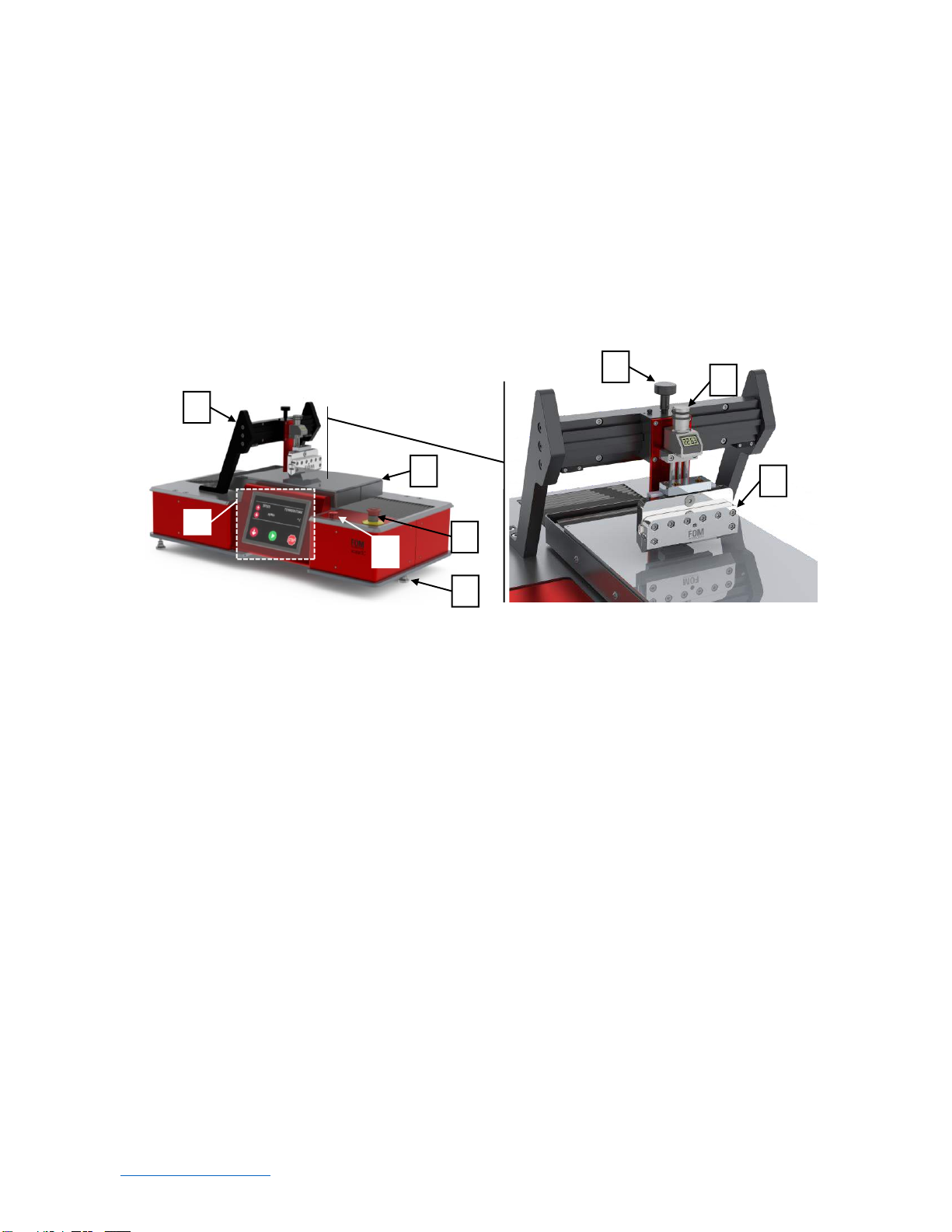

Figure 2: FOM scalarSC tool render (left) and a closeup of the slot-die head and bridge elements

(right). (1) Gantry system for lateral adjustment, (2) integrated touch screen panel control, (3)

heating-enabled substrate holder (chuck), (4) emergency stop button, (5) Heat-hazard indicator (for

temperature >50 °C), (6) leveling and height mount feet 1/3, (7) slot-die head (L), (8) lateral

positioning dial (9) Vertical position positioning dial with digital display.

1. Coating bridge: supports the slot-die positioning gantry over the substrate.

2. Panel control: touch screen panel for process control.

3. Heating-enabled substrate holder: it is used to position the material to be

coated.

