Forbo Trimmer User manual

Filling strip

Instructions for use

FORBO-TRIMMER

Indoff

SELLING NATIONWIDE

(860) 632-2026

FAX (860) 632-2028

www.ahutton.com

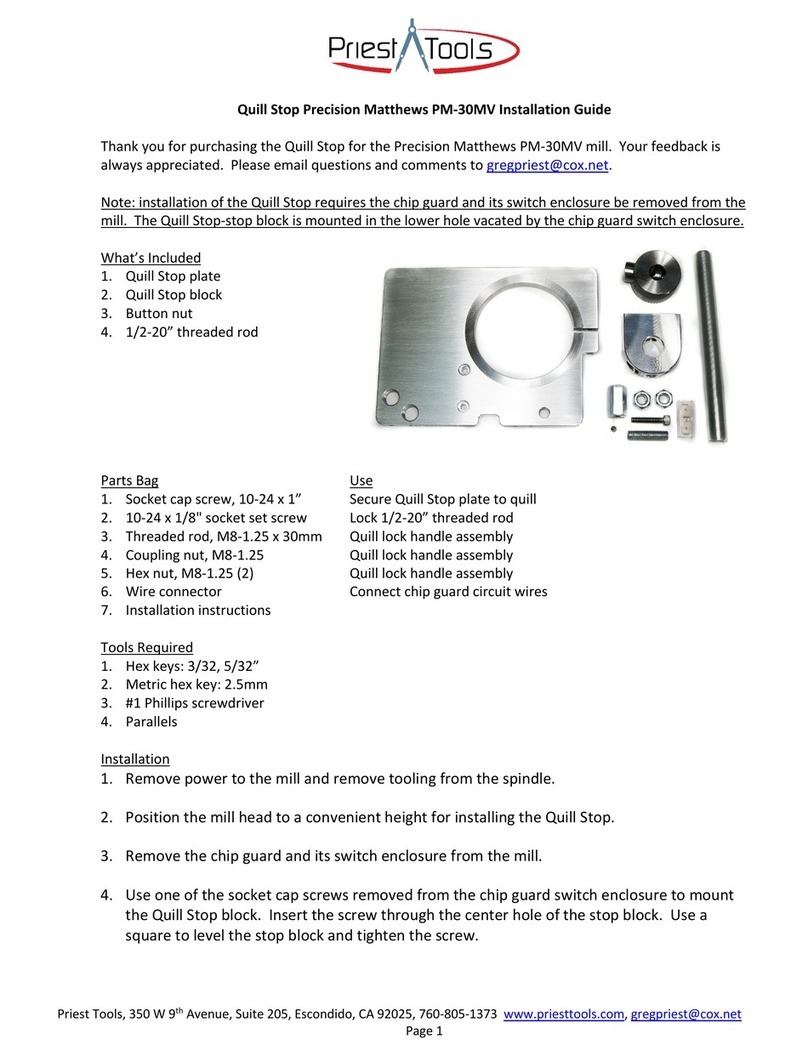

Parts

The Forbo-Trimmer consists of a frame fitted to a base plate.

The frame - which is provided with a casing made of a synthetic

material - contains knife blades.

