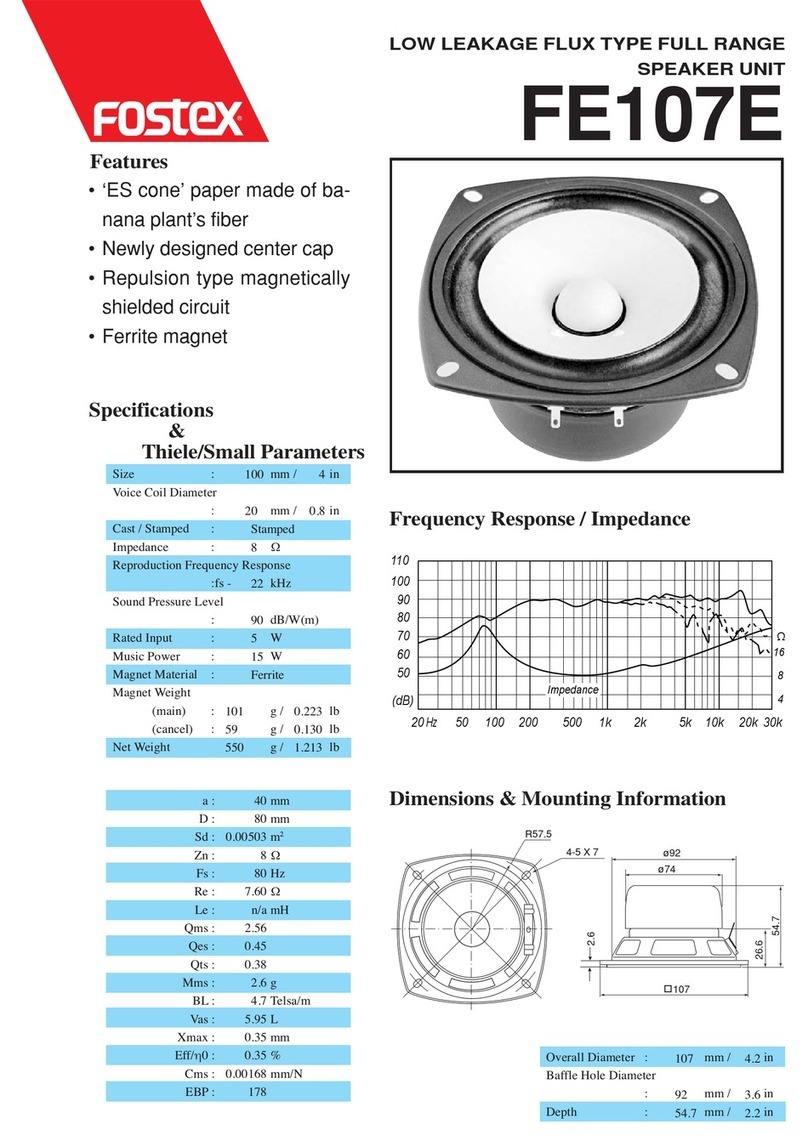

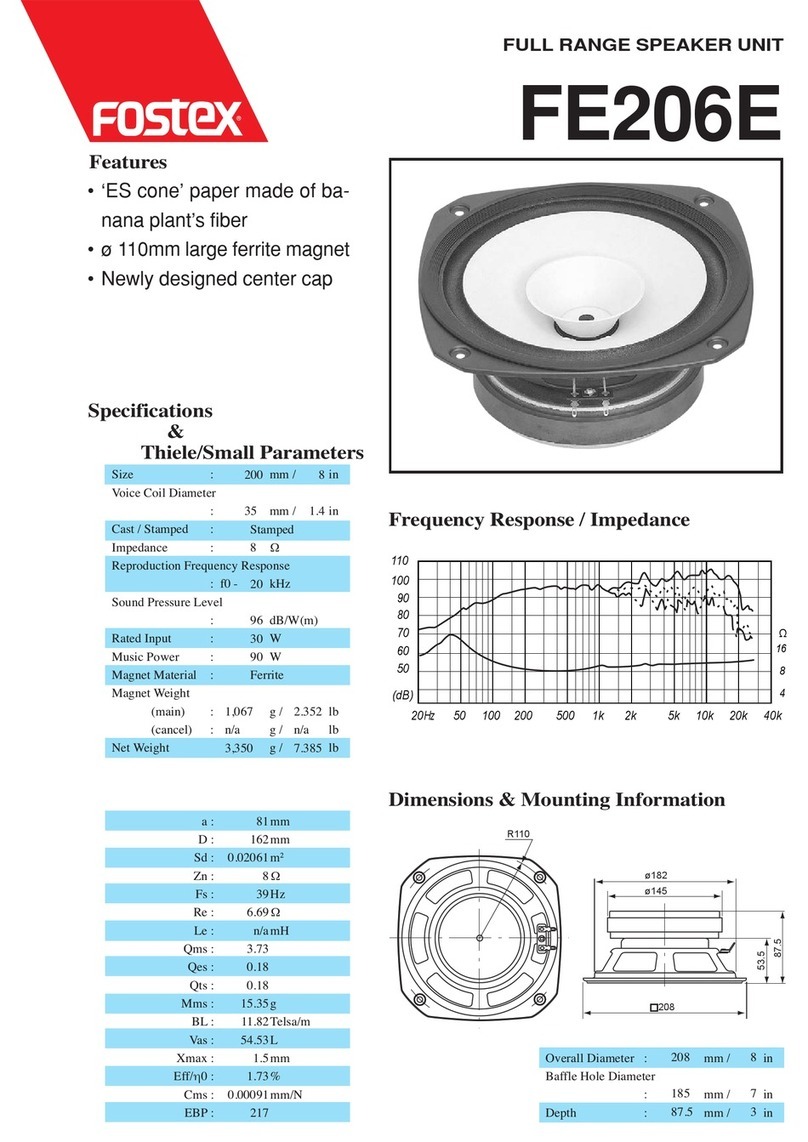

Fostex NF-1 Quick reference guide

Technical White Paper

NEAR FIELD STUDIO MONITOR

- 2 -

- 3 -

♦Employment of a 16 cm woofer featuring a

newly developed HP diaphragm has made it a

reality to reproduce low distortion and highly

transient sound which used to be only a dream

with conventional diaphragms.

♦Anti-resonance of diaphragm edges has been

successfully eliminated. The newly developed

UDR tangential diaphragm edge and push-pull

damper used in the woofer provide a breakthrough

in linearity and responsiveness to subtle signals.

♦Highly rigid die-cast aluminum frames

engineered to eliminate sound colorization often

occurring due to undesirable natural resonances

are used on the woofer and tweeter.

♦Tweeters, comprising a newly developed UFLC

diaphragm (soft dome) offering excellent response

and reproduction performance, are capable of

handling a wide frequency coverage of up to 40

kHz.

♦The network used is of an exceptionally low

loss 6 dB crossover design which ensures

extremely natural transition between the woofer

and tweeter.

♦The time-aligned enclosure has a baffle shaped

to keep it free of natural resonances caused by

diffracted reflection sounds.

♦The use of an HP diaphragm and dome tweeter

has widened the listening area, which was not

possible with previous technology.

♦An ideal internal processing method of natural

resonances developed by reflected sounds within

enclosures is now an actuality by removing such

natural resonances by an HP sound reflector.

♦Terminals for bi-amplification systems are

provided for convenience in meeting studio-

specific environmental requirements.

♦Employment of minimal magnetic leakage

design on both woofers and tweeters makes

placement of the system in close proximity to

monitors viable.

FEATURES

THE "SHOULD BE" OF MONITOR

Before undertaking development of NF-1, we recognized

anew the following 5 points as mandatory requirements

near-field monitors should satisfy.

1)To elevate the ability to analyze and check

original sounds and to reproduce said original

sounds to an absolutely optimal level.

