Fortex RF100 User manual

Fortex Engineering Ltd, Unit 16, Freeman Road, Lincoln, LN6 9AP, United Kingdom

www.fortex.co.uk s[email protected] +44(0)1522 718 168

RF100 CONVECTION REFLOW

OVEN

Fortex Engineering Ltd, Unit 16, Freeman Road, Lincoln, LN6 9AP, United Kingdom

www.fortex.co.uk s[email protected] +44(0)1522 718 168

Tabel of Content

Prospect .................................................................................................................................... 3

Technical Data ............................................................................................................................. 3

Intended Use of Machine .......................................................................................................... 4

Safety Regulations .................................................................................................................... 4

Scope of delivery ....................................................................................................................... 6

Installation ................................................................................................................................. 6

Overview ................................................................................................................................... 7

Description of the function keys ................................................................................................. 7

The temperature curve ............................................................................................................. 8

Setting of Parameters ................................................................................................................ 9

Reflow-Process ....................................................................................................................... 12

Characteristics of soldering alloys ........................................................................................... 13

Temperature curve parameters ................................................................................................ 14

Cleaning and Maintenance ...................................................................................................... 14

Error message ......................................................................................................................... 15

Spare Parts and Options ......................................................................................................... 15

Guarantee ............................................................................................................................... 15

Disclaimer of Warranty ............................................................................................................ 15

Copyright ................................................................................................................................. 16

Fortex Engineering Ltd, Unit 16, Freeman Road, Lincoln, LN6 9AP, United Kingdom

www.fortex.co.uk s[email protected] +44(0)1522 718 168

Prospect

The RF100 is a stylish, practical reflow oven for manufacturing and reworking of SMT

products. The oven has a large display. The intuitive menu navigation is controlled by a

membrane keyboard. The product uses highly efficient infrared heating elements and has

several thermocouple temperature gauges. Due to this and the precise evaluation in the

microprocessor, the temperature curve of the reflow process is highly accurate and the

temperature in the respective reflow sections very uniform.

With the RF100 all common alloys can be processed. The oven has an automatic error

detection with alarm.

This product has a variety of applications such as reflow soldering, repairing, drying and so

on. It is suitable for SMT small series, for research and development of electronic products,

school, education and study. The operating system software is in English.

The stove is well insulated by a special Aluminium silicate cotton, which reduces energy

consumption, protects the circuit and allows optimal operation and keeps the temperature in

the furnace constant.

Technical Data

Power connection 200 – 230 VAC. / 50-60Hz

Max. Power Consumption 2400 W

Max. PCB-Board Size 350 x 300 mm

Time Settings 00:00 – 99:59 sec.

Temperature 60 -300 °C

Setting Options 5 Phases adjustable in time and temperature:

Preheat

Heat

Soldering

Holding

Cool down

Working Mode Automatic Reflow-Soldering

Permanent Heating or Drying function

Option to store 4 different Reflow profiles

Interface Graphic display with Keyboard

automatic Alarm function

Display of Process progress

Heat up Time ca. 8 min

Extraction Sheet metal outer diameter 101,5 mm inner 99,5 mm, internal ventilator with 84

cfm

Dimensions (LxWxH) (mm) 504 x 500 x 314 mm

Weight +/- 28 kg

Technical Changes reserved

Fortex Engineering Ltd, Unit 16, Freeman Road, Lincoln, LN6 9AP, United Kingdom

www.fortex.co.uk s[email protected] +44(0)1522 718 168

Intended Use of Machine

The RF100 is a soldering furnace for SMD components and also designed for lead-free

soldering processes.

All other applications require our written consent or at the user's own risk.

Safety Regulations

IMPORTANT SAFETY INSTRUCTIONS FOR THE FORCED CONVECTION OVEN

Generally

Please read the following text carefully and pay particular attention to the instructions on

safety at work and on commissioning.

Please keep this manual at a safe place. It contains instructions that are also important

for later maintenance or cleaning work.

The machines are not intended for integration or interconnection with other machines or

equipment. They may only be operated in rooms equipped for this purpose and operated

only by qualified specialist personnel (soldering skills). Children and pets are to be kept

away!

Do not use the oven if it is damaged or does not work properly.

