Forbes Marshall FMPP30 Manual

Pressure Pump with Insulation Jacket

FMPP30

Installation and Maintenance Manual

Energy Conservation | Environment | Process Efficiency www.forbesmarshall.com

1. Preface .................................................................................1

2. Important Safety Notes ........................................................1

3. Brief Product Information ....................................................3

4. Product Working Principle.....................................................10

5. Installation Guidelines .........................................................12

6. Startup and Commissioning ................................................14

7. Maintenance Guidelines .....................................................16

8. Troubleshooting ..................................................................19

9. Available Spares ................................................................21

10. Warranty Period ..................................................................21

Table of Contents

PLEASE NOTE - Throughout this manual this cautionary symbol is used to

describe a potential damage or injury that might occur if the safety

considerations are overlooked. This symbol denotes CAUTION, WARNING or

DANGER.

Pressure Powered Pump Package Unit with IJ and CRM485R

1

1.

2.

Preface:

This manual is intended for anyone using, commissioning, servicing, or disposing the below

mentionedproductssafelyandefficiently.

PressurePumpInsulationJacket ,[FMPP30

Size: DN40 (1 ½”), DN50 (2”), DN80 (3”)

Importantsafetynotes:

Read this section carefully before installing/operating/maintaining the product. The

precautions listed in this manual are provided for personnel and equipment safety.

Furthermore, Forbes Marshall accepts no responsibility for accidents or damage

occurring as a result of failure to observe these precautions. Note that the product is

designedtoperformfornon-contaminatedfluidsonly.Acontaminationintheformof

chemical, foreign particle etc. can lead to problem with product performance and life

oftheproduct.

If these products in compliance with the operating instructions are, properly installed,

commissioned, maintained and installed by qualified personnel (refer Section 2.8) the safety

operationsoftheseproductscanbeguaranteed.Generalinstructionsfor proper use of toolsand

safetyofequipments,pipelineandplantconstructionmustalsobecompliedwith.

2.1 Intendeduse:

Check if the product is suitable for intended use/ application by referring to the installation

andmaintenanceinstructions,nameplatesandtechnicalinformationsheets

1. Theproduct issuitablefor useasdefinedinthetechnicalinformationsheet.Incasethe

need arises to use the product on any other fluid please contact Forbes Marshall for

assistance.

2. Checkforthesuitabilityinconformancetothelimitingconditionsspecifiedintechnical

informationsheetoftheproduct.

3. Thecorrectinstallationanddirectionoffluidflowhastobedetermined.

4. Forbes Marshall products are not intended to resist external stresses, hence necessary

precautionstobetakentominimizethesame.

2.2 AccessibilityandLighting:

Safeaccessibilityandworkingconditionsaretobeensuredpriortoworkingontheproduct.

2.3 Hazardousliquidsorgasesinthepipeline:

Contemplate what may have been in the pipe or is in the pipe and also for flammable

materials,substanceshazardoustohealth,extremesoftemperature.

PPPPU

2

2.4 Hazardousenvironmentandmedia:

The product has to be protected from hazardous environment and check to ensure that no

hazardousliquidsorgasespassthroughtheproduct.

2.5 Depressurizingofsystemsandnormalizingoftemperature:

Ensure isolation and safety venting of any pressure to the atmospheric pressure. Even if the

pressure gauge indicates zero, do not make an assumption that the system has been

depressurized.

Toavoiddangerofburnsallowtemperaturetonormalizeafterisolation.

2.6 Toolsandconsumables:

Ensure you have appropriate tools and / or consumables available before starting the work.

UseoforiginalForbesMarshallreplacementpartsisrecommended.

2.7 Protectiveclothing:

Consider for the requirement of any protective clothing for you/ or others in the vicinity for

protection against hazards of temperature (high or low), chemicals, radiation, dangers to

eyesandface,noiseandfallingobjects.

2.8 Permitstowork:

All work to be carried out under supervision of a competent person. Training should be

imparted to operating personnel on correct usage of product as per Installation and

Maintenance instruction. “Permit to work” to be complied with (wherever applicable), in

case of absence of this system a responsible person should have complete information and

knowledgeonwhatworkisgoingonandwhererequired,arrangetohaveanassistantwith

his primary goal and responsibility being safety. “Warning Notices” should be posted

wherevernecessary.

