FORNI FEM207SC Manual

- 1 -

LAST REVISION: 27/06/00 IMFOC 00201

INSTALLATION, OPERATION AND

MAINTENANCE INSTRUCTIONS

ANALOGUEELECTRIC-ELECTRONIC“COMBINED”OVEN

InaccordancewithstandardsEN60335partI

EN 60335 part II - 42

FEM67

FEM107

FEM207

FEM67SC

FEM107SC

FEM207SC

- 2 -

CONTENTS

SECTION DESCRIPTION PAGE

1. Warnings ............................................................................................................................................ 3

1.1 General warnings ............................................................................................................................... 3

2. Technical data ................................................................................................................................... 4

2.1 Electrical equipment ......................................................................................................................... 4

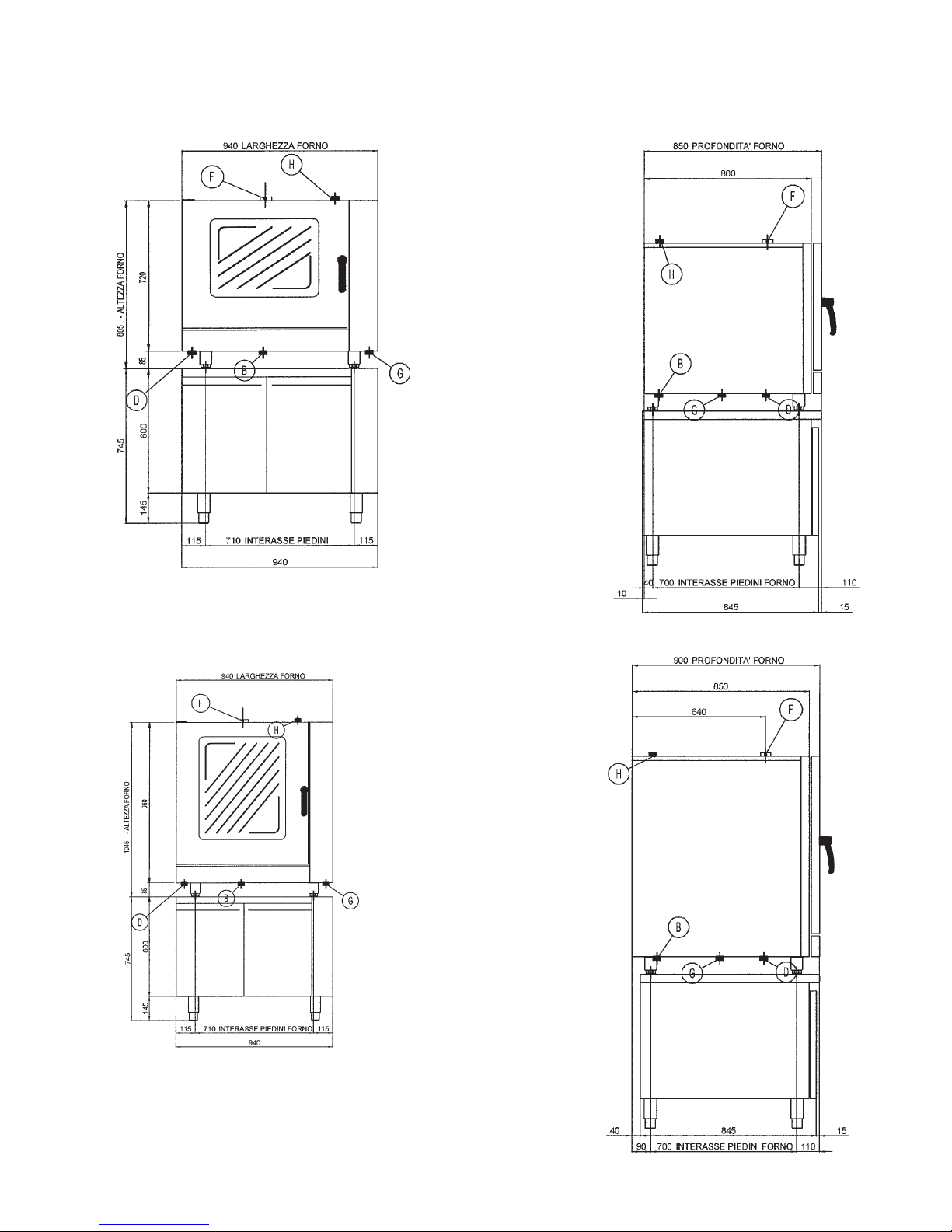

3. Installation diagrams ......................................................................................................................... 5

3.1 “Combined” electric oven FEM67/FEM67SC ................................................................................. 5

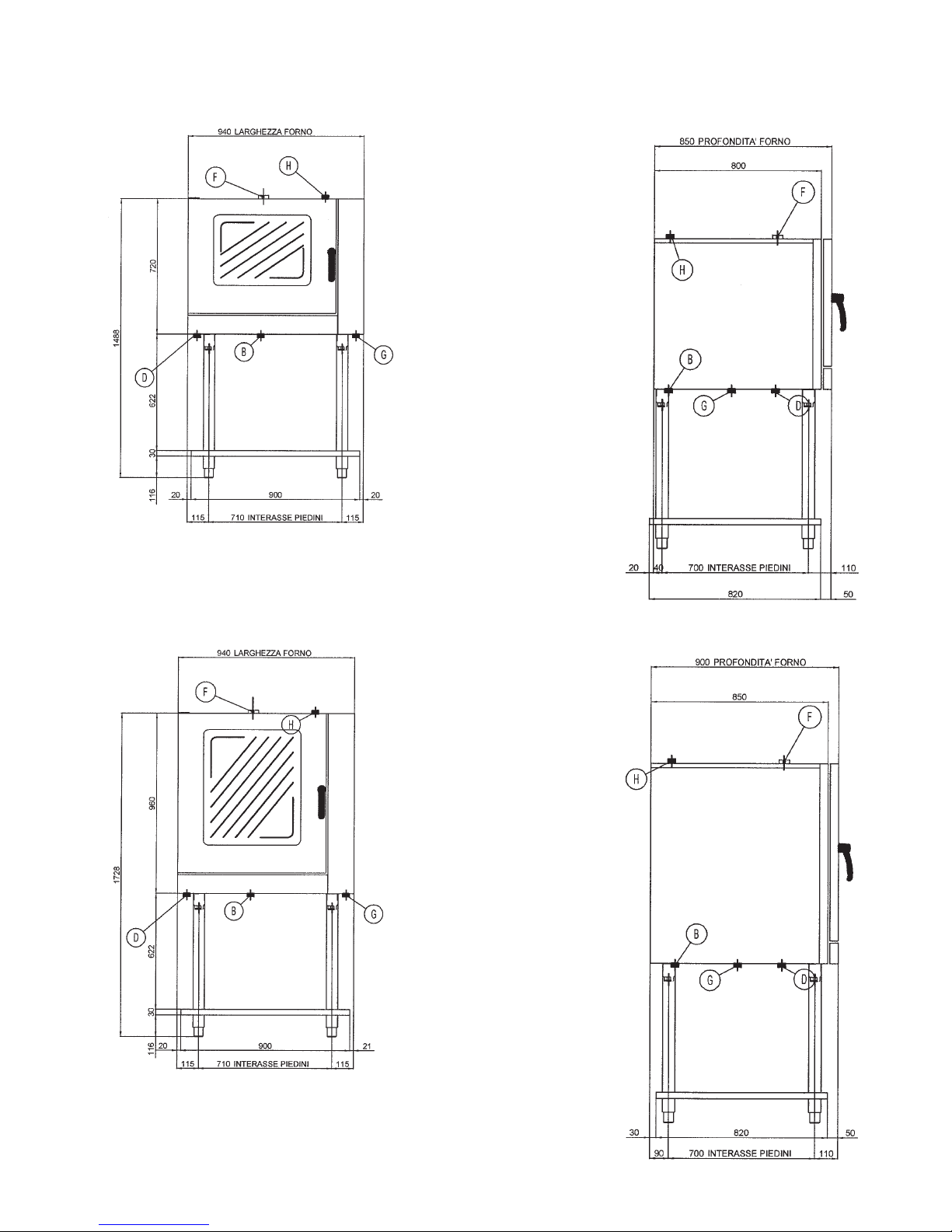

3.2 “Combined” electric oven with cabinet SFA - SFRU........................................................................ 7