Avoid strong shocks and collisions. This could damage the glass heating rods. If the

glass heating elements are damaged, switch off the machine immediately and replace

with original glass heating rods.

Do not run the oven unattended !

Site

The oven must be level and dry and there must be enough space around the oven for

service and maintenance (about 1m on all sides). Do not use this device outdoors! The

table must be able to carry a weight of at least 30 kg. The oven should be used at normal

room temperatures of 15 to 25 degrees.

It is not allowed and even dangerous to install the oven in a cabinet or box. Do not install

this unit near a heating element or stove, even in a damp environment.

Electricity

The machine is manufactured using tested parts according to the usual electrical safety

regulations. However, this does not relieve the user of his duty of care when handling

electrically operated devices.

The main switch disconnects the machine from the power supply. The protection of the

circuit and the fault circuit must be carried out by the customer (13A).

After completion of work, the main switch should always be switched off.

Before carrying out any work on the machine (cleaning, etc.), switch off the machine and

pull out the mains plug. The power outlet should be near the machine and accessible so

that the plug can be pulled quickly in an emergency. This stove must have its own socket,

which may only be used by this stove.

High voltage - the housing may only be opened by qualified persons. High voltages can

cause death or serious injury.

Keep the plug and power cord away from liquid. Avoid liquids entering through the door

or through the ventilation grilles.

Should this nevertheless happen once:

Immediately switch off the oven and unplug the appliance from the socket.

In case of damage, the power cord may only be replaced by qualified persons.

Fortex Engineering Ltd, Unit 16, Freeman Road, Lincoln, LN6 9AP, United Kingdom

www.fortex.co.uk s[email protected] +44(0)1522 718 168

Danger of fire and burns

During operation, the stove becomes hot and it must therefore only be operated under

supervision. Long heating times and high heating temperatures can lead to overheating

of the stove, which in turn may cause fire.

When placing PCBs into the oven or removing them, wear suitable gloves or use

fireproof equipment.

If the stove generates too much smoke, pull the plug and close the door. That stifles the

flames.

Do not place flammable materials in the vicinity or on the reflow oven.

Do not block the ventilation grilles.

Do not touch the cover of the stove, it can be very hot and you risk severe skin burns.

Do not place flammable, explosive or other hazardous substances near the reflow oven.

Do not dry objects that emit flammable and explosive gases!

Never set a temperature higher than 300 ° C! The stove is not designed for that and

could be damaged. We exclude a guarantee for this!

Exhaust

Use the oven only in well-ventilated areas. Follow the safety rules of the solder paste and

adhesive suppliers. During the soldering process gases can arise. These gases may

endanger your health. We recommend the use of a hood or an alternative extractor

option!

1. Check the proper function of the stove using the following checklist:

2. Check the drawer. The drawer must not be kinked or damaged. Do not use the

oven if something is stuck between the lock and the ceiling. If the drawer is

damaged, do not use the oven

3. Check the seal for damage

4. Check if the oven room is free of dents.

5. Check the power cord, plug and socket for damage.

Maintenance

Clean the oven regularly. A dirty stove can lead to dangerous situations.

Do not insert wire or other foreign objects into the air inlet and outlet to avoid burns or

damage to ventilation and heat.

Do not wash the machine directly with water in order not to affect the insulation

performance of the machine.

Note: The oven temperature is measured from the air in the upper area of the heating

compartment. The temperature on the workpiece can vary due to radiation, conduction

and reflection. For sensitive materials, we recommend test runs to determine the optimal

process parameters. Different measuring devices may be recommended.

Fortex Engineering Ltd, Unit 16, Freeman Road, Lincoln, LN6 9AP, United Kingdom

www.fortex.co.uk s[email protected] +44(0)1522 718 168

Scope of delivery

• Reflow-Oven RF100

• Foil tube D100 x 1.5 x 2 m for Exhaust

• Hose clamp

• This manual

Installation

Takeover from transport companies

After receiving and unpacking the machine, check for possible transport damage. In case

of transport damage, please inform your insurance company, the carrier and the

manufacturer / supplier.

Site

The oven must be level and around the machine there must be sufficient space for

operation and maintenance (about 1 m on all sides). When setting up the machine,

observe all safety prevention regulations and other local regulations.

The oven should be set up on a well accessible table. The surface must be level and

heat resistant and be able to carry at least a load of 30 kg.

