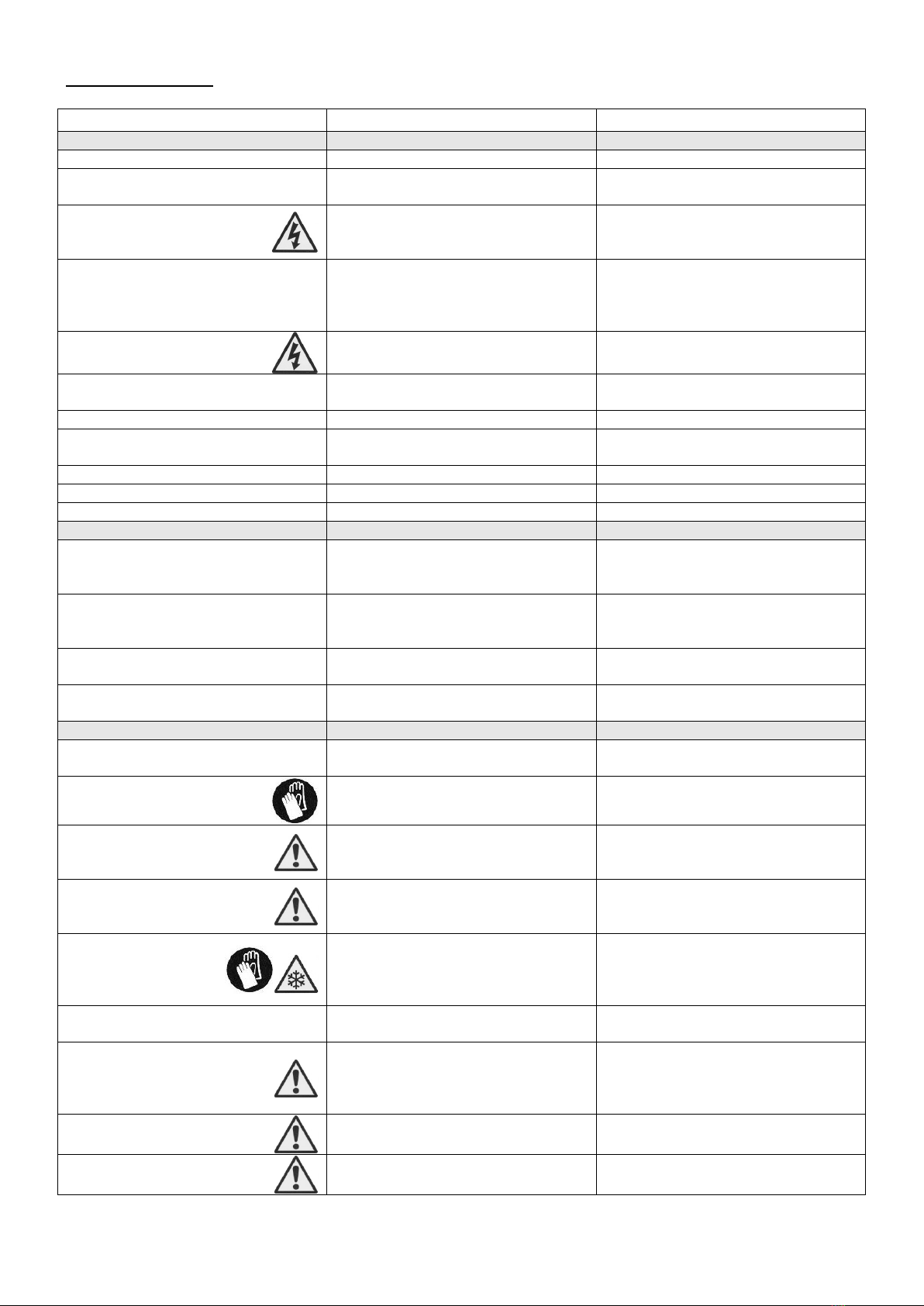

Environmental Management Policy for Service Manuals and Duets.

Product Support and Installation Contractors

Foster Refrigerator recognises that its activities, products and services can have an adverse impact upon the

environment.

The organisation is committed to implementing systems and controls to manage, reduce and eliminate its adverse

environmental impacts wherever possible, and has formulated an Environmental Policy outlining our core aims. A

copy of the Environmental Policy is available to all contractors and suppliers upon request.

The organisation is committed to working with suppliers and contractors where their activities have the potential to

impact upon the environment. To achieve the aims stated in the Environmental Policy we require that all suppliers

and contractors operate in compliance with the law and are committed to best practice in environmental

management.

Product Support and Installation contractors are required to:

1. Ensure that wherever possible waste is removed from the client‟s site, where arrangements are in place all

waste should be returned to Foster Refrigerator‟s premises. In certain circumstances waste may be disposed

of on the client‟s site; if permission is given, if the client has arrangements in place for the type of waste.

2. If arranging for the disposal of your waste, handle, store and dispose of it in such a way as to prevent its

escape into the environment, harm to human health, and to ensure the compliance with the environmental law.

Guidance is available from the Environment Agency on how to comply with the waste management „duty of

care‟.