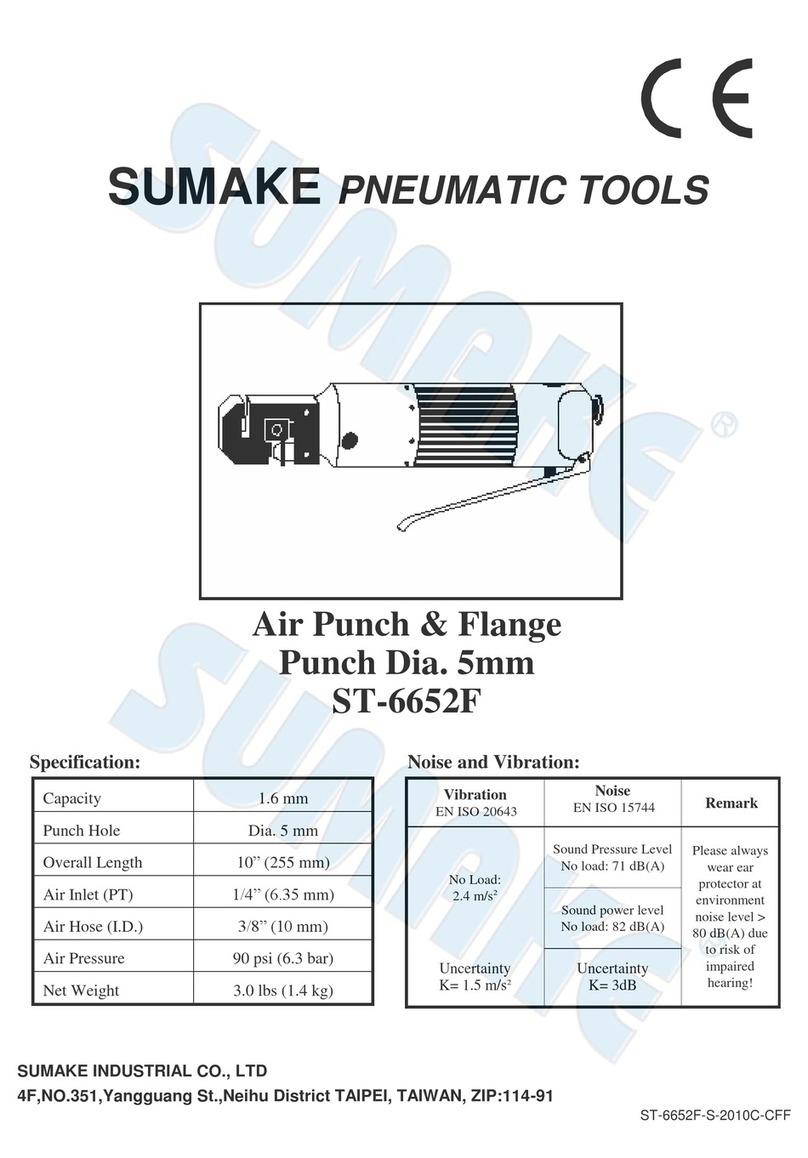

Parts of the Forbo-Trimmer

1.

Synthetic casing

2.

Locking screw

3.

Base plate

4. Filling strips (3 strips, width 5 mm, 10 mm and 15 mm)

Order numbers:

103 Forbo-Trimmer

139 Filling strips

141 Hooked blades, Roberts

142 Straight blades, Roberts

Forbo-Trimmer application possibilities

The Forbo-Trimmer is designed to remove factory edges from

linoleum, to cut strips and to cut seams ready to fit. The Forbo-

Trimmer may be used with such linoleum products as Marmoleum,

Artoleum, Walton, Desk Top, Corklinoleum and Bulletin Board, as

well as with homogeneous vinyl products.

Adjusting the Forbo-Trimmer

Arranging the knives

Which type of knife blade is to be placed in the Forbo-Trimmer

depends on the product for which it is to be used:

linoleum products such as Marmoleum, Artoleum and Walton

are first scribed with a straight blade and then cut with a

hooked blade. These two blades should therefore be arranged

behind one another in the Forbo-Trimmer;

for homogeneous vinyl products, only a hooked blade is used

and it should be placed in the rearmost position in the

Forbo-Trimmer;

for Corklinoleum and Bulletin Board, only a straight blade is

used and it should be placed in the

rearmost position in

the

Forbo-Trimmer.

The casing needs to be removed in order to arrange or replace

blades. The plate positioned against the blades should then be

removed, after which the blades can be positioned or replaced.