2.9 Handling:

There is a risk of injury if heavy products are handled manually. Analyze the risk and use

appropriatehandling method by takingintoconsiderationthetask,individual,the working

environmentandtheload.

2.10 Freezing:

Provision should be made to protect systems which are not self-draining, against frost

damage(inenvironmentwheretheymaybeexposedtotemperaturesbelowfreezingpoint)

tobemade.

2.11 Returningproducts:

CustomersandStockistareremindedthat,whenreturningproductstoForbesMarshallthey

must provide information on any hazards and the precautions to be taken due to

contamination residues or mechanical damage which may present a health, safety or

environmentalrisk.

This information must be provided in writing including Health and Safety data sheets

relatingtoanysubstancesidentifiedashazardousorpotentiallyhazardous.

Pressure Powered Pump Package Unit with IJ and CRM485R

3

3. BriefProductInformation:

PPPPU

3.1 Description:

The Forbes Marshall Pressure Powered Pump Package Unit, PPPPU, is a positive

displacement pump unit operated by steam, compressed air or pressurized gas designed

to pump hot condensate.

3.2 Sizes and Pipe Connections:

SIZE : DN40, 50 and 80 pressure powered pump package unit.

Condensate inlet : vent flanged to class 150

Condensate outlet : use flange provided with pump

3.3 Limiting Conditions:

Note: For lower operating temperatures consult Forbes Marshall

Size Condensate Pump Vent Empty

(DN) inlet conn. (A) (DN) (DN) conn. weight

40 50 50 100 245kg

50 50 80 100 350kg

80 80 80 100 395kg

outlet

conn. (B) (DN)

PMA Maximum design pressure 8.7 bar g

TMA Maximum design temperature 220°C

Operating inlet motive pressure Steam / Compressed Air /

Pressurised gas 3 - 8.7 bar g (max)