3.3 “Combined” electric oven with stand SF.......................................................................................... 8

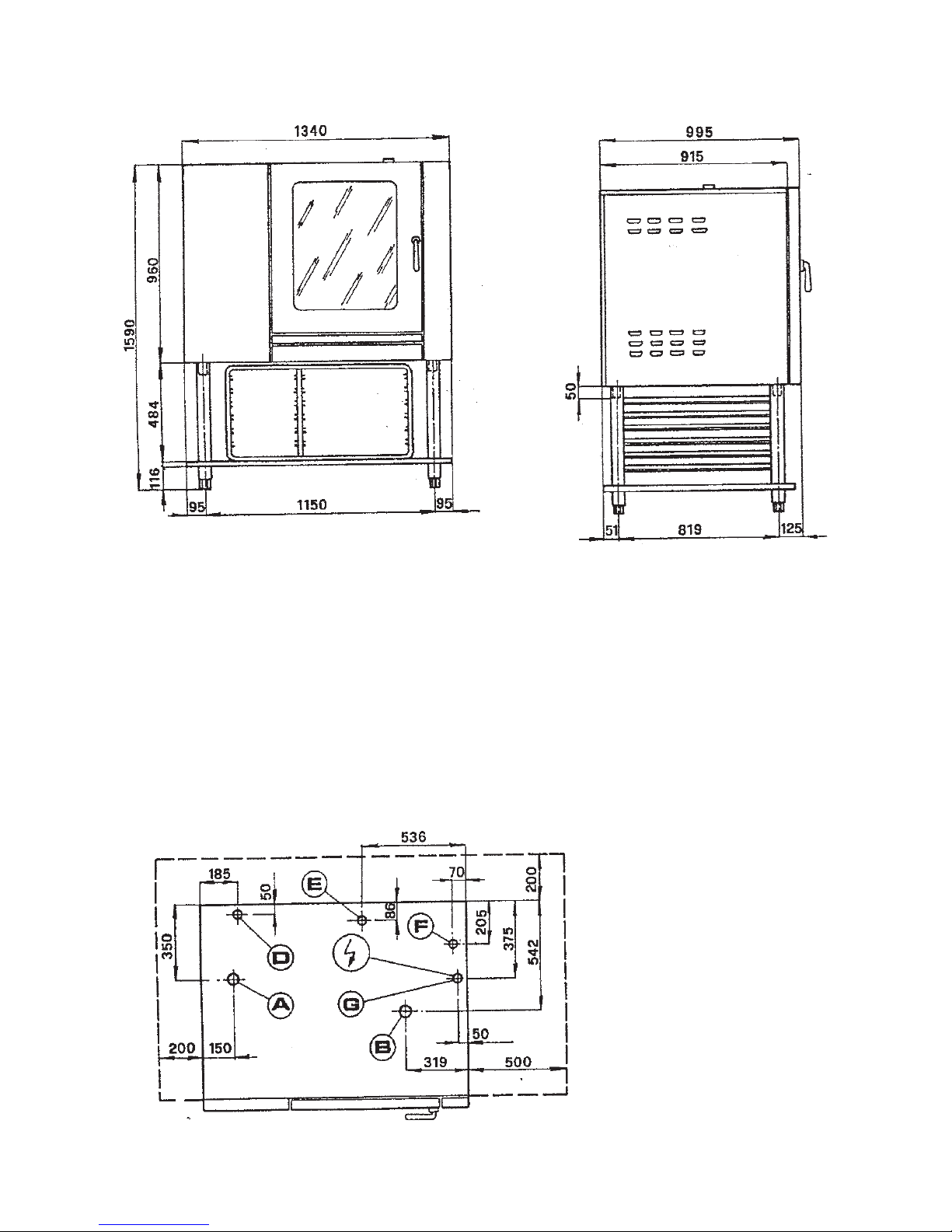

3.4 “Combined” electric oven FEM207/FEM207SC with stand SF2 .................................................... 9

4. Installation instructions .................................................................................................................... 10

4.1 Preparing for installation................................................................................................................... 10

4.1.1 Laws, regulations and technical directives ....................................................................................... 10

4.2 Positioning ........................................................................................................................................ 10

4.3 Cold water connection ...................................................................................................................... 10

4.4 Waste water outlet ............................................................................................................................. 11

4.5 Electrical connection ........................................................................................................................ 11

4.5.1 Earthing ............................................................................................................................................. 11

4.5.2 Equipotential system......................................................................................................................... 11

4.5.3 Power supply cable............................................................................................................................ 11

4.5.4 Transformation to operate with different electric power distribution networks ............................... 12

4.6 Other outlets ...................................................................................................................................... 13

4.7 Room ventilation .............................................................................................................................. 13

4.8 Presenting the oven to the user ......................................................................................................... 13

5. Use ..................................................................................................................................................... 13

5.1 User instructions: commissioning..................................................................................................... 13

6. Using the electronic oven ................................................................................................................. 15

6.1 Cooking selection ............................................................................................................................. 15

6.2 Vent valve in cooking chamber ........................................................................................................ 15

6.3 Humidifier ......................................................................................................................................... 16

6.4 Chamber light.................................................................................................................................... 16

6.5 Fan speed ........................................................................................................................................... 16

6.6 Cooking chamber temperature .......................................................................................................... 16

6.7 Cooking time and starting the oven ................................................................................................. 16

6.8 Core probe ......................................................................................................................................... 17

6.9 Cook & Hold ..................................................................................................................................... 17

6.10 Displaying and modifying cooking parameters ............................................................................... 17

6.11 Draining the boiler ............................................................................................................................ 18

6.12 Messages and alarms ......................................................................................................................... 18

7. Cleaning and maintenance................................................................................................................ 19

7.1 Cleaning ............................................................................................................................................ 19

7.1.1 Cleaning after cooking and at the end of the day............................................................................. 19

7.1.2 Descaling the boiler .......................................................................................................................... 19

7.1.3 Troubleshooting................................................................................................................................19

7.2 Maintenance...................................................................................................................................... 20

7.2.1 Replacing components...................................................................................................................... 20

A) Electric components and electronic card ..................................................................................... 20

B) Resistor ......................................................................................................................................... 20

C) Oven lamp..................................................................................................................................... 20

D) Oven door gasket.......................................................................................................................... 20

E) Cleaning solenoid valve filters .................................................................................................... 20

7.2.2 Yearly maintenance ........................................................................................................................... 21

7.2.3 Safety devices Equipment control and safety systems .................................................................... 22

7.3 Switching off in the event of equipment faults................................................................................. 22

7.3.1 Precautions if the oven is not to be used for a lengthy period.......................................................... 22

- 3 -

1. WARNINGS

-Installation,start-upandmaintenanceoftheovenaretobecarriedoutonlybyskilledpersonnelauthorizedbyourfirmor

by licensed installers.

-Readtheinstructionscontainedinthismanualcarefullyastheyprovideimportantinformationonthecorrectinstallation,

operationandmaintenanceprocedures.

- Store this manual carefully for future reference by the operators.

-Afterremovingthe packing,checktheintegrity of theequipment.

-Inthe eventofequipment failureortrouble, donotoperate theequipment,call professionallyqualifiedpersonnel.

- Packaging elements (plastic bags, polystyrene foam, nails, etc.) are potentially dangerous and should not be left within the

reachofchildren.

- Before connecting the equipment, make sure that the data reported on the plate correspond to those of the electric and water

supply networks.

- The plate is located on the front lower right side.

- The equipment is to be operated by specifically trained staff only.

-Thisequipment mustonlybeused forthepurposes forwhichitwas designed,i.e.cooking or warmingupfood; anyotheruse

is to be considered improper and therefore dangerous.

- Do not obstruct air vents or heat dissipation openings.

- Switch off the oven after use.

The manufacturer disclaims all responsibility for any inaccuracies in this booklet that may be due to typing or printing

mistakes.The manufacturer, moreover, reserves the right to make the modifications to the productitconsidersusefulor

necessary,withoutaffectingitsbasicfeatures.

In the event of the user or the installation technician failing to observe the instructions given in this manual, the Firm

disclaimsallresponsibilitythereofandcannotbeheldliableforanyaccidentsortroublecausedbysuchnon-observance.

