FOM vectorSC Manual

FOM vectorSC

OPERATION & MAINTENANCE MANUAL

Revised January 2023

i

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

Contents

1. Introduction ..............................................................................................................1

1.1. Equipment specifications ...................................................................................1

1.2. Safety: disclaimers & equipment hazards ..........................................................2

2. Description of equipment .........................................................................................5

2.1. Relevant standards............................................................................................9

2.1.1. Machine standards ......................................................................................9

2.1.2. Electrical panel standards............................................................................9

2.2. System requirements.......................................................................................10

2.2.1. Wiring information......................................................................................12

2.2.2. Compressed air .........................................................................................12

3. Setup instructions...................................................................................................13

3.1. Safe startup......................................................................................................13

3.2. Installation........................................................................................................14

3.3. Connecting a FOM machine to the internet......................................................18

3.3.1. Introduction to IXON Router ......................................................................19

3.3.2. Get connected to the internet ....................................................................20

4. Laptop control interface..........................................................................................23

4.1. Home screen & Quick Access Ribbon .............................................................23

4.2. Coating screen.................................................................................................26

4.3. Protocol screen................................................................................................31

4.4. Import and save protocol screen......................................................................35

4.5. Settings screen ................................................................................................38

4.6. Motion settings screen.....................................................................................41

ii

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

4.7. Heating settings screen....................................................................................43

4.8. Miscellaneous settings screen .........................................................................45

4.9. Alarms screen..................................................................................................46

5. Slot-die, syringe, the substrate mounting...............................................................48

5.1. Slot-die assembly, syringe & tubing connection...............................................48

5.2. Slot-die mounting.............................................................................................51

5.3. Mounting syringe into the pump.......................................................................56

5.4. Reversing syringe mounting orientation...........................................................59

5.5. Substrate mounting..........................................................................................61

6. Getting started with coating....................................................................................62

7. Service & maintenance ..........................................................................................66

7.1. Standard maintenance.....................................................................................66

8. Appendices ............................................................................................................68

8.1. Appendix 1: Software background calculations for film thickness, pump rate, and

coating width..............................................................................................................68

1

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

1. Introduction

This document is the operation and maintenance manual for the FOM Technologies

vectorSC. The FOM vectorSC is a benchtop slot-die coating tool with rigid and flexible

substrates. The tool is designed to deposit thin films composed of a wide variety of

solution-processed precursor materials onto an additionally wide variety of coating

substrates. It, therefore, represents a miniaturized demonstration of industrial-scale roll-

to-roll and sheet-to-sheet manufacturing technologies. Furthermore, by providing simple,

precise control over coating speed, thickness, and substrate heating, the FOM vectorSC

offers a user-friendly coating experience that is ideally suited for a lab-scale materials

research environment and upscaling to pilot scale coating processes.

1.1. Equipment specifications

Several key specifications of the FOM vectorSC are outlined below:

Table 1 Key equipment specifications of the FOM vectorSC.

Specification

Value

Coating width

≤ 200 mm

Substrate compatibility

Rigid and flexible

Substrate throughput

≤ 5.0 m min-1

Syringe pump

Integrated

Substrate heating

≤ 200 °C

Slot-die heating

≤ 80 °C (optional)

Slot-die height repeatability

± 12.5 μm

Protocol control

Yes

Dimensions (D x W x H)

870 x 630 x 505 mm3

Weight

71 kg

Intended lifetime of equipment and safety components

20 years

Site workspace requirement

Suitable extraction

2

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

The FOM vectorSC has been designed and dimensioned for convenient glovebox

compatibility. In addition, the stated temperature rating and coating speed are ideally

suited to achieve stable coating of a wide range of materials with thicknesses of less than

one to several tens of microns.

1.2. Safety: disclaimers & equipment hazards

IMPORTANT

To ensure successful operation of the FOM vectorSC and the safety of all lab users,

operators, trainees and maintenance personnel should read and understand this manual

before beginning with any coating experiments or tool maintenance. Operators must be

of sound mind and body before operating this equipment. Operators under the age of 18

should not attempt to operate this equipment. The general public should not be permitted

to use this equipment.

It is recommended that new users should be trained in the use of this equipment by

experienced operators, any deviation from the instructions provided in this manual may

lead to personal and material damage for which FOM Technologies A/S cannot be held

responsible.

The FOM vectorSC is equipped with an emergency stop button, which immediately halts

all ongoing operations in case of an emergency. Thisbutton must be tested once per year

to guarantee its function.

Further information on the risks and hazards associated with the operation of the FOM

vectorSC is provided below.

3

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

Table 2 Risks and hazards associated with the use of the FOM vectorSC.

Risk

Comment

Hot surfaces

Operators should avoid touching the heated vacuum chuck when it is hot,

as temperatures can reach 200 °C. Operators should also avoid touching

the heated slot-die when hot, as temperatures can reach 80 °C. It should

be noted that both the chuck and the heated slot-die will remain hot for

some time even after the equipment has been shut down, representing a

burn risk for operators even when power is not supplied to the tool.

