Force Flow WIZARD 4000 Guide

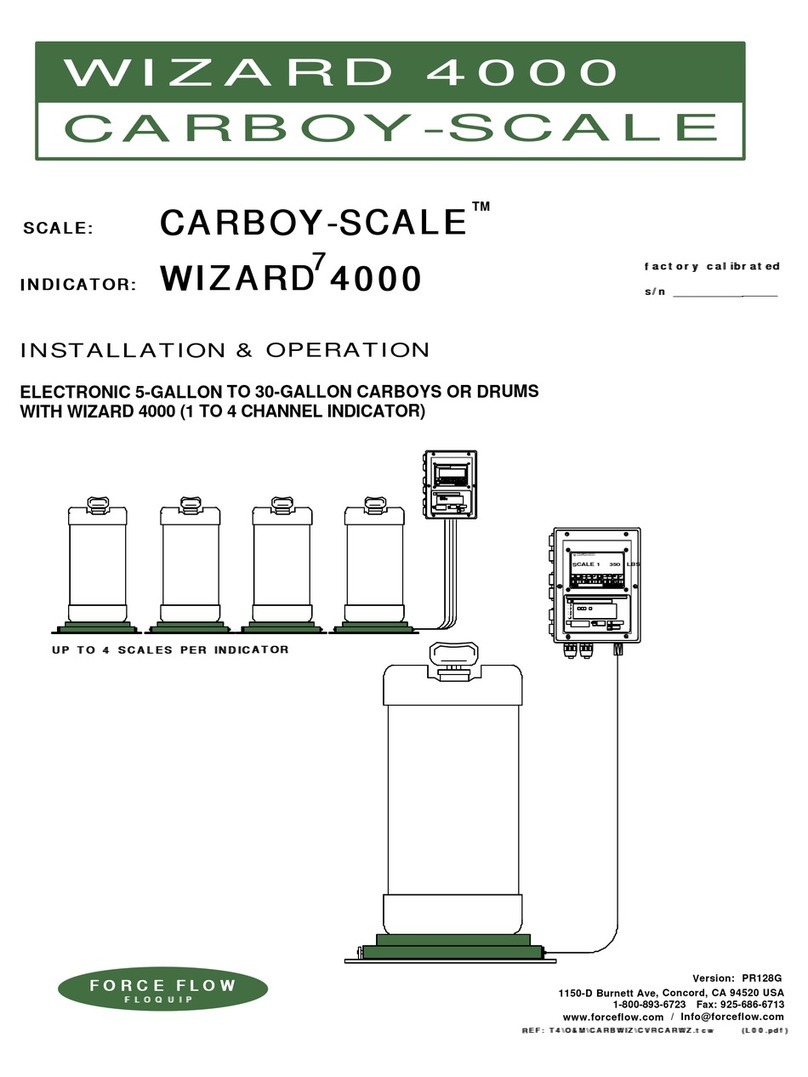

WIZARD 4000

DRUMM-SCALE

DRUMM-SCALE

INSTALLATION & OPERATION

electronic 30- to 55-gallon drums

electronic 30- to 55-gallon drums

to 1,000 lb. with

to 1,000 lb. with

1- to 4-Channel Wizard Indicator

1- to 4-Channel Wizard Indicator

factory calibrated

factory calibrated

s/n __________________

s/n __________________

1150-D Burnett Ave, Concord, CA 94520 USA

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 Fax: 925-686-6713

1-800-893-6723 Fax: 925-686-6713

TM

Version: PR128G

Version: PR128G

REF: T4\O&M\DRUMWIZ\CVRDRMWZ.tcw (G00.pdf)

REF: T4\O&M\DRUMWIZ\CVRDRMWZ.tcw (G00.pdf)

WIZARD 4000

WIZARD 40007

7

INDICATOR:

INDICATOR:

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

DRUMM-SCALE

SCALE:

SCALE:

WIZARD 4000

WIZARD 4000

09

12345678

SCALE 1 350 LBS

FORCE FLOW

FORCE FLOW

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

INCLUDES MODELS:

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

REF: T4\O&M\DRUMELEC\MODELNOS.tcw (G0A.pdf)

ELECTRONIC

DRUMM-SCALE

with WIZARD 4000 DIGITAL INDICATOR

FOR CAPACITIES:

27-1/2" x 27-1/2" (699mm x 699mm)

FOR PLATFORM SIZES:

COVERING MODELS:

400 lbs. (181 kg) thru 1,000 lbs. (454 kg)

400 lbs.

600 lbs.

800 lbs.

1000 lbs.

27-DR4DS

27-DR6DS

27-DR8DS

27-DR10DS

(Metric: DR2KDS 200 kg)

(Metric: DR3KDS 300 kg)

(Metric: DR4KDS 400 kg)

(Metric: DR5KDS 500 kg)

Includes Stainless Steel Models

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

W.1.000

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

REF: T4\O&M\INDEX.\Y07.tcw etc (Y07.pdf etc) 1/24/02

SECTION

W.2.000 INDICATOR OPERATION

W.2.101

W.2.102

W.2.103

Keyboard Display Selections

Keyboard Menu - Quick Reference

Tank Load Mode

W.3.000 Code 9081 (Field Calibration)

Checking Calibration via Water Test

Troubleshooting Tips

Spare Parts List

WIZARD Indicator with DRUMM-SCALE

INDEX

Code 9080 (Scale Set Up)

Code 9082-9083 (Feed Rate Format/Display Units)

Code 9084-9086 (Single or Dual Display/Tank Loading/Printer)

Code 9086 (cont...)-9089 (Time/Date/Calibration/Channels)

Code 4200 & 3256 (Set Point Configuration/4-20mA Output Configuration)

Code 3256 (cont...)