1.1 GENERAL WARNINGS

- 4 -

2. TECHNICAL DATA

2.1 ELECTRIC APPLIANCES

•) With 3N AC 400 V 50 Hz. N.B. With 3N AC 380 V 50 Hz. the thermal power drawn is approximately 9% lower.

With3NAC 415V50Hz. thethermalpowerdrawn isapproximately9%higher.

MODEL

Standards

Outsidedimensions

Width

Depth

Height

Height

Netweight

Cookingchamberdimensions

Width

Depth

Height

Usefulvolume

CapacityNo.GrillesGN1/1-2/1

Oven load capacity

Guidec/cdistanceGN1/1

Tray depth

Power supply voltage

3NAC380....415V50Hz(or60Hz)

Externalresidual

currentdevice

Total absorbed electric power Motor

absorbed electric power

Convectionabsorbedelectricpower

Boilerabsorbedelectricpower

Power supply

Powersupplycable typeH07RN-F

Cable no. 5 wires Cross-section

Water supply

Softened water

Consumption

Steam generation

Steamelimination

* NB:1 bar=100 kpa

Waste water outlet

Max.temperature

Ovenperformance

Hotairtemperaturerange

Steam temperature range

Coreprobetemperaturerange

Timetoreach180-215°C

Consumptiontokeepaverage215°C

Fan speed

mm

mm

min.mm

max.mm

kg

mm

mm

mm

dm3

max.kg

mm

min.mm

A/ph.

kW

kW

kW

kW

min.mm2

(min÷max)bar*

l/h

l/h

Ømm

max.°C

°C

°C

°C

min.

kWh

min.g/min

max.g/min

EN60335-I

EN60335-II- 42

FEM67

FEM67SC FEM107

FEM107SC FEM207

FEM207SC

940

850

805

855

120

640

420

430

129

6/-

18÷24

60

20

x

16

9,5

0.5

9.0

6.0

1.5

G3/4”

0.5÷4

9

90

40

100

20÷270

20÷100

20÷99

4/5.0

1,2

1400

2800

940

900

1050

1100

175

640

420

670

199

10/-

30÷40

60

20

x

32

15.6

0.6

15.0

12.0

2.5

G3/4”

0.5÷4

18

140

40

100

20÷270

20÷100

20÷99

3.5/4

1,4

700

1400

1340

980

1045

1095

330

640

860

670

322

20/10

60÷80

60

20

x

40

22.3

0.7

21.6

15.0

6.0

(2X) G 3/4”

0.5÷4

22

140

40

100

20÷270

20÷100

20÷99

5.5/6

1.8

700

1400

- 5 -

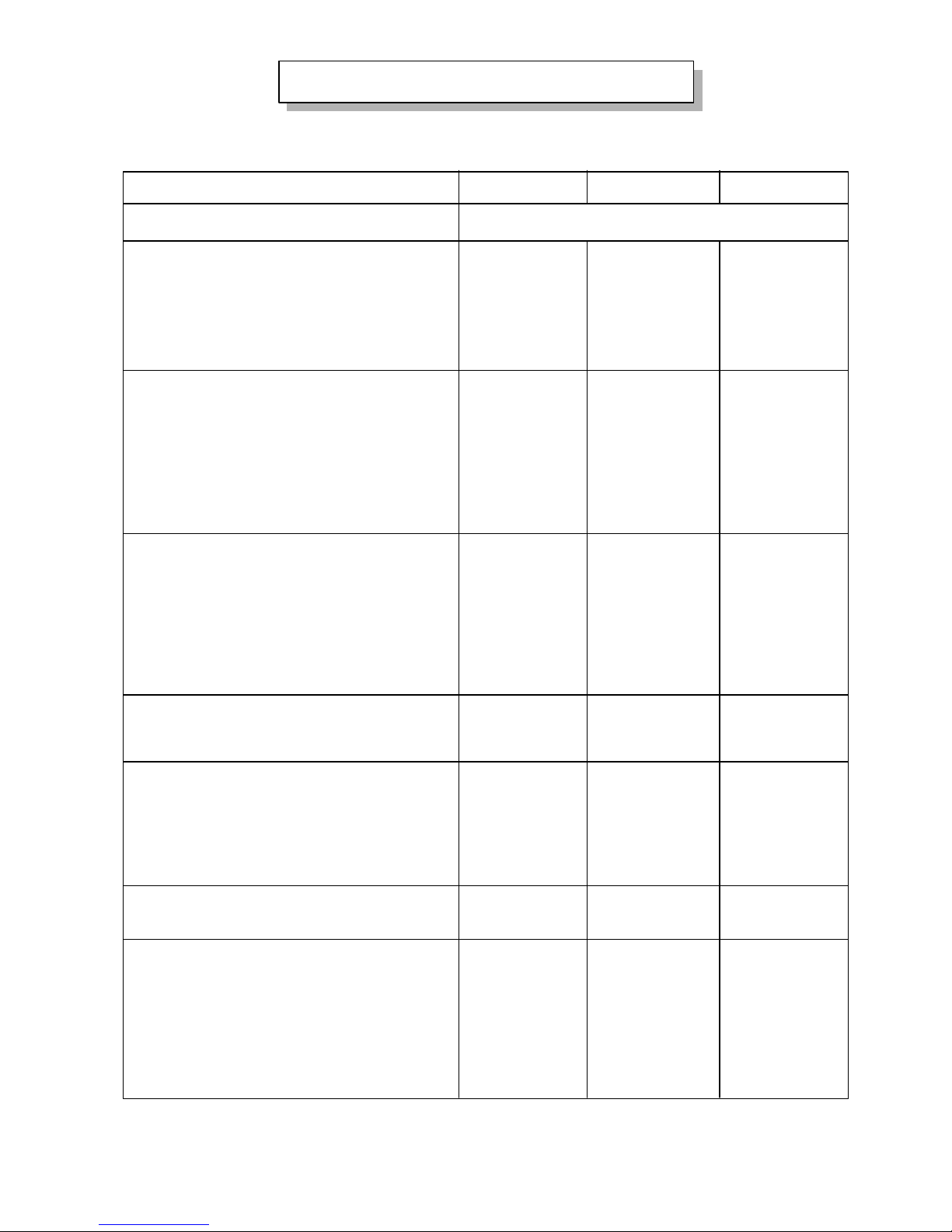

3. INSTALLATION DIAGRAMS

3.1 “COMBINED” ELECTRIC OVEN FEM067/FEM67SC

D) Water outlet Ø 40 mm

F) Vent pipe Ø 50 mm

G) Powersupply cable entry

B) Softened water inlet G 3/4”

H) Descaling agent inlet

- 6 -

“COMBINED” ELECTRIC OVEN FEM107/FEM107SC

D) Water outlet Ø 30 mm

F) Vent pipe Ø 40 mm

G) Powersupply cable entry

B) Softened water inlet G 3/4”

H) Descaling agent inlet/

Safety valve

- 7 -

3.2 “COMBINED” ELECTRIC OVEN WITH CABINET SFA - SFRU

FEM67

FEM67SC

FEM107

FEM107SC

D) Water outlet Ø 40 mm

F) Vent pipe Ø 50 mm

G) Power supply cable entry

B) Softened water inlet G 3/4”

H) Descaling agent inlet

D) Water outlet Ø 30 mm

F) Vent pipe Ø 40 mm

G) Power supply cable entry

B) Softened water inlet G 3/4”

H) Descaling agent inlet/Safety valve

- 8 -

3.3 “COMBINED” ELECTRIC OVEN WITH MOUNTING SF

FEM67

FEM67SC

FEM107

FEM107SC

D) Water outlet Ø 40 mm

F) Vent pipe Ø 50 mm

G) Power supply cable entry

B) Softened water inlet G 3/4”

H) Descaling agent inlet

D) Water outlet Ø 30 mm

F) Vent pipe Ø 40 mm

G) Power supply cable entry

B) Softened water inlet G 3/4”

H) Descaling agent inlet/Safety valve

- 9 -

3.4 “COMBINED” ELECTRIC OVEN FEM207/FEM207SC WITH MOUNTING SF2

D) Humidifierwaterinlet

and steam generator G 3/4”

E) Water outlet Ø40 mm

F) Coldwaterinlet

eliminating steam G 3/4”

B) Top steam outlet

adjustable Ø 50 mm

G) Powersupplycableentry

A) Steamgenerator weight valve

(descaling agent inlet)

- 10 -

4. INSTALLATION INSTRUCTIONS

Installationandadjustmentoperationsaretobecarriedoutbyqualifiedpersonnelaccordingtothenormsinforce.