Install the device near exhaust vent. For the connection between the stove and the vent,

use the supplied Aluminium foil pipe D100.

Make sure the power supply is correctly protected (13A) and residual current protection.

The outlet height of the exhaust air should be about 1m above the machine to use the

chimney effect.

Do not place any other objects on the device, especially no flammable liquids, such as:

As water, hot water, alcohol, methanol, gasoline.

The machine can be cleaned in the cooled state. Wipe the inside of the machine with a

dishcloth. You can use some rinse water or anhydrous alcohol. Do not switch on the

machine until it is completely dry.

At the beginning of operation, odours may occur during operation. This is a normal

phenomenon. After a while, this kind of smell disappears.

When not in use, turn off the main switch and unplug the power cord

If you are not going to use the device for a long time, you should take it out, pack it and

put it back in the original container in order to avoid moisture damage.

If you want to solder small PCB or FPC board pieces, use a high temperature mica

board. Leave at least 30 mm space between the boards on four sides to ensure uniform

heating.

The manufacturer's specifications in the menu are only clues. Use tests to determine the

optimal parameters for your application. Temperature-sensitive precision devices such

as LED, s laser head, micro connectors, soft packages, ICs or similar. Can be soldered

by gently lowering the temperature while lengthening the times.

For components that can withstand high temperatures, you can increase the soldering

temperature accordingly to shorten the reflow soldering time.

Fortex Engineering Ltd, Unit 16, Freeman Road, Lincoln, LN6 9AP, United Kingdom

www.fortex.co.uk s[email protected] +44(0)1522 718 168

Overview

Description of the function keys

There are 5 buttons on the front panel of the unit: POWER, UP, DOWN, SET, and RUN,

with the RUN and SET buttons being multifunction buttons. Depending on the dialog,

there are various commands above the keys that are activated by pressing the keys.

Fortex Engineering Ltd, Unit 16, Freeman Road, Lincoln, LN6 9AP, United Kingdom

www.fortex.co.uk s[email protected] +44(0)1522 718 168

The temperature curve

In the SMT production process, the temperature curve must be adapted to different alloy

compositions of solder paste. This temperature curve is one of the most important

parameters to ensure product quality. A standard reflow process typically has five

temperature zones. For this reason, you can define 5 temperature zones in the RF100

software to map the standard reflow process.

Each temperature plane with the appropriate temperature and time performs another

function during the soldering process. The requirement and function of each temperature

section are explained below.

Preheating (READY)

Here, the circuit board is heated from room temperature to 120-150°C to remove residual

moisture or residual gas and possibly reduce internal stress in the circuit board. It also

achieves a smooth transition to the next section. The duration is usually 1 - 5 minutes.

The specific time and temperature depends on the size of the board and the number of

components.

Heating up (HEAT)

Here, the preheated circuit board is further heated until the flux contained in the solder

paste becomes liquid. The flux removes oxides of tin paste and component.

Usually the following temperatures are set in this section:

Lead alloy solder and precious metal alloy solder (Sn 42% -Bi58% lead-free or

Sn43% -Pb43% -Bi14% lead containing low-temperature solder)

150 – 180°C

Lead-containing medium temperature solder 180 – 220°C

Lead-free high-temperature solder 220 – 250°C

Fortex Engineering Ltd, Unit 16, Freeman Road, Lincoln, LN6 9AP, United Kingdom

www.fortex.co.uk s[email protected] +44(0)1522 718 168

Soldering (WELD)

Here the reflow process is basically completed. Since the highest temperature is used

here, temperature-sensitive components can easily be damaged. The physical and

chemical changes within the solder paste are the biggest here and the molten solder can

easily oxidise by air in combination with high temperature. The settings of this stage are

based primarily on the data of tin pastes.

Solder pastes are usually classified into low temperature solder pastes (150-180°C),

medium temperature solder pastes (190-220°C) and high temperature solder pastes

(230-260°C).

The lead-free solder used today is a high-temperature solder.

Lead-free low-temperature solder paste usually contains precious metals. Leaded low

temperature solder paste is rarely used and then for special applications. Lead solder

has excellent electrical, physical and mechanical properties, e.g. Temperature change

and oxidation resistance.