Pump discharge per cycle 30 kg

Steam consumption 3 Kg of steam per

1000 Kg liquid pumped

Air consumption 22 SCF per 1000 Kg

liquid pumped

Minimum operating temperature 0°C

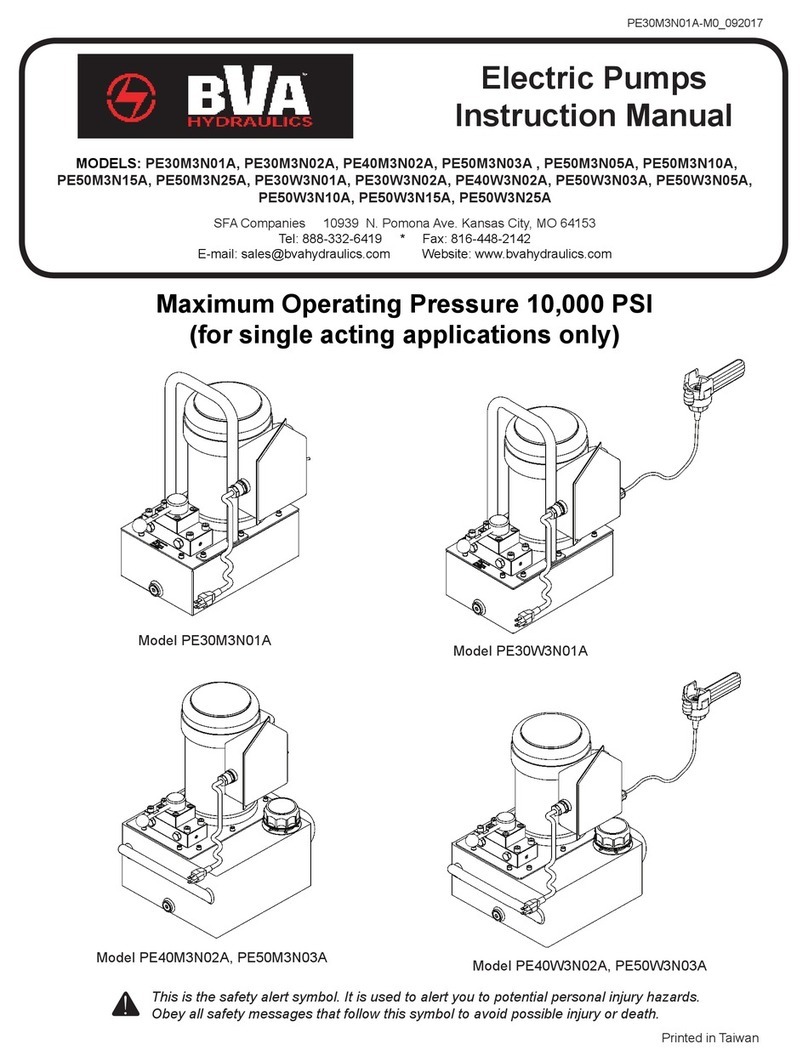

Figure 1 : Pressure Powered Pump Package Unit

4Pressure Powered Pump Package Unit with IJ and CRM485R

3.5 Standard Accessories:

Condensate recovery meter - 485 (CRM485R)

and insulation jacket

3.4 Operating Range:

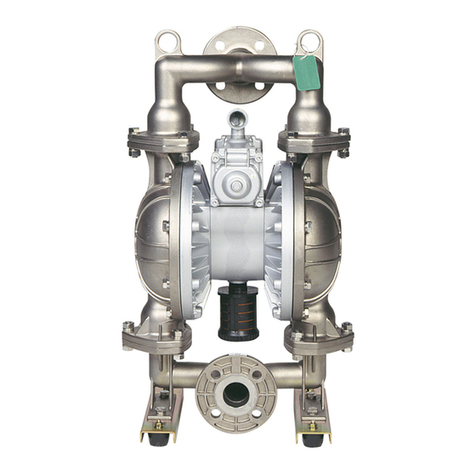

Figure 2 : Detail of Pressure Powered Pump Package Unit with IJ and CRM485R

35

24

29

6

4

25

305

5

PPPPU

35

24

29

6

4

25

(305)

37

38

6Pressure Powered Pump Package Unit with IJ and CRM485R

3.6 How to Select and Size:

Select the pump size according to the capacity requirement of the application from the

inlet, back pressure and filling head conditions given in the table below.

Back pressure (h) = [H X 0.1 bar g] + FP bar g + LP bar g

where H=height to which condensate is to be lifted in mtrs.

FP= Frictional pressure drop of discharge

LP=Line Pressure

22

1

2318

17

21

20

16

15

19

14

13

12

2

3

6

7

4

5

11

10

9(b)

9(a)

1

8

7

PPPPU

3.7 Capacity kg/hr.:

When installed with recommended filling head above top of pump :- 305 mm.

For liquid specific gravity (0.9 to 1)

MOTIVE STEAM

Pressure(barg) Capacity(kg/hr)

Motive Back DN40 DN50 DN80

8.7 0 4090 6765 10355

1 3295 4655 6165

2 2980 3765 5090

3 2730 3605 3925

4 2405 3100 3495

8 0 4015 6680 10245

1 3260 4440 5830

2 2890 3660 4555

3 2475 2995 3770

4 2350 2645 2950

7 0 3935 6605 10135

1 3230 4195 5545

2 2830 3415 4440

3 2420 2930 3515

4 2195 2605 2855

6 0 3880 6365 9880

1 3115 3775 5210

2 2800 3270 4290

3 2325 2700 3425

4 2095 2195 2720

5 0 3830 6275 9605

1 3005 3705 5050

2 2635 3055 4140

3 2290 2505 3070

4 0 3705 5910 9175

0.5 3095 3885 5440

1 2835 3410 4460

2 2380 2705 3215

3 0 3525 5420 8090

0.5 2970 3540 4705

1 2570 2950 3675

8Pressure Powered Pump Package Unit with IJ and CRM485R

MOTIVE AIR

Pressure(barg) Capacity(kg/hr)