(Seetechnicalspecificationtablespage 4).

WARNINGS:

- If the oven is installed against a wall, the wall needs to withstand temperatures of 80°C and must be incombustible.

- Inlets (water and electricity) and outlets (waste water, steam etc.) are signalled by dedicated tags.

- The top of the oven is not to be used to store goods!

4.1 PREPARING FOR INSTALLATION

Beforeproceedingto installation, removetheprotective plastic filmandeliminate any adhesiveresiduesby means ofasuitable

product for cleaning stainless steel.

4.1.1 LAWS, REGULATIONS AND TECHNICAL DIRECTIVES

Thefollowing regulationsmustbeobservedduringinstallation:

-Currentaccident-preventionregulations.

-”Electricsystem installation”standards.

-Theregulationsof the electricity board.

- The regulations of the water board.

-Local”municipal”norms on the drainageofwastewater.

- Health regulations.

-Italianlawno.4605/03/1990.

4.2 POSITIONING

Place the oven under a ventilation hood to make sure all vapours are extracted.

Installtheoven horizontally andcheckthe correct positioningbymeans ofalevel;rotate levellingfeettoadjust.

The oven may be installed on its own or in a group of several elements; but make sure it is not placed next to combustible

objects.

- Never obstruct the air vents and heat dissipation openings of the oven.

- The electric cable must never be subject to traction.

-Provide clearance of1/2metre ontherightfor maintenance.

4.3 COLD WATER CONNECTION

(SOFTENED)

Waterpressure:min. 50kPamax. 400 kPa(0.5<PH2O<4bar).

The water inlets must be connected to the softened supply

networkata maximumtemperatureof 50°Cbymeans of

shut-off valves, to be closed when the oven

is not being used or for maintenance work.

The water is used to condense the vapours in the

waste water outlet, to supply the humidifier and

to generate steam; between the shut-off valve and

the oven connection pipe, there must be a mechanical

filter so as to prevent any ferrous waste getting

insidethatcould overtimecause oxidationofthe

oven.

If the hardness of the water is greater than 5-7°Fr, it is

necessary to install a softener with automatic

regeneration,tobe positioned afterthemechanical filter.

As regards the flow rate per hour of the softener, refer to the Table on page 4.

REAR WATER

CONNECTION

- 11 -

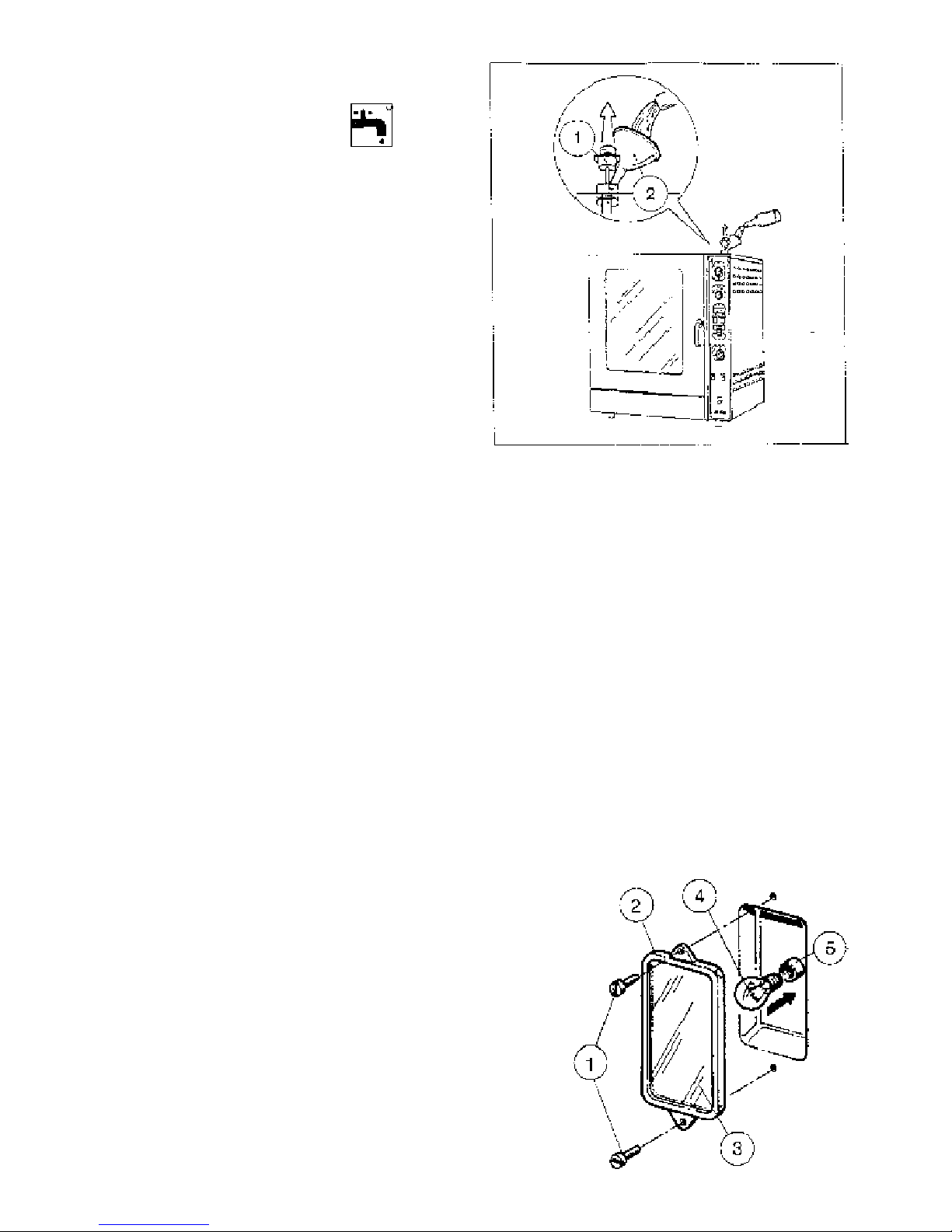

4.4 WASTE WATER OUTLET

The water outlet “1” must lead

to an open siphon “2” so as

to allow no contact between the outlet pipe

of the oven and the collecting siphon

as per the current local health regulations

and for the oven to work properly.

To prevent bad smells and waste water getting

back into the oven, after the open siphon there

should be a normal siphon “3”.

The drain pipe is to be manufactured

withmaterialsabletowithstand temperatures

of100°C.

N.B.A“closed”connection to thechannel

is not permitted!

To condense outlet vapours of the oven FEM207/FEM207SC

connect cold water supply to the solenoid valve C as

shown in the figure.

The water pressure must be between

50and400kPa(0.5 <PH2O<4bar).

4.5 ELECTRICAL CONNECTION

- Theelectricalconnectionmustbe carried out byqualifiedauthorizedpersonnelonly, in compliance withtheregulationsin

force.Check thedatareportedinthetechnicaldataTableon page4 ofthismanual,ontheadhesiveconnectionlabelon page

11andinthe wiringdiagram.Theconnection envisaged isfixed.

IMPORTANT:Amulti-polarmains cut-off device mustbeprovidedupstream from each oven,withacontact opening gap of

at least 3 mm.

For example:

- a manual switch of suitable capacity, equipped with fuses

- residual current device.

4.5.1 EARTHING

It is vital to earth the oven.

Connect the terminals marked by the symbols ( ) positioned on the line-in terminal block to an efficient grounding

complying with the regulations in force.

CAUTION: NEVER CUT THE GROUNDING CABLE (yellow-green)

THE MANUFACTURER DISCLAIMS ALL RESPONSIBILITY IF THESE SAFETY STANDARDS ARE NOT

COMPLIED WITH.

4.5.2 EQUIPOTENTIAL SYSTEM

The oven must be included in an equipotential system whose efficiency must be checked according to the

standards in force. The screw marked by the ”Equipotential” label is near the terminal block on the base.

