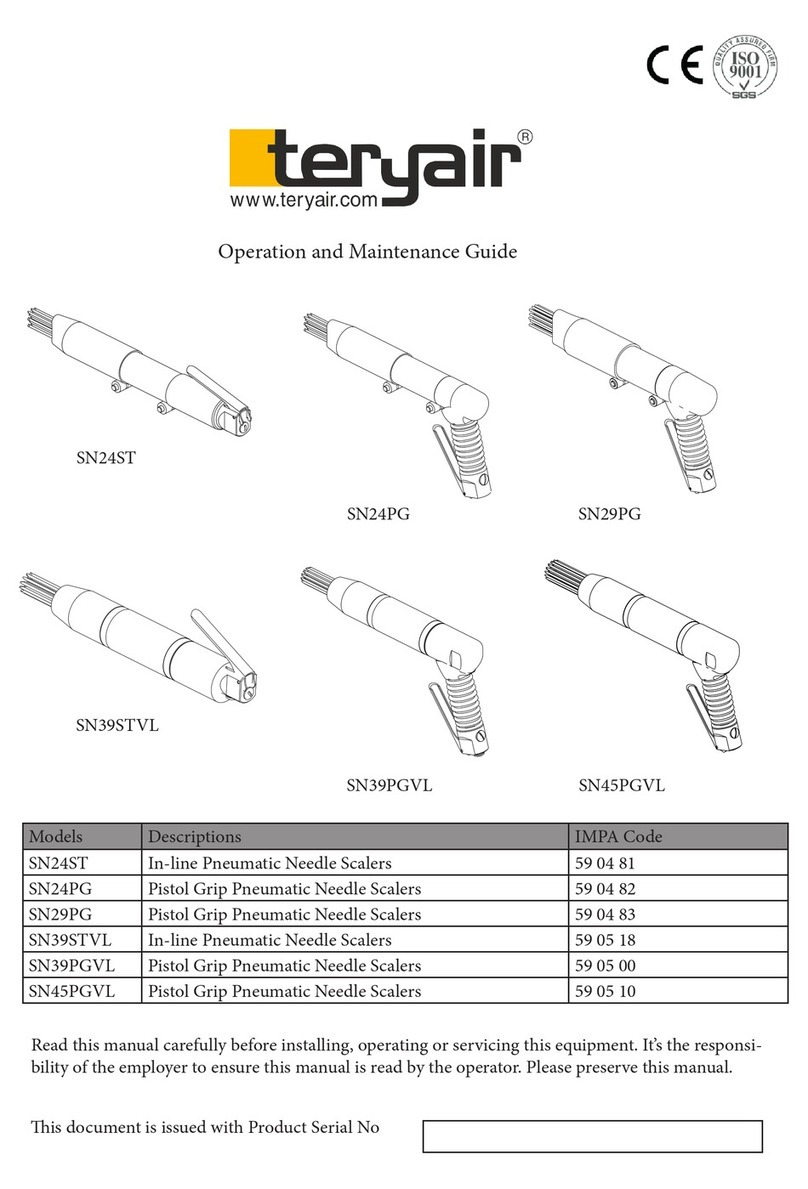

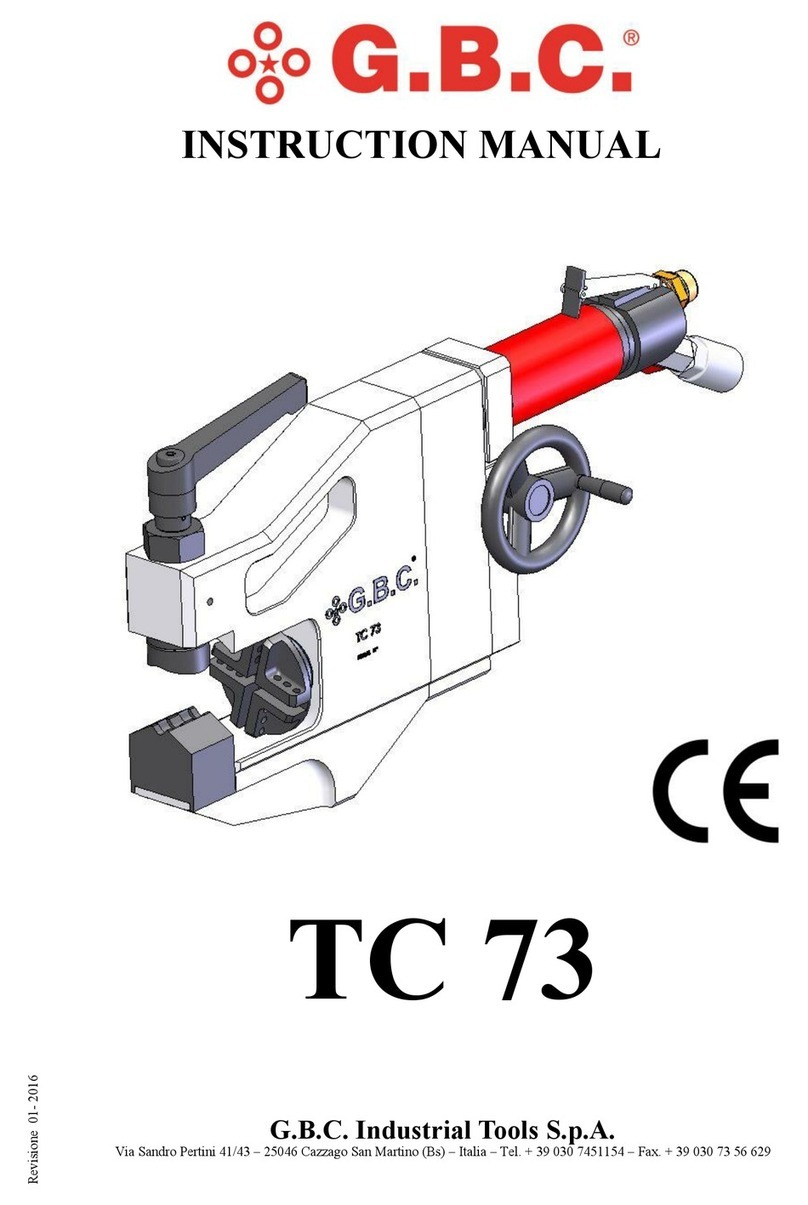

Teryair TEFD 75-110V Instruction Manual

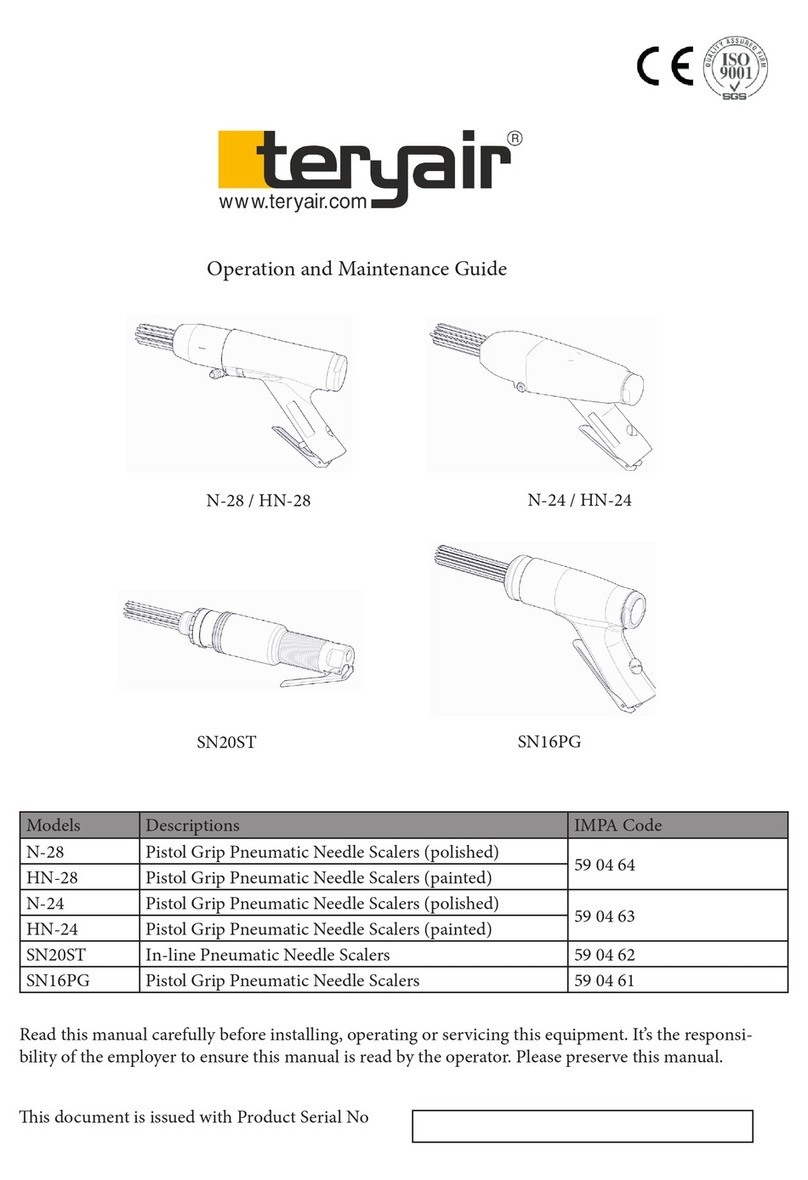

Models Descriptions IMPA Number

TEFD 75-110V Electric Flexible Descaler TEFD75-110V 59 12 17

TEFD 75-220V Electric Flexible Descaler TEFD75-220V 59 12 18

TEFD75-110V & 220V

Read this manual carefully before installing, operating or servicing this equipment. It’s the responsi-

bility of the employer to ensure this manual is read by the operator. Please preserve this manual.

is document is issued with Product Serial No

Operation and Maintenance Guide

FF-MM-44-REV - 00

Page 2

Operation and Maintenance Guide Electric Flexible Descaler TEFD75

Table of Contents

3 Introducon

3 Technical Data

3 OperangInstrucons

4 DisassemblyandRe-assembly

5 Exploded View for TEFD75

6 BillofMaterialsforTEFD75

8 EuDeclaraonOfConformity

9 WarrantyCercate

FF-MM-44-REV - 00

Page 3

Operation and Maintenance Guide Electric Flexible Descaler TEFD75

Technical Data

IMPA Number

Equivalent Model No Voltage H.P KW No Load

Speed R.P.M Weight, Kgs

59 12 17 TEFD75-11V 110V 0.75 0.55 2800 48

59 12 18 TEFD75-220V 220V 0.75 0.55 2850 48

Forward

