Fontaine Aquanox 98 Series Manual

SERIES 98

EXTRUDED ALUMINUM

STOP LOGS

INSTALLATION AND MAINTENANCE

MANUAL

(Revision 0)

Page 2 sur 15

1. TABLE OF CONTENTS

1. Table of contents...................................................................................................2

2. Introduction ...........................................................................................................3

2.1. Warnings ........................................................................................................................ 3

3. Receiving ...............................................................................................................4

4. Storage ...................................................................................................................4

5. Glossary for stop logs ..........................................................................................5

6. Preparation for installation...................................................................................6

6.1. New concrete channel with boxouts ........................................................................... 6

6.2. Existing concrete channel (Surface mount) ............................................................... 6

7. Embedded frame installation ...............................................................................8

8. In channel surface installation.............................................................................9

9. Operation with lifting device ..............................................................................11

9.1. Lowering a stop log..................................................................................................... 11

9.2. Removing a stop log ................................................................................................... 11

10. Troubleshooting ..................................................................................................12

10.1. Stop logs jamming ................................................................................................... 12

10.2. Stop log lifting beam doesn’t perform well ........................................................... 12

10.3. Stop logs leak ........................................................................................................... 12

10.4. Lip (HY-Q) Seal ......................................................................................................... 13

11. Inspection and maintenance ..............................................................................14

11.1. Inspection frequency ............................................................................................... 14

11.2. Maintenance.............................................................................................................. 14

12. Warranty...............................................................................................................15

13. Contact Fontaine Aquanox.................................................................................15

Page 3 sur 15

2. INTRODUCTION

his manual is intended to provide all the necessary information for the installation, operation and

maintenance of Fontaine Aquanox Stop Logs. It is intended for contractors responsible for the

installation, for owners and operators of the equipment, for preventive maintenance supervisor

and potential repairers to clearly diagnose problems and make to proper basic adjustments.

2.1.WARNINGS

It is important to read this manual before starting any work on the equipement.

When installing the equipment, always apply an anti-seize on the stainless steel fasteners. Use

PTFE based pipe joint compound if the equipement is installed in drinking water.

Reduce as much as possible the contact between stainless steel and carbon steel to prevent

corrosion contamination.

At all times make sure to comply with local safety standards and wear personal protective

equipment.

T

Page 4 sur 15

3. RECEIVING

Despite all the precautions taken during packing, some damage may have occurred during transportation

of the goods to their destination. We recommend that you follow the following instructions when receiving

your equipment.

Ensure the conformity of the delivered goods before signing the bill of lading.

Look for any anomaly concerning the delivery (damage, missing items in relation to bill of lading,

broken pallet, parcel damaged, dented part , deformed pipe , etc.) as this may be a sign of events that

may have caused greater damage. Indicate on the bill of lading any abnormality detected, otherwise no

claim will be accepted.

After the reception of the goods, and within 5 working days, verify with the bill of lading that all equipment

has been received. Also verify the equipment tag. They must match the items listed on the bill of lading.

No claims for missing parts will be accepted after the period of 5 working days.

Contact Fontaine Aquanox to report any anomalies found or missing parts.

4. STORAGE

Cover and protect all equipment that will not be installed immediately.

•Leave the equipment attached to the pallet;

•Cover with a canvas or tarp;

•Store in a dry, and flat area;

•Place the other parts in a safe place;

•Protect from dust and sand;

•Avoid exposure to UV rays;

•For long-term storage, place inside in a dry and temperate area;

•Do not store plastic tightly as this may increase condensation;

•Stop logs should be stored by stacking logs off the floor or ground;

•Logs should be separated by using two 4” spacers between each logs;

•Stacked stop logs should not exceed four high.