4.5.3 POWER SUPPLY CABLE

The oven is supplied without a power cable. The specifications of the power supply connection flexible

cable must match or be superior to those of the cable with rubber insulation H07RN-F.

As regards the cross-sections of cables, refer to the table on page 11. Introduce the cable through the cable clamp

andsecureitfirmly. During operation,thepowersupplyvoltage shouldnotdifferfromthe voltage ratingby +/-10%.

INDIRECT WASTE WATER OUTLET THROUGH

OPEN SIPHON

- 12 -

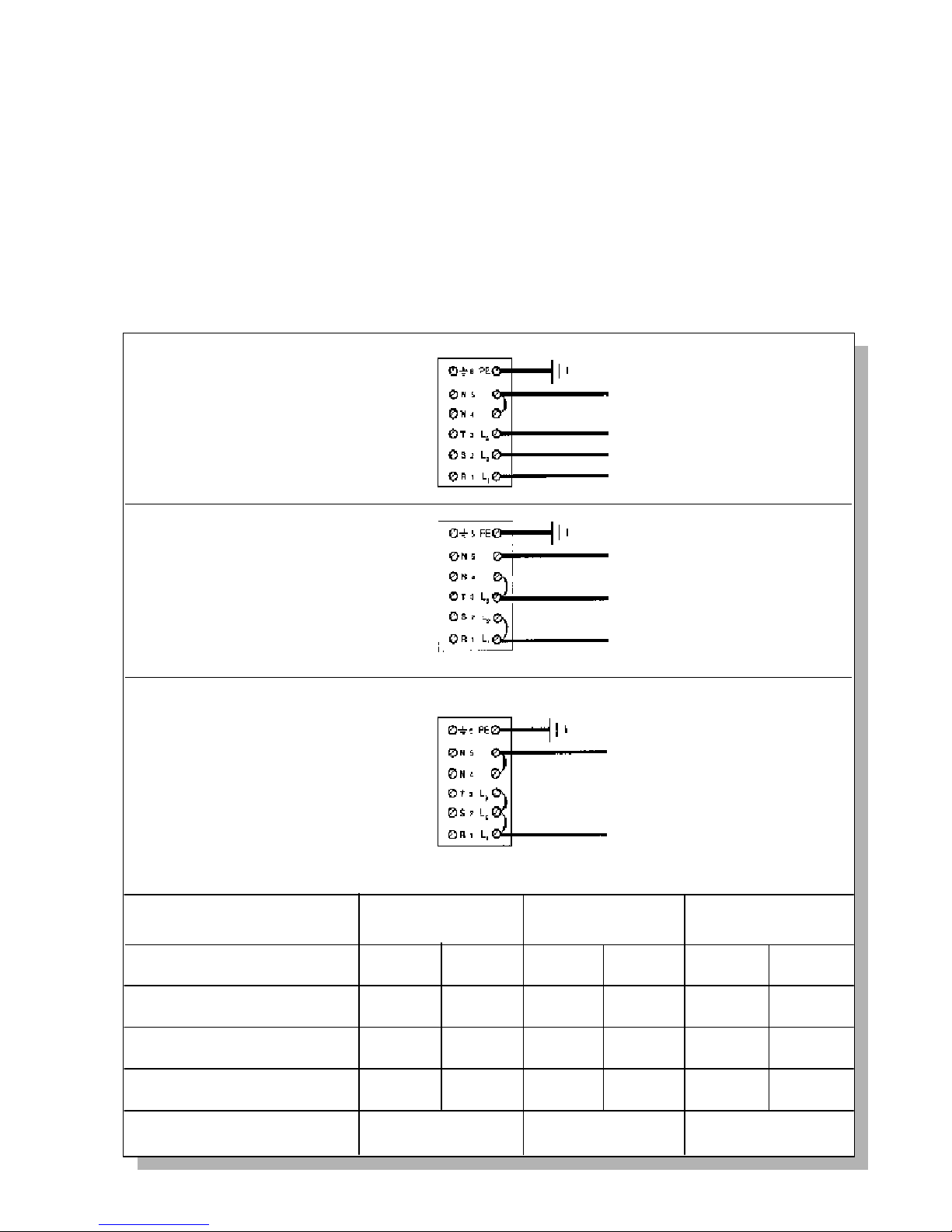

4.5.4 TRANSFORMATION FOR OPERATION WITH DIFFERENT ELECTRICAL

NETWORKS FOR DISTRIBUTION

Equipmentismanufacturedtooperatewiththefollowingvoltagevalues: 3NAC380...415V;3AC220....240VorAC220....240

V50Hz.(in case of60Hz. power supply, requesttheappropriate kit).

If it is to be connected to one of these voltages, proceed as follows:

•Removethe rightpanel.

•Connectthepower supplycabletothe terminal blockaccordingto the mainsvoltage,followingthe wiring diagramandthe

adhesiveconnectionlabel placed neartheterminal block.

Fastenthe cable-clamp firmlyafterinserting a sufficientlengthof cable.

CONNECTIONS TO THE DIFFERENT ELECTRICAL NETWORKS

TYPEOFVOLTAGE

3NAC380...415V50Hz

3AC220...240V50Hz

AC220...240V50Hz

WIRINGDIAGRAM

DRAWING No.

15.2

24.5

41.3

Imax.

A/f No.cables

mm2

MODEL FEM67

FEM67SC

PE (Earth) yellow-green

N (NP) blue

L3 (T) black

L2 (S) black

L1(R) brown

3N AC 380...415 V 50 Hz

PE (Earth) yellow-green

L3(T) blue

L2 (S) black

L1(R) brown

3 AC 220...240 V 50 Hz

PE (Earth) yellow-green

N (NP) blue

L1(R) brown

AC 220...240 V 50 Hz

5x 1.5

4x 2.5

3x 10

FEM107

FEM107SC

11344

FEM207

FEM207SC

11346 12402

Imax.

A/f Imax.

A/f

No.cables

mm2No.cables

mm2

5x 2.5

4x 6

-

5x 6

4x 10

-

24.3

39.9

-

33.0

57.0

-

- 13 -

4.6 OTHER OUTLETS

Fornoreasonmay the food vapourventorwaste water outlet oftheappliancebe closed, blockedorchannelledtogether with

other pipes.

4.7 ROOM VENTILATION

It is necessary to have plenty of air coming into the rooms to take the place of the volume of air expelled through the flues,

approximately 30 m3/h. Air should be introduced into the room without causing any dangerous draughts or being directed

towardsthe operators.Adjust theventilationoutletflapsproperly.Regularlycleantheintakefan,filtersandpipetopreventthe

fans getting clogged. Never use flammable solvents to clean the filters. Periodically check the outlet for any damage or

obstruction.

4.8 PRESENTING THE OVEN TO THE USER

Explain the operation and use of the oven to the user with the aid of the instructions booklet.

Leave the instructions booklet with the user and explain he needs it for further reference.

A technical service and maintenance contract should be recommended for the user.

5.1 USER INSTRUCTIONS: COMMISSIONING

CAUTION: For supervised operation only.

Afterpositioningand connectingtheoven, theinsideis tobecleaned thoroughly.Spraythe insideoftheoven withaspecific

degreasing product (make sure not to use products that can leave residues that smell in the oven). Select the ”convection”

function,a temperatureof 90°Candahumidityof40%,thenoperatetheovenfor 30÷40minutes.Turntheovenoffanddrywith

acloth.

Thecombinedovenbelongstothesecondgenerationofconvectionovens.Itisaconvectionovenandapressurelesssteam oven

combined into one. The steam is generated inside the oven and set in circulation by a powerful fan. Any food can be prepared in

theideal mannerwithasingleoven.Thecombinedovenmaybeusedeverydayforanykindofcooking.Thanks toits numerous

features,itcanbeusedforsteam cooking,gratinating,stewing,browning,grilling,braising,pre-cooking, reheatinganddefrosting.

Utilization:

1) CONVECTIONOVEN:like aconventionaloven, butwiththewell-knownadvantage offorced-ventilation.

2) STEAM OVEN pressureless: to steam-cook, defrost and heat.

3)COMBINED:forall foods thatneedtobe cooked verydifferentlywithout having to changeoven.

