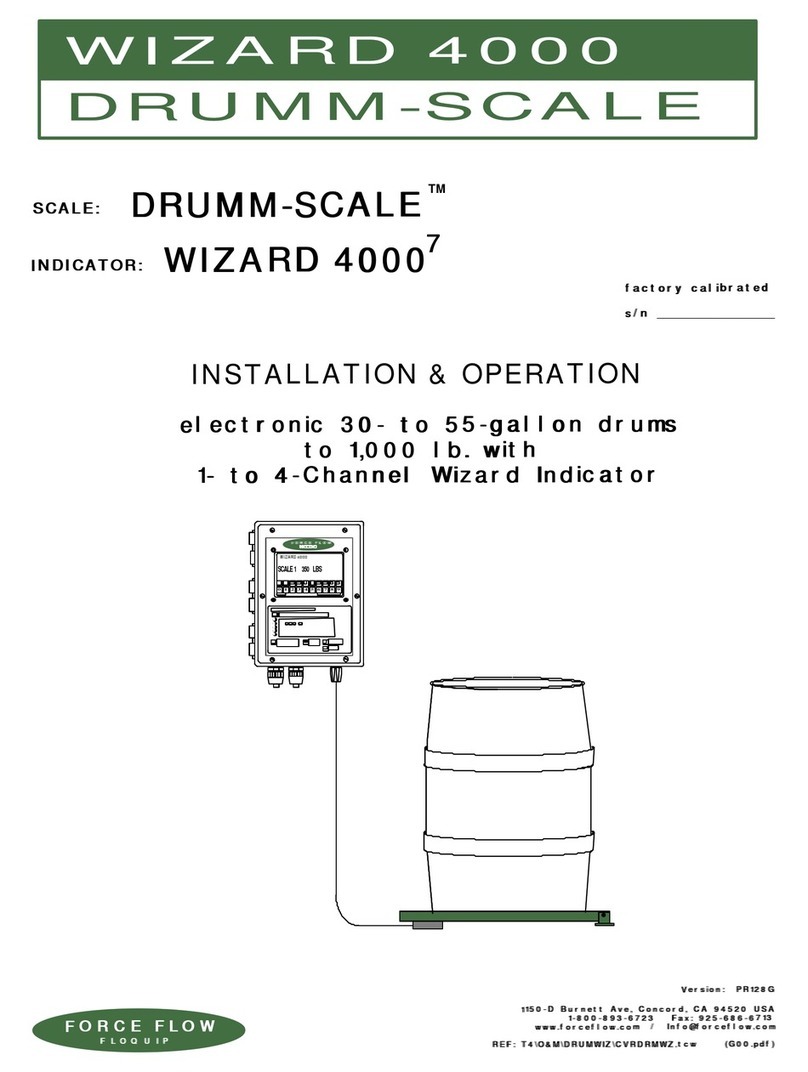

Force Flow WIZARD 4000 Guide

INSTALLATION & OPERATION

ELECTRONIC 5-GALLON TO 30-GALLON CARBOYS OR DRUMS

WITH WIZARD 4000 (1 TO 4 CHANNEL INDICATOR)

factory calibrated

factory calibrated

s/n __________________

s/n __________________

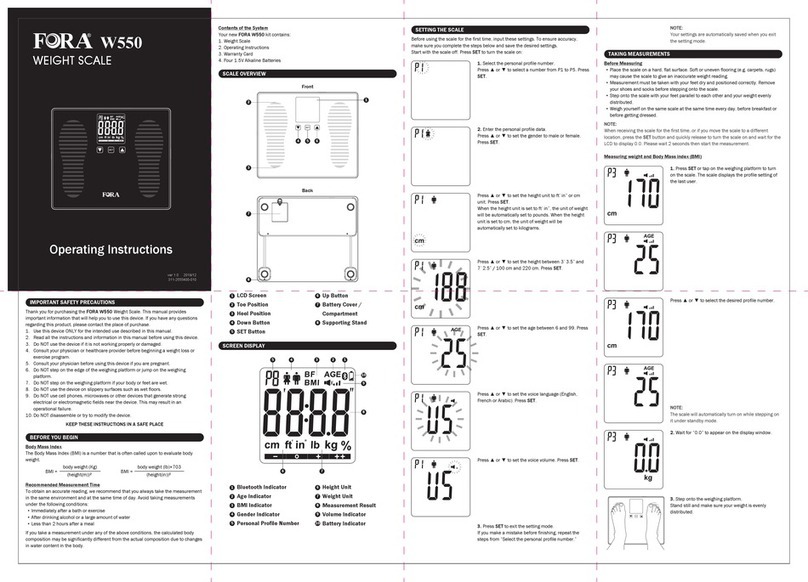

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 Fax: 925-686-6713

Version: PR128G

REF: T4\O&M\CARBWIZ\CVRCARWZ.tcw (L00.pdf)