4. The emergency stop button immediately stops all ongoing processes. Twist to

release the button and return the tool to a normal functioning state.

5. Heat-hazard indicator: the light switches on when the temperature of the

substrate holder is above 50 °C.

6. Height-adjustable feet allow for tool leveling.

8

7

9

6

3

1

24

5

6

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

7. Slot-die: receives coating fluid from external pump and syringe elements and

distributes it evenly across the desired coating width on the substrate.

8. Lateral positioning dial: for manual positioning of the slot-die head across the

coating area width.

9. Vertical positioning dial: for manual positioning of the slot-die to the desired

coating height.

The FOM scalarSC also features several ports on the rear panel of the tool for power

and control of tool functions, as seen below (Figure 3):

Figure 3: Rear and top view of ScalarSC tool showing connection hub, stop button, and warning light.

(1) stop button and warning light; (2) Power and control plugs.

1. Power and control plugs: supply power and control data for heating and motion

functions from the electrical cabinet.

2. Stop button and warning light.

2

1

2

1

7

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

FOM scalarSC electrical cabinet:

Figure 4: Photograph of the electrical cabinet showing (1) Physical power switch and (2) mains power

socket.

1. Physical power switch: controls the primary power supply to the coating unit via

the electrical cabinet.

2. Mains power socket: to supply electrical power.

NOTE: the FOM scalarSC and its electrical cabinet are designed to be used and stored

indoors, out of direct sunlight, at room temperature. The tool is compatible with dry

environments such as glovebox environments but is not designed for extended exposure

to high humidity.

8

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

2.1. Relevant standards

2.1.1. Machine standards

The machine is built according to machine directive EN 60204-1 and ISO 13849-1. Also

refer to Certificate of Quality Directive 2006 / 42 / EC Annex IIB, Declaration of conformity

of machinery.

2.1.2. Electrical panel standards

The panel additionally conforms to the following European Standards:

Table 3 Table of relevant European standards.

Parameter

Applicable standard

Symbols

EN 60617

Wire code

EN 60757

Reference Designations

ISO/IEC 81346, table 1 and table 2

Machine Safety

EN 60204-1

Electrical Safety

EN 61439-1 and EN 61439-2

9

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

2.2. System requirements

Table 4 Power and cabling specs.

Parameter

Spec

Supply Voltage (Un)

1 ph + N + PE. 230 V

Supply Frequency (Hz)

60

Nominal Current (In)

16 Amps

Short Circuit Strength (Isc)

10 kA

Protection (maximum size)

C25A

Cable (minimum size)

12AWG / 2.5mm2

Earthing System

WYE/ TN-S

Cable Entry

Side

10

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

3. Setup instructions

The following sections describe the recommended procedure for safe installation and

operation of the FOM scalarSC.

3.1. Safe startup

Before beginning any work with the FOM scalarSC, operators should ensure that they

have taken the following safety precautions:

•All operators of the tool must read and understand this user manual.

•Equipment should be used only for slot-die coating experiments, as recommended

by this user manual. Using this equipment for unintended applications and

conducting additional after-market modifications may result in damage to the

equipment and its operators.

•Users should apply the following personal protective equipment (PPE) when

operating the tool:

oSafety glasses

oLab coat

oSafety gloves (e.g. nitrile)

oAdditional precautions may apply depending on material use and

application (e.g. anti-static coat for hazardous nanomaterials or clean room

work)

•Do not operate the machine with loose clothing, wristbands, long loose hair or

anything that could get caught by the moving parts of the tool.

•The tool should be placed in a location with suitable ventilation to ensure that

operators are not exposed to volatile solvents and/or aerosolized materials (e.g.

fume hood, laminar flow housing or glove box)

11

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

•The physical power switch must be in the “ON” position at all times, to turn the

machine on and off should only be done through the software and the "engage

software" button. An exception can be done when plugging the tool into the main

power, installation (see section Error! Reference source not found.) or p

erforming tool maintenance, in which case the physical power switch can be set to

the “OFF” position.

•The Emergency stop button should be tested at least annually to ensure its

function.

3.2. Installation

The FOM scalarSC has been designed to allow a quick, simple installation process. The

following steps ensure successful installation.

1. Placing the tool and electrical cabinet

Place the tool in a location with suitable ventilation to ensure that operators are not

exposed to volatile solvents (e.g., fume hood or glove box). The surface should be roughly

waist high and strong enough to support the tool’s weight (ca. 50 kg). Ensure that the

equipment and personnel assigned to lifting and moving the FOM scalarSC are suitably

dimensioned for the task. For safety, the FOM scalarSC should always be lifted/moved

by two or more personnel members at once. When placed, the tool should be accessible

from the operator side, with sufficient clearance behind the back panel to connect the

required plugs, cabling, and tubing.