Motive Back DN40 DN50 DN80

6 0 4055 6360 9645

1 3835 5555 7925

2 3635 4845 6710

3 3335 4390 5765

4 3055 3815 4810

5 0 4060 6335 9605

1 3750 5485 7700

2 3555 4800 6460

3 3275 4130 5465

4 0 4110 6305 9555

0.5 3905 5590 8425

1 3680 5380 7550

2 3450 4520 6105

3 0 4060 6265 9500

0.5 3935 5695 8085

1 3610 5125 7085

9

PPPPU

3.8 Capacity Multiplying Factors for Other Filling Heads

FillingHead DN40 DN50 Dn80

152 0.7 0.7 0.84

305 1.0 1.0 1.0

610 1.2 1.2 1.08

914 1.35 1.35 1.20

3.9 Capacity Multiplying Factors for Motive Gas Supplies

% Back pressure vs. Motive pressure BP/ MP)

10% 20% 30% 40% 50% 60% 70% 80% 90%

1.04 1.06 1.08 1.10 1.12 1.15 1.18 1.23 1.28

3.10Example:

Condensate load 1600 kg/hr.

Steam/air pressure available for operating pump 5.0 bar g

Vertical lift from pump to return piping 9 m

Pressure in return piping (piping friction negligible) 1.72 bar g

Filling head on pump 0.3048 mtrs.

Solution:

1 Calculate “h”, the total lift or back pressure against

which the condensate must be pumped.

= (9mx 0.1) + 1.72 = 2.62 bar g

2 From capacity table with 5.0 bar g operating inlet pressure

and 3.0 bar g back pressure choose a DN 40 pump which has a capacity of 2290 kg/hr.

Note from Capacity Factor Charts

A Pumpcapacityiffillingheadis0.610mtr.

=1.2x2290=2748kg/hr.

10

4. Product WorkingPrinciple:

Note:ForthissectionrefertoFigure4

A PPPPU unit consists of a receiver (1), Inlet Isolation valve (2), Strainer (3), a body shell (4)

containing a float mechanism which operates a set of motive steam / air inlet (5) and exhaust

valves (6) and inlet (7) & outlet (8) disc check valves. The steam or air is used as motive media to

operate the pump. Condensate comes into the pump receiver (1) from flash vessel or plant

condensate header and is allowed to flow in to the pump body (4) having float mechanism by

openingtheinletisolationvalve(2).

Figure 4: Pressure Powered Pump Package Unit

Note:ForthissectionrefertoFigure3

In the normal position before startup the float is at the lowest position with the motive steam/air

valve(5)closedandtheexhaustvalve(9A)open.Whencondensateflowsbygravitythroughinlet

checkvalveintopumpbody(15),thefloat(16)willbecomebuoyantandrise.

1

2

3

7

4

8

65

Pressure Powered Pump Package Unit with IJ and CRM485R

11

Asthefloat(16) continuestorise,themechanismlink(17) isengaged which increasestensionin

the springs (19). When the float (16) has risen to its upper tripping position, the linkage

mechanism (17) snaps upward over center. The energy in the springs (19) is released as the push

rod (18) is moved upward, to simultaneously open the motive steam inlet valve (5) and close the

exhaust valve (9A). Steam flow through the inlet valve (5) increases the pressure within the body

and closes the inlet check valve. When the pressure in the body shell (15) exceeds the

backpressure inthecondensate dischargeline,itopenstheoutletcheck valve(21)and forcesout

thecondensateinthedischargeline.

Asthecondensatelevelinthe pump body (15) falls,thefloat(16) islowered and mechanism link

(17) is engaged, which again increases the tension in the springs (19). When the float (16)

reaches the lower tripping position, the linkage mechanism (17) snaps downward over center.

The energy in the springs (19) is released as the push rod (18) is moved downward, to

simultaneouslyopentheexhaustvalve(9A)andclosethesteaminletvalve(5).Steam/airutilized

for pumping the condensate gets released through the exhaust valve and this completes one

pumpingstroke.

When the pressure in the pump body (15) has fallen to the same level as the pressure in the inlet

pipe, the inlet check valve opens. Condensate will again flow through the check valve to fill the

bodyandbeginnextcycle.

PPPPU

12

5. InstallationGuidelines:

Note: Before implementing any installations observe the 'Important Safety notes” in

section 2. Referring to the Installation and Maintenance Instructions, name-plate and

Technical Information Sheet, check that the product is suitable for the intended

installation.