REF: T4\O&M\CARBWIZ\CVRCARWZ.tcw (L00.pdf)

WIZARD4000

WIZARD4000

SCALE 1 350 LBS

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

WIZARD 4000

CARBOY-SCALE

CARBOY-SCALETM

WIZARD 4000

WIZARD 4000

7

7

INDICATOR:

INDICATOR:

CARBOY-SCALE

SCALE:

SCALE:

UP TO 4 SCALES PER INDICATOR

UP TO 4 SCALES PER INDICATOR

FORCEFLOW

FLOQI

UP

INCLUDESMODELS:

1150-DBurnettAve,Concord,CA94520USA

1-800-893-6723US&Canada,Fax:925-686-6713

WWW.FORCEFLOW.COM/INFO@FORCEFLOW.COM

REF:T4\O&M\CARBWIZ\MODELNO.tcw(L0A.pdf)

ELECTRONIC

CARBOY-SCALES

withWIZARDINDICATOR

1-to4-ChannelIndicator

FORCAPACITIES:

8"(203mm)to24"(610mm)Diameters

FORCARBOYS&DRUMS:

COVERINGMODELS:

5-Gallonto30-GallonCarboys&Drums

WR200-1toWR200-4(200lbs)

WR400-1toWR400-4(400lbs)

WR600-1toWR600-4(600lbs)

NOTE:Carboy-Scalemodelnumbers"WR"

wereformerly"DR"andinterchangable.

(WR100K-1toWR100K-4100kg.)

(WR200K-1toWR200K-4200kg.)

(WR300K-1toWR300K-4300kg.)

MODELNUMBERS(METRICMODELS)

FORCEFLOW

HELPHOTLINE

1-800-893-6723

www.forceflow.com

info@forceflow.com

NOTES:

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

W.1.000

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

REF: T4\O&M\INDEX.\Y06.tcw etc (Y06.pdf etc)

SECTION

W.2.000 INDICATOR OPERATION

W.2.101

W.2.102

W.2.103

Keyboard Display Selections

Keyboard Menu - Quick Reference

Tank Load Mode

W.3.000 Code 9081 (Field Calibration)

Calibration of Slotted Platforms

Troubleshooting Tips

Parts List

WIZARD Indicator with CARBOY-SCALE

INDEX

Code 9080 (Scale Set Up)

Code 9082-9083 (Feed Rate Format/Display Units)

Code 9084-9086 (Single or Dual Display/Tank Loading/Printer)

Code 9086 (cont...)-9089 (Time/Date/Calibration/Channels)

Code 4200 & 3256 (Set Point Configuration/4-20mA Output Configuration)

Code 3256 (cont...)

Indicator Wiring & Plumbing

Indicator Installation Instructions

Wizard Component Layout

INSTALLATION CHECK OFF LISTS

W.1.301

W.1.305

INDICATOR INSTALLATION

W.1.201

W.1.202-203

W.1.204

Installation Check-Off List

Installation Start-Up Check-Off List

SET-UP CODES - CUSTOM FORMATTING

W.2.201

W.2.202

W.2.203

W.2.204

W.2.205

W.2.206

MEMU OF DAY-TO-DAY OPERATIONS

W.2.104

W.2.105

W.2.106

W.2.107

W.2.108

MISCELLANEOUS

W.3.101

W.3.102

W.3.301

W.3.401

Low Level Alarm & Date Last Cleared

Clear Amount Used & Set Scale Zero

Set Scale Zero cont... & Allarm Reset

Review Daily Usage & Printing Report

Report (example) & Protocol

YOU

ARE

HERE !