2)To express to the fullest extent all the musical

nuances intended by the musicians and

engineers.

3)To provide engineers with a highly efficient

work environment where they can work,

unconscious of the existence and intervention of

sound reproduction speakers, free of stress and

fatigue caused by the necessity of corrections of

properties inherent to conventional speakers.

4)To be with horizontal directivity wide enough

to ensure minimal changes in timbre and sound

field regardless of engineers' horizontal

position. Vertical directivity, on the other hand,

is better to be narrow to enable circumvention of

reflection from mixing consoles.

5)To meet trends in recording studios of using

small yet high performance speakers. In recent

years, cases abound where small speakers are

used in the near field.

NF-1 has been developed to incorporate the following

elements as the engineering development themes

necessary not to miss any of these 5 points.

REQUIREMENTS OF SPEAKER DRIVERS

Reproduction frequency range to be the widest

possible (60Hz to 40kHz)

Fast response perceptible in the original sound to be

retained

Sufficient resolution to allow for desired signals and

noise present in floods of information to be

discernible

Localization of individual sound images to be

excellent

High input and output capability without altering

sound quality

Driver diameters to be as small as feasible, as dictated

by the idea that a point sound source is an ideal sound

source, and systems to be no more than 2-way

No specific sound to develop from any of diaphragm

materials, shape or structure

Good directivity

REQUIREMENTS OF SPEAKER ENCLOSURES

FEATURES THE "SHOULD BE" OF MONITOR

a.

b.

c.

d.

e.

f.

g.

h.

Size to be small enough to provide convenience in

securely locating systems on mixing consoles to

ensure optimal proximity to the listening point

Time alignment to be impeccable within the listening

area

Natural resonance sounds not to be generated from

enclosures

To provide rich and deep sound to give listeners the

sensation of presence of a natural sound field

(Listeners are not to perceive that the sound source is

speakers in an enclosure.)

a.

b.

c.

d.

- 4 -

In addition, upon development of a near-field

monitor, we decided to expose our speakers to

users' evaluation as to its true value, by placing the

focus on a passive type, or non-amplified type,

which will provide users with an opportunity for

optimum speaker driving in a manner meeting

studio-specific requirements.