Indicator Wiring & Plumbing

Indicator Installation Instructions

Wizard Component Layout

INDICATOR INSTALLATION

W.1.201

W.1.202-203

W.1.204

SET-UP CODES - CUSTOM FORMATTING

W.2.201

W.2.202

W.2.203

W.2.204

W.2.205

W.2.206

MEMU OF DAY-TO-DAY OPERATIONS

W.2.104

W.2.105

W.2.106

W.2.107

W.2.108

MISCELLANEOUS

W.3.101

W.3.201

W.3.301

W.3.401

Low Level Alarm & Date Last Cleared

Clear Amount Used & Set Scale Zero

Set Scale Zero cont... & Allarm Reset

Review Daily Usage & Printing Report

Report (example) & Protocol

YOU

ARE

HERE !

INSTALLATION OF SCALE PLATFORM:

W.1.101

W.1.102 Installation Instructions

Dimensional Drawing

INSTALLATION CHECK OFF LISTS

W.1.301

W.1.305 Installation Check-Off List

Installation Start-Up Check-Off List

INSTALLATION OF LOAD CELL

W.1.141 Load Cell Installation Drawing

INSTALLATION

DRUMM-SCALE with ELECTRONIC INDICATOR

(1,000 lb. or 500 kg. Capacity)

DRUMM-SCALE SCALES

for PORTABLE Drums

INSTALLATION:

(See Installation Drawings 29886 and 29895 for Drumm-Scale)

1Position scale platform on level surface. The hinge and load cell must be adequately supported

by concrete slab or other suitable substrate.

2Anchor hinge to ground or substrate using suitable anchors. DO NOT OPERATE SCALE

UNLESS IT IS ANCHORED TO GROUND !

3Install shear-beam load cell using 2 flat head socket screws, shim plate and threaded nuts per

Drawing 29886 and Drawing 29895. Load cell “arrow” should point upward, load button with jam

nut should face toward ground with shim plate between load cell and platform.

4Level the platform by threading the load button in or out and locking the jam nut in place when

level. DO NOT extend the load button beyond the available threads in the load cell. This will

cause the improper operation of your scale. The load button is all that contacts the ground.

5Feed load cell cable through notch in side of platform and use tab to keep cable suspended and

clear of platform edge and obstructions.

6The Load Cell is equipped with 20' of shielded cable which connects to the inside of the bottom of

the indicator (see page 6). If you are imbedding conduit in your concrete pad, between your scale

and indicator, we recommend 1-1/2" ID conduit so you can fit all your load cell cables in one

conduit. DO NOT run any other inductive load with your load cell cable. Wire load cell cable to

indicator per indicator wiring instructions Page 9.

7Measure the diameter of your drum and set the backstop on the platform to the drum diameter

using the calibration grid.

REF: WP File: O&M\DRUMWIZ\ELECDRUM.wpd (T01.pdf) QUESTIONS ? Call ourHELP HOTLINE 1-800-893-6723

W.1.101

S.1.101

C

L

________ Model Number of Platform

________ Model Number of Indicator

________ Feet of Cable (20' Std)

________ Pound or Kilo Indicator

________ Number of Scales

27 1/2"

(699mm)

27 1/2"

(699mm) 27 3/4"

(705mm)

2"

(51mm)

31 1/2" (800mm)

Mounting Bolt Sleeves

Mounting Bolt Sleeves

Load Button & Jam Nut

Arrow Facing Up

Scale Platform

Spacer

Shear Beam Load Cell

Platform

Cross Brace

Calibration

Grid

Backstop

Load Cell Anchor

Bolt Holes in Platform

Tab Guide

for Cable

Load Cell

Cable to

Indicator

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

Drawn by: SLP

Date: 09/01/95

Revised:

Scale: NONE

Drawing Number

File: T4\O&M\DRUMELEC\DRUMWIZ.tcw (G02.pdf) (WEB: DRUMWIZ.pdf) 01/24/02

30290

ELECTRONIC DRUMM-SCALE

with WIZARD INDICATOR

for 30- to 55-Gallon Drums

(Capacities to 1000 lbs or 500 kg)

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

1/2"

9/16"

Hole

DR4DSS ( 400 lb) DR2KDSS (200 kg)

DR5DSS ( 500 lb) DR2.5KDSS (250 kg)

DR6DSS ( 600 lb) DR3KDSS (300 kg)

DR8DSS ( 800 lb) DR4KDSS (400 kg)

DR10DSS (1,000 lb) DR5KDSS (500 kg)

DR4DS ( 400 lb) DR2KDS (200 kg)

DR5DS ( 500 lb) DR2.5KDS (250 kg)

DR6DS ( 600 lb) DR3KDS (300 kg)

DR8DS ( 800 lb) DR4KDS (400 kg)

DR10DS (1,000 lb) DR5KDS (500 kg)

MODEL NUMBER (for WIZARD 4000 Indicator)

4000-1 1-Channel WIZARD 4000 Indicator

4000-2 2-Channel WIZARD 4000 Indicator

4000-3 3-Channel WIZARD 4000 Indicator

4000-4 4-Channel WIZARD 4000 Indicator

EPOXY MODEL (Platform with Load Cell)