INSTALLATION INSTRUCTIONS

W.1.101

W.1.101-4

W.1.102

W.1.103

W.1.104

W.1.105

W.1.106

W.1.108

Scale Drawing

1 to 4 Channel Configuration Drawing

Installation Drawing

Installation Introduction

Installation Instructions Steps 1 thru 4a

Installation Instructions Steps 4b thru 4f

Installation Instructions Steps 4g thru 5

Scale Operation

X

Z

Y

PLATFORM

ELECTRICAL

CABLE

WIZARD4000

INDICATOR

FLOQUIP

FORCEFLOWEQUIPMENT

SCALE

SELECT

DISPLAY

SELECTTOTALSPRINT

F1

TANK

LOAD

MENUMENU

DELENTER

09

123456

7

8

SCALE1150LBS

SCALE2300LBS

Allowschangingoftanks.Tomaintainaccurateusagedata,

DONOTchangetanksuntilSTEP4.

PressTANKLOADbutton

Press123or4toselectwhichscale,thenpressENTER.

PressMENUtoselectAUTOorMANUALtareentry,thenpressENTER

Changeyourtank(s)now!ThenpressENTER.

IfMANUALischosen:Keyintanktareweight(s)vianumerickeypad,

thenpressENTER.

Togglesthroughdisplay

options:

NetRem

aining,A

m

ountUsed,

A

verageFeedRate,Day

sUntil

Em

pty

,Daily

Usage,TareW

eight

andGrossW

eight.

Togglesthrough

display

forthe

totalsofall

scales

BackspaceorEscape

MenuOperations

A

cceptDataor

Proceedto

nextfunction

1

2

3

4

5

TANK

LOAD

DISPLAY

SELECTTOTALS

DEL

ENTER

CALIBRATION

RING

1-5/8"(41mm)

PLATFORMMOUNTEDLEVELVIAL

ADJUSTABLEBACKSTOP

1150-DBurnettAve,Concord,CA94520USA

1-800-893-6723US&Canada,Fax:925-686-6713

www.forceflow.com/info@forceflow.com

Drawnby:SLP

Date:01/04/94

Revised:05/07/98

Scale:NONE

DrawingNumber

File:T4\O&M\CARBWIZ\CARBWIZ.tcw(L08.pdf)(WEB:CARBWIZ.pdf)7/01

30277

ELECTRONICCARBOY-SCALE

withWIZARD4000INDICATOR

FORCEFLOW

WR200

WR400

WR600

(IncludesWIZARD4000indicator)

Consultfactoryforothercapacities;multiplechannelsormetricmodels.

NOTE:ModellettersWRwereformerlyDRandinterchangeable.

181/2"(470mm)

213/4"(546mm)

24"(610mm)

131/2"(343mm)

153/4"(400mm)

24"(610mm)

FORCEFLOW

FLOQI

UP

200lbcap.

400lbcap.

600lbcap.

161/2"(419mm)

183/4"(475mm)

27"(686mm)

ModelNumbersXYZ

TankDiameter

8"to16"

14"to19"

18"to24"

W.1.101

UPTO4SCALESPERINDICATOR

Three 4-20 mA Output

One 120 Volt AC Power Four 4-20 mA Output

One 120 Volt AC Power

Two 4-20 mA Output

One 120 Volt AC Power

One 4-20 mA Output

One 120 Volt AC Power

Models:

DR200-3 (Metric: DR100K-3)

DR400-3 (Metric: DR200K-3)

DR600-3 (Metric: DR300K-3)

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

Drawn by: SLP

Date: 04/21/97

Revised: 08/16/00

Scale: NONE

Drawing Number

File: T4\O&M\CARBWIZ\CARBWIZ1.tcw (L01.pdf) 30011

CARBOY-SCALE with WIZARD INDICATOR

Model DR200 thru DR600 Series

(Metric Models also available)

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

W.1.101-4

Models:

DR200 (Metric: DR100K)

DR400 (Metric: DR200K)

DR600 (Metric: DR300K)

Models:

DR200-2 (Metric: DR100K-2)

DR400-2 (Metric: DR200K-2)

DR600-2 (Metric: DR300K-2)

Models:

DR200-4 (Metric: DR100K-4)

DR400-4 (Metric: DR200K-4)

DR600-4 (Metric: DR300K-4)

1 Single Carboy Electronic Scale with

1 Wizard 4000-1 (1 each Channel /4-20mA Output)

Optinoal Accessory: Low Level Alarm (1 required per channel)

3 Single Carboy Electronic Scales with

1 Wizard 4000-3 (3 each Channel /4-20mA Output)

Optinoal Accessory: Low Level Alarm (1 required per channel)

4 Single Carboy Electronic Scales with

1 Wizard 4000-4 (4 each Channel /4-20mA Output)

Optinoal Accessory: Low Level Alarm (1 required per channel)

2 Single Carboy Electronic Scales with

1 Wizard 4000-2 (2 each Channel /4-20mA Output)

Optinoal Accessory: Low Level Alarm (1 required per channel)

INSTALLATION PROCEDURE

Read Installation Instructions thoroughly

before installing.