In this phase, the solder should be liquid so that the components will float and

automatically center and align with the surface tension of the liquid solder. In addition, 2

intermetallic phases are formed between the circuit board and component, in which the

tin mixes with the copper of the circuit board and the metal of the component and forms

the ideal brazing structure.

The soldering time is usually about 10-30 s. Larger boards and circuit boards with

components that form large soldering shadows require a longer soldering time.

Generally, the soldering time should be kept as long as necessary and as short as

possible so as not to expose the components to unnecessary thermal stress, which can

lead to component malfunction.

Hold time (HOLD)

The holding time plays a role especially for high temperature solders. When high

temperature solder paste rapidly cools, the tin forms very coarse crystals with

undesirable mechanical and physical properties.

At high temperatures and mechanical effects, the welding spots may easily tear off and

lose the mechanical and electrical connection function, thereby reducing the durability of

the product.

By the holding time, the solidification occurs slowly and it form fine crystals.

The temperature is generally set 10-20 ° C lower than the solder melting point.

Cooling time (COOL)

Here the oven is no longer heated and the natural cooling accelerated by a fan. In

principle, you can remove the printed circuit boards when the temperature has fallen

below 150 ° C. Please use tools and personal protective equipment to avoid burns.

Annotation

In general, the soldering temperatures are set as low as possible, so that the

components as well as the printed circuit board are not damaged by thermal stress.

The temperature can also be lowered by extending the reflow time accordingly. This is

advantageous for protecting heat sensitive components, connectors and connectors.

Setting of Parameters

In general, the parameters are set during commissioning and each time the requirements

change due to other materials, components or solder pastes.

Start

Fortex Engineering Ltd, Unit 16, Freeman Road, Lincoln, LN6 9AP, United Kingdom

www.fortex.co.uk s[email protected] +44(0)1522 718 168

Turn on the main power switch on the back of the unit and the indicator light in the upper

left of the screen lights up in green. If you press the red ON-OFF button, the display on

the picture below will show USE, WELD and CONST.

Soldering Mode (WELD)

Preliminary note: the temperature and time settings in the

delivery condition of the stove are only indicative. The

parameters suitable for your application must be determined

by test soldering. Please also refer to the information

provided by the solder paste manufacturer.

After pressing ON-OFF, WELD is highlighted. Press RUN to

display the dialogue as shown in the picture on the left.

RUN starts the cycle, the indicator light in the upper left

corner of the display turns red and the oven starts to heat up.

The soldering cycle will be explained later. Here we first

explain the setting options.

If you press SET instead of RUN, then READY (pre-heat-phase) will be highlighted. Use

the arrow keys to change the text to HEAT, WELD, HOLD or COOL. Stay on READY

and press SET. The marking jumps to TEMP (temperature) and you can adjust the

temperature between 70 and 130°C with the arrow keys. Another press on SET and you

can change the time between 00:00 and 99:99 (minutes: seconds).

Button SET takes you back to READY and here you can use the arrow keys to go e.g. to

HEAT to set the parameters for the heating phase. Press SET to go to the temperature

settings and use the arrow keys to set values between 120 and 300°C. Another SET

takes you to the time setting for the heating phase.

Back to HEAT, press arrow down to get to the actual soldering phase. WELD is marked

and with SET you can change the temperature again between 120 and 300 ° C and set

the time with another SET.

For HOLD, the holding time, the same applies, but the temperatures can only be

adjusted between 70 and 230 ° C here.

When you have finally arrived at COOL, the cooling phase, you can only set the

temperature between 70 and 200 ° C here. A time is not set in section COOL, but a

signal terminates the entire soldering cycle when the set temperature is reached.

Fortex Engineering Ltd, Unit 16, Freeman Road, Lincoln, LN6 9AP, United Kingdom

www.fortex.co.uk s[email protected] +44(0)1522 718 168

To exit the WELD dialogue, press ON-OFF.

Permanent heating mode

In the main menu, you can use the arrow keys to switch

between USE, WELD and CONST. Highlight CONST and

press RUN. The dialogue on the left side appears.

With RUN you switch on the heating, the control light turns

red and the oven heats up to the set temperature (= SET

TEMP). The current temperature is displayed to the left. At the

same time the display changes RUN upwards and STOP

downwards, so that you can end the heating process at any

time by pressing the green RUN button. In this case, RUN

returns to the bottom of the display and STOP to the top and you can restart heating by

pressing the RUN key.