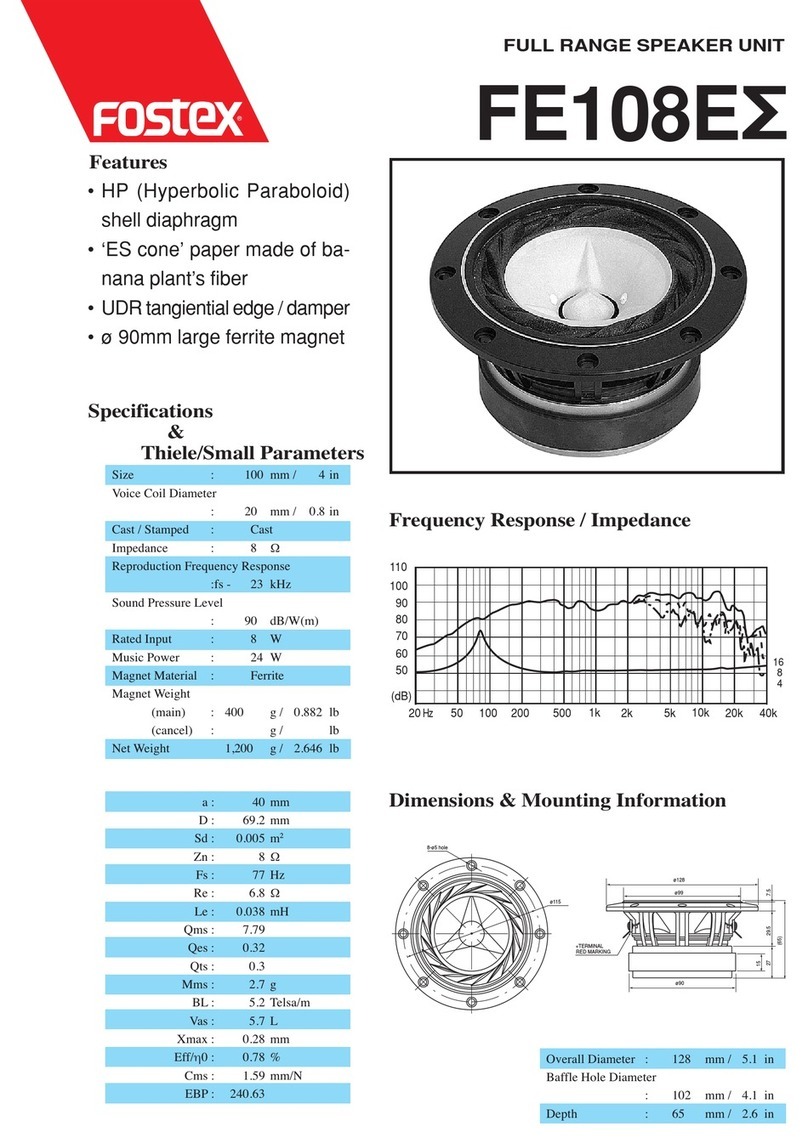

BASICS OF THE HP SYSTEM

'HP' is an abbreviation of hyperbolic paraboloid

which is normally called an 'HP shell' or hyper

shell, and is a 3rd-order curved surface structure.

This structural theory has long been well known in

the field of the structural mechanics.

The Orchestra House in Sydney, Australia, a good

example to which the HP structure is applied, is

famed world-wide for its beautiful form.

The HP structure is characterized primarily by the

fact that movement of a line connecting 2

line segments which exist on different surfaces

results in composition of a hyperboloid and

paraboloid.

Our purpose and reason for the world's first

application of this HP structure to the NF-1 near-

field monitor as an ideal diaphragm configuration

can be explained by 3 acoustic advantages which

were not available from conventional diaphragms.

Without solution to these 3 items, it would be

impossible to predict what the next generation near-

field monitors should be.

APPLICATION TO DIAPHRAGMS OF THE HPSYSTEM

1) HP diaphragms composed of lines

Being a curved surface, and unlike conventional

diaphragms structured with curved lines, the HP

structure basically consists of straight line

structures.

As a result, involved in-plane stress is only a

shearing force without the presence of bending

stress, culminating in strength at high level.

Strength of such level can raise the resonance

frequency of diaphragms to reproduce fast-rising

sounds that make listeners perceive faster

responsiveness over conventional diaphragms.

Besides, the straight lines, being of varied lengths,

prevent any specific standing waves from being

created on diaphragms, with subsequent freedom

from peaks, and thus, resulting in smooth response.

2) HP Diaphragms having torsional curved surface

Nothing is free of natural self-resonance frequency.

It has been known that self-resonance frequency

creates sound inherent to the material, perceptible

as sound unique to it. Speaker diaphragms are no

exception and have material-specific sound which

characterizes the speaker. In the case of home use

speakers, such timbre may appeal to listeners as

being comfortable

and pleasant.

However, when

using speakers A

and B for the

purposes of

monitoring the

same program

source in different

timbre will mean

that some particular

frequencies are

restricted by

speakers with their

natural resonance

frequency. It can

be, therefore,

reasonably assumed

that ideal

diaphragms for

monitor speakers

should have natural

resonance

suppressed to the

fullest possible

extent.

The HP structure is

characterized by its

torsionally curved

surface structure.

Figures 2 and 3

show FEM modal

analysis results of

the 1st to 4th free

resonances

observed on a

150torsional HP

structure and on

plane structure,

where no evidence

of major resonance

is apparent on the

HP structure.

BASICS OF THE HP SYSTEM

FEM modal analyses of freely

vibrating aluminum plane

FEM modal analyses of a

freely vibrating HPshell

1st order mode

358Hz

2nd order mode

378Hz

3rd order mode

488Hz

4th order mode

498Hz

1st order mode

30.7Hz

2nd order mode

39.3Hz

3rd order mode

54.9Hz

4th order mode

77.7Hz

Figure 2

Figure 3

Resonance

is large.