4

1

2

3

5

Step

Step

Step

Step

Step

1. Place Platform on Floor

2. Level Platform

3. Anchor the Platform

4. Anchor the Load Cell

5. Mounting Additional Scales

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

Drawn by: SLJ

Date: 02/15/93

Revised: 07/29/98

Scale: NONE

Drawing Number

File: T4\O&M\CARBWIZ\CARBO&M5.tcw (LS03.pdf) 30012

CARBOY-SCALE

Electronic Scale for Weighing

5- to 30-Gallon Carboys & Drums

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

S.1.102

W.1.102

INSTALLATION INSTRUCTIONS

Two (2) Adjustable Wrenches

Screw Driver and Tape Measure

Hammer (for pounding in anchor bolts)

Carboy/Drum (for aligning platform)

To prevent possible personal injury or damage to the equipment

through misuse, this equipment should be installed, operated and

serviced only by trained, qualified personnel who are thoroughly familiar with the

entire contents of this Instruction Manual, which should be thoroughly reviewed and

understood prior to installing and operating the equipment.

Power Drill and Drill Bits

Hammer Drill and Masonry Bit (5/16")

Two (2) 1/4" Diameter Anchors (for platform)

Four (4) properly chosen Anchors (for Indicator)

Your Electronic CARBOY-SCALE consists of two basic assemblies:

1. Load Cell System (Load Cell, Cable and Indicator)

2. PVC Platform (Backstop, Platform with Hinge and leveling shims)

Electronic CARBOY-SCALE

If you have any questions regarding the installation, operation or maintenance on your

CARBOY-SCALE, please do not hesitate to call our.... HELP HOTLINE 1-800-893-6723.

COMMENTS:

ITEMS REQUIRED FOR INSTALLATION:

WARNING:

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

REF: T4\O&M\CARBWIZ\CARBO&M1.tcw (L02.pdf)

S.1.103

W.1.103

1" Clearance between

platform and wall

DO NOT anchor platform to floor until Step 3 !

(A) Place the platform on the floor with the backstop

side of the platform at the wall. (NOTE: Allow at

least 1" clearance between wall and platform)

CAUTION: For proper operation and to avoid possible damage to the scale or injury to yourself, you MUST install

these items in the following Step-by-Step manner. The Electronic CARBOY-SCALE should be used with carboys

which have outside diameters of 8" to 19", and gross weights from 200 to 400 lbs. Remove all items from box.

The load cell system is wired and calibrated at the factory.

(B) Remove stud from Load Cell and place Load Cell

underneath Platform so that the "BLACK DOT" on

Load Button is centered in the hole in the back

of the Platform.

CORRECT

CLOSE-UP DETAIL

PLATFORM

CENTER THE BLACK DOT

LINE OF SIGHT

INCORRECT

STEP 1: PLACE PLATFORM ON FLOOR

INSTALLATION NOTES:

STEP 2: LEVEL PLATFORM

Check the platform-mounted level to assure

that the scale is level from front to rear.

If the platform is not level, either:

(A) Raise rear of platform by placing shims

underneath the load cell, or

(B) Raise front by placing shims

underneath the hinge on the

anchor bolts (shims provided

with scale).

WASHERS

LOAD CELL

FRONT

MOUNTING FOOT

PLATFORM

REAR

A

WASHERS

Platform must not touch wall or scale will not function

properly. Mark mounting holes on the floor. Drill holes

with 5/16" bit and bolt scale to the floor using two (2) 1/4"

diameter anchor bolts. Make sure your anchor bolts

are properly sized and compatible with your floor material !!

To avoid injury caused by a tipping

carboy, DO NOT use until platform

is bolted to floor.

STEP 3: ANCHORING THE PLATFORM

CAUTION:

STEP 4: ANCHORING THE LOAD CELL

(A) Using Platform as a template, mark floor

to drill Load Cell anchoring hole.

Using this hole,

mark on the floor

for load cell anchoring.