Crushing/pinching

Operators should avoid placing their fingers or other body parts in the

path of the slot-die, chuck, or syringe pump while moving. Damage to

items and persons may occur if they become caught between the slot-die

and chuck, the chuck and the vectorSC housing case, or the syringe pump

shaft and plates as they move.

Electric shock

Operators should avoid contact with cables and plugs at the rear of the

tool while the main power is being supplied. Operators should avoid

contact with wiring for the chuck energy chain and heated slot-die while

mains power is being supplied. Operators should avoid contact with

electrical cabinet wiring while mains power is being supplied. Operators

should take care to only touch the physical power switch on the exterior

of the electrical cabinet when switching on the mains power supply for

the tool.

Chemical exposure

In some cases, processing solutions without enclosure may lead to the

evaporation of solvents and other hazardous materials. Therefore,

operators should ensure that the tool is installed in a suitably ventilated

location to avoid unintended exposure to these chemical hazards. In

addition, operators should be fully aware of the material risks associated

with their work.

Misc.

Repairs and servicing of the FOM vectorSC along with all electrical

components should only be carried out by authorized, trained

technicians. If on-site servicing is required, please contact FOM

Technologies directly.

4

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

Figure 1: Burn risk. Hot surface hazards are present on the FOM vectorSC. (1) Hazard due to heated

vacuum chuck surface, (2) Hazard due to heated slot-die head.

Figure 2: Crushing/pinching. (a) VectorSC render showing crushing and pinching hazards; (1) Hazard

between moving syringe pump components, (2) Hazard between slot-die and moving chuck

component, (3) Hazard between moving chuck and end-stop components.

12

3

1

32

1

2

ab

5

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

2. Description of equipment

The FOM vectorSC is a compact slot-die coating tool with a simple, user-friendly design.

The exterior of the tool consists of several simple components, as seen below:

Figure 3: FOM vectorSC renders (right) along with a closeup of the slot-die head and bridge elements.

(1) Gantry system for lateral adjustment, (2) integrated syringe pump, (3) heated vacuum pump, (4)

emergency stop button, (5) quick buttons panel, (6) leveling and height mount feet, (7) slot-die head,

(8) lateral positioning dial (9) Vertical position positioning dial with digital display.

1. Coating bridge: supports the slot-die positioning gantry over the substrate.

2. Syringe pump: holds the syringe and pumps solution into the slot-die at the rate

set by software.

3. Vacuum chuck enabled with heating allows for substrate fixation via microporous

flat material for laminar flow suction.

4. The emergency stop button immediately stops all ongoing processes. Twist to

release the button and return the tool to a normal functioning state.

5. Hardware quick buttons: provide quick access to standard tool functions such as

pumping, chuck motion, vacuum activation, and experiment execution.

6. Height-adjustable feet: allows for tool leveling via easy height adjustment of

individual feet.

6

5

4

3

2

1

8

7

9

6

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

7. Slot-die: receives coating fluid from the syringe and distributes it evenly across

the desired coating width on the substrate.

8. Horizontal position knot: for manual positioning of the slot-die head across the

coating area width.

9. Vertical positioning knot: for manual positioning of the slot-die to the desired

coating height.

The FOM vectorSC also features several ports on the rear panel of the tool for power

and control of tool functions, as seen below (Figure 4):

Figure 4: Rear side of VectorSC tool showing connection hub. (1) 8 mm vacuum supply tube; (2) Power

and control plugs.

1. Power and control plugs: supply power and control data for heating and motion

functions from the electrical cabinet.

2. 8 mm vacuum supply tube: supplies a vacuum via an 8 mm push-fit connection

to drive suction on the heated vacuum chuck.