Note:ForthissectionrefertoFigure5

1. Ensurethatthereisnodamageintransit.Beforeinstallationisdoneensurethatallsteam,air

or gas lines are closed. Select correct pipeline sizes as per the pump and connections are

available.Leveltheunitbylevelbottle.

2. The reservoir has 3 ports, two of them should be connected for condensate inlet (A) and

thirdis usedforventline©. Most importantisthatreservoirmustbevented to atmosphere.

Thisistoensurefreeflowofcondensateundergravitytothepump.

3. ItisrecommendedtoinstallPPPPUalongwithaForbesMarshallFlashvesselarrangement,if

condensateflashingisexpectedwhenexposedtoatmosphere.

4. Connect the condensate line coming from plant to the flash vessel inlet port. Install strainer

(1), single orifice float trap (2) and view glass (3) after the flash vessel and connect

condensateoutletlinetothepumpreceiver(6). Installthesafetyreliefvalve(4)andpressure

gauge(5)atrespectivelocationsprovidedon theflashvessel.Ensurethatthepump receiver

inlet is at a lower level than the condensate outlet line of flash vessel so the condensate

travelsbygravitytothepumpreceiver.

5. Ventline(C)shouldbepiped,unrestrictedtosafelocationintheatmosphere.

6. Connectthemotivesteamorcompressedairline(7)tothemotivesupplyinlet.

7. A pressure gauge (8) is supplied loose along with the pump. Install the same on motive line

syphon. Condensate discharge line (B) of pump should be routed to the boiler feed water

tankandconnectthesametothecondensatenozzleofde-aeratorhead.

Figure 5: Installation of PPPPU with Forbes Marshall Flash Vessel

Pressure Powered Pump Package Unit with IJ and CRM485R

13

2

4

Condensate

Inlet

5

Condensate Line

Flash Steam

A

C

B

A

13

5.1 Caretobetakenwhileroutingthecondensatepumpdischargeline:(RefertoFig.6)

1. The outlet line size should be equal to or more than pump outlet flange size provided

withpump.

2. As far as possible, the discharge line should have minimum bends. Ideally the

condensate pump discharge line should be lifted immediately after the pump to the

maximum elevation in the circuit and then to be connected to feed water tank with a

downwardslope.Thisensuresminimumbackpressureonthepump.

Figure 6 : Routing the condensate line to the Feed Water Tank

5.2 In case more than one condensate pump is connected to a common Condensate

line:(RefertoFigure7)

1. Make sure that NRV supplied with pump is installed with flow direction towards FWT.

TheNRVsizeshouldbeequaltothepumpoutletlinesize.

2. If more than one-pump discharge lines are to be connected to a common condensate

line, please ensure that the individual line is connected from the top with a non-return

valve. The common condensate line should be sized to take care of connected

condensateloadofallthepumps.

Figure 7: More than one pump connected to common condensate line

PPPPU

14

6. StartupandCommissioning:

It is recommended to install Forbes Marshall PPPPU along with a Flash vessel arrangement, if

condensate flashing is expected when exposed to atmosphere. For trouble free operation of

PPPPU,itis importantthatthesingle orificefloattrap internals,pump internals& checkvalvesare

notsubjectedtodirtorotherhardparticles.

Therefore, prior to bringing the PPPPU in to operation, please ensure that the entire condensate

pipingcircuitisthoroughlyflushed.

6.1 FlushingProcedureinthepresenceofaForbesMarshallFlashVessel(ReferFig.8)

1. Open the Forbes Marshall flash vessel drain line and allow the process condensate to

flow through the drain till all the foreign particles & contaminated condensate is

flushedoutandcleancondensatecanbeseencomingout.