Forexample: -steaming and thengrilling

- browning and then steaming

-steamingand latergratinating

- cooking and roasting meat, baking bread and pastries

-steamingat100°C

- second cooking

-slowcooking50/97°C

-boiling,braising androasting

- defrosting and warming up

- defrosting, heating and cooking different products at the same time

CAUTION: Never use coarse salt since it would not dissolve completely.

In the long run, undissolved salt can cause corrosion at contact points.

Lowertemperaturesthan staticovensareused, theymaybe from 20to30°C lowerdependingon the typeoffood tobecooked.

Two cooking cycles are possible to have different temperatures and humidity levels.

Makesurethat the foodisplaced soastoavoid anymodificationofthe balancedaircirculation inside thechamber(max. load

approx.4kg/GN1/1).

The dual speed allows very high performance in the cooking of pastries.

Warning:whenthe ovenishot,open thedoorcautiouslysince theaccumulatedsteamcanscald.

Hotsurfacesoftheoven:door,glassandfront.

5. USE

- 14 -

TAB.1

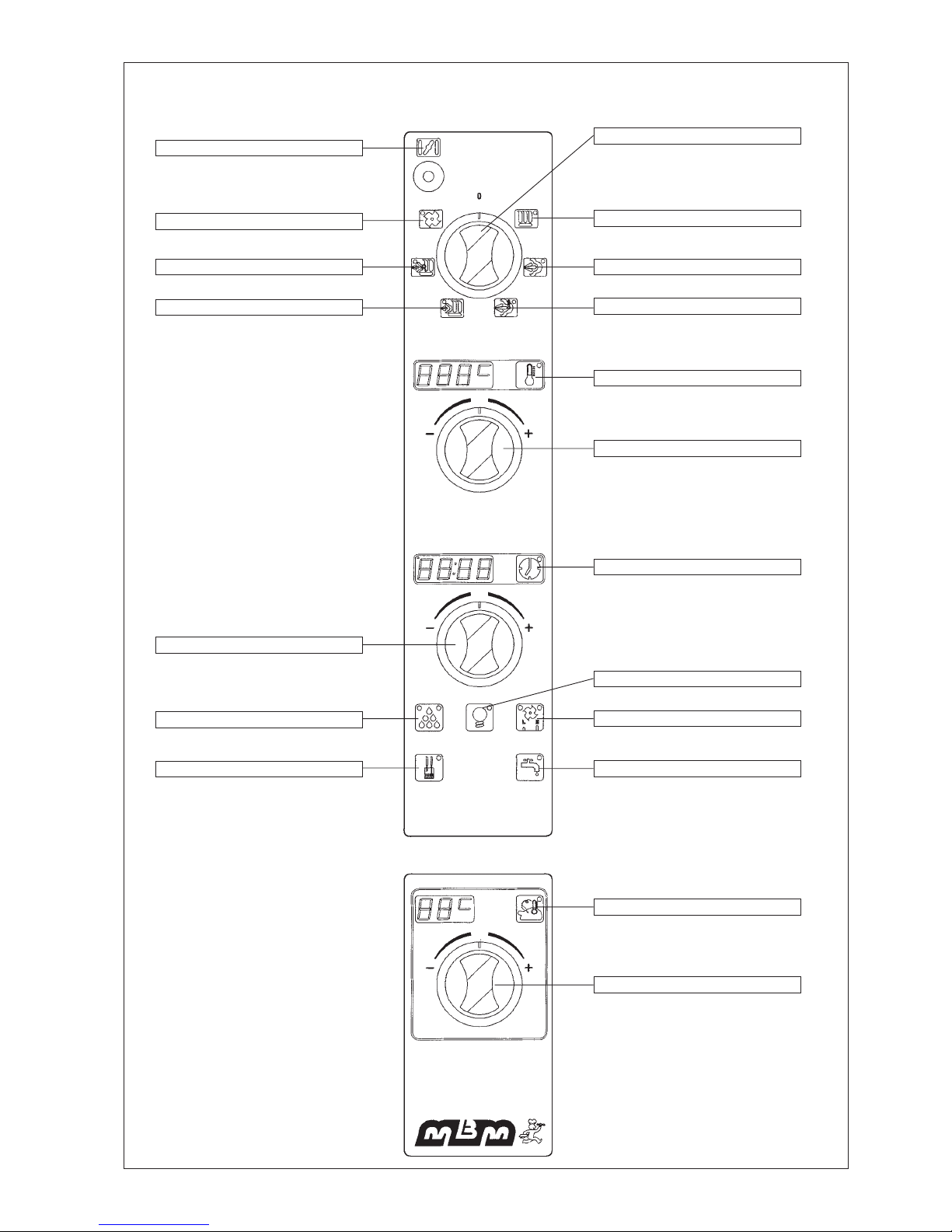

ELECTRONIC COMBINED OVEN INSTRUCTIONS - CONTROL PANEL

- 1 VALVOLA SFIATO -

-7RAFFREDDAMENTOCAMERA-

-6RIGENERAZIONE-

- 5 MISTO -

-11MANOPOLATIMER -

-12UMIDIFICATORE-

-15 LEDSONDE BOILER- - 16SCARICO BOILER-

-17SONDACUORE-

-18 MANOPOLATEMPERATURA-

-14 DOPPIAVENTILAZIONE-

-13 ILLUMINAZIONECAMERA-

-10DISPLAYTIMER-

-19 MANOPOLASELETTORE -

-2CONVEZIONE-

- 3 VAPORE -

-4 VAPORETERMOSTATO-

-8DISPLAYTEMP. CAMERA-

-9 MANOPOLATEMPERATURA-

- 15 -

6. USINGTHEELECTRONICOVEN

6.1 COOKING SELECTION

Theselectionismadebyturningtheselectorontooneofthesixpositionscorrespondingtothedifferentcookingmodes:the

respectiveLEDs(2,3,4,5,6,7)flashand,afterafewseconds,thefunctionisaccepted.Thecontrolpanelthencomesonandthe

ovenispreparedforcooking:theboilerisloadedandthenpre-heatingtakesplace.Itisthereforeadvisabletoturntheselector

at least ten minutes before starting cooking in order to have the oven ready.

CONVECTIONCOOKING

From 20°C to 270°C this is the fastest cooking method. It offers the opportunity of combining different cooking

methods without altering the flavour, thanks to the hot air evenly distributed in the chamber by a fan. Ideal for

roasting,gratinating,toastingandgrilling.

STEAMING100°C

Themainadvantagesofsteamingcomprisemaintainingnutritionvalues,greaterefficiencyandlowerweightloss,

thepossibilityofmultiplecookingandtheconsiderablesavingsinsauces.

THERMOSTATTEDSTEAMING

From50°to99°Citpermitscookingfoodsthathavealreadybeenprocessed,portionedandvacuumpackaged.The

mainadvantagesderivingfromusingthistypeofcookingcompriseprogrammingandthebatchingofwork,longer

preservationofcookedfoods,virtuallynoweight lossandnutritionvaluesaremaintained.

COMBINEDCOOKING

From100°Cto270°C this cookingmodecombinesthebenefits of steamandconvection.Itcan cut cookingtime

downto30%evenfortraditionallydifficultfoodssuchaspotatoes,carrots,etc.Itispossibletosteamfoodsandthen

gratinatethem,orglazethemormakethemcrispy.Combinedcooking,thankstotheintensehumidityandheatof

theair,decreasestheweight loss of traditional dishes (roasts, hams, etc.).

AUTOMATICALLYLOWERINGOVENTEMPERATURE

Ifsteamingor thermostattedsteamingareselected whentheoven isstillhotdue topreviouscookingathightemperature,

waterisinjectedintotheovenandsteamisnotgeneratedsoastoquicklylowerthetemperatureandpreventspoilingproduct

putintoa chamberthatistoohot.

WARMING

This type of heating makes it both possible and cost-effective to warm up refrigerated products. It is done in

combinedmode,160°C,lowspeed.Itisrecommendedtokeeptheventvalve1open.

6.2 COOKING CHAMBER VENT VALVE (1)

Thislevermakesitpossibletoopenandclosethecookingchamberventvalvesoastoadjust theamountofsteam

leavingthecookingchamber.