LOAD CELL

ALLIGNMENT

B

B

A

. . .Step 4 continued on page 6

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

REF: T4\O&M\CARBWIZ\CARBO&M2.tcw (L04.pdf)

S.1.104

W.1.104

(D) Slide leveling washer(s) if needed onto stud.

(E) 1. Insert Load Cell Stud into hole

in the floor.

2. Be certain that the Load

Cell is seated "flush" on the floor.

Position Load Cell so that the cable

runs straight out to either side of the

Platform.

(B) After mark is established on the floor, pivot

Platform out of the way. Centerpunch the mark to

ensure accurate hole location. Drill a 5/16" hole

using an appropriate bit. Drill the hole approximately

1 inch deep.

Cable to exit straight

out on either side of

Platform.

Drill 5/16" diameter

hole, 1 inch deep.

(F) Pivot Platform back into place. Site through the

mounting hole on the platform to ensure that the

"BLACK DOT" on the Load Cell button is

centered in the hole on the platform.

Correct

Incorrect

B

(C) Install stud into threaded hole on

Load Cell. FINGER TIGHTEN ONLY !

STEP 4: ANCHORING THE LOAD CELL cont....

C

E1

D

E2

F

F

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

REF: T4\O&M\CARBWIZ\CARBO&M3.tcw (L05.pdf)

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

PW.1.105

S.1.105

To mount additional scales side-by-side, be sure to allow for the frame hinge when determining the

distance between platforms (if minimizing floor area) and repeat Step 1 - 5.

(G) If the "BLACK DOT" on the Load Cell Button is not centered

in the hole on the platform loosen the floor anchor bolts slightly and

adjust platform as needed. Once proper alignment is achieved,

tighten the anchor bolts.

Adjust platform for

proper alignment.

Loosen

"BLACK DOT" on

Load Cell should

be centered in hole

on platform.

STEP 4: ANCHORING THE LOAD CELL cont....

STEP 5: MOUNTING ADDITIONAL SCALES

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

REF: T4\O&M\CARBWIZ\CARBO&M4.tcw (L06.pdf)

S.1.106

W.1.106

The scale accuracy is plus or minus 1% (2 lbs on 200 lb. Dial,

4 lbs. on 400 lb. Dial) of the actual gross weight. If scale weighs light,

loosen nuts on backstop and move backstop back (away from hinge).

If scale weighs heavy, move backstop forward (toward hinge).

OPERATION

NOTE:

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

REF: T4\O&M\CARBWIZ\CARBPG7.tcw (L07.pdf)

W.1.108

With carboy opening caps in place, roll a carboy onto the platform until the base

of the carboy touches the platform backstop.

FOR ACCURATE MEASUREMENT, THE CARBOY MUST BE

AGAINST THE BACKSTOP.

1)

Follow "TANK LOAD" Instructions in the Section W.2.103.

2)

FORCEFLOW

HELPHOTLINE

1-800-893-6723

www.forceflow.com

info@forceflow.com

NOTES:

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

W.1.000

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

REF: T4\O&M\INDEX.\Y06.tcw etc (Y06.pdf etc)

SECTION

W.2.000 INDICATOR OPERATION

W.2.101

W.2.102

W.2.103

Keyboard Display Selections

Keyboard Menu - Quick Reference

Tank Load Mode

W.3.000 Code 9081 (Field Calibration)

Calibration of Slotted Platforms

Troubleshooting Tips

Parts List

WIZARD Indicator with CARBOY-SCALE

INDEX

Code 9080 (Scale Set Up)

Code 9082-9083 (Feed Rate Format/Display Units)

Code 9084-9086 (Single or Dual Display/Tank Loading/Printer)

Code 9086 (cont...)-9089 (Time/Date/Calibration/Channels)

Code 4200 & 3256 (Set Point Configuration/4-20mA Output Configuration)

Code 3256 (cont...)

Indicator Wiring & Plumbing

Indicator Installation Instructions

Wizard Component Layout

INSTALLATION CHECK OFF LISTS

W.1.301

W.1.305

INDICATOR INSTALLATION

W.1.201

W.1.202-203

W.1.204

Installation Check-Off List

Installation Start-Up Check-Off List

SET-UP CODES - CUSTOM FORMATTING

W.2.201

W.2.202

W.2.203

W.2.204

W.2.205

W.2.206

MEMU OF DAY-TO-DAY OPERATIONS

W.2.104

W.2.105

W.2.106

W.2.107

W.2.108

MISCELLANEOUS

W.3.101

W.3.102

W.3.301

W.3.401

Low Level Alarm & Date Last Cleared

Clear Amount Used & Set Scale Zero

Set Scale Zero cont... & Allarm Reset

Review Daily Usage & Printing Report

Report (example) & Protocol

YOU

ARE

HERE !