1

2

7

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

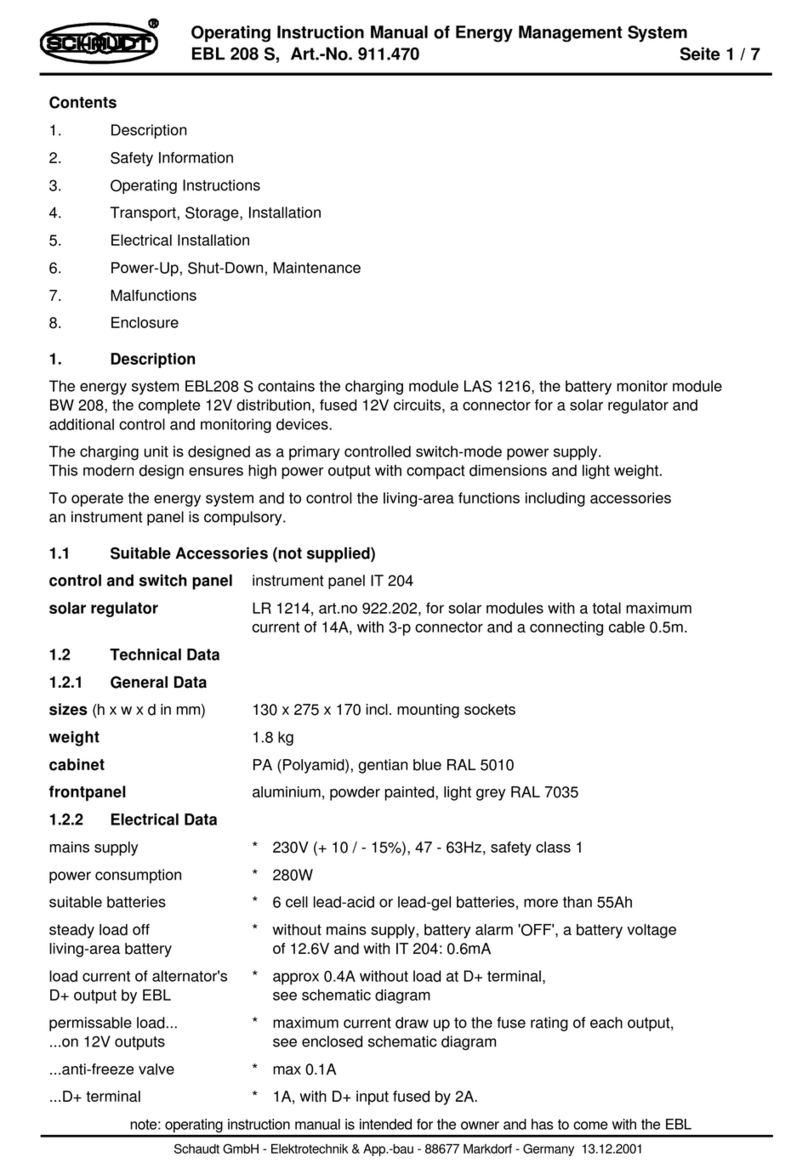

FOM VectorsSC electrical cabinet:

Figure 5: Front side photograph of the electrical panel showing some elements such as the physical,

electrical switch, and the compressed air-to-vacuum generator.

Figure 6: FOM vectorSC electrical cabinet. (1) Ethernet connection port, (2) compressed air vacuum

generator, (3) controlling electronics. The right-hand-side panel shows the CPU unit placed in the

door.

Physical power switch

Vacuum generator

Ethernet cable inlet

Compressed air

Vacuum line

connected to

chuck

1

1

3

2

8

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

1. Ethernet connection port: enables a wired control connection via ethernet

between the FOM vectorSC and any PC. Beneficial for remote servicing

situations where a connection to both the tool and the internet are required.

2. Compressed air vacuum generator: accepts a compressed air supply (5-6 bar

line pressure recommended) to generate a venturi vacuum, which is supplied via

8 mm tubing to the vacuum chuck on the FOM vectorSC coating unit.

3. Controlling electronics: responsible for controlling heating, motion, and

communication between the coating unit and the control PC.

NOTE: the FOM vectorSC and its electrical cabinet are designed to be used and stored

indoors, out of direct sunlight, at room temperature. The tool is compatible with dry

environments such as glovebox environments but is not designed for extended exposure

to high humidity.

9

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

2.1. Relevant standards

2.1.1. Machine standards

The machine is built according to machine directive EN 60204-1 and ISO 13849-1. Also

refer to Certificate of Quality Directive 2006 / 42 / EC Annex IIB, Declaration of conformity

of machinery.

2.1.2. Electrical panel standards

This panel is built according to UL508A Standard.

The panel additionally conforms to the following European Standards:

Table 3 Table of relevant European standards.

Parameter

Applicable standard

Symbols

EN 60617

Wire code

EN 60757

Reference Designations

ISO/IEC 81346, table 1 and table 2

Machine Safety

EN 60204-1

Electrical Safety

EN 61439-1 and EN 61439-2

10

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

2.2. System requirements

Table 4 Power and cabling specs.

Parameter

Spec

Supply Voltage (Un)

(3+N) 3x 380..415 / 200..240 V a.c. and 3 x

200..230 / 115..132V

Supply Frequency (Hz)

50/60

Nominal Current (In)

24 Amps

Short Circuit Strength (Isc)

10 kA

Protection (maximum size)

C25A

Cable (minimum size)

12AWG / 2.5mm2

Earthing System

WYE/ TN-S

Cable Entry

Side

Figure 7: Tool power connection diagram.

12

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

2.2.1. Wiring information

Table 5 Wiring information table.

Spec list

LAPP multi-standard SC2.1

POWER - Black (Phase), White (Neutral), Green/Yellow (Ground)

24VDC CONTROL - Dark Blue (Positive), White with Dark Blue stripe (Negative)

INTERFACE SIGNALS - Orange (Signal), Orange with White stripe (Common)

This panel is built according to UL508A Standard

2.2.2. Compressed air

Table 6 Compressed air information table.