When the set temperature is reached, the indicator changes to green and the oven keeps

the temperature.

Saving custom temperature profiles

The RF100 oven allows you to store and recall 4 different

temperature curves.

Select USE in the main dialogue and press RUN. On the now

appearing dialogue, you can see Use curve 1 with the

currently set temperature curve.

RUN selects this temperature curve and using the arrow keys

you can toggle between the 4 possible curves.

With SET, the word READY appears below the selected curve

and the word ESC above the RUN key. Here you can change the temperature curve 1

now.

With RUN you leave the setting mode and with the arrow keys you switch back and forth

between READY, HEAT, WELD, HOLD and COOL in the mode Soldering (WELD).

Pressing SET jumps to the temperature first and, if you press again, to the time. All

settings can now be made as explained in the chapter Soldering Mode (WELD).

Pressing RUN quits the insert mode and the settings are saved.

Above the RUN key, the word SEL appears for Select. If you now press RUN, then user

curve 1 will be selected. Attention! If you have previously made settings in the WELD

dialogue, they will now be overwritten

Fortex Engineering Ltd, Unit 16, Freeman Road, Lincoln, LN6 9AP, United Kingdom

www.fortex.co.uk s[email protected] +44(0)1522 718 168

Reflow-Process

When the adjustment is complete and all safety precautions

have been taken, place the board with the components in the

middle of the drawer and slide the drawer closed.

Highlight WELD in the main menu and press the "RUN" key

to enter the soldering menu.

If you press RUN again, the cycle starts. ON is marked and

the current oven temperature is displayed. The indicator will

turn red to indicate a heating process. In this case the

heating process for the preheat phase (READY). The

temperature rises in the display.

When the temperature reaches the set value, the indicator

turns green and starts counting down the preset time. The

indicator light may also flicker in the transitional phase. If the

temperature is set above 5°C, the fan will switch on to lower

the temperature. Temperature and the power indicator on the

top panel will flash at this time.

At the end of the countdown, the HEAT phase begins.

Control light switches back to red, the heating starts,

temperature rises. When the temperature is reached, the

indicator goes green and the next countdown starts.

If you want to stop the soldering process, you can do this at any time by pressing SET.

After HEAT, the soldering phase WELD starts, then the holding time HOLD and then

automatically follows the cooling phase COOL. The fan turns on and a timer shows the

elapsed cooling time.

When the set cooling temperature is reached, the warning light goes out and a buzzer

sounds.

The message END appears on the display. For safety reasons, the fan will continue to

operate until the temperature has dropped to 80 ° C.