INSTALLATION INSTRUCTIONS

W.1.101

W.1.101-4

W.1.102

W.1.103

W.1.104

W.1.105

W.1.106

W.1.108

Scale Drawing

1 to 4 Channel Configuration Drawing

Installation Drawing

Installation Introduction

Installation Instructions Steps 1 thru 4a

Installation Instructions Steps 4b thru 4f

Installation Instructions Steps 4g thru 5

Scale Operation

4-20mA

CONNECTIONS

LOAD CELL/ULTRASONIC CONNECTIONS

RELAYS

#1 #2 #3 #4

RS485/RS232

#1 #2 #3 #4

DISPLAY ANGLE

ADJUSTMENT (BLUE)

EPROM

RAM

CPU

POWER SUPPLY

POWER IN

CONNECTOR SLEEVE

PLASTIC WASHER

RUBBER GROMMET

CABLE

CONDUIT FITTING

BOX

#1 #2 #3 #4

BOX (FRONT VIEW)

1/4" CORD CONNECTOR, USED FOR:

32

4

1

6 SLOTTED PAN HEAD SCREWS.

(TIGHTEN SCREWS EVENLY TO

GET UNIFORM SEAL ON COVER GASKET)

3RD: ATTACH TO CONDUIT

OR CABLE CONNECTOR

FITTING ON BOX

2ND: SCREW CONDUIT

CONNECTOR ONTO

CONDUIT

1ST: SLIP CONDUIT

FITTING BASE

OVER CONDUIT

1/2" CONDUIT CONNECTOR, USED FOR:

5

LOAD CELL CABLE

ULTRASONIC CABLE

POWER

4-20 MA SIGNAL

RELAY WIRING

COMMUNICATIONS)

6

NOTE:

Mount Indicator at "EYE LEVEL"

with the mounting fixtures provided.

FUSE

BOX (BOTTOM VIEW)

1

3

42

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

Drawn by: SLP

Date: 09/01/95

Revised: 01/17/01

Scale: NONE

Drawing Number

File: T4\O&M\AWIZMSTR\WIZINDI.tcw (B01.pdf)

29893

INDICATOR WIRING &

PLUMBING INSTRUCTIONS

FORCE FLOW

FORCE FLOW

F

F

L

L

O

O

Q

Q

I

I

U

U

P

P

4-20mA WIRING,

LOAD CELL CABLE,

ULTRASONIC CABLE

WIRE/CABLE

CLAMP

WIRE/CABLE

CLAMP

OPTIONAL

AUDIBLE

ALARM

CORD

CONNECTION

CONDUIT

CONNECTION

LOAD CELL/ULTRASONIC (1 & 3)

(1/4" CORD CONNECTION)

4-20mA OUTPUT

(1/2" CONDUIT

CONNECTION)

RS485/RS232

(1/2" CONDUIT

CONNECTION)

110V POWER CONNECTION

(1/2" CONDUIT CONNECTION)

RELAYS (1/2" CONDUIT CONNECTION) OPTINOAL LOAD CELL

or ULTRASONIC (2 & 4)

(1/4" CORD CONNECTION)

BOX

CONDUIT

CONNECTION CORD

CONNECTION

W.1.201

W.1.201

TURN OFF MAIN POWER BEFORE CONNECTING !! Use a clean 110 Volt AC (or 220 Volt, if provided)

power line, connected directly to the main power panel at the facility. DO NOT connect any other inductive

loads, relays, etc. to this power line ! Resulting power surges can damage the electronics !!! Use far left

bottom port and connect per following: (NOTE: Use 1/2" conduit connector)

QUESTIONS ? Help Hotline: 1-800-893-6723

When routing load cell cable into box, use a separate 1/2" cord connector per cable. DO NOT

run load cell cable with any other inductive load or power cables !! Run load cell cable up right

hand side of enclosure and use the cable clamps provided to keep cables from laying on the

PC board. Connect load cell wires per following: (NOTE: Use 1/2" conduit connector)

All connectors have a "PLUG IN" feature to assist in connecting wires. Remove the connector

from the board before attaching wires.