316 SS MODEL (Platform with Load Cell)

W.1.102

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

W.1.000

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

REF: T4\O&M\INDEX.\Y07.tcw etc (Y07.pdf etc) 1/24/02

SECTION

W.2.000 INDICATOR OPERATION

W.2.101

W.2.102

W.2.103

Keyboard Display Selections

Keyboard Menu - Quick Reference

Tank Load Mode

W.3.000 Code 9081 (Field Calibration)

Checking Calibration via Water Test

Troubleshooting Tips

Spare Parts List

WIZARD Indicator with DRUMM-SCALE

INDEX

Code 9080 (Scale Set Up)

Code 9082-9083 (Feed Rate Format/Display Units)

Code 9084-9086 (Single or Dual Display/Tank Loading/Printer)

Code 9086 (cont...)-9089 (Time/Date/Calibration/Channels)

Code 4200 & 3256 (Set Point Configuration/4-20mA Output Configuration)

Code 3256 (cont...)

Indicator Wiring & Plumbing

Indicator Installation Instructions

Wizard Component Layout

INDICATOR INSTALLATION

W.1.201

W.1.202-203

W.1.204

SET-UP CODES - CUSTOM FORMATTING

W.2.201

W.2.202

W.2.203

W.2.204

W.2.205

W.2.206

MEMU OF DAY-TO-DAY OPERATIONS

W.2.104

W.2.105

W.2.106

W.2.107

W.2.108

MISCELLANEOUS

W.3.101

W.3.201

W.3.301

W.3.401

Low Level Alarm & Date Last Cleared

Clear Amount Used & Set Scale Zero

Set Scale Zero cont... & Allarm Reset

Review Daily Usage & Printing Report

Report (example) & Protocol

YOU

ARE

HERE !

INSTALLATION OF SCALE PLATFORM:

W.1.101

W.1.102 Installation Instructions

Dimensional Drawing

INSTALLATION CHECK OFF LISTS

W.1.301

W.1.305 Installation Check-Off List

Installation Start-Up Check-Off List

INSTALLATION OF LOAD CELL

W.1.141 Load Cell Installation Drawing

Mounting Bolts

Spacer

Arrow facing up

Load Button

Mounting Bolt Sleeves

Drumm-Scale

Platform Frame

Jam Nut

Strain Relief

Cable

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

Drawn by: SLP

Date: 09/01/95

Revised: 05/20/97

Scale: NONE

Drawing Number

File: T4\O&M\DRUMWIZ\DRDRUMLC.tcw (T03.pdf)

29886

DRUMM-SCALE

Load Cell Mounting Drawing

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

S.1.141

W.1.141

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

W.1.000

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

REF: T4\O&M\INDEX.\Y07.tcw etc (Y07.pdf etc) 1/24/02

SECTION

W.2.000 INDICATOR OPERATION

W.2.101

W.2.102

W.2.103

Keyboard Display Selections

Keyboard Menu - Quick Reference

Tank Load Mode

W.3.000 Code 9081 (Field Calibration)

Checking Calibration via Water Test

Troubleshooting Tips

Spare Parts List

WIZARD Indicator with DRUMM-SCALE

INDEX

Code 9080 (Scale Set Up)

Code 9082-9083 (Feed Rate Format/Display Units)

Code 9084-9086 (Single or Dual Display/Tank Loading/Printer)

Code 9086 (cont...)-9089 (Time/Date/Calibration/Channels)

Code 4200 & 3256 (Set Point Configuration/4-20mA Output Configuration)

Code 3256 (cont...)

Indicator Wiring & Plumbing

Indicator Installation Instructions

Wizard Component Layout

INDICATOR INSTALLATION

W.1.201

W.1.202-203

W.1.204

SET-UP CODES - CUSTOM FORMATTING

W.2.201

W.2.202

W.2.203

W.2.204

W.2.205

W.2.206

MEMU OF DAY-TO-DAY OPERATIONS

W.2.104

W.2.105

W.2.106

W.2.107

W.2.108

MISCELLANEOUS

W.3.101

W.3.201

W.3.301

W.3.401

Low Level Alarm & Date Last Cleared

Clear Amount Used & Set Scale Zero

Set Scale Zero cont... & Allarm Reset

Review Daily Usage & Printing Report

Report (example) & Protocol

YOU

ARE

HERE !

INSTALLATION OF SCALE PLATFORM:

W.1.101

W.1.102 Installation Instructions

Dimensional Drawing

INSTALLATION CHECK OFF LISTS

W.1.301

W.1.305 Installation Check-Off List

Installation Start-Up Check-Off List

INSTALLATION OF LOAD CELL

W.1.141 Load Cell Installation Drawing

4-20mA

CONNECTIONS

LOAD CELL/ULTRASONIC CONNECTIONS

RELAYS

#1 #2 #3 #4

RS485/RS232

#1 #2 #3 #4

DISPLAY ANGLE

ADJUSTMENT (BLUE)

EPROM

RAM

CPU

POWER SUPPLY

POWER IN

CONNECTOR SLEEVE

PLASTIC WASHER

RUBBER GROMMET

CABLE

CONDUIT FITTING

BOX

#1 #2 #3 #4

BOX (FRONT VIEW)

1/4" CORD CONNECTOR, USED FOR:

32

4

1

6 SLOTTED PAN HEAD SCREWS.

(TIGHTEN SCREWS EVENLY TO

GET UNIFORM SEAL ON COVER GASKET)

3RD: ATTACH TO CONDUIT

OR CABLE CONNECTOR

FITTING ON BOX

2ND: SCREW CONDUIT

CONNECTOR ONTO

CONDUIT

1ST: SLIP CONDUIT

FITTING BASE

OVER CONDUIT

1/2" CONDUIT CONNECTOR, USED FOR:

5

LOAD CELL CABLE

ULTRASONIC CABLE

POWER

4-20 MA SIGNAL

RELAY WIRING

COMMUNICATIONS)

6

NOTE:

Mount Indicator at "EYE LEVEL"

with the mounting fixtures provided.