Page 5 sur 15

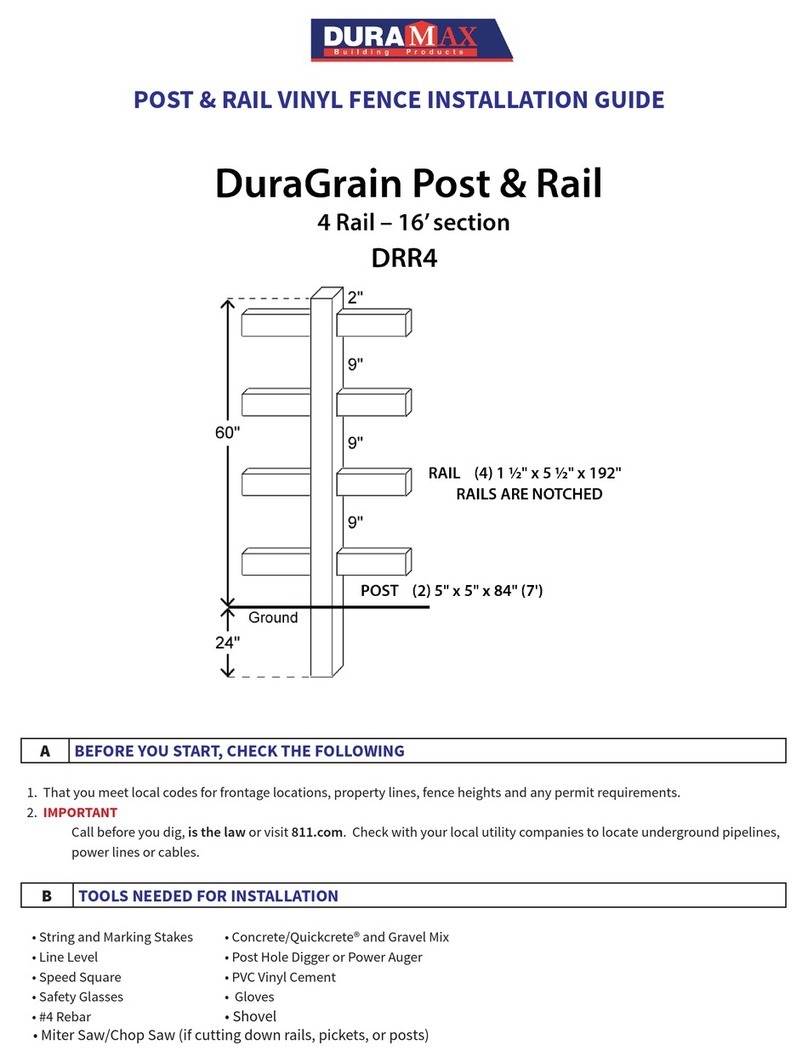

5. GLOSSARY FOR STOP LOGS

Figure 1

Page 6 sur 15

6. PREPARATION FOR INSTALLATION

6.1.NEW CONCRETE CHANNEL WITH BOXOUTS

Verify the straightness of the channel and boxouts where the frame will be installed. A plumb line, a laser

and/or a straight edge can be used.

1. First verify the channel depth (height) against the submittal drawing. A variation of ± 25mm (1’’) is

acceptable and will not impact the installation or operation.

2. Verify the position of the boxouts. They must be aligned and face to face within ± 6mm (1/4’’).

3. Measure the boxout width, making sure they are at least 50mm (2") larger than the frame.

4. Measure the channel width at the bottom and mark the channel center on both the upstream and

downstream sides of the boxout, on the channel bottom slab. The channel width should be the

same as the gate clear opening inside the frame.

5. Measure the overall width of the frame. From the channel center previously marked, place

another mark in the boxouts equivalent to half of the frame overall width. Repeat the other side.

The outside limits of the frame will be positioned to those marks.

6. Drop a plumb line into the boxout, centered on the mark indicating the outside limit of the frame.

There should be a gap of at least 16mm (5/8"), for the whole channel depth. (see Figure 2)

Figure 2

7. Make sure the boxout is straight and vertical within ± 20mm (3/4") for the whole channel depth.

8. Repeat points 6 & 7 on the other side of the channel.

If corrective work is needed, have it done by a skilled professional.

6.2.EXISTING CONCRETE CHANNEL (SURFACE MOUNT)

Verify the straightness of the channel walls and floor where the gates will be installed.A plumb line, a

laser and/or a straight edge can be used.

Page 7 sur 15

1. First, measure the channel width. It must be larger than the overall gate’s frame by at least 32mm

(1-1/4").

2. Verify the channel depth. A maximum difference of ± 25mm (1”) vs the depth indicated on the

approved submittal drawing is acceptable and will not impact the installation or operation.

3. Locate the position of the stop logs or stop plate on one side of the channel. The logs or plate

must be installed perpendicular to the channel wall. Pull a straight line at 90° across the

channel and mark the position on the opposite side. A tolerance of ± 6mm (1/4’’) is acceptable.

(see Figure 3)

If corrective work is needed, contact a qualified professional.