Fortex Engineering Ltd, Unit 16, Freeman Road, Lincoln, LN6 9AP, United Kingdom

www.fortex.co.uk s[email protected] +44(0)1522 718 168

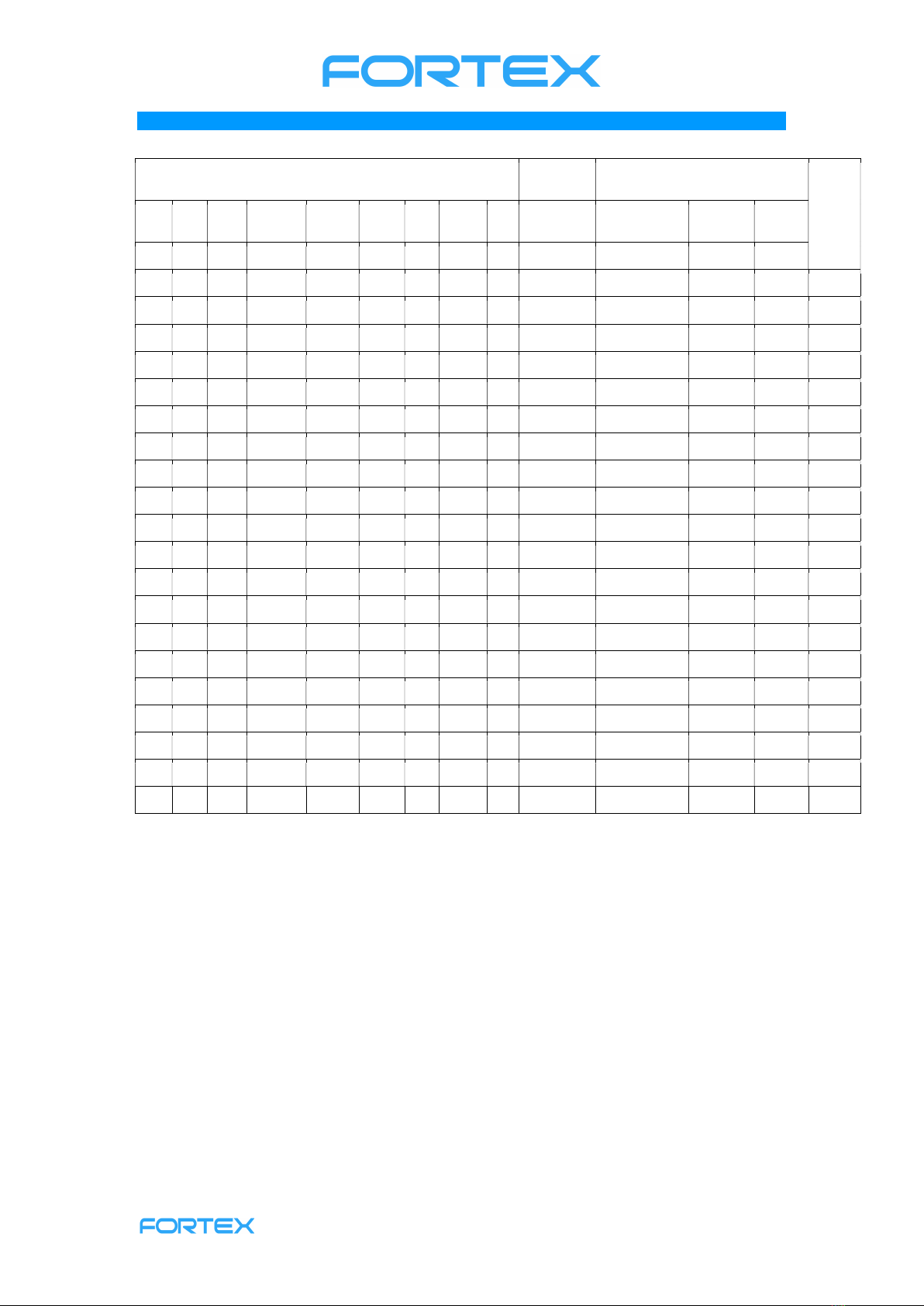

Characteristics of soldering alloys

Filler metal Melting

point

Mechanical Properties Condu

ctivity

Tin Lea

d

Silve

r

Antimon

y

Bismut

h

Indiu

m

Gol

d

Coppe

r

Zin

c

Liquid line Tensile

strength

Elongatio

n

Hardne

ss

Sn Pb Ag Sb Bi In Au Cu Zn (°C) (Mpa) (%) (HB)