FUSE

BOX (BOTTOM VIEW)

1

3

42

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

Drawn by: SLP

Date: 09/01/95

Revised: 01/17/01

Scale: NONE

Drawing Number

File: T4\O&M\AWIZMSTR\WIZINDI.tcw (B01.pdf)

29893

INDICATOR WIRING &

PLUMBING INSTRUCTIONS

FORCE FLOW

FORCE FLOW

F

F

L

L

O

O

Q

Q

I

I

U

U

P

P

4-20mA WIRING,

LOAD CELL CABLE,

ULTRASONIC CABLE

WIRE/CABLE

CLAMP

WIRE/CABLE

CLAMP

OPTIONAL

AUDIBLE

ALARM

CORD

CONNECTION

CONDUIT

CONNECTION

LOAD CELL/ULTRASONIC (1 & 3)

(1/4" CORD CONNECTION)

4-20mA OUTPUT

(1/2" CONDUIT

CONNECTION)

RS485/RS232

(1/2" CONDUIT

CONNECTION)

110V POWER CONNECTION

(1/2" CONDUIT CONNECTION)

RELAYS (1/2" CONDUIT CONNECTION) OPTINOAL LOAD CELL

or ULTRASONIC (2 & 4)

(1/4" CORD CONNECTION)

BOX

CONDUIT

CONNECTION CORD

CONNECTION

W.1.201

W.1.201

TURN OFF MAIN POWER BEFORE CONNECTING !! Use a clean 110 Volt AC (or 220 Volt, if provided)

power line, connected directly to the main power panel at the facility. DO NOT connect any other inductive

loads, relays, etc. to this power line ! Resulting power surges can damage the electronics !!! Use far left

bottom port and connect per following: (NOTE: Use 1/2" conduit connector)

QUESTIONS ? Help Hotline: 1-800-893-6723

When routing load cell cable into box, use a separate 1/2" cord connector per cable. DO NOT

run load cell cable with any other inductive load or power cables !! Run load cell cable up right

hand side of enclosure and use the cable clamps provided to keep cables from laying on the

PC board. Connect load cell wires per following: (NOTE: Use 1/2" conduit connector)

All connectors have a "PLUG IN" feature to assist in connecting wires. Remove the connector

from the board before attaching wires.

Your 4-20 MA signals are internally powered for up to 900 OHMS each. DO NOT use external loop power.

Run 4-20 MA wiring up the right hand side of enclosure using the cableclamps to keep wires off of PC Board.

(NOTE: Use 1/2" conduit connector). If more than one (1) 4-20 MA signal is used, you may use the same conduit

and connector, but DO NOT run 4-20 MA signals with any other power lines, which carry an inductive load..

+ EXCITATION

- EXCITATION

INDICATOR INSTALLATION & WIRING

ALWAYS SHUT OFF MAIN POWER, AS WELL AS POWER TO ANY AUXILIARY EQUIPMENT

THAT WILL BE INSTALLED IN THIS UNIT, BEFORE OPENING FRONT OF CASE !!

DESCRIPTION

POWER IN PC BOARD

DO NOT CUT LOAD CELL CABLE !! This may void your warranty!! Your WIZARD 4000

Indicator is shipped with the load cells connected and ready to power up. Should you

need to run the load cell cable through conduit, first unplug the connector from the board,

then disconnect wires, and remove by unscrewing cord connectors.

+ EXCITATION

+ SIGNAL

- SIGNAL

- EXCITATION

SHIELD

WIRE COLOR

RED

GREEN

WHITE

BLACK

BRAIDED WIRE

PC BOARD

+ X

+ S

- S

- X

SH

+X4

+S4

- S4

- X4

SH

+X3

+S3

- S3

- X3

SH

+X2

+S2

- S2

- X2

SH

+X1

+S1

- S1

- X1

SH

Scale #4

Scale #1

Scale #2

Scale #3

PC BOARD DESCRIPTION

+

-

+

-

+

-

+

-

11

12

13

14

+

-

Scale #1

110 Volt

Hot

Ground

Common

3 4-20 MA SIGNALS

2 LOAD CELL CONNECTION

1 POWER HOOK-UP

+

G

C

+ G C

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

File: T4\O&M\AWIZMSTR\WZININST.tcw (B02.pdf)

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

Scale #2

Scale #3

Scale #4

POWER IN PC BOARD 230 Volt

Hot

Ground

Hot

+

G

+

+ G +

230 VOLT AC

110 VOLT AC

W.1.202

Use a separate conduit connector for your serial port communication. DO NOT RUN ANY OTHER

CONDUCTIVE LOAD or power lines with your communicationn wiring. Wire your communications

per the following: (NOTE: Use 1/2" conduit connector).

If it is not possible to mount the indicator at eye level, you may adjust the angle of display by

turning the screw potentiometer clockwise (for down) or counterclockwise (for up). Rotate

1/2 turn at a time until display is clear.