4. Drop a plumb line on one side of the channel at the installation location. Pull the line toward the

wall until the nearest point for the whole channel depth is at 16mm (5/8") from the wall. Mark the

position on the bottom of teh channel. (see Figure 3)

5. Drop the plumb line on the other side of the channel from the position located at point 3. Repeat

the process to locate the bottom position at 16mm (5/8") from the wall.

Figure 3

6. Measure precisely the distance between the 2 marks at the bottom of the channel. That

dimension must be equal or greater to the overall width of the frame. Draw a line on the channel

floor reaching both marks.

7. Measure and mark the center of the line. That will locate the center of the frame.

If corrective work is needed, please have it done by a skilled professional.

Page 8 sur 15

7. EMBEDDED FRAME INSTALLATION

Always apply an anti-seize on the stainless steel fasteners.

1- Frames are usually shipped unassembled. The first step is to place the bottom section of the frame

(sill).

2- Start by precisely measuring and marking the

exact center of the sill.

3- Place the sill into the boxout in the channel floor,

making sure to align the center to the center of

the channel that was previously marked on the

concrete.

4- Level the sill with a calibrated 24” or 48” spirit

level. Use shims to adjust the level as needed.

For frames having a free opening width

exceeding 1500mm (60”) use a calibrated laser

level.

5- Bolt the 2 frame sides to the sill and tighten the

bolts firmly.

Figure 4

6- Place a plumb line on both side of the channel near the frame sides. Check and adjust verticality of

the frame sides in both axes along the whole channel depth. Tolerance on verticality is ± 3mm (1/8’’)

on the channel depth. Maintain the frame sides in position

using temporary wood shims.

7- Make sure to maintain a minimum gap of 16mm (5/8")

between all parts of the frame and the boxouts to allow

proper grouting. If needed, reposition the gate while

maintaining the sill level and verticality of the sides.

8- Check squareness of the free opening using a straight-edge

or a tight string from one corner to the other. A variation of

2mm or less is acceptable. Correct if needed with the

wooden shims.

9- Measure across the channel, the distance between the frame

sides at the top and bottom. The distance at the top and

bottom should be the same. Adjust if needed.

10- Lower one stop log or the stop plate into the frame. Check

the contact between the bottom seal and the bottom section

of the frame (sill) by using a flashlight. The seals on the log

or plate have a lip that should be in contact with the sill on its

entire width. Remove the log or plate before grouting.

Figure 5

11- Taking precautions not to displace the frame, install wooden forms to close the boxouts and pour the

grout. Be careful to avoid spilling grout inside the guide frame.

12- With clear water, clean the slides and bottom seal to remove any dirt (grout, metal, etc.), Make sure

the area where the frames are installed is clean from any residue that could interfere with proper

operation of the logs or plates.

Page 9 sur 15

8. IN CHANNEL SURFACE INSTALLATION

Always apply an anti-seize on the stainless

steel fasteners.

1- Frames are usually shipped unassembled.

The first step is to place the bottom section of

the frame (sill).

2- Start by precisely measuring and marking the

exact center of the sill.

3- Place the sill on the channel floor, making sure

to align the center to the center of the channel

that was previously marked on the concrete.

(Figure 6)

4- Level the sill with a calibrated 24” or 48” spirit level. Use

stainless steel shims to adjust the level as needed. For

frames having a free opening width exceeding 1500mm (60”)

use a calibrated laser level.

5- Mark and drill the 2 anchor holes of the sill at the extremities

(closest to the side wall of the channel). Install these 4

anchors.

6- Bolt the 2 frame sides to the sill and tighten the bolts firmly.

The 2 frame sides may comprise more than one section.

Sections can be bolted together and the bolts firmly tightened.

7- Place a plumb line on both side of the channel near the frame

sides. Check and adjust verticality of the frame sides in both

axes along the whole channel depth. Tolerance on verticality

is ± 3mm (1/8’’) on the channel depth. Maintain the frame

sides in position using the crane or other method depending

on the available tools. (Figure 6)

8- Make sure to maintain a minimum gap of 16mm (5/8")

between all parts of the frame and the sidewalls to allow

enough clearance to pour the grout. If needed, reposition the

gate while maintaining the sill level and verticality of the

sides.

9- Mark and drill the remaining anchor holes on the bottom frame (sill). Install and tigthen the anchors

(see figure 6)

Apply anti-seize on each anchor rods.

10- Check straightness of the bottom frame (sill) using a straight-edge or a tight string from one corner to

the other. A maximum variation of 2mm or less is acceptable. Correct if needed by tightening the

intermediate anchor(s) and/or adding shims.