Your 4-20 MA signals are internally powered for up to 900 OHMS each. DO NOT use external loop power.

Run 4-20 MA wiring up the right hand side of enclosure using the cableclamps to keep wires off of PC Board.

(NOTE: Use 1/2" conduit connector). If more than one (1) 4-20 MA signal is used, you may use the same conduit

and connector, but DO NOT run 4-20 MA signals with any other power lines, which carry an inductive load..

+ EXCITATION

- EXCITATION

INDICATOR INSTALLATION & WIRING

ALWAYS SHUT OFF MAIN POWER, AS WELL AS POWER TO ANY AUXILIARY EQUIPMENT

THAT WILL BE INSTALLED IN THIS UNIT, BEFORE OPENING FRONT OF CASE !!

DESCRIPTION

POWER IN PC BOARD

DO NOT CUT LOAD CELL CABLE !! This may void your warranty!! Your WIZARD 4000

Indicator is shipped with the load cells connected and ready to power up. Should you

need to run the load cell cable through conduit, first unplug the connector from the board,

then disconnect wires, and remove by unscrewing cord connectors.

+ EXCITATION

+ SIGNAL

- SIGNAL

- EXCITATION

SHIELD

WIRE COLOR

RED

GREEN

WHITE

BLACK

BRAIDED WIRE

PC BOARD

+ X

+ S

- S

- X

SH

+X4

+S4

- S4

- X4

SH

+X3

+S3

- S3

- X3

SH

+X2

+S2

- S2

- X2

SH

+X1

+S1

- S1

- X1

SH

Scale #4

Scale #1

Scale #2

Scale #3

PC BOARD DESCRIPTION

+

-

+

-

+

-

+

-

11

12

13

14

+

-

Scale #1

110 Volt

Hot

Ground

Common

3 4-20 MA SIGNALS

2 LOAD CELL CONNECTION

1 POWER HOOK-UP

+

G

C

+ G C

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

File: T4\O&M\AWIZMSTR\WZININST.tcw (B02.pdf)

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

Scale #2

Scale #3

Scale #4

POWER IN PC BOARD 230 Volt

Hot

Ground

Hot

+

G

+

+ G +

230 VOLT AC

110 VOLT AC

W.1.202

Use a separate conduit connector for your serial port communication. DO NOT RUN ANY OTHER

CONDUCTIVE LOAD or power lines with your communicationn wiring. Wire your communications

per the following: (NOTE: Use 1/2" conduit connector).

If it is not possible to mount the indicator at eye level, you may adjust the angle of display by

turning the screw potentiometer clockwise (for down) or counterclockwise (for up). Rotate

1/2 turn at a time until display is clear.

CAUTION should be observed whenever box is open to avoid damage or memory loss by static

electricity. DO NOT touch any of the circuit board, other than the intended contact noted in these

instructions. Carpets, especially can build up static electricity.

If ordered NORMALLY CLOSED:

T G R

RS232

Circuit IS complete until relay is activated.

(Example: Turning OFF a pump)

External apparatus (pumps, valves, alarms, etc) may be ordered either normally open

(N O) or normally closed (N C) These relays are rated at 5 AMPS maximum! To

format your relays, see Set-Up Code #4200 in Chapter "SCALE SET-UP CODES".

If more than one relay is being used, you may use the same conduit connector, but

DO NOT run any other wiring with your relays. (NOTE: Use 1/2" conduit connector).

RS232

RS485 PC BOARD DESCRIPTION

+

-Positive

Negative

PC BOARD

T

G

R

DESCRIPTION

Transmitted Data (printer data output line)

Signal Ground (signal)

Received Data (printer data input line)

RELAYS

If ordered NORMALLY OPEN: Circuit is NOT complete until the relay is activated.

(Example: Turning ON a warning light). We

recommend normally open for all "low level"

applications.

Before adjusting the Display Angle Adjustment, make sure of the following:

A Indicator is mounted at "Eye Level". (Display angle is factory set for "eye level")

#1

#2

#3

#4

IN (1)

OUT (1)

IN (2)

OUT (2)

IN (3)

OUT (3)

IN (4)

OUT (4)

Be sure that all power coming into the facility is sufficiently protected for transient lighting strikes and power

surges. Improper protection may void your warranty.

B POWER IS OFF !