Spec list

5-7 bar. Clean and dry, non-lubricated. ISO 8573-1:2010 Class 1.2.3 or better

To be fitted to Ø8mm Festo push-fit connection

13

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

3. Setup instructions

The following sections describe the recommended procedure for safe installation and

operation of the FOM vectorSC.

3.1. Safe startup

Before beginning any work with the FOM alphaSC, operators should ensure that they

have taken the following safety precautions:

•All operators of the tool must read and understand this user manual.

•Equipment should be used only for slot-die coating experiments, as recommended

by this user manual. Using this equipment for unintended applications and

conducting additional after-market modifications may result in damage to the

equipment and its operators.

•Users should apply the following personal protective equipment (PPE) when

operating the tool:

oSafety glasses

oLab coat

oSafety gloves (e.g. nitrile)

oAdditional precautions may apply depending on material use and

application (e.g. anti-static coat for hazardous nanomaterials or clean room

work)

•Do not operate the machine with loose clothing, wristbands, long loose hair or

anything that could get caught by the moving parts of the tool.

•The tool should be placed in a location with suitable ventilation to ensure that

operators are not exposed to volatile solvents and/or aerosolized materials (e.g.

fume hood, laminar flow housing or glove box)

•The physical power switch must be in the “ON” position at all times, to turn the

machine on and off should only be done through the software and the "engage

software" button. An exception can be done when plugging the tool into the main

power, installation (see section Error! Reference source not found.) or p

14

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

erforming tool maintenance, in which case the physical power switch can be set to

the “OFF” position.

•The Emergency stop button should be tested at least annually to ensure its

function.

3.2. Installation

The FOM vectorSC has been designed to allow a quick, simple installation process. The

following steps ensure successful installation.

1. Placing the tool and electrical cabinet

Place the tool in a location with suitable ventilation to ensure that operators are not

exposed to volatile solvents (e.g., fume hood or glove box). The surface should be roughly

waist high and strong enough to support the tool’s weight (ca. 71 kg). Ensure that the

equipment and personnel assigned to lifting and moving the FOM vectorSC are suitably

dimensioned for the task. For safety, the FOM vectorSC should always be lifted/moved

by two or more personnel members at once. When placed, the tool should be accessible

from the operator side, with sufficient clearance behind the back panel to connect the

required plugs, cabling, and tubing.

The electrical cabinet should be placed no more than 10 m away from the FOM vectorSC

tool. Cables of a suitable length will be provided with the electrical cabinet based on

requirements identified during the site survey.

2. Connecting tool to the electrical cabinet, vacuum, and mains electricity

Ensure that the main power switch on the electrical cabinet is set to the “off”position. For

safety, the tool should never be connected to the power supply during connection and

installation. Power should only be supplied to begin regular use once the tool has been

placed, installed, and connected to the unpowered electrical cabinet.

Connect the labeled power and control cables from the electrical cabinet into their

respective labeled plugs on the back panel of the FOM vectorSC tool, as shown

previously in the “Description of equipment”section of this manual.

15

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

Connect the vacuum generator unit on the electrical cabinet to a compressed air supply

at the inlet (5-6 bar feed pressure recommended) and to the FOM vectorSC tool at the

outlet. These connections should be made via 8 mm tubing into the push-fit connection

ports at each point.

When the above connections have been established, connect the electrical cabinet to

mains power via the provided mains plug (typically a standard three-phase connection).

3. Adjusting tool height and levelness

The FOM vectorSC should be reasonably level before initiating any coating trials. The

tool is fitted with height-adjustable feet on the bottom, enabling easy leveling of the tool

along the down-web and across-web axes.

Figure 9: Schematic of a top-down view of the heated vacuum chuck with labels for the down-web

and across-web axes.

To ensure the tool is leveled, place a precision leveling tool in the center of the heated

vacuum chuck, parallel with either the down-web or across-web axis. Adjust the height of

16

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

each foot until the tool is level to at least 0.1 mm/m. Next, reposition the leveling tool and

repeat this process for the other coating axis. It is recommended to level the across-web

axis first, followed by the down-web axis.

4. Powering on the tool

To power, the tool, turn the main switch to the “On”position. The internal electronics of

the electrical cabinet should light up, indicating that power is being supplied. It may take

several minutes for the electrical cabinet to fully boot.

Figure 10: front side electrical cabinet with the physical power switch in the ON position.

While the electrical cabinet is booting up, scan for available WiFi networks on the control

PC. When the cabinet has finished booting, it will broadcast its WiFi network named after

the build number of your particular tool. Connect to this WiFi network on the control PC

to control the tool wirelessly. The password for this network is typically 70169 or

FOM70169. Alternatively, the tool may be controlled via a wired ethernet connection, as

shown previously in this manual’s “Description of equipment”section.

17

FOM TECHNOLOGIES A/S

Enabling Functional Materials R&D

info@fomtechnologies.com

Artillerivej 86, 1.

Copenhagen 2300, Denmark

(+45) 88 70 89 00

To connect to the tool interface, double-click the FOM shortcut on the desktop

environment of the supplied control PC. Alternatively, open a web browser and the

following link: https://fom-tech/webRH

You will be greeted by the User Login window when a successful connection is achieved.