63 37 183 61 45 16.6 11

60 40 183 60 43 16.4 11

10 90 299 41 45 12.7 8.2

5 95 312 30 46 12 7.8

63 36 2 179 64 39 16.5 11.3

1 97.5

2.5 309 31 50 9.5 7.2

96.5

3.5 221 45 55 13 13.4

97.5

2.5 304 30 52 9 8.8

95 5 245 40 38 13.3 11.9

43 43 14 163 55 57 14 8

42 80 138 77 20-30 19.3 5

48 52 117 11 83 5 11.7

15 5 80 157 17 58 5 13

20 80 280 28 - 118 75

96.5

3.5 21 20 73 40 14

87 3 7 7 3 21 45 60 14 9

91 9 199

95.7

3.1 1.5 217

99.3

0.7 227

95 5 240

Fortex Engineering Ltd, Unit 16, Freeman Road, Lincoln, LN6 9AP, United Kingdom

www.fortex.co.uk s[email protected] +44(0)1522 718 168

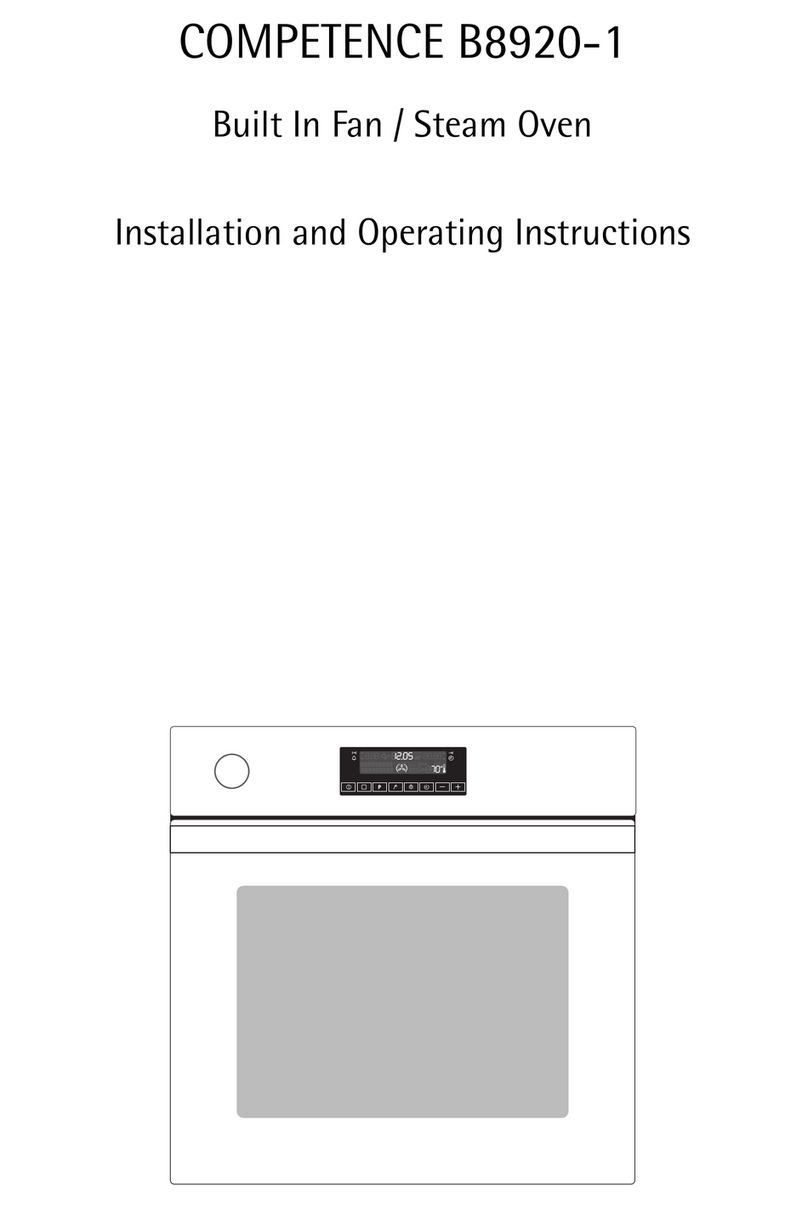

Temperature curve parameters

Type of filler Formula

proportion

Pre-Heat

Temperature

range (°C)

Heat

Temperature

range (°C)

Solder

Temperature

range (°C)

Hold

Temperature

range(°C)

Cool

Temperature

range (°C)

Lead cypogenic

material Sn43-Pb43-Bi14

100-120 130-150 200-210 170 150

Lead-free low

cypogenic

material

SN42-Bi58 100-120 120-130 180-200 150 150

Lead-free low

cypogenic

material

Sn48-In52 100-120 120-130 180-200 150 150

Lead cypogenic

material Sn63-Pb37 130-150 170-180 230-240 180 150

Lead cypogenic

material Sn60-Pb40 130-150 170-180 230-240 180 150

Lead cypogenic

material Sn62-Pb46-Ag2 130-150 170-180 230-240 180 150

Lead-free low

cypogenic

material

Sn96.5-Ag3.5 130-150 180-190 240-250 240 150

Lead-free low

cypogenic

material

Sn87-Ag3-Cu3-

In7 130-150 180-190 240-250 240 150

Lead-free low

cypogenic

material

Sn91-Zn9 130-150 180-190 240-250 230 150

Lead-free low

cypogenic

material

Sn95.4-Ag3.1-

Cn1.5 130-150 180-190 250-260 240 150

Lead-free low

cypogenic

material

Sn99.3-Cu0.7 130-150 180-190 270-280 260 150

Lead-free low

cypogenic

material

Sn94-Ag3-Cu3 130-150 190-220 240-250 240 150

Lead-free low

cypogenic

material

Sn97-Cu3 130-150 190-220 270-280 250 150

Lead-free low

cypogenic

material

Sn95-Sd5 130-150 190-220 270-280 250 150

Cleaning and Maintenance

The machine can be cleaned in the cooled state. Wipe the inside of the machine with a

dishcloth. You can use rinse water or anhydrous alcohol. Do not switch on the machine

until it is completely dry.