Figure 8 : Flushing procedure of Forbes Marshall flash vessel

Drain

Line

Condensate Outlet

Condensate Intlet

Flash

Steam

Outlet

Pressure Powered Pump Package Unit with IJ and CRM485R

15

6.2 FlushingProcedureintheabsenceofaForbesMarshallFlashVessel(ReferFigure9)

1. Whereverprocesscondensateisdirectlyconnectedtopumpreceiver&ForbesMarshall

flash vessel module is not part of PPPPU, open the pump condensate strainer cap (3) &

screen to flush the foreign particles and contaminated condensate. Similarly, motive

steam/airline (5) shouldalsobe flushedbyremoving strainercap&screenuntilwe see

cleanmotivemediacomingout.

2. Once flushing of condensate and motive line is completed, open the motive line

isolation valve (6) and ensure that the motive media pressure should not exceed as

mentionedonthepumpnameplate.

3. Makesurethatthemotivelinedraintrap(7)isoperational.

4. Openthepump condensateisolationvalve (2) andallowthecondensatetoflow tothe

pumpreceiver(1)andsubsequentlytopumpingchamber(4).

5. Nowthepumpshouldpumpperiodically.

6. Steamorairutilizedforpumpingisreleasedwithanaudibleexhaustattheendofeach

pumping cycle. Observe the condensate return line pressure gauge (8) & ensure that

themotivepressureisatleast1.5to2bargmorethanthebackpressure.

Figure 9 : Flushing procedure of Pressure Powered Pump Package Unit

PPPPU

16

7. MaintenanceGuidelines:

Before undertaking any maintenance on the product it must be isolated from both supply line and

return line and any pressure should be allowed to safely normalize to atmosphere. The product

shouldthenbeallowedtocool.Aftersuitableisolationrepairscanbecarriedoutwiththeproductin

the line. PPPPU units are designed for trouble free operation. In normal course of action

maintenanceisnotrequiredprovidedcertaincareofthesystemistaken.

7.1 RoutineandPreventiveMaintenance:

Please refer to the maintenance schedule mentioned in the table below to undertake

routinemaintenanceofthePressurePoweredPumpPackageUnit.

NO. PARAMETERS TO BE CHECKED FREQUENCY FOR CHECKING VARIOUS

PARAMETERS

A Pressure Powered Pump Package Unit / Flash Vessel Daily Weekly Monthly Quarterly Half

Yearly Annually

1 Clean strainer of motive media line Y

2 Clean condensate inlet strainer Y

3 Visual inspection and cleaning of complete set of internals Y

4 Condensate pump chamber draining Y

5 Inlet / Exhaust valve leakage testing Y

6 Check Valve Cleaning Y

7 Operate motive line valve Y

8 Operate Condensate inlet valve Y

9 Lubrication of piston valves Y

10 Pr. Gauge calibration Y

11 Checking of PPPPU motive pressure Y

12 Checking of flash steam pressure in flash vessel Y

13 Cleaning of motive line trap internals Y

14 Cleaning of steam traps internals Y

15 Visual inspection for leakages Y

16 Arresting leaks Y

17 Checking of float trap SLR setting Y

18 Cleaning of strainer between flash vessel and pump Y

19 Check air quality(in case motive media is air) Y

20 Visual inspection of safety relief valve Y

21 Overhauling and cleaning of safety relief valve Y

Pressure Powered Pump Package Unit with IJ and CRM485R

17

7.2 ToolKit:

TocarryoutanymaintenanceofthePPPPUusethetoolsmentionedinthetablebelow.

7.3 Maintenance/ReplacementProcedure:(RefertoFigure3)

Foradetailedmaintenance/replacementprocedureofthepumpbodyinternals,pleaserefer

totheinstructionsgiveninthesubsequentsections;

7.3.1 ProceduretoMaintain/ReplacethewholePPPPUinternalassembly:

1. Beforecarryingoutanymaintenance,removealltheconnectionstothepump

cover(1).Isolatethepumpbodybyclosingtheinletisolationbutterflyvalve.

2. Unscrew all eight nuts (3) present on the cover (1) and lift the cover and

internalmechanismassemblyfromthepumpbody(15).

3. Arrange the whole assembly onto the vice such that the internals are placed

ontopandclampthecover.

4. Removetheassemblynutstofreethewholeassemblyfromthecover.

5. Remove the old gasket (2), andclean the gasket area.Ifrequired replacewith

anewone.