At the outset we sincerely thank you for

choosing our product. We at TERYAIR always

believe in oering high quality products at the

most reasonable prices. is belief has helped

us to innovate and incorporate new ideas and

thus enjoy a high degree of customer satisfac-

tion.

is manual is designed keeping in mind all

the requirements of the customer in knowing

the product and its use. is product is almost

maintenance free. Only the electric supply

required to run the electric motor should be

smooth

Operating Instructions

Place Electric Motor with trolley on oor. Open

Hose assembly. On one of the ends - Of rotary

socket has female threads. Screw on this socket

on motor sha .Tighten it fully. en screw on

xing adaptor on motor end shield. With little

force this will t tight on motor. en select

which of these assemblies do you prefer to use.

Following is the guideline for

selection

A. For Heavy rusting - Use No.1 H.D.Tool

(59 12 55)

B. For Light rusting - Use either No.2

L.G.Brush (59 12 60)

C. For wide rusting - Use Hammer Head

(59 12 66) equipment.

Aer selecting proper assembly, screw it on

to the another end of hose assembly. Also t

rubber guard over the exible sha (tool end)

connect it with electric socket. Hold scaling

device (selected assembly) in hand and switch

on the button. Hold revolving part against the

surface to be de-scaled. If the selection of as-

sembly is properly done as per application, you

will get the surface cleaned in very short time.

Introduction

Teryair Electric de-Scaling Machines are lightweight electric machines for continuous heavy duty

use. An ideal unit for de-rusting and de-scaling jobs. ey are portable and tted with wheels. Can

be used with a 110 volt or 220 volt AC power supply.

FF-MM-44-REV - 00

Page 4

Operation and Maintenance Guide Electric Flexible Descaler TEFD75

General Precautions

1) Ensure that the sha is always driven in the

correct direction i.e. Anti-clockwise as seen

from front of the tool end.

2) Do not drag the unit with the help of exible

sha.

3) Excessive force on the outer casing or on the

inner sha while disconnecting from Motor or

tool end will damage the sha. Avoid excessive

force.

4) At least once in a month, remove the inner

sha and lubricate with graphite grease or

multipurpose 3 grease to get the better life of

the sha.

5) Do not weld or braze the inner end ttings.