Fortex Engineering Ltd, Unit 16, Freeman Road, Lincoln, LN6 9AP, United Kingdom

www.fortex.co.uk s[email protected] +44(0)1522 718 168

Error message

Sensor error

If the temperature measuring element is damaged during operation of the device, an

alarm is automatically triggered and the display shows "Sensor error".

Heating errors

If the oven temperature cannot be detected during the reflow process, the unit will report

a heater failure alarm and the display will show "Heating Failure".

Spare Parts and Options

Spare Heater

Guarantee

All machines are submitted before distribution to examination on tightness, function and

continuous operation firmness. On the machine we grant a work warranty of 12 months

to our customers starting from purchase date on accuracy in material and processing.

We warrant at our choice by exchange of incorrect parts or by repair of the machine in

our house. Old parts change into our possession.

Disclaimer of Warranty

Fortex Engineering Ltd reserves the right to change or enhance its machines or machine

specifications according to its judgement, if necessary. Fortex cannot be held responsible to

implement aforesaid changes into machines sold already.

Fortex products and services are liable to the current prices and conditions, which are subject

to change.

The instructions and definitions in this document are also subject to change and mark no

assurance on the part of Fortex.

Please regard the “Sales terms and delivery conditions”. These are available after fulfilment of

the contract. We don't furnish a guarantee or warranty in cause of damages at material or

hurts of people because of

Incorrect use of the machine

Wrong setup, installing and operating of the machine or incapable service

Use of the machine with defective safety equipment

Non-observance of the service manual in regard to transport, stocking, setup, installation and

service of the machine

Unlicensed modifications at the machine

Incorrect or incomplete repairs

Destructive force effect at the machine in cause of foreign objects or external use of force

Use of non-original spare parts

normal wear parts.

We cannot accept subsequent claims from damage or destruction of work pieces worked on

in the machine, because we have no knowledge or control over the operating conditions at

your site. This is valid in a general manner also for requirements from damage to articles,

buildings and persons as well as the environment.

Fortex Engineering Ltd, Unit 16, Freeman Road, Lincoln, LN6 9AP, United Kingdom

www.fortex.co.uk s[email protected] +44(0)1522 718 168

We do not warrant that the function of the machine will meet the customer's requirements or

that the operation of the machine will to this regard be error free.

In no event will we be liable to the customer for any incidental, consequential, or indirect

damages of any kind, including loss of profit and prosecution for environmental pollution, even

if we could have been aware of the possibility of such damages.

All information was arranged with great care. We reserve ourselves however mistake and

technical changes without previous announcement.

Running the machine in corroding, humid, dusty, extremely hot or explosive atmosphere

happens at the operator's own risk and responsibility.

We explicitly exclude any warranty for damages resulting from running the machine in in

corroding, humid, dusty, extremely hot or explosive atmosphere.

Copyright

(C) 2021 Fortex Engineering Ltd

Table of contents

Popular Oven manuals by other brands

AEG

AEG COMPETENCE B8920-1 Installation and operating instructions

Bakers Pride

Bakers Pride Y-600-DSP Specifications

Kleenmaid

Kleenmaid TO550X user manual

Gorenje

Gorenje B2000P2 Instructions for use, installation, and connection

Gaggenau

Gaggenau BX 281 instruction manual

Gaggenau

Gaggenau BO 450 610 installation instructions

North

North SPM-30 Technical Instruction

Blomberg

Blomberg BWOS 30100 Service manual

SCHOLTES

SCHOLTES FN 46 T XA operating instructions

Hamilton Beach

Hamilton Beach 31180 - Convection Oven manual

Electrolux

Electrolux EOB42100 user manual

AEG Electrolux

AEG Electrolux COMPETENCE B41012-4 operating instructions