The electrical cabinet should be placed no more than 10 m away from the FOM scalarSC

tool. Cables of a suitable length will be provided with the electrical cabinet based on

requirements identified during the site survey.

2. Connecting tool to the electrical cabinet, and mains electricity

Ensure that the main power switch on the electrical cabinet is set to the “off”position. For

safety, the tool should never be connected to the power supply during connection and

installation. Power should only be supplied to begin regular use once the tool has been

placed, installed, and connected to the unpowered electrical cabinet.

12

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

Connect the labeled power and control cables from the electrical cabinet into their

respective labeled plugs on the back panel of the FOM scalarSC tool.

When the above connections have been established, connect the electrical cabinet to

mains power via the provided mains plug (typically a standard three-phase connection).

3. Adjusting tool height and levelness

The FOM scalarSC should be reasonably level before initiating any coating trials. The

tool is fitted with height-adjustable feet on the bottom, enabling easy leveling of the tool

along the down-web and across-web axes.

Figure 5: Schematic of a top-down view of the heated vacuum chuck with labels for the down-web

and across-web axes.

To ensure the tool is leveled, place a precision leveling tool in the center of the substrate

holder, parallel with either the down-web or across-web axis. Adjust the height of each

foot until the tool is level to at least 0.1 mm/m. Next, reposition the leveling tool and repeat

14

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

4. Powering on the tool

To power, the tool, turn the main switch to the “On”position. The internal electronics of

the electrical cabinet should light up, indicating that power is being supplied. It may take

few minutes for the electrical cabinet to fully boot.

Figure 6: Side of the electrical cabinet with the physical power switch in the ON position.

15

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

After the electrical cabinet main switch is in ON position, the start center screen will be

shown in the touch screen of the scalarSC. Press Start.

Figure 7: Start screen.

16

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

After pressing Start in start screen you will be directed to the software interface Home

screen. To start using the tool it is necessary to engage the software by pressing the

“Engage” button on the home screen (see Figure 8). You are now ready to begin using

the FOM scalarSC.

Figure 8: The Home screen is displayed with the control software engaged.

NOTE: if the tool was previously fully powered down from mains electricity, Homing of the

chuck is required. More information on Homing can be found in the settings screen

section of this manual.

17

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

4. Software interface

The following section describes the functionality of each interface screen from the FOM

scalarSC tool.

4.1. Home screen & Quick Access Ribbon

The Home screen is automatically displayed upon starting the software. The functionality

of the Home screen is outlined below:

Figure 9: The Home screen is displayed upon starting the software. (1) Engage software button, (2)

coating screen button, (3) quick access ribbon (4) software on/off button.

1. Engage software button powers the tool on and off.

2. Coating screen button transports the user to the Coating screen, where coating

parameters can be easily adjusted, and movement/heating can be manually

controlled.

3. The Quick Access Ribbon is always at the bottom of the control interface,

regardless of the current screen.