You can then log in to the FOM vectorSC with username: USER and password:

Fom_1234.

Figure 11: The User Login window.

NOTE: This profile provides user permissions to the operator. If you are having difficulty

connecting to the tool at any point, or if admin permissions are required, for example, for

editing of default tool motion and heating settings, please get in touch with FOM

Technologies directly.

Other manuals for vectorSC

1

Table of contents

Other FOM Industrial Electrical manuals

Popular Industrial Electrical manuals by other brands

ABB

ABB SAHARA Series operating instructions

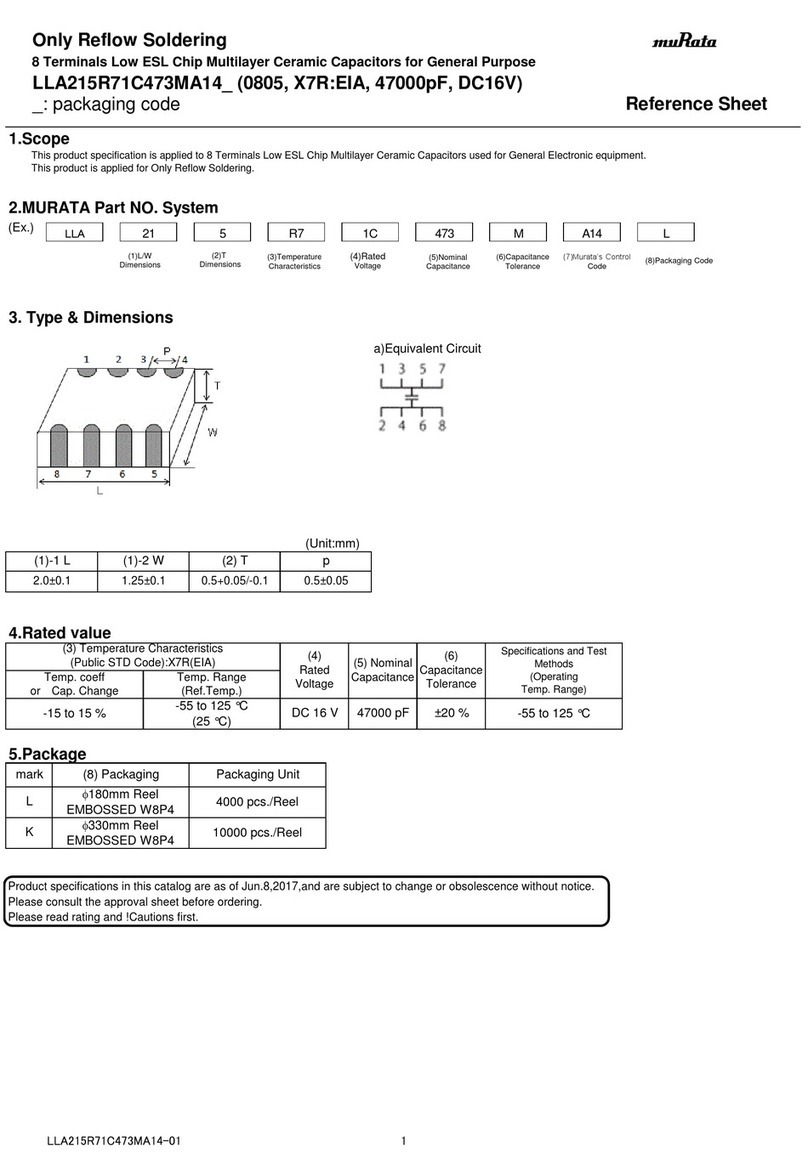

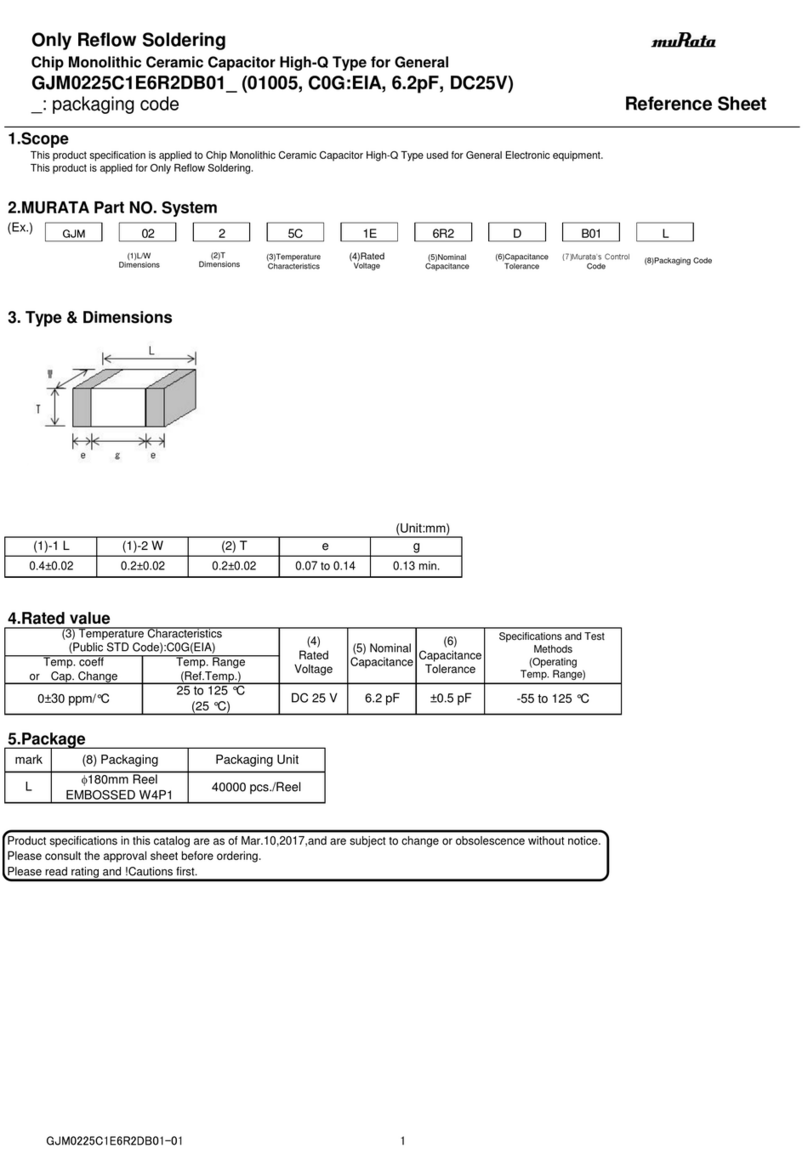

Murata

Murata GRM0335C1HR70WA01 Series Reference sheet

Siemens