Resonance is

small and dispersed.

- 5 -

One of the properties of the HP structure is the

unlikelihood of development of inherent timbre

because of widely dispersed resonance.

This finding has made it possible to use, without

encountering any particular major

resonance, materials such as metal and carbon

fibers having high propagation velocity and low tan

δ(internal loss) which used to be regarded as

properties to be overcome. The Figures 2 and 3

indicate that resonance is shifted up on HP

diaphragms by one decimal point and is narrower,

when compared to a plane surface. This represents

that HP diaphragms provide higher strength and

finely dispersed resonance. This property of

dispersed resonance can be used as a good proof

that HP diaphragms are ideal where no particular

resonance disturbs reproduced sound.

3) HP diaphragms, easy to analyze and

excellent in reproducibility of simulation

HP diaphragms' complexity in configuration can be

overcome by development of a design method

which involves CAD/CAM techniques, whereby

optimal configuration design of curved surfaces and

mold machining will become possible.

Configuration of HP shells is optional, i.e., the

number of divisions and degree of torsion of curved

surfaces (height of ridges and depth of troughs) can

be determined by the aimed response

characteristics/sound quality. In addition, articulate

configuration, though the curved surfaces are

complex, provides ease in analysis and

reproducibility of simulation.

Figure 5 represents a conventional straight cone.

Cone break-up is present at 596 Hz in the axis-

symmetry mode (in the direction of circumference),

causing the 3rd harmonic distortion which is said to

be detrimental to sound quality, to develop.

Figure 6 shows an HP diaphragm. Axis-symmetry

mode resonances can be seen at neither of the

vicinity of 596 Hz nor at any other frequencies.

At this stage, we can say that it is has been

successfully verified that the use of HP diaphragms

can surmount the shortcomings of conventional

cones, eliminate speaker-specific sound

colorization, and finally, attain ideal speakers

capable of offering precise sound reproduction.

Figure 4 presents comparison data of frequency

responses taken from 16 cm woofers with an HP or

conventional straight diaphragms. The HP

diaphragm speaker is free of evidence of either dips

at around 600 Hz or peaks at the high end of around

4500 Hz due to anti-resonance of the edge. Figures

5 and 6 compare the FEM modal analysis results.

20 50 100 200 500

1000

2000 5000

10000

20000

50

60

70

80

90

100

110

(db)

Hz

Figure 4

Comparison of frequency responses of

a straight cone and HP diaphragm

Figure 5

Figure 6

FEM modal analysis of a straight cone

FEM modal analysis of an HP diaphragm

Large split resonance is seen in

the direction of the circumference.

No axis-symmetry mode

resonance is occurring.

HP diaphragm Straight cone

- 6 -

FEATURES OF THE WOOFER UNIT

FEATURES OF THE WOOFER UNIT

Development of speaker systems vitally involves

the 3 elements of driver units, networks and

enclosures.

On development of NF-1, thorough investigation of

these 3 elements was made to have them well

balanced, so as to achieve total quality by attaining

incomparable performance from the same size

drivers.

Woofers which are responsible for reproduction of

base sound must meet the following 3 points which

are major sound quality-determining factors:

The introduction of HP diaphragms and newly

developed Biodyna composite material in the

vibratory system, being the key portion for

successful achievement of the above 3 factors, has

made theNF-1 woofer an ideal bass unit.

1) Configuration of HP diaphragms

In order to disperse stress, inflection points are

located at the top and bottom to form vertical

symmetry, and the height of curved surfaces is set

for optimal frequency

dispersion as dictated by

FEM modal analysis

results, with pentagonal

divisions which create

asymmetry to the center

as the basic option.