11- Drill the 2 anchor holes, on each side of the frame, closest to the top of the door. Install the anchors.

Figure 6

Figure 7

Page 10 sur 15

12- Measure across the channel, the distance between the frame sides at the top and bottom. The

distance at the top and bottom should be the same. Adjust if needed.

13- Place stainless steel shims behind the frame, close to the anchors, before tightening. The frame

must remain in position while the anchors are tightened.

14- Install the intermediate anchors on the frame sides. All intermediate anchors must be installed, since

the frame is not embeded. The distance between the UHMWPE guides must be verified at each pair

of intermediate anchors. Adjust as needed with the shims and anchors making sure the distance is

the same as at the sill.

15- Lower one stop log or the stop plate into the frame. Check the contact between the bottom seal and

the bottom section of the frame (sill) by using a flashlight. The seal on the log or plate has a lip that

should be in contact with the sill on its entire width. Remove the log or plate before grouting

16- Taking precausions not to displace the frame, install the forms to shape and pour the grout. Be

careful to avoid spilling grout inside the guide frame.

17- With clear water, clean the slides and bottom seal to remove any dirt (grout, metal, etc.), Make sure

the area is clean from any residue that could interfere with the proper operation of the logs or plates.

Page 11 sur 15

9. OPERATION WITH LIFTING DEVICE

When supplied, a lifting device can be used to help placing and removing stop logs from the frame. It is

basically a beam that travels in the same guide frame than the logs. It has 2 hooks aligned with the 2

handles that are located on each log.

9.1.LOWERING A STOP LOG

1- Hook the lifting device to the chainblock or crane (not supplied)

2- Bring the lifting device over a stop log and pull the rope so that the 2 hooks pivot backwards.

3- Lower the lifting device at the proper height so that the hooks can enter the stop logs handle

when they pivot forward. Let go of the rope. Log is now hooked.

4- Lift the log & device and bring them above the frame. Lower the log into the frame until it reaches

the bottom or the top of the logs that were previously lowered into the frame.

5- Continue to lower the device an inch or two, and then pull the rope to unhook the log. Lift the

lifting device out of the frame with the crane or chainblock.

6- Repeat the steps with the other logs.

9.2.REMOVING A STOP LOG

1- Hook the lifting device to the chainblock or crane (not supplied)

2- Bring the lifting device over the frame where logs are installed. Lower the device into the frame

until it reaches the top log and continue lowering.

3- Hook should engage themselves onto the handles by the weight of the lifting device.

4- Lift the log & device and bring them out of the frame. Bring to place of storage and unhook the log

from the lifting device. Use the rope to pivot the hooks if necessary.

Page 12 sur 15

10.TROUBLESHOOTING

Never use excessive force with the lifting equipment, permanent damage to seals and lifting

equipment may result.

10.1. STOP LOGS JAMMING

Check installation of guides for proper dimensions. Have the guides been installed straight and plumb?

!Since the guides are embedded in the concrete, corrections of the guides will be difficult if

not possible. Modifications to the stop logs may be necessary.

Check the condition of the stop log. Has it been bent, twisted, dented, or otherwise damaged to

sufficiently impair its normal operation? Consult drawings for dimensional details.

!Correct or Repair logs as necessary

Are stop log lifting eyes in good condition? Consult the drawings for original dimensions and location data.

!Correct or repair lifting eyes as necessary

Is the stop log lifting beam in good condition and operating correctly? Check latch plates and

counterweights for damage, or if equipped with latching hooks, check them.

!Correct or repair lifting beam and latch plates and/or hook assemblies as necessary.

Is hoisting mechanism or crane (by others) positioned correctly for insertingor removing logs? It should be

positioned directly over the guides, centered left to right and front to back.

!Reposition hoisting mechanism as necessary.

Are all gate seals properly attached to the stop logs? Do any of them interfere with insertion or removal of

stop logs?

!Re-tighten retainer strips and bolts and /or other attaching hardware. Re-bond mitered

joints. Undertake seal repair.

10.2. STOP LOG LIFTING BEAM DOESN’T PERFORM WELL

Is the stop log lifting beam in good condition? Are there any bent or broken sections? Has it been

modified in any way?

!Correct stop log lifting beam problems as necessary.

Do the latching plate or hook assemblies function correctly? Check the condition of latches and

counterweights or hooks. Use the lifting device drawings to verify the correct dimension and condition of

the latching plate or hooks.

!Correct operating latch plate or hook assemblies as necessary.