CAUTION should be observed whenever box is open to avoid damage or memory loss by static

electricity. DO NOT touch any of the circuit board, other than the intended contact noted in these

instructions. Carpets, especially can build up static electricity.

If ordered NORMALLY CLOSED:

T G R

RS232

Circuit IS complete until relay is activated.

(Example: Turning OFF a pump)

External apparatus (pumps, valves, alarms, etc) may be ordered either normally open

(N O) or normally closed (N C) These relays are rated at 5 AMPS maximum! To

format your relays, see Set-Up Code #4200 in Chapter "SCALE SET-UP CODES".

If more than one relay is being used, you may use the same conduit connector, but

DO NOT run any other wiring with your relays. (NOTE: Use 1/2" conduit connector).

RS232

RS485 PC BOARD DESCRIPTION

+

-Positive

Negative

PC BOARD

T

G

R

DESCRIPTION

Transmitted Data (printer data output line)

Signal Ground (signal)

Received Data (printer data input line)

RELAYS

If ordered NORMALLY OPEN: Circuit is NOT complete until the relay is activated.

(Example: Turning ON a warning light). We

recommend normally open for all "low level"

applications.

Before adjusting the Display Angle Adjustment, make sure of the following:

A Indicator is mounted at "Eye Level". (Display angle is factory set for "eye level")

#1

#2

#3

#4

IN (1)

OUT (1)

IN (2)

OUT (2)

IN (3)

OUT (3)

IN (4)

OUT (4)

Be sure that all power coming into the facility is sufficiently protected for transient lighting strikes and power

surges. Improper protection may void your warranty.

B POWER IS OFF !

+ -

STATIC ELECTRICITY PROTECTION

LIGHTNING ~ SURGE PROTECTION:

6 DISPLAY ANGLE ADJUSTMENTS

5 RELAYS

4 PRINTER COMMUNICATIONS

RS485

QUESTIONS ? Help Hotline: 1-800-893-6723 W.1.203

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

File: T4\O&M\AWIZMSTR\WZININ2A.tcw (5/27/99) (B03.pdf)

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

RS485

RS232

EPROM

RAM

CPU

POWER

SUPPLY

POWER IN

Scale #1

+ -

T

G

R

HI

LO

+

C

Scale #1 #2 #3 #4

- + - + - + - +

11 12 13 14

SH

-X1

+X1

+S1

-S1

+X2

+S2

-S2

-X2

SH

+X3

+S3

-S3

-X3

SH

+X4

+S4

-S4

-X4

SH

3

6

5

4

1

NOTE: For best viewing, mount indicator at "eye level"

with the mounting fixtures provided.

2

LOAD CELLS

or

ULTRASONIC

SENSORS

FUSE

RELAYS

#1

#2

#3

#4

OUR (1)

IN (1)

OUR (2)

IN (2)

OUT (3)

IN (3)

OUT (4)

IN (4)

6"

13"

WIRE CABLE CLAMP

DISPLAY ANGLE

ADJUSTMENT (Blue)

OPTIONAL

AUDIBLE

ALARM

MOUNTING

FIXTURE

4-20mA OUTPUT

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

Drawn by: SLP

Date: 09/01/95

Revised: 05/27/99

Scale: NONE

Drawing Number

File: T4\O&M\AWZMSTR\WIZINDIA.tcw (B04.pdf) 05/27/99

29892

WIZARD INDICATOR

COMPONENT LAYOUT

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

Scale #2

Scale #3

Scale #4

W.1.204

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

W.1.000

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

REF: T4\O&M\INDEX.\Y07.tcw etc (Y07.pdf etc) 1/24/02

SECTION

W.2.000 INDICATOR OPERATION

W.2.101

W.2.102

W.2.103

Keyboard Display Selections

Keyboard Menu - Quick Reference

Tank Load Mode

W.3.000 Code 9081 (Field Calibration)

Checking Calibration via Water Test

Troubleshooting Tips

Spare Parts List

WIZARD Indicator with DRUMM-SCALE

INDEX

Code 9080 (Scale Set Up)

Code 9082-9083 (Feed Rate Format/Display Units)

Code 9084-9086 (Single or Dual Display/Tank Loading/Printer)

Code 9086 (cont...)-9089 (Time/Date/Calibration/Channels)

Code 4200 & 3256 (Set Point Configuration/4-20mA Output Configuration)

Code 3256 (cont...)

Indicator Wiring & Plumbing

Indicator Installation Instructions

Wizard Component Layout

INDICATOR INSTALLATION

W.1.201

W.1.202-203

W.1.204

SET-UP CODES - CUSTOM FORMATTING

W.2.201

W.2.202

W.2.203

W.2.204

W.2.205

W.2.206

MEMU OF DAY-TO-DAY OPERATIONS

W.2.104

W.2.105

W.2.106

W.2.107

W.2.108

MISCELLANEOUS

W.3.101

W.3.201

W.3.301

W.3.401

Low Level Alarm & Date Last Cleared

Clear Amount Used & Set Scale Zero

Set Scale Zero cont... & Allarm Reset

Review Daily Usage & Printing Report

Report (example) & Protocol

YOU

ARE

HERE !

INSTALLATION OF SCALE PLATFORM:

W.1.101

W.1.102 Installation Instructions

Dimensional Drawing

INSTALLATION CHECK OFF LISTS

W.1.301

W.1.305 Installation Check-Off List

Installation Start-Up Check-Off List

INSTALLATION OF LOAD CELL

W.1.141 Load Cell Installation Drawing

-Lineuploadlellandplatformforanchorboltlocationtoavoid

bindingframehingesandensureloadcellbuttonisproperlyseated.