3. The following waste must be stored of separately from other wastes, as they are hazardous to the environment:

refrigerants, polyurethane foam, and oils.

4. When arranging for disposal of waste, ensure a waste transfer note or consignment note is completed as

appropriate. Ensure that all waste is correctly described on the waste note and include the appropriate six-digit

code from the European Waste Catalogue. Your waste contractor or Foster can provide further information if

necessary.

5. Ensure that all waste is removed by a registered waste carrier, a carrier in possession of a waste management

licence, or a carrier holding an appropriate exemption. Ensure the person receiving the waste at its ultimate

destination is in receipt of a waste management licence or valid exemption.

6. Handle and store refrigerants in such a way as to prevent their emission to atmosphere, and ensure they are

disposed of safely and in accordance with environmental law.

7. Make arrangements to ensure all staff who handle refrigerants do so at a level of competence consistent with

the City Guilds 2078 Handling Refrigerants qualification or equivalent qualification.

8. Ensure all liquid substances are securely stored to prevent leaks and spill, and are not disposed of to storm

drains, foul drain, or surface water to soil.

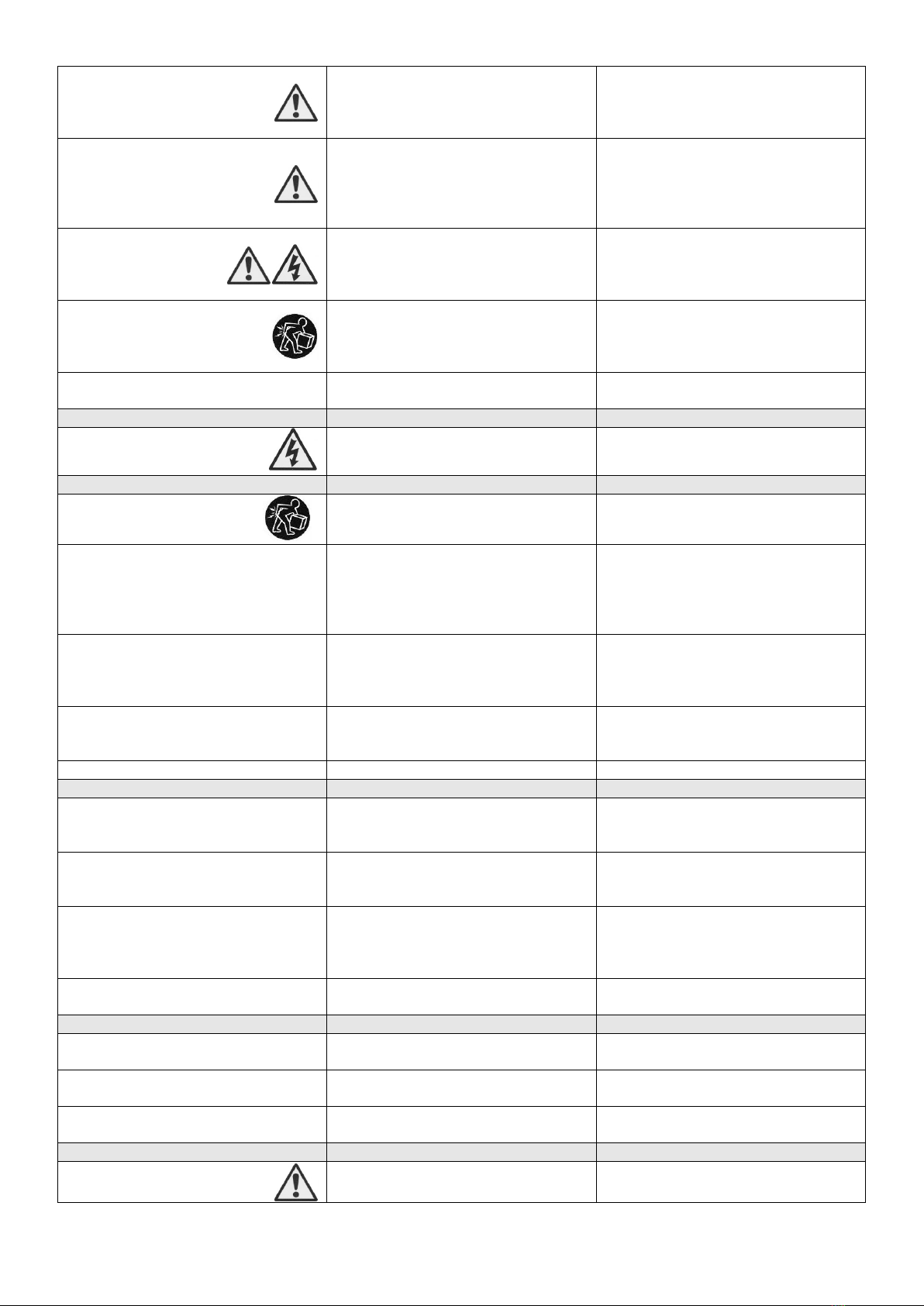

Disposal Requirements

If not disposed of properly all refrigerators have components that can be harmful to the environment. All old

refrigerators must be disposed of by appropriately registered and licensed waste contractors, and in accordance

with national laws and regulations.