10.3. STOP LOGS LEAK

Have the guides been properly installed? Check installation dimensions. Are the guides straight and

plumb? Use the drawings to verify the correct dimensions.

!With the guides embedded in the concrete, re-aligning of the guides will be difficult if not

impossible. Some modifications to the guides or stop logs may be necessary.

Are the stop logs in good condition? Have they been properly stored and properly insterted into the

guides? Has any damage occurred to them which would interfere with their proper sealing?

!Use drawings to verify and correct as necessary. If damage is not correctable, new logs

will need to be ordered from Fontaine-Aquanox.

Page 13 sur 15

Are the stop logs properly installed? Do they fit one against the other evenly?

!Remove and re-insert the stop logs to correct installation.

Are any of the seals damaged? Are all seating and sealing surfaces making contact with one another?

!Correct as necessary. Re-tighten retainer strips and bolts and/or other attaching

hardware. Re-bond mitered joints. Undertake seal repair.

10.4. LIP (HY-Q) SEAL

If the HY-Q seal is damaged for any reason, it should be replaced.

!Mesure entire length of the seal required and order replacement from Fontaine-Aquanox.

Provide the shop order and the gate drawing numberat the time of ordering the seal. Cut

the replacement seal to length, using the existing seal as a template. Place the attaching

bar on the new seal in the same in the same relative location it was on the damaged seal.

Use this bar for a template to mark the seal in order to drill or punch the holes. Put the

replacement seal on the bottom of the disc and attach in place with the attaching bar and

attaching bolts.

If there are problems in the operation of a system and troubleshooting described above offers no solution,

contact Fontaine Aquanox (see section 13) and have, if possible, the following information:

•Equipment serial number

•Detailed description of the situation

•Photos or videos that can help understand and address the situation

Page 14 sur 15

11.INSPECTION AND MAINTENANCE

In order to maintain the gates performances at its best, Fontaine Aquanox recommends the following

procedure.

11.1. INSPECTION FREQUENCY

Initial inspection: after 5 uses or two weeks after start up, whichever comes first.

Second inspection: 20 uses after the initial inspection or six months after start up, whichever comes first.

Subsequent inspections: Every 50 uses or every six months, whichever comes first.

If the stop plates or logs intensively or in extreme conditions, perform inspection every three months.

11.2. MAINTENANCE

Clean the plates and logs and their seals with clean water to get rid of any deposit.

Verify that the seals are in good condition

Verify that the guides are in good condition.

Page 15 sur 15

12.WARRANTY

ISE Metal inc. warrants that the stop logs it manufactures and delivers to the Buyer are free from defects

in material, workmanship and fabrication for a period of 60 months from the date of receipt of the

equipment at their installation location. To benefit from this warranty, the Buyer shall promptly report in

writing any failure during the warranty period. Provided that the buyer has stored, installed, maintained

and used the equipment in a workmanlike manner and has complied with the manufacturer’s instructions

and recommendations put forth in the Installation, Operation and Maintenance Manual, at its discretion,

ISE Metal will either correct the defect at its factory or provide the required parts. Shipping costs from the

factory to the installation site and/or labor on the equipment installation site are not covered by this

warranty. Accessories and equipment supplied by ISE Metal inc. with the gates, but manufactured by

others will be protected by the warranty offered to ISE Metal by the manufacturers of the equipment which

are transferable to Buyer. ISE Metal inc. will not be held responsible for any direct, indirect,

consequential, contingent or incidental damages, repairs, replacements or other fixes and adjustments to

the equipment nor any labor costs incurred by the Buyer or its subcontractors or others without the prior

written consent of ISE Metal Inc. The effects of corrosion, erosion and normal wear and tear are

specifically excluded from this warranty. The Buyer shall not use equipment that is considered defective

without first obtaining a written consent of ISE Metal inc., otherwise the Buyer uses the equipment at their

own risk and responsibility.

ISE Metal Inc. provides no other warranty or makes no other express or implied representation and any

implied warranty of fitness for a particular purpose is declared non-existent.

Corrections by ISE Metal inc. of non-compliance described above constitute complete fulfillment of its

responsibility in this manner.

13.CONTACT FONTAINE AQUANOX

If needed, Fontaine-Aquanox can be contacted with the following methods:

Web site: http://www.ISEAquanox.com

Phone: (819) 769-0157 or toll free: 1-855-769-0157

Mailing address: 20 route de Windsor, Sherbrooke (Quebec), Canada, J1C 0E5

Table of contents