Siemens RAJA+ 3TE7421 Installation, operation & maintenance instructions

Endress+Hauser

Endress+Hauser RSG40 Appendix to the Operating Manual

Murata

Murata GRJ216R72A222KE01 Series Reference sheet

Murata

Murata GRM188R60J105KA01 Series Reference sheet

Murata

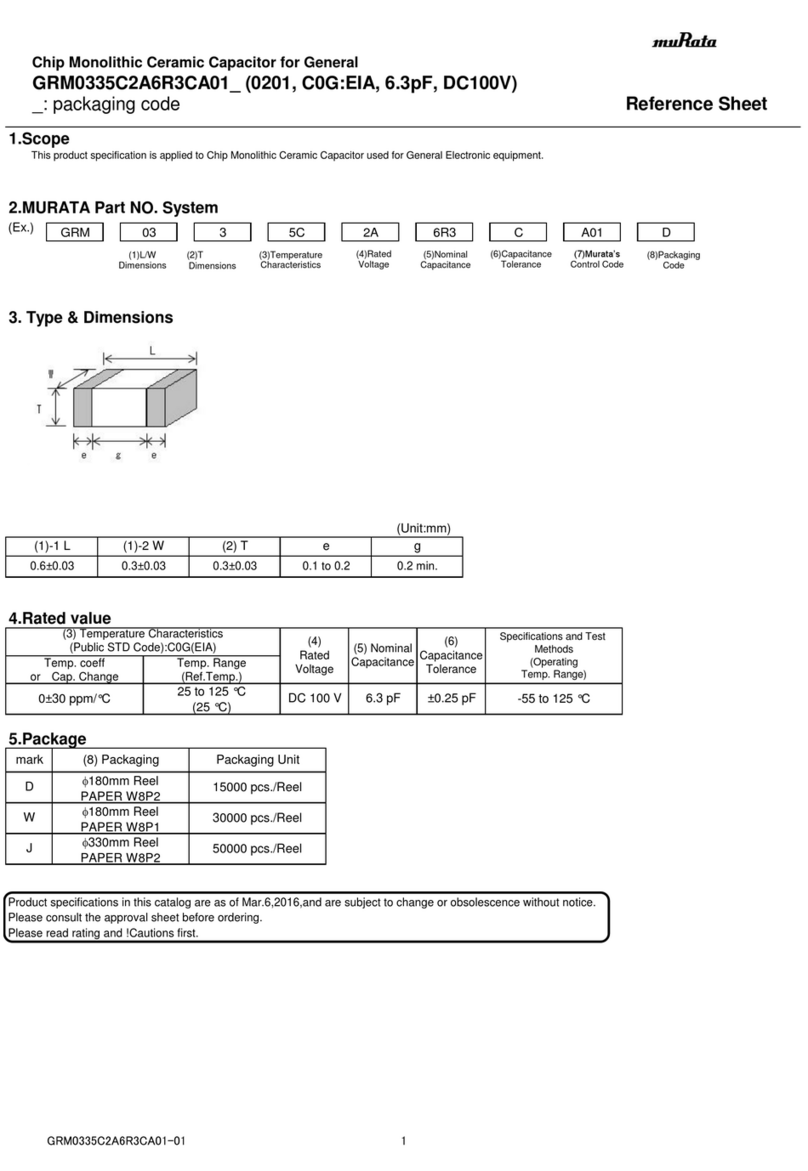

Murata GRM0335C2A6R3CA01 Series Reference sheet

ABB