+ -

STATIC ELECTRICITY PROTECTION

LIGHTNING ~ SURGE PROTECTION:

6 DISPLAY ANGLE ADJUSTMENTS

5 RELAYS

4 PRINTER COMMUNICATIONS

RS485

QUESTIONS ? Help Hotline: 1-800-893-6723 W.1.203

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

File: T4\O&M\AWIZMSTR\WZININ2A.tcw (5/27/99) (B03.pdf)

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

RS485

RS232

EPROM

RAM

CPU

POWER

SUPPLY

POWER IN

Scale #1

+ -

T

G

R

HI

LO

+

C

Scale #1 #2 #3 #4

- + - + - + - +

11 12 13 14

SH

-X1

+X1

+S1

-S1

+X2

+S2

-S2

-X2

SH

+X3

+S3

-S3

-X3

SH

+X4

+S4

-S4

-X4

SH

3

6

5

4

1

NOTE: For best viewing, mount indicator at "eye level"

with the mounting fixtures provided.

2

LOAD CELLS

or

ULTRASONIC

SENSORS

FUSE

RELAYS

#1

#2

#3

#4

OUR (1)

IN (1)

OUR (2)

IN (2)

OUT (3)

IN (3)

OUT (4)

IN (4)

6"

13"

WIRE CABLE CLAMP

DISPLAY ANGLE

ADJUSTMENT (Blue)

OPTIONAL

AUDIBLE

ALARM

MOUNTING

FIXTURE

4-20mA OUTPUT

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

Drawn by: SLP

Date: 09/01/95

Revised: 05/27/99

Scale: NONE

Drawing Number

File: T4\O&M\AWZMSTR\WIZINDIA.tcw (B04.pdf) 05/27/99

29892

WIZARD INDICATOR

COMPONENT LAYOUT

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

Scale #2

Scale #3

Scale #4

W.1.204

FORCEFLOW

HELPHOTLINE

1-800-893-6723

www.forceflow.com

info@forceflow.com

NOTES:

FORCE FLOW

FORCE FLOW

F

FL

LO

OQ

QI

I

U

UP

P

W.1.000

1150-D Burnett Ave, Concord, CA 94520 USA

1-800-893-6723 US & Canada, Fax: 925-686-6713

REF: T4\O&M\INDEX.\Y06.tcw etc (Y06.pdf etc)

SECTION

W.2.000 INDICATOR OPERATION

W.2.101

W.2.102

W.2.103

Keyboard Display Selections

Keyboard Menu - Quick Reference

Tank Load Mode

W.3.000 Code 9081 (Field Calibration)

Calibration of Slotted Platforms

Troubleshooting Tips

Parts List

WIZARD Indicator with CARBOY-SCALE

INDEX

Code 9080 (Scale Set Up)

Code 9082-9083 (Feed Rate Format/Display Units)

Code 9084-9086 (Single or Dual Display/Tank Loading/Printer)

Code 9086 (cont...)-9089 (Time/Date/Calibration/Channels)

Code 4200 & 3256 (Set Point Configuration/4-20mA Output Configuration)

Code 3256 (cont...)

Indicator Wiring & Plumbing

Indicator Installation Instructions

Wizard Component Layout

INSTALLATION CHECK OFF LISTS

W.1.301

W.1.305

INDICATOR INSTALLATION

W.1.201

W.1.202-203

W.1.204

Installation Check-Off List

Installation Start-Up Check-Off List

SET-UP CODES - CUSTOM FORMATTING

W.2.201

W.2.202

W.2.203

W.2.204

W.2.205

W.2.206

MEMU OF DAY-TO-DAY OPERATIONS

W.2.104

W.2.105

W.2.106

W.2.107

W.2.108

MISCELLANEOUS

W.3.101

W.3.102

W.3.301

W.3.401

Low Level Alarm & Date Last Cleared

Clear Amount Used & Set Scale Zero

Set Scale Zero cont... & Allarm Reset

Review Daily Usage & Printing Report

Report (example) & Protocol

YOU

ARE

HERE !

INSTALLATION INSTRUCTIONS

W.1.101

W.1.101-4

W.1.102

W.1.103

W.1.104

W.1.105

W.1.106

W.1.108

Scale Drawing

1 to 4 Channel Configuration Drawing

Installation Drawing

Installation Introduction

Installation Instructions Steps 1 thru 4a

Installation Instructions Steps 4b thru 4f

Installation Instructions Steps 4g thru 5

Scale Operation

Other manuals for WIZARD 4000

2

This manual suits for next models

25

Other Force Flow Scale manuals