-Checkforflexiblesupplyconnectionsto/fromtank(ifapplicable).

INSTALLATIONCHECK-OFFLIST

QUESTIONS?HelpHotline:1-800-893-6723

W.1.301

1150-DBurnettAve,Concord,CA94520USA

1-800-893-6723US&Canada,Fax:925-686-6713

www.forceflow.com/info@forceflow.com

File:T4\O&M\AWZMSTR\WZINSCHK.tcw(J09.pdf)

FORCEFLOW

INSTALLSCALEPLATFORM&LOADCELL

-Mountatproperlocation,at"eyelevel".

-DONOTmountWizardin"direct"sunlight.

MOUNTINDICATOR

-TURNOFFallPOWERbeforewiring.Alwaysfollow"Lock-Out","TagOut"

procedures.

-Connectdedicatedclean110voltACpowerlinethrough1/2"conduitconnector.

-Connectloadcellcablesthrough1/4"cordconnector.

-Connect4-20mAsignalsthrough1/2"conduitconnector.

-Connectcommunicationsthrough1/2"conduitconnector.

-Connectrelaysthrough1/2"conduitconnector.

-Adjust"DisplayAdjust"ifnecessary

WIREINDICATOR-TURNOFFALLPOWERBEFOREWIRING!

-Checkalldefaultsettingsin"Set-UpCodes"andifnecessary,

makechangestobetterfityourapplication.

NOTE:AnychangestoSet-UpCode"9080SCALESET-UP"

willrequirerecalibrationofyourscale.

CUSTOMFORMATTING

-Tightenallsix(6)doorscrewstomaintainNEMA4Xsealinbox.

-Doublecheckallcordconnectorsfortightseal.

-Doublecheckall1/2"conduitconnectorsfortightseal.

SEALINDICATORENCLOSURETOMAINTAIN4XRATING!!!

(SectionW.1.000)

(SectionW.1.201thruW.1.204)

(SectionW.1.202)

(SectionW.1.201)

(SectionW.2.201thruW.3.101)

DRUMM-SCALEPLATFORMS

-Routeloadcellcabletoindicatormountinglocationperinstructions.

CHEM-SCALEPLATFORMS

-LineuploadcellandFrame(s)foranchorboltlocationtoavoid

bindingframehingesandensureloadcellbuttonisproperlyseated.

TONCONTAINERFRAMES

POWER-UP: Scale display should read "NET WEIGHT REMAINING". The value will be the tare weight

of your SCALE PLATFORM(s) in "PORTABLE" Tank applications, or your VESSEL & PLATFORM in "FIXED" tank

applications.

Press and verify correct time and date. If incorrect, see SET-UP CODE 9087 (Section W.2.204).

Press until "SET SCALE ZERO" appears

on display. Zero scale as per instructions in Section

W.2.106 "Menu of Day-To-Day Operations". For

future reference, record ZERO FACTOR on a

sticker inside Wizard cover. Refer to Section

W.2.204 "Custom Formatting your Scale",

CODE 9088, to obtain zero factor.

Before LOADING Tank(s), press and wait

until Step 4 "CHANGE TANKS NOW" appears.

See instructions on Tank Load Mode Section W.2.103.

NOTE: If you load tank before reaching the "CHANGE TANK NOW" or the "FILL TANK NOW" step, your

usage data will be inaccurate.

TIME

DATE

TANK

LOAD

"PORTABLE" TANKS - Tank is REPLACED

2

1

START-UP CHECK-OFF LIST

Press until "CLEAR AMOUNT USED" appears on display. Clear the memory per

instructions in Menu of Day-To-Day Operations (Section W.2.105).

MENU

6

Apply pressure to platform to see if indicator responds to changes in weight.

3

Review SET-UP CODES, especially 9082, 9084, 9085 and 9089 (Starting at Section W.2.201)

4

QUESTIONS ? Help Hotline: 1-800-893-6723 W.1.305

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

File: T4\O&M\AWZMSTR\CHKOFF.tcw (J10.pdf) 01/24/02 BD

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

MENU

With EMPTY tank on platform, press

until scale indicator reads "ENTER TARE". Zero scale as

per instructions in Section W.2.106 "Menu of Day-To-Day

Operations". For future reference, record ZERO FACTOR

on a sticker inside Wizard cover. Refer to Section W.2.204

"Custom Formatting your Scale", CODE 9088, to obtain

zero factor.

"FIXED" TANKS - Tank is REFILLED

MENU

"PORTABLE" TANK - Tank is REPLACED "FIXED" TANK - Tank is REFILLED

Before FILLING Tank(s), press and proceed

as directed. Refer to "Operating Instructions",

Section W.2.103 TANK LOAD MODE.

55

7

7

TANK

LOAD

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

W.1.000

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

REF: T4\O&M\INDEX.\Y07.tcw etc (Y07.pdf etc) 1/24/02

SECTION

W.2.000 INDICATOR OPERATION

W.2.101

W.2.102

W.2.103

Keyboard Display Selections

Keyboard Menu - Quick Reference

Tank Load Mode

W.3.000 Code 9081 (Field Calibration)

Checking Calibration via Water Test

Troubleshooting Tips

Spare Parts List

WIZARD Indicator with DRUMM-SCALE

INDEX

Code 9080 (Scale Set Up)

Code 9082-9083 (Feed Rate Format/Display Units)

Code 9084-9086 (Single or Dual Display/Tank Loading/Printer)

Code 9086 (cont...)-9089 (Time/Date/Calibration/Channels)

Code 4200 & 3256 (Set Point Configuration/4-20mA Output Configuration)

Code 3256 (cont...)