6) e stieners are provided at either ends of

both outer casings to prevent excessive bending

of the sha at the ends. Do not apply excessive

load on the stieners while Working.

7) On initial running aer re-greasing or on

tment of new inner sha. e inner sha Will

beat up heavily for few minutes before setting

to run smoothly. Hence run it Without any as-

sembly screwed on the tool end, till the initial

vibration settles down And then screw on any

selected assembly on the tool end.

8) Recommended minimum operating radius

for the sha is 500mm.

9) Incorrect method of starting the sha, gives

deformation to inner components. e Sha

should be stored straight in racks with proper

at support of wooden planks.

Contents

1. A tool Kit Containing : -

a) 2 Nos - Fixed Spanner 20/22

2. 1 No - Electric Motor mounted on

trolley

3. 5 meter cable - 1 No. - 342 91 27

4. Rubberised sha Assembly ( 342 9733 )

5. Rubber Wheel Guard & Clamp

(342 40 16)

Disassembly and Re-assembly

a. Shut o air supply and water supply allow

residual Pressure to bleed o.

b. Unscrew Cutter set (4) from Sha (9) and

replace it with new ones. (If found dam-

aged/worn-out)

c. Remove Split pin (6), Plain washer (14),

Wheel (7) & Plain washer (14) from Base

plate (2) and replace it with new ones. (If

found damaged/worn-out)

d. Unscrew Hex Nut (3) with Spring washer

(5) and Plain washer (11) from Hex bolt

(10) to remove Motor (1) and replace it

with new one. (If found damaged/worn-

out)

e. Unscrew Allen bolt (12) from Hex nut (3)

to remove Wheel cover (8) from Sha

(9) and replace it with new one. (If found

damaged/worn-out)

f. Now follow the above steps in reverse

manner to reassemble the TEFD-75.

6. Accessories : -

No.1 H.D.Tool (59 12 55)

No.2 L.G.Brush (59 12 60)

No.4 Hammer Head (59 12 66)

Wire Wheel Brush Complete (59 12 73 A)

FF-MM-44-REV - 00

Page 5

Operation and Maintenance Guide Electric Flexible Descaler TEFD75

Exploded View for TEFD75

1

3

5

11

2

4

6

7

14

10

8

9

12

13

FF-MM-44-REV - 00

Page 6

Operation and Maintenance Guide Electric Flexible Descaler TEFD75

Bill of Materials for TEFD75

Illustration

Number Part Number Description TEFD75 -110V TEFD75-220V

1 3429141 MOTOR (110V) 1 -

1 3429115 MOTOR (220V) - 1

2 3423225/A BASE PLATE 1 1

3 0224021 HEX NUT 6 6

4 59.12.55 CUTTER SET 1 1

5 1999047 SPRING WASHER 4 4

6 23.24.80.1.2 SPIT PIN 4 4

7 3424023 WHEEL 4 4

8 3424016 WHEEL COVER 1 1

9 3429733 SHAFT 1 1

10 3429046 HEX BOLT 4 4

11 1719050 PLAIN WASHER 8 8

12 3429026 ALLEN BOLT 2 2

13 3429127 CABLE 5 5

14 2109036 PLAIN WASHER 8 8

FF-MM-44-REV - 00

Page 7

Operation and Maintenance Guide Electric Flexible Descaler TEFD75

Parts Required for Different Accessories

Part No Qty Description

No. 1 H.D. Tool 59 12 55 Consists of

59 12 56 18 Cutter # 1:1

59 12 57 6 Disc Pin # 1:2

59 12 58 1 1-3 Centre Bolt with Nut & Washer

59 12 59 2 Disc # 2:4

Part No Qty Description

No. 2 L.G. Brush 59 12 60 Consists of

59 12 61 72 L.G. Blade # 2:1

59 12 62 6 Disc Pin # 2:2

59 12 63 1 2-3 Centre Bolt with Nut & Washer

59 12 64 2 Disc # 2:4

Part No Qty Description

No. 4 Hammer Head 59 12 66 Consists of

59 12 67 12 Hammer Head #4:1

59 12 68 3 Disc Pin #4:2

59 12 69 1 4-3 Centre Bolt with Nut & Washer

59 12 70 2 Disc # 4:5

59 12 71 1 Collar #4:5

59 12 72 15 Washer # 4:6

FF-MM-44-REV - 00

Page 8

Operation and Maintenance Guide Electric Flexible Descaler TEFD75

EU DECLARATION OF CONFORMITY

We hereby certify that the Listed Product stipulated below comply with all relevant provisions of the machinery direc-

tive (2006/42/EC) and the national laws and regulations adopting this directive.