2) Properties required of diaphragm materials

Factors of importance with diaphragm materials

are:

1) Propagation speed

2) Modulus of flexural rigidity

3) Internal loss (tanδ)

For NF-1 diaphragms, we have set the following

target values, which we think the next generation

near-field monitors cannot be without.

To achieve these values, the materials described

below are introduced:

A) Base pulp: a mix of NBKP and banana fibers

Conventionally used NBKP wood pulp alone is

accompanied by sound distortion due to lack of

bonding strength at the pulp fiber level. This

distortion component present in reproduced sound

has been considered to be an integral element

with wood pulp, as seen in comments such as

'reminds listeners of paper'. Continual study for

usability of various

types of materials

such as carbon

fibers, PP, nylon,

polystyrene, metal,

etc. for vibratory

systems, made ever

since development

of wood pulp cones,

has failed to find

any material

compatible with

wood pulp which

has well balanced

tanδand

propagation velocity. Meanwhile, Fostex has

succeeded in development of banana pulp

materials comprising long fine fibers with a high

level of bonding strength provided by the intrinsic

starchy component. This banana pulp provided

an opportunity for exploration into new

dimensions where distortion-free pulp cones can

be embodied without sacrificing the intrinsic

properties of pulp. Adoption of banana pulp and

NKP as the base pulp has made an excellent well-

balanced cone available for NF-1.

To be light in weight and high in

rigidity, with smoother response

To have a reasonably extended

high end and wider directivity

To achieve ideal performance

without need of any cross-over

provision

a.

b.

c.

Propagation speed:3000 m/sec., minimum.

Conventional pulp materials:2600 m

PP (polypropylene):1290 m

Modulus of flexural rigidity:6.0 (2 times

that of conventional materials, or greater)

Conventional pulp materials:2.81

PP (polypropylene):1.43 m

Internal loss (tanδ): 0.06, minimum.

Conventional pulp materials:0.033

PP (polypropylene):0.08

1)

2)

3)

Banana pulp fibers

HP diaphragms

- 7 -

Optimum performance

B) Enforcement materialA: Carbon fiber of

a super high elasticity modulus

Cases abound where carbon fibers are used for

cones. The carbon fibers contained in NF-1 cones

combine the property of super high elasticity

modulus working as an enforcement material. With

propagation speed of 16,000 m/s, equal to that of

diamond, they allow for higher sound velocity and

more preferrable modulus of flexural rigidity.

C) Enforcement material B: Super-fiber, PBO

(poly-ρ-phenylene benzooxazole)

a family of aramid fibers.This fiber, used in

combination with the enforcement material A, with

a strength 2 times that of previous aramid fibers,

adds flexural rigidity and permits substantial

improvement in rupture resistance.

D) Enforcement material C: Pearl mica

Attainment of ideal diaphragms is impossible

without success in getting elements which raise

propagation velocity well balanced, with high

internal loss maintained. Pearl mica allows for

Diamond

Boron

Al

Ti

Mg

Aramid/epoxy Carbon graphite

Biocellulose gel sheet

Aluminum

honeycomb

Be

Shirakawa pulp Polyethylene foam, glass cloth

PP (polypropylene)

Delta olefin

Polyethylene

Hard polyvinyl

chloride

PPTA

PP graphite

Biocellulose of sea squirts

Aramid honeycomb

Ceramic carbon

10,000

9,000

8,000

7,000

6,000

5,000

4,000

3,000

2,000

1,000

0.001 0.002 0.003 0.004 0.005 0.006 0.008 0.01 0.02 0.03 0.04 0.05 0.06 0.08 0.1

Propagation velocity(m/sec)

20,000

Physical properties of diaphragms

(propagation velocity/internal loss)

Internal loss (tanδ)

- 8 -

faster surface propagation velocity of HP

diaphragms. Combining properties of enforcement

material A, B and C, sound quality giving the

sensation of the fastest response, which has not

been available, is now an actuality.

E) Super damping fiber: Cellgaia pulp

F) Matrix material:bio-cellulose

This material elevates bonding strength of each pulp

and enforcement materials, and permits diaphragms

of high airtightness to be formed due to the fiber

filament diameter being as fine as only 30nm,

which no other pulp cones have ever materialized.