VENTILATIONTOLOWEROVENTEMPERATURE

Thisisusedtolower the temperatureofthecookingchamberquickly. In thisfunctionthefanturnsalso with the

dooropen:tohavethistype ofoperation,close thedoor,settheventilationfunction,proceedbystartingtheoven,

settingatime,thenopenthedoor.

- 16 -

6.4 OVEN LIGHT (13)

6.5 FAN SPEED (14)

Twospeedsareavailable: a highonefor fast cookingandalow one fordelicatecooking or steaming.TheLEDsat the corners

of the button indicate which speed has been selected.

6.6 OVEN TEMPERATURE (8)

6.7 COOKING TIME AND STARTING THE OVEN (10)

During oven operation, the display 10 shows the time passed. On reaching the set value, the oven stops, emits the end-of-

cooking sound for 1 min. and displays the message “End”.

Tocancelthis message(orto terminatebeforethe end-of-cookingsound),in ordertoset anewcooking time,youneed topress

theclockbutton(10).

In the case of continuous operation, to end cooking you need to zero the cooking time or turn the selector onto Ø.

Payattentionto thesepoints:

1)Ifsteaming,thermostattedsteaming, combined cooking or warming areselected,theovenwill not start until theboilerhas

finished loading, it will stay on standby (in other words as long as LED 16 is on).

2)Inthe100°C steam function,thefan will notturnuntilthe chamber reaches80°C.This makes itpossibletoput the product

inside even when the oven is closed without having any movements of air that can affect the cooking.

3) The oven is equipped with a cooling fan for the internal components. It starts when the oven is switched on and stops

approximatelytenminutes aftertheoven hasstoppedworking.

Button13switchestheovenchamberlightonoroffat anytimeas preferred.

TWIN FAN SPEED

Thisfunctionmakesitpossibletohalvetheamountofair inthecooking chamberasrequiredfordelicatecooking,

whichneedsless airflowwhile ensuringhomogeneouscooking.Thiscontrolthereforemakes itpossibletousea

single oven for two preparations.

Afterselectingthedesiredcookingfunction,display 8 will show a pre-settemperature.Tochangeityouneedto

turnknob9clockwisetoincrease,anticlockwisetodecreaseit.

Duringovenoperation,display8showsthetemperatureinthecookingchamber.

Toseta cookingtimeandstart theovenyouneed toturnknob11:afew secondsafter lettinggo oftheknob,theoven

will start up. Turning the knob clockwise makes it possible to set a cooking time. Whereas, to have continuous

operation you need to turn the knob anticlockwise until the appearanceofCont onthedisplay10.

6.3 HUMIDIFIER (12)

Caution:Inthesteaming,thermostattedsteamingandcombinedcookingmodes,thehumidifierisdisabledsoitisnotpossible

to add more water into the chamber when the boiler is already in operation.

Itispossible toadjustthe percentageofmoistureinthecookingchamber. Itisessentialtoobtainproductswith a

lowmoisturecontent,suchasbread,biscuitsandcakes, soft items.

Thehumidifierisalsousedtopreventroastsfromburningorlosingalotoftheirliquid.Pressingthisbuttononce

(leftLEDon)introducesapproximately 4l/hofwater.Pressing itagain (rightLEDon)introduceswater continuously

(approximately18l/h). Toswitchoff thehumidifier,press thebuttonagain (LEDsoff).

- 17 -

Duringoperationwiththecoreprobe,theminutecounterwillinanycasedisplaythetimepassed.

Theinnerprobeonlystopscookingonreachingthetemperatureinsidethefoodpre-setonthespecific display.

Thetemperaturerangethatcanbeadjustedinthe displayis20°C -99°C.

Caution: It is anyhow always necessary to set the temperature and cooking process (e.g. convection, steam, combined or

convectionwith humidification)in thecookingchamber.If99°CisexceededthedisplaywillshowOvl(Overflow).Attheendof

cookingwiththe core probe,cook& hold triggersautomatically(see par.6.9).

If at the start of cooking the core probe is hot because of pre-heating the oven (when the core probe was in the cooking

chamber),display 18will flashuntil theactual temperatureofthefoodisdisplayed;onlythenwillcookingcommence.

Tocookwiththecoreprobe,firstofall turn the selector onto one ofthefunctions.Pressingthispush-buttonwill

light up the core probe temperature display, showing a set temperature, and the minute counter display will be

deactivated.Setthe desiredcoretemperaturewithknob18.A fewsecondsafterlettinggoofthe knobtheoven will

startandthetemperatureinsidethefoodwillbedisplayed.

6.8 CORE PROBE (Only for models -SC)

For many foods (for instance roast-beef, pâté, fatty roasted meat, etc.) the temperature inside the product is very important.

Withtheinnerprobe, it ispossibleto switch offtheovenat the righttime,that is whenthedesiredtemperature (previously set

on display 17) has been reached.

You do not need to set the cooking time because, by setting the temperature on the thermostat of the ”inner probe”, the timer

isautomaticallyexcluded.

The thermostat shows the temperature inside the product.

Thecookingtime isobtainedfromthe”inner probe”thermostat.You canusethe ”innerprobe”cookingprocesstogether with

alltheother cooking processes(forinstance, steaming, convectioncooking,mixed cooking andsoon).

Here is a table giving the temperature to set:

Inner temperature °C Application

40÷45 Rawmeat

45÷50 Raremeat

50÷70 Redmeat

75÷95 Well-donemeat

- Insert the probe into the most representative piece.

-Placethe piece ofmeatcontainingthe core probeinthe geometrical centreofthe cooking chamber.

- Make sure that the probe tip is as much in the centre of the piece to be cooked as possible.

6.9 COOK & HOLD

Cook & hold is only activated in the core probe cycle. At the end of cooking, the product is kept hot without its temperature

fallingunder 70°Candtherebyexcludingtheriskofbacteriaspreading.

At the end of cooking with the core probe, the oven automatically goes onto hold, shown on display 10 with the flashing

message Hold. If after ten minutes the oven is not switched off and the product taken out, the holding process shown by the

steady message Hold commences. Pressing the clock button (10) displays the time passed since the start of holding. During

holdingtheoven automaticallyheatsup if thecoretemperature fallsunder70°C.

To end holding, you need to turn the selector onto Ø.

6.10 DISPLAYING AND MODIFYING COOKING PARAMETERS (8, 10, 17)

DISPLAY:Justpressoneof thebuttons8,10,17 (LEDon)andtherelevant displayswillshowthechamber temperatureandthe

settimeor thesetcoretemperature. Waitfora few sec.andthe displayswillgo back toshowingthe chambertemperature,time

passed or core temperature (LED off).

CHANGE.While theovenisoperating,tochangethesettemperatureortimeorcore temperature,you needtopresstherelevant

button (LED on) and turn the knob: after a few seconds the new parameter will be accepted (LED off).

- 18 -

6.11 DRAINING THE BOILER (16)

Caution: After manually draining the boiler you need to switch off the control panel selector on Ø; otherwise, the boiler will

no longer be loaded. Afterwards, switching the control panel back on, turning the selector, the valve will automatically close

and the boiler will start loading.

AUTOMATIC BOILER DRAINING + WASHING

After approximately 5 hours of the oven not working, the boiler is automatically drained and rinsed with a second load and

a second draining.

Caution: For the oven to do this, you need to leave the multi-polar switch on and the water shut-off valves upstream from the

oven open.

6.12 MESSAGES AND ALARMS

Service messages

Door : door open

Cont : continuous operation

Hold flashing: waiting to hold

Hold steady: holding in process

End : cooking has ended.

Alarm messages

H20 : Not enough water in the boiler. See if the water valve is shut or if there is no water in the supply network.

To cancel the message and restart loading the boiler, press the clock button (10).

P1 no : Chamber temperature sensor broken or disconnected.

P2 no : Core probe broken or disconnected (it is still possible to continue using the oven without the core probe).

P3 no : Boiler pre-heating probe disconnected.

IMPORTANT: In the case of the last three messages, it is recommended to call a technician to restore normal conditions.

Button16makesitpossibletodraintheboilermanually(onlywhentheovenisnotinoperation).WhentheLED

ison,thevalveisopen,whenitis off,thevalve isshut.

7.1 CLEANING

CAUTION:

Neverwashthe outsideofthe ovenwithdirectorhigh-pressurejetsof waterasthiswoulddamagetheelectriccomponentsinside.