Indicator Wiring & Plumbing

Indicator Installation Instructions

Wizard Component Layout

INDICATOR INSTALLATION

W.1.201

W.1.202-203

W.1.204

SET-UP CODES - CUSTOM FORMATTING

W.2.201

W.2.202

W.2.203

W.2.204

W.2.205

W.2.206

MEMU OF DAY-TO-DAY OPERATIONS

W.2.104

W.2.105

W.2.106

W.2.107

W.2.108

MISCELLANEOUS

W.3.101

W.3.201

W.3.301

W.3.401

Low Level Alarm & Date Last Cleared

Clear Amount Used & Set Scale Zero

Set Scale Zero cont... & Allarm Reset

Review Daily Usage & Printing Report

Report (example) & Protocol

YOU

ARE

HERE !

INSTALLATION OF SCALE PLATFORM:

W.1.101

W.1.102 Installation Instructions

Dimensional Drawing

INSTALLATION CHECK OFF LISTS

W.1.301

W.1.305 Installation Check-Off List

Installation Start-Up Check-Off List

INSTALLATION OF LOAD CELL

W.1.141 Load Cell Installation Drawing

WIZARD 4000

0123456789

SCALE

SELECT

DISPLAY

SELECT

TOTALS

TANK

LOAD

MENU MENU

ENTER

AMOUNT USED

SCALE 1 = 7687 LB

SCALE 2 = 6521 LB

MENU MENU

DEL

DEL

TANK

LOAD

SCALE

SELECT

ENTER

%

TOTALS

Toggles through a

multi-function display

for each scale.

Toggles through a

multi-function display

for the totals of all scales.

Toggles

Between

Individual

Scales

Scrolls

Back

Through

the Menu

OPERATIONS MENU

LOW LEVEL ALARM........................

DATE LAST CLEARED....................

CLEAR AMOUNT USED..................

SET SCALE ZERO/ENTER TARE..

ALARM RESET................................

REVIEW DAILY USE.......................

FUNCTION DESCRIPTION

Entering of low level setpoint

Date the "amount used" was last reset

Clears the "amount used" display

Zero's the display

Resets the low level alarm (if set in

the latching mode)

Reviews past 10 days usage

Backspace

or Escape

Menu Operations

Data Entry

and Menu

Function

Access

"Time" and

"Date"

Displays

Percent

of Full

Reset Button (Resets

screen to opening menu

in case of entry error)

Single or Dual

Display (16

Characters

per Line Screen)

Total Remaining

Total Used

Total Feed Rate

Net Remaining

Amount Used

Average Feed Rate

Days Until Empty

Daily Usage

If applicable:

Tare Weight

Gross Weight

Scrolls

Forward

Through

the Menu

Loading

New Tanks

or Chemicals

Numeric

Data Entry

Key Pad

DISPLAY

SELECT

TIME

DATE

TIME

DATE

%

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

Drawn by: SLP

Date: 09/01/95

Revised: 11/01/99

Scale: NONE

Drawing Number

File: T4\O&M\AWZMSTR\WZBUTTON.tcw (B05.pdf) 10/20/99

29887

WIZ

INDICATOR BUTTON

FUNCTIONS LIST FOR

WIZARD INDICATOR

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

W.2.101

KEYBOARD & MENU FUNCTIONS

QUICK REFERENCE GUIDE

QUESTIONS ? Help Hotline: 1-800-893-6723

W.2.102

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

File: T4\O&M\AWZMSTR\WZKEYBD2.tcw (B06.pdf) 10/20/99

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

Scrolls forward through individual scales.

SCALE SELECT

Toggles through a multi-function display for each scale in the

following decending order:

DISPLAY SELECT

NET REMAINING............

AMOUNT USED..............

AVERAGE FEED RATE..

DAYS UNTIL EMPTY......

DAILY USAGE................

If applicable:

TARE WEIGHT...............

GROSS WEIGHT...........

Chemical remaining in tank or cylinder

A running total of net chemical used since last reset

Current chemical feed rate in lbs. or gallons per day

Days until empty at the current feed rate

Previous day's total chemical usage

Tank tare weight

Tank tare plus chemical weight

Toggles through a multi-function display for the totals of all scales,

in the following descending order:

TOTALS

TOTAL REMAINING.........

TOTAL USED...................

TOTAL FEED RATE.........

Chemical remaining in all tanks

Chemical used in all tanks

Chemical feed rate of all tanks

Displays NET REMAINING as a PERCENTAGE of full.

%

Time and Date

TIME DATE

Loading new tanks or chemicals and entering tank tare weights.

TANK LOAD

Scroll through a list of day-to-day operations in DESCENDING order.

See Section "OPERATING INSTRUCTIONS", under

"MENU OF DAY-TO-DAY OPERATIONS":

MENU DOWN

LOW LEVEL ALARM...........

DATE LAST CLEARED.......

CLEAR AMOUNT USED.....

SET SCALE ZERO/TARE...

ALARM RESET...................

REVIEW DAILY USE..........

PRINT.................................