4. Software on/off button enables and disenables the software

Table of contents

Other FOM Industrial Electrical manuals

Popular Industrial Electrical manuals by other brands

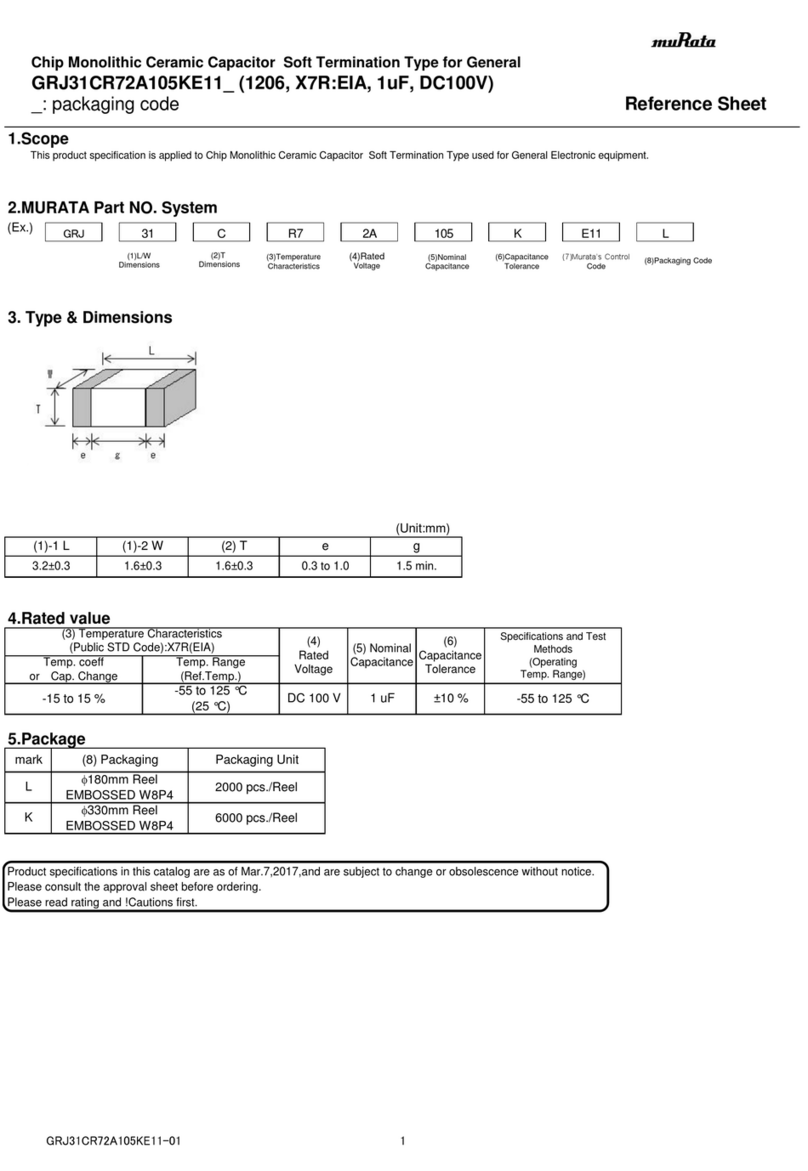

Murata

Murata GRJ31CR72A105KE11 Series Reference sheet

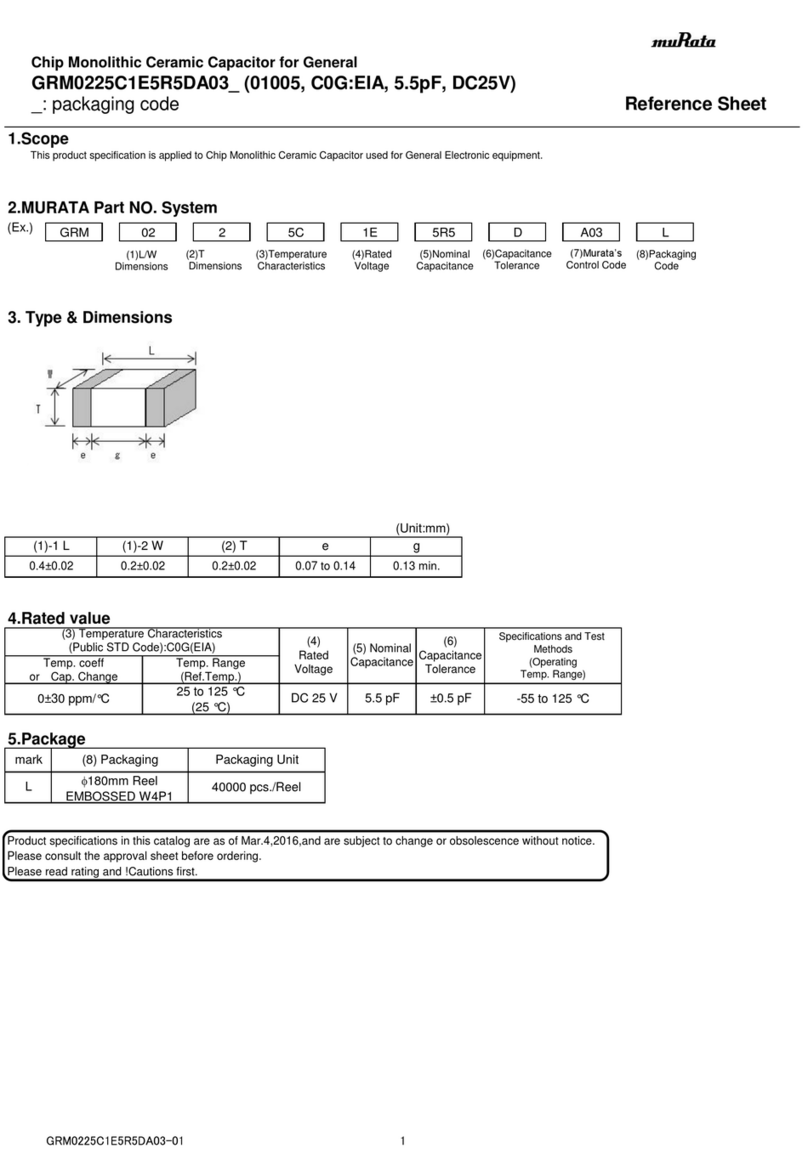

Murata

Murata GRM0225C1E5R5DA03 Series Reference sheet

TRAK

TRAK ProtoTRAK KMX K3 Safety, installation, maintenance, service & parts list manual

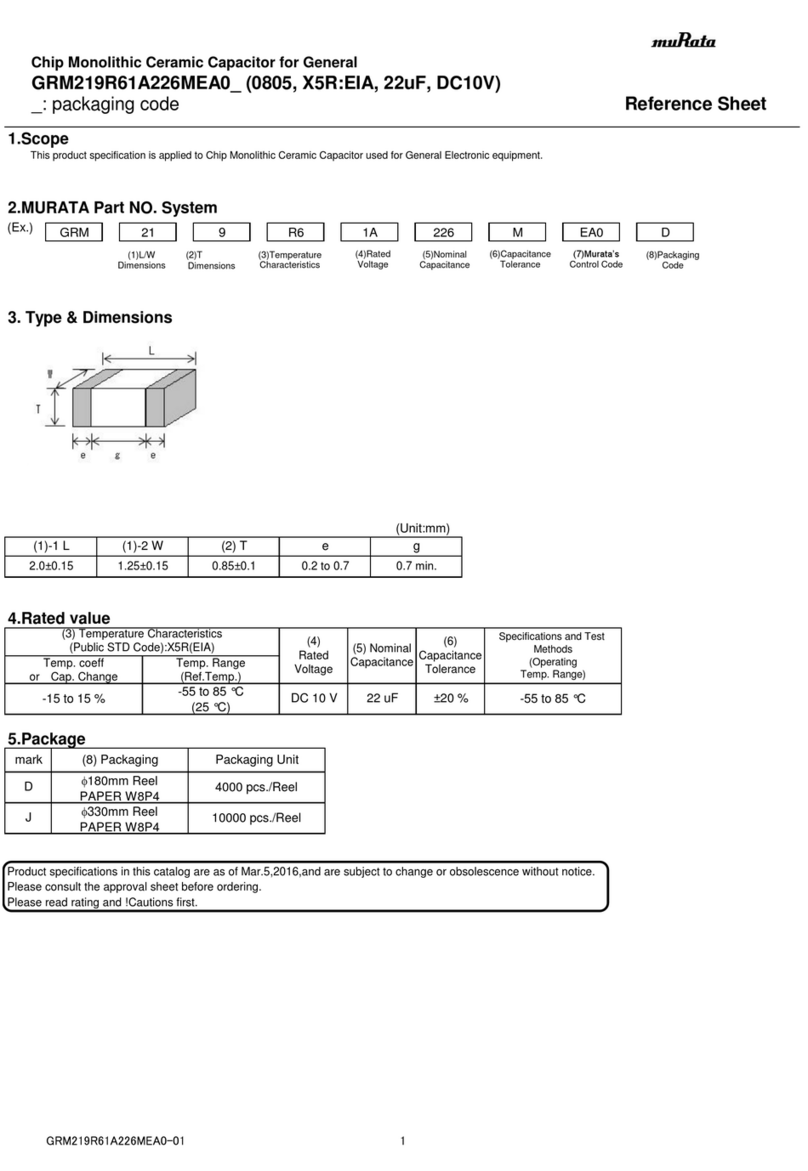

Murata

Murata GRM219R61A226MEA0 Series Reference sheet

Murata

Murata GRM155D70J225ME44 Series Reference sheet

Murata

Murata GRM033R60G105MEA2 Series Reference sheet

Eaton

Eaton DX-COM-STICK Instruction leaflet

Bravo

Bravo OS V12 USER INTERFACE MANUAL

National Instruments

National Instruments TBX-1325 installation guide

Hubbell

Hubbell PD2217 installation instructions

Siemens

Siemens 3RT1955-5A/N Series Original operating instructions

Murata

Murata GRM219R71C564KA01 Series Reference sheet