E

E

Position of the base plate

The position of the base plate must be adjusted depending on

which product is to be cut with the Forbo-Trimmer:

- linoleum products such as Marmoleum, Artoleum, Walton and

homogeneous vinyl products must have approximately 1.5 mm

more space in the opening of the Forbo-Trimmer.;

- with Corklinoleum and Bulletin Board, the opening between

the base plate and the frame needs to be.approximately

10 mm, so that the straight blade does not protrude from

under the base plate.

The position of the base plate may be altered by loosening the

two screws on the side of the Forbo-Trimmer. To make a quick

adjustment, a piece of floor covering may be inserted into the

trimmer on top of which can be placed a few metal shims with a

combined thickness of 1.5 mm (which is the combined thickness

of two blades). When the correct position has been achieved,

the screws may be refastened.

Parallel and horizontal position of base plate

It is important that the base plate is parallel to the frame of

the Forbo-Trimmer. The base plate is to some extent adjustable

sideways. To get the settings right at the beginning, proper

sideways adjustment of the base plate is essential.

The procedure is as follows:

- Remove the casing and the plate positioned against the blades;

- Place two hooked blades in the Forbo-Trimmer;

- Replace the plate against the blades;

- Unscrew the two screws at the bottom of the base plate;

- Push the base plate snugly against the blades;

- After adjustment, the correct blades may be positioned,

C t off strip

Length

2

Length

1

Length

2

1

Factory edge

,

Length

Clean edge

Length

Filling strip

N

Blade

o".."

Len

Left-handed and right-handed use

Both left-handed and right-handed people can use the Forbo-

Trimmer. To this end, the blades can be placed in the correct

cutting direction and the casing can be turned around. For

right-handed use, the blades should be positioned on the right,

and for left-handed use, on the left.

Working with the Forbo-Trimmer

Cutting clean

When installing linoleum, one should always remove the factory

edges. This is called 'cutting clean: When doing so, the strip of

floor covering is undercut. This canbe done in one go by sliding

one or more filling strips into the Forbo-Trimmer in such a way

that 15 mm is cut from the floor covering; Bend the filling

strips a little before inserting them into the Forbo-Trimmer, so

that they are wedged tightly in position.

Cutting seams

The Forbo-Trimmer may be used to cut seams in one go.

Cut the first length of floor covering on three sides ready to fit,

and cut it clean on the side which is to be positioned against

the second length of floor covering. Stick this length into

position and roll it. Now cut the second length of floor covering

ready to fit. This can be done as follows:

- Clean cut the second strip at the seam side over a length of

approximately 15 mm and place it with the clean-cut portion

against the first length of floor covering;

- Draw a line on the floor along the other longitudinal side of

the second length:

- Cut the transverse sides of the second length of floor covering

ready to fit;

- Position the Forbo-Trimmer and cut the seam.

When cutting seams in linoleum products, it is also possible to

use the Forbo-Trimmer only for scribing and to use the hooked

knife for cutting. This will prevent the floor covering from beco-

ming unusable if• the ForbO-Trimmer slips.

When cutting seams, it is important to exert substantial lateral

pressure on the Forbo-Trimmer, so that the base plate accurately

follows the edge of the bottom strip of floor covering.

Cutting strips

The Forbo-Trimmer can be used to cut-strifis

—

of various widths

(i.e. 5 mm, 10 mm, 15 mm, 20 mm, 25 mm and 30 mm). To do

so, one or more filling strips may be used. Each strip will have

an overcut and an undercut side, which should be kept in mind

when sticking the strips into position.

If seams are not welded, they can be cut to fit against each

other tightly. After cutting seams in linoleum products, a small

gap the thickness of a business card should be left so that after

sticking and expansion, an almost closed seam is achieved.

If seams are welded, it is useful to allow a space approximately

1 mm wide along which to guide the Forbo-Groover or a slotting

machine. For this purpose, the base plate may be adjusted

slightly in a horizontal direction.

6,054

goe

n-31- 1

.0

VI

2-3

WI

)14

"27

1

2--

1

0

I)/Alrt 2

/Or,/

-07Y5 "