6. Fit the PPPPUinternal assemblyontothecover. Carefullyengagethe exhaust

valve(9A)ontotheactuatordisc(11)andscrewthenuts.

7. Unclamp the coverandinsertthewholeassembly back insidethepumpbody

(15).

8. Tightenthecovernuts(3).

PPPPU

Size Part Component Tool used and Size

DN 40 / 50

/ 80 Internal MechanismAssembly

Motive inlet and exhaustValve Open Spanner 26 mm (A/F)

Float Mechanism Open Spanner 19 mm (A/F)

Push Rod and Lock Nut Open Spanner 17 mm (A/F)

Bush assembly and stop bolt Box Spanner 13 mm (A/F)

Stopper bracket bolt Box spanner 8 mm (A/F)

FloatArm Bolt Open Spanner 10 mm (A/F)

For Split PinAssembly Nose Plier

DN 40 / 50

/ 80 ExternalAssembly

Read switch assembly 4 No M6 studs;M6

X 4mm nuts Ring spanner 10 mm (A/F)

Internal assembly cover (M12 X 50) Open spanner 18 / 19 mm (A/F)

Motive inlet and exhaust hose pipe

connection Pipe wrench

DN 40 Condensate inlet connection Butterfly valve (M12 X 90mm) Box spanner 18/19 mm (A/F)

Strainer assembly (M12 X 50mm) Box spanner 18/19 mm (A/F)

Disc check valve (M16 X 100mm) Box spanner 24 mm (A/F)

Condensate return connection Disc check valve (M16 X 100mm) Box spanner 24 mm (A/F)

DN 50 Condensate inlet connection Butterfly valve (M16 X 110mm) Box spanner 24 mm (A/F)

Strainer assembly (M16 X 65mm) Box spanner 24 mm(A/F)

Disc check valve (M16 X 120mm) Box spanner 24 mm (A/F)

Condensate return connection Disc check valve (M16 X 120mm) Box spanner 24 mm (A/F)

DN 80 Condensate inlet connection Butterfly valve (M16 X 120mm) Box spanner 24 mm (A/F)

Strainer assembly (M16 X 70mm) Box spanner 24 mm(A/F)

Disc check valve (M16 X 130mm) Box spanner 24 mm (A/F)

Condensate return connection Disc check valve (M16 X 130mm) Box spanner 24 mm (A/F)

7.3.2 ProceduretoMaintain/Replacefloatassembly:

1. Followsteps1to3ofsection7.3.1

2. Unscrewthefloat(16)fromthefloatarmusingappropriatespanner.

3. ScrewthenewfloatusingLoctite272adhesiveontothethreads.

4. Insert the whole assembly insidethepumpbodyasdescribedinsteps 7 and 8

ofsection7.3.1

7.3.3 ProceduretoMaintain/ReplaceExhaustvalveseat&headassembly:

1. Unscrew all eight nuts (3) present on the cover (1) and lift the cover and

mechanismassemblyfromthepumpbody(15).

2. Arrange the whole assembly onto the vice such that the internals are placed

ontopandclampthecover.

3. Removetheassemblynutstofreethewholeassemblyfromthecover.

4. If required, remove the old gasket (2), and clean the gasket area before

replacingwithanewone.

5. UnscrewtheExhaustvalvehead(9B).

6. Cleanthemetalgasketandreplaceifrequired.

7. Fittheexhaustvalveheadandseat.

8. Now fit the PPPPU internal assembly onto the cover. Carefully engage the

exhaustvalveontotheactuatordisc(11)andscrewthenuts.

9. Unclampthecoverandinsertthewholeassemblybackinsidethepumpbody.

Whilereinstallingthecover.

10. Tightenthecovernuts(3).

7.3.4 ProceduretoMaintain/ReplaceInletvalveseatandheadassembly:

1. Followsteps1throughto4ofsection7.3.3

2. UnscrewtheInletvalvehead(6).

3. Cleanthemetalgasketandreplaceifrequired.

4. Fittheinletvalveheadandseat.

5. NowfitthePPPPUinternalassemblyontothecover(1). Carefullyengagethe

exhaustvalve(9A)ontotheactuatordisc(11)andscrewthenuts.