Entering of low level set point values

Date the "amount used" display was last cleared

Clears the "amount used" display and "daily usage" display

Zero's the display

Resetsthe low level alarm (if set in the latching mode)

Stores the last 10 days Daily Usage

Outputs date via serial port to a printer

These are the functions that are used on a day-to-day basis.

WARNING ! DO NOT UNLOAD or LOAD tanks until "CHANGE TANKS NOW, THEN

PRESS ENTER" appears on the display. If you load or unload tanks

before reaching this step, the "amount used" and "daily usage" displays

will be incorrect.

It also allows you to enter the tare weight(s) of your tanks if you choose "Manual" tank load mode, or load the

net weight of a cylinder if you chose the "Auto" tank load mode. (See Code Set-up 9085)

Allows you to load new tanks without adversly affecting

the "AMOUNT USED" and "DAILY USAGE" displays.

MENU

Press to enter the tank load mode.

Remove empty tanks and place new tank(s) onto the scale

then press

SCALE #2 TANK #1

TARE = XXXX

NET REMAINING

SCALE 1 = XXXX

Enter the scale NUMBER that you want to load/unload tanks.

This "freezes" or "holds" the AMOUNT USED and DAILY

USAGE displays until feeding resumes).

12

ENTER SCALE #

1 THRU 2 X

....If you chose "AUTO" the WIZARD automatically loads the

net weight and goes into the weighing mode (skip Step 6).

ENTER

CHANGE TANKS NOW

THEN PRESS ENTER

WAIT

TARE MODE

*AUTO MANUAL

Press or then

Press to select which method, then press

MANUAL Mode: Requires that you enter tare weight of EACH tank on

EACH scale. (Example: Scale #2, tare weight of TANK #1, then

TANK #2, etc). After entering the tare weights of all your tanks, the

WIZARD 4000 automatically adds them up and subtracts them from

the gross weight.

ENTER

ENTER

TANK

LOAD

Step 6

Digital Display Action Required - Press "ENTER" after completing each step.

Step 2

Step 4

Step 5

Step 3

Step 1

Wait until this clears to continue.

TANK

LOAD

....If you chose "MANUAL" you will manually enter tank

tare weight in Step 6.

....If MANUAL chosen above in Step 3...

Use "MANUAL" for PARTIALLY FULL containers.

Use "AUTO" for FULL containers.

TANK LOAD MODE

Fill your tank with chemicals, then press

FILL TANK NOW

THEN PRESS ENTER ENTER

Step 7

"PORTABLE" Tank Applications (Follow Steps 1 thru 6 only)

(such as Ton Containers, Drums and Cylinders)

"FIXED" Tank Applications (Follow Steps 1, 2 and 7 only)

(such as Chem-Scale, Hoppers, Powercells and Ultrasonic)

Skip to STEP 7 in "FIXED" Tank Applications.

QUESTIONS ? Help Hotline: 1-800-893-6723 W.2.103

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

File: T4\O&M\AWZMSTR\WZDAY1B.tcw 11/99 (B07.pdf)

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

W.1.000

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

REF: T4\O&M\INDEX.\Y07.tcw etc (Y07.pdf etc) 1/24/02

SECTION

W.2.000 INDICATOR OPERATION

W.2.101

W.2.102

W.2.103

Keyboard Display Selections

Keyboard Menu - Quick Reference

Tank Load Mode

W.3.000 Code 9081 (Field Calibration)

Checking Calibration via Water Test

Troubleshooting Tips

Spare Parts List

WIZARD Indicator with DRUMM-SCALE

INDEX

Code 9080 (Scale Set Up)

Code 9082-9083 (Feed Rate Format/Display Units)

Code 9084-9086 (Single or Dual Display/Tank Loading/Printer)

Code 9086 (cont...)-9089 (Time/Date/Calibration/Channels)

Code 4200 & 3256 (Set Point Configuration/4-20mA Output Configuration)

Code 3256 (cont...)

Indicator Wiring & Plumbing

Indicator Installation Instructions

Wizard Component Layout

INDICATOR INSTALLATION

W.1.201

W.1.202-203

W.1.204

SET-UP CODES - CUSTOM FORMATTING

W.2.201

W.2.202

W.2.203

W.2.204

W.2.205

W.2.206

MEMU OF DAY-TO-DAY OPERATIONS

W.2.104

W.2.105

W.2.106

W.2.107

W.2.108

MISCELLANEOUS

W.3.101

W.3.201

W.3.301

W.3.401

Low Level Alarm & Date Last Cleared

Clear Amount Used & Set Scale Zero

Set Scale Zero cont... & Allarm Reset

Review Daily Usage & Printing Report

Report (example) & Protocol

YOU

ARE

HERE !

INSTALLATION OF SCALE PLATFORM:

W.1.101

W.1.102 Installation Instructions

Dimensional Drawing

INSTALLATION CHECK OFF LISTS

W.1.301

W.1.305 Installation Check-Off List

Installation Start-Up Check-Off List

INSTALLATION OF LOAD CELL

W.1.141 Load Cell Installation Drawing

Other manuals for WIZARD 4000

2

Table of contents

Other Force Flow Scale manuals

Popular Scale manuals by other brands

Jata hogar

Jata hogar 294K Instructions of use

Right Weigh

Right Weigh 310-PP Series Installation & operation manual

iHealth

iHealth Lite user manual

KERN

KERN FES 33K0.1 IPM Operating instruction

Health O Meter

Health O Meter 500KLWA User instructions

Weight Watchers

Weight Watchers WW910F Instructions for use