The oven needs cleaning every day as a matter of hygiene and to prevent its operation getting impaired over time.

7.1.1 CLEANING AFTER COOKING AND AT THE END OF THE DAY

Use a specific degreasing product to clean the oven (do not use corrosive or chlorine-based detergents). It is recommended to

follow the detergent manufacturer’s directions.

1) Carry out the cleaning program as described in par. 6.5.

2) Then open the oven and wipe it with a damp cloth

or dry it with hot air at 100°C.

3) Take out the filter and the removable parts and wash them

fully open.

4) Rinse the oven and accessories with water, possibly

using the external handshower (optional on all

versions).

5) Dust the door gasket regularly with talcum powder,

at least once a week.

6) See that the outlet is cleaned regularly and

check it is clear.

FEM207-FEM207SC

7. CLEANING AND MAINTENANCE

- 19 -

7.1.3 TROUBLESHOOTING

THE OVEN DOES NOT COOK EVENLY

* The products to cook have been pressed too close to each other.

You should always check there is good air circulation between the products.

YOUR PRODUCT IS DRY AND IS UNFIT FOR CONSUMPTION

* Check whether the humidifier is working and whether the temperature is the right one for your product.

7.2 MAINTENANCE

Before doing any maintenance work you must cut off the electricity and water supplies to the oven.

All the oven components, being subject to wear, are easy to reach from the right-hand side.

7.2.1 REPLACING COMPONENTS

CAUTION: Have this done by a skilled technician only!

Disconnect the electricity and water supplies.

Follow the wiring diagram.

A) Electric components and electronic card

All the electric components and the electronic card are on the right-hand side of the oven.

In order to replace them, you therefore need to take off the right-hand side panel.

This is why the oven should be installed with sufficient clearance on the right-hand side.

B) Resistor

To replace the resistor:

- Remove the rear panel.

- Open the screen inside the oven.

- Detach all the wires.

- Remove the resistors.

- Fit it all back together in reverse order to the above

and using the wiring diagram.

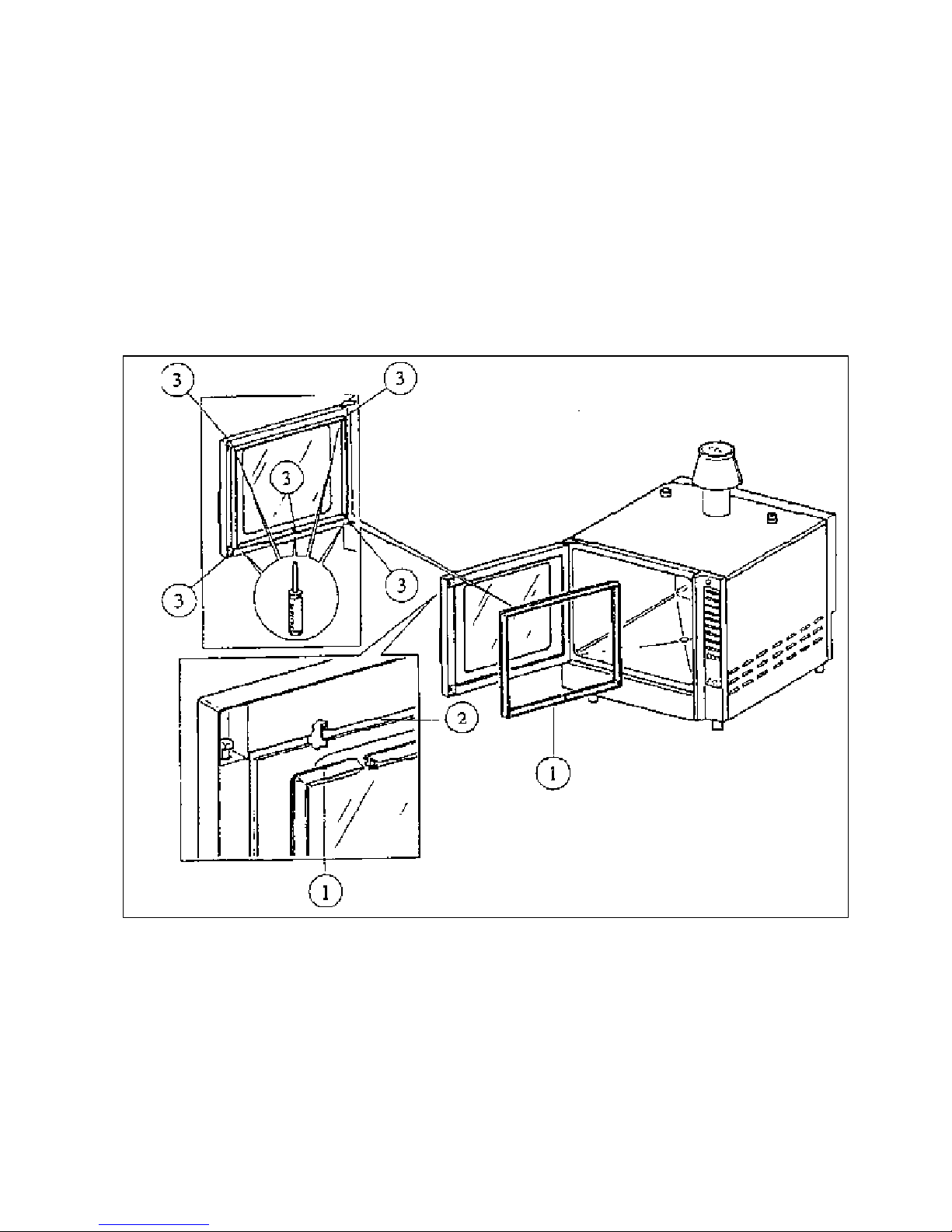

C) Oven lamp Tab.3

- Remove both screws (1).

- Remove the frame (2) with glass (3).

N.B. Check that the silicone rubber gasket is not damaged.

- Replace the oven lamp (4).

- Fit it all back together in reverse order to the above.

7.1.2 DESCALING THE BOILER

Every 7 - 15 days it is advisable to carry out descaling.

- Drain the boiler by pressing the

button then close it again.

-Prepare asolutionofdescalingliquidfollowing

the manufacturer’s directions.

Quantityofdilutedsolution:

FEM67=4l

FEM107=5.5l

FEM207=5.5l

- Lift the cap 1 (Tab.7) and pour the solution into the boiler.

-Operatethe ovenwiththe steamfunctionfor approximately

2-3minutestopre-heatthe solution.

-Lettheliquidact approximately10'then drainthegenerator.

- Switch the control panel off and back on again by turning the

selector so as to load the boiler. When loaded, drain it again.

N.B. For the steam generator to function properly

the water softener requires thorough maintenance

in order to avoid scale. TAB. 7

- 20 -

D)OvendoorgasketTab.8

- Take the gasket out of its seat.

- Clean the seat of the gasket of all

trace of dirt.

- Place the new gasket in its seat (2),

seal the 4 corners with a silicone-based

mastic.

E) Cleaningsolenoidvalvefilters

-Removethe rearpanel.

- Remove the water supply pipe.

- Take out the filter and wash it thoroughly.

-Fititallbacktogether.

TAB. 8

7.2.2 YEARLY MAINTENANCE

This is only to be done by an authorized, skilled technician!

1) Check the seal of the door gasket.

2) Check the seal of the gaskets of the door double-glazing.

3) Check the seal of the lamp-holder glass gasket.

4) Removing and thoroughly cleaning the fan. Open the screen by pushing on the pins and turning them through 90°C.

Remove the fan and clean it thoroughly (left-hand nut).

Fit the screen back on, putting the pins back in their original positions and pushing them

fully in so you hear them click home.

5) It is also recommended to oil the seal of the driving pin passage.

6) Descale the probes, taking care not to swap the wires over.

This manual suits for next models

5

Table of contents

Other FORNI Oven manuals

Popular Oven manuals by other brands

Bakers Pride

Bakers Pride EP-2-2828 Single Installation and operating instructions

Capital

Capital Maestro Series MWOV301ES installation instructions

Bosch

Bosch HBF113B 0Q Series User manual and installation instructions

Wolf

Wolf Wall Oven-2 Series Technical & service manual

AEG

AEG BSE792280M user manual

Mono

Mono Artisan Mini Deck Installation and operation manual