Description :

Model Number :

Date :

Serial Number :

Is in conformity with the provisions of the following European Directives: (2006/42/EC) Machinery Safety and

Harmonized standards

ISO 12100-1: 2010: Safety of Machinery –general Principles for Design –Risk Assessment and Risk Reduction.

Registered Oce : 416 Gundecha Industrial Complex, Akuril Road,

Kandivali East, Mumbai – 400101, Maharashtra, India.

Web site : www.teryair.com

Works : A-1, Tirupati Udyog Nagar, Sativali Road, Vasai East,

Palghar – 401208, Maharashtra, India.

CE certication registration no – C E 16831

Issued by – BMQR Certications Pvt Ltd.

www.cemarking-india.com

Valid Till – 03/11/2021

Signed for and on behalf of

TERYAIR EQUIPMENT PVT. LTD. Place of Issue:

Date:

FF-MM-44-REV - 00

Page 9

Operation and Maintenance Guide Electric Flexible Descaler TEFD75

Warranty Certicate

Every product manufactured by Teryair

is built to meet the highest standards of quality.

Teryair warrants that the Products, accessories and parts manufactured or supplied by the company be

free from defects in material and workmanship for a period of six months from date of Teryair authorized

dealer invoice to customer, or one year from date of Teryair invoice to dealer, whichever is earlier. Failure

due to normal wear, misapplication, or abuse is, of course, excluded from this warranty.

Since the use of Teryair products and parts is beyond our control, Teryair cannot guarantee the suitability

of any product or part for a particular application and Teryair shall not be liable for any consequential dam-

age or expense arising from the use or misuse of its products on any application. Teryair does not war-

ranty bought out products or components such as electric motors and hardware but will assist in directing

warranty queries to the dealer/manufacturer responsible. Teryair responsibility is limited solely to replace-

ment or repair of defective Teryair products or components.

Dealer/End User shall have no right or remedy and Teryair shall have no liability or obligation under the warranty, if: (i) a Product is altered,

changed, modied or tampered with in any way, (ii) a Product is damaged after deposit with the transporter for shipment; (iii) a Product is not

properly preserved, packaged, stored, processed or handled after receipt; (iv) a Product is not used and maintained in accordance with Teryair’s

recommended operating and maintenance manuals, instructions and procedures, if any; (v) a Product is not properly incorporated or installed in,

or not properly combined with, an Other Product; (vi) the issue with a Product is directly or indirectly attributable to, or directly or indirectly results

from or arises out of, a failure, substandard performance or other issue with another product, material, component or part not supplied by Teryair;

(vii) the issue with a Product is directly or indirectly attributable to, or directly or indirectly results from or arises out of, compliance with any de-

sign, specication or other specic requirement of Dealer/End User; (viii) a Product is used in a manner, with a substance or for a purpose other

than the normal manner, substance and purpose for which it is intended or is otherwise subjected to abnormal use or service; (ix) a Product is

subjected to a power surge, brown out or other similar occurrence; (x) the issue with a Product is directly or indirectly attributable to, or directly or

indirectly results from or arises out of, normal wear and tear of such Product (including, without limitation, things such as worn seals, diaphragms,

balls, O rings, gaskets, chisels, cutters, hoses and other such wearing components; (xi) the issue with a Product is directly or indirectly.

Model Number :

Serial Numbar :

Dated : Ajay Bhagat, Q.A. Manager

(Company Seal)

FF-MM-44-REV - 00

Page 10

Operation and Maintenance Guide Electric Flexible Descaler TEFD75

is page is intentionally

Le blank.

This manual suits for next models

3

Table of contents

Other Teryair Tools manuals

Popular Tools manuals by other brands

Idex

Idex HURST eDRAULIC SC 258 E2 instruction manual

Hilti

Hilti BX 3-ME Original operating instructions

Beechcraft

Beechcraft Debonair 35-C33 Pilot's operating handbook and faa approved airplane flight manual

Nederman

Nederman 744 Series user manual

MSW Motor Technics

MSW Motor Technics MSW-EGN-14 user manual

Klutch

Klutch 49651 owner's manual