6. Unclamp the coverandinsertthewholeassembly back insidethepumpbody

(15).Whilereinstallingthecover.

7. Tightenthecovernuts(3).

7.3.5 ProceduretoMaintain/Replacethesprings:

1. Unscrew all eight nuts (3) present on the cover (1) and lift the cover and

mechanismassemblyfromthepumpbody(15).

2. Arrange the whole assembly onto the vice such that the internals are placed

ontopandclampthecover.

3. Removethesplitpins.

4. Removethewasherandthesprings(19)fromthelinkagemechanism(17)

5. Cleanthesprings(19)andreplaceifrequired.

6. Putthewasherandsplitpinsback

7. Reassemblethewholemechanismfollowingsteps7and8ofsection7.3.1

18 Pressure Powered Pump Package Unit with IJ and CRM485R

Table of contents

Popular Water Pump manuals by other brands

Goulds Pumps

Goulds Pumps DWT Installation, operation and maintenance instructions

BLACKMER

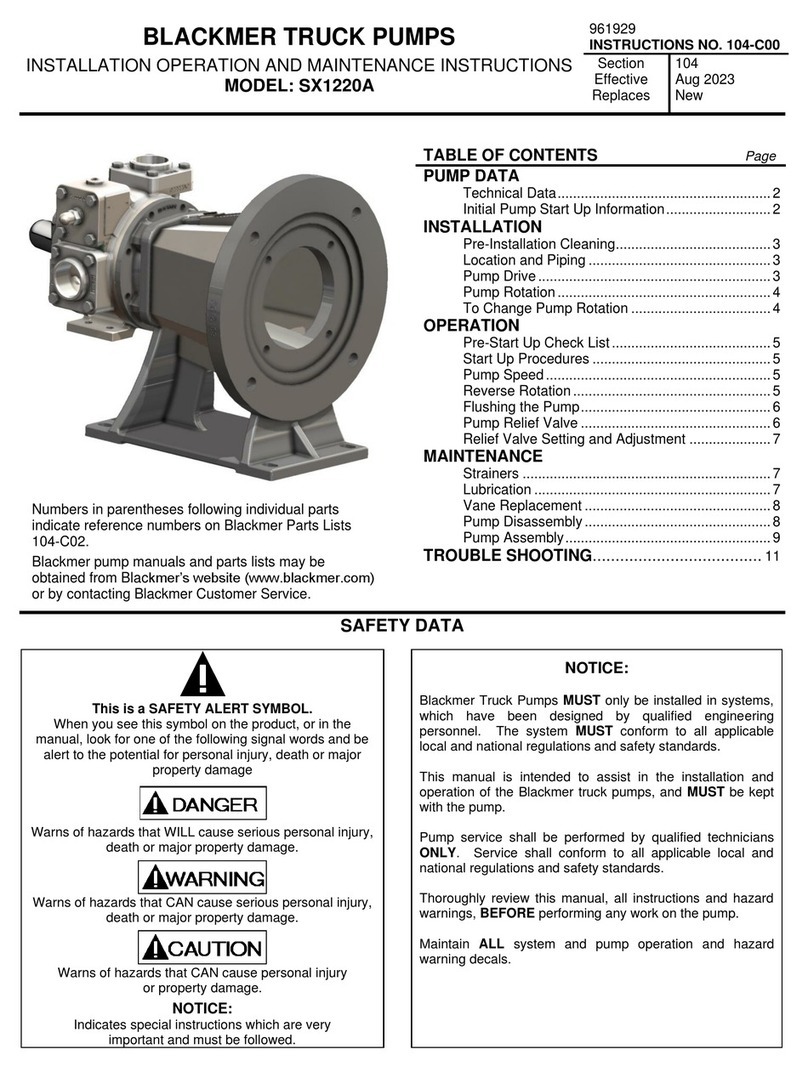

BLACKMER SX1220A Installation, operation and maintenance instructions

Edwards

Edwards STP Series instruction manual

Reefe

Reefe RCE160 Exploded View & Instruction Manual

FläktGroup

FläktGroup Semco NEUTON owner's manual

SPX

SPX Johnson Pump Viking Power 16 instruction manual