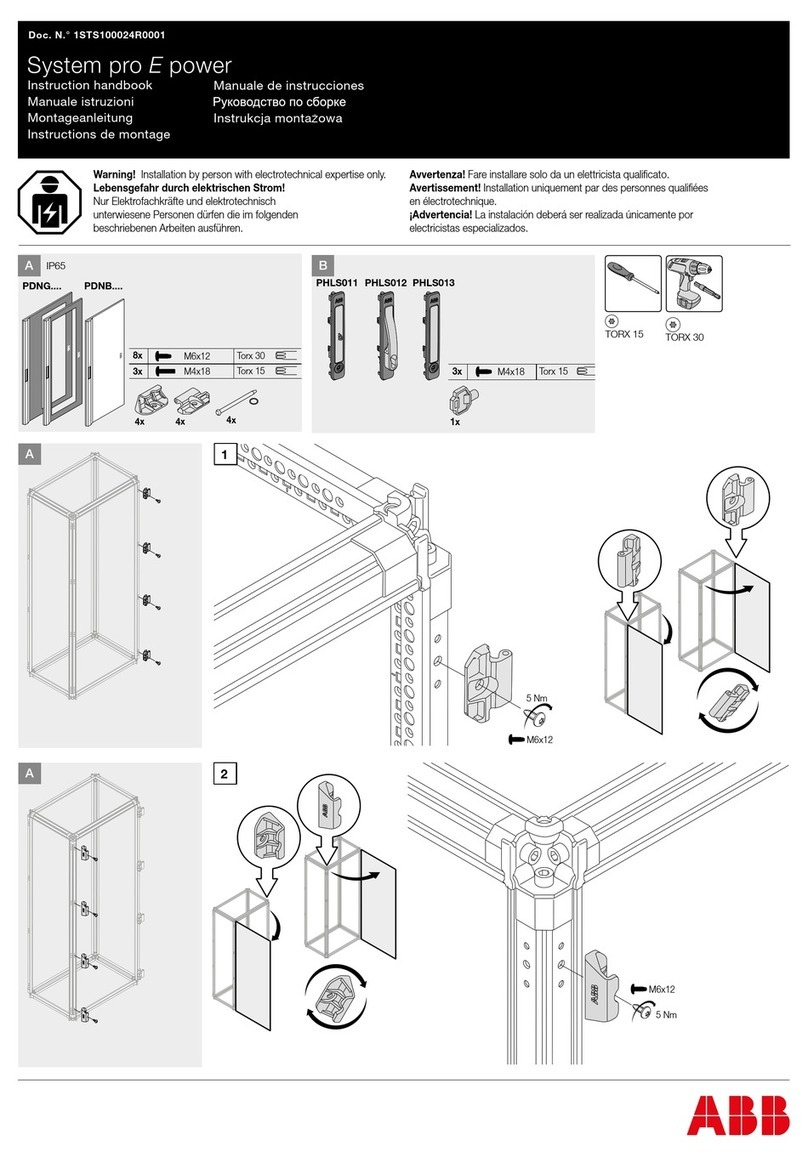

ABB System pro E power Instruction handbook

Murata

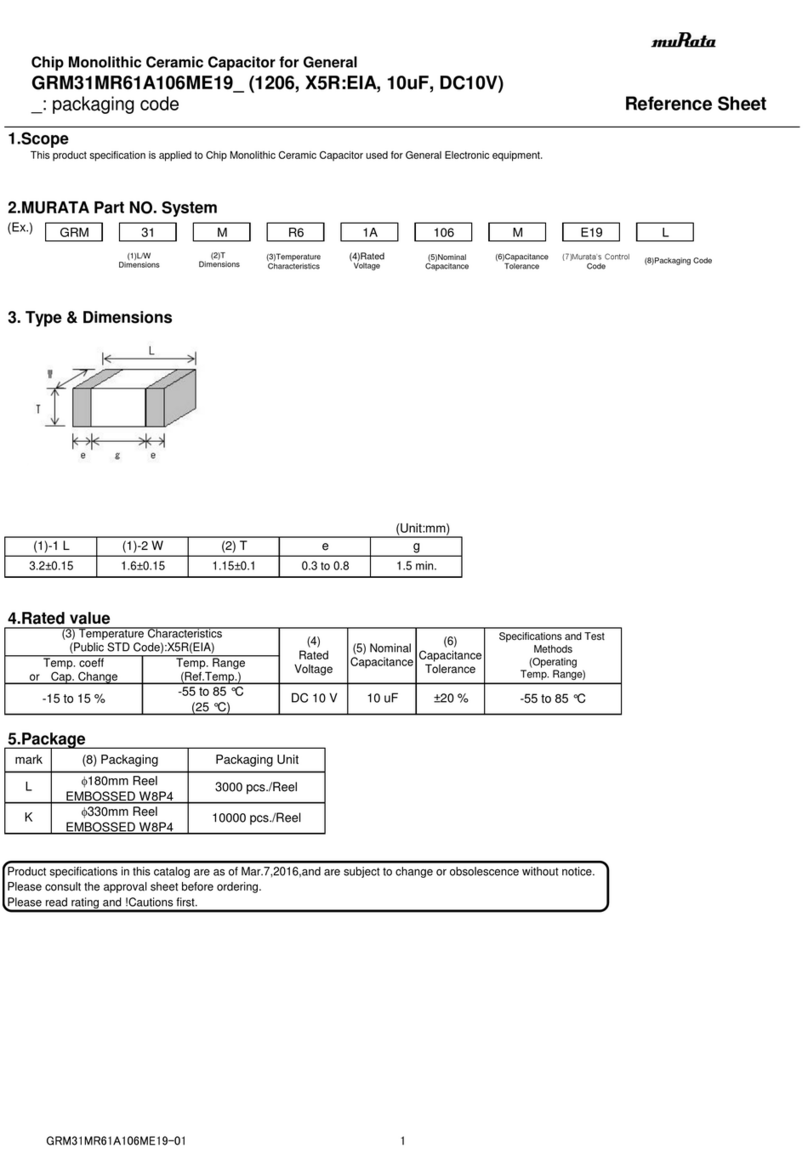

Murata GRM31MR61A106ME19 Series Reference sheet

Murata

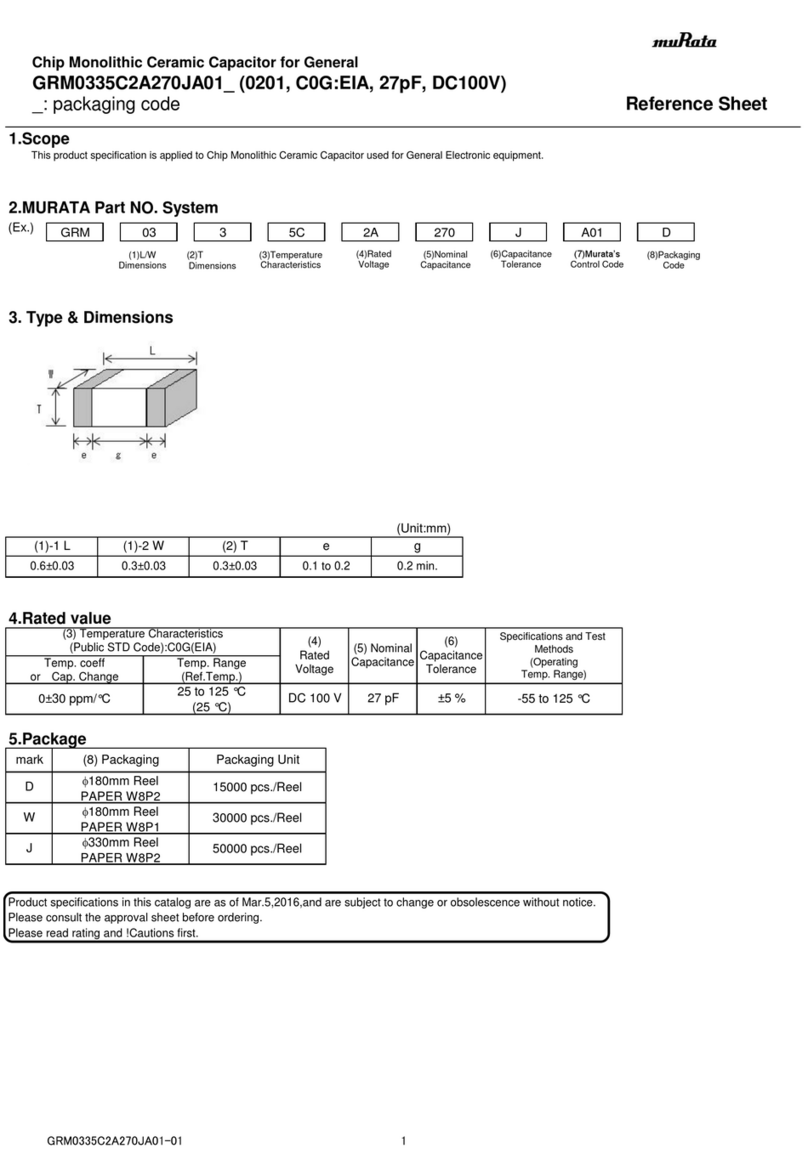

Murata GRM0335C2A270JA01 Series Reference sheet

Eaton

Eaton CI-K2 Series Instruction leaflet

Murata

Murata GJM0225C1E6R2DB01 Series Reference sheet