G) Secondary impregnant

Smooth roll-off response can only be achieved with

an appropriate thickness-stiffness parameter.

Previous techniques do not allow for compatibility

of thickness-stiffness parameter and propagation

velocity, requiring that propagation velocity be

sacrificed to a certain extent to attain the desired

thickness-stiffness parameter. Fostex has succeeded

in development of new materials which will allow

us to achieve ideal internal loss without impairing

propagation velocity. The fruit of our labor is the

use of Cellgaia pulp resulting in an increase in

internal loss without resorting to reduction in

propagation velocity of materials.

Sound quality of wood pulp cones is said to

fluctuate depending on ambient humidity.

The woofer for NF-1 is engineered to be humidity-

resistant to an extent incomparable to previous

wood pulp-based vibratory systems, by using

special nitrocellulose materials capable of

0.001 0.002 0.003 0.004 0.005 0.008 0.01 0.02 0.03 0.04 0.05 0.06 0.08 0.1 0.2

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

2.0

3.0

4.0

5.0

6.0

7.0

8.0

9.0

10.0

20.0

30.0

40.0

50.0

60.0

70.0

80.0

90.0

100.0

200.0

300.0

Polystyrene (3)

Hard urethane foam (6)

Polyethylene foam (25)

Polyethylene (62)

Polypropylene

PP (148)

Wood pulp

(178)

Aluminum (19)

Titanium (11)

Magnesium

(91) Carbon fiber cone (754)

Carbon cloth (167)

Aramid cloth/epoxy (660)

Internal loss(tanδ)

Propagation velocity XModulus of flexural rigidity:E/

ρ

2

X10

3

()Figures in parenthesis represent propagation velocit Xxflexural rigidity Xtan

δ

= E/ρ

2

Xtan

δ

.

Physical properties of diaphragms (internal loss/propagation

velocity/modulus of flexural rigidity)

NF-1 diaphragm

Beryllium (417 )

Optimum performance

- 9 -

enhancing the bonding strength of all materials, and

subsequently, substantially improving resistance to

humidity. These materials, being equivalent to the

coating applied on the famed Stradivarius violins,

help give the feeling of being present in a natural

sound field and reproduce the true sound of musical

instruments in higher fidelity.

Previously used olefin-based PP materials caused

strength to fluctuate greatly depending on the

temperature. This means that changes in room

temperature and rise in the voice coil temperature,

when driven, will result in considerable changes in

sound quality. They are fated to be a source of

changes in sound quality due to seasonal

temperature changes.

The woofer found in NF-1 is the incomparably

successful compilation of our 50-year long research

and development efforts for elementary

technologies in wood pulp-based

diaphragms.

Physical properties of this new Biodyna are given

below:

3) HP diaphragm adapter

4) UDR tangential edge

When speakers are driven, the roll of edges

(surrounds) plays a major part as the suspending

member. They, as part of diaphragm systems, are

also greatly responsible for the reproduced sound

quality.

This fact makes it essential to be most careful

when designing edges, where more points of

difficulty than in diaphragms are involved, when

deciding on configuration and materials.

What we chose for this project are special

urethane foam materials having greater internal

loss and elongation performance, as well as

excellent durability. They are a breakthrough of a

newly developed structure called a UDR

tangential edge, on which up-roll and down-roll

are bonded at their tangential surfaces. They are

configured, through FEM modal analyses, to

function optimally as edges. Targets set at that

time include:

Reduction in anti-resonance at mid-

frequencies:

No previous rolled edges were without anti-

resonance. The voice coils we adopted are

structured

tangentially to

voice coil

movement.

Freedom from

axis-symmetry

anti-resonance

caused by

movement of the

outer periphery of

cones and inner

periphery of rolls

in the mutually

reversed direction

produces flat

response and

reduces harmonic

distortions to an

absolutely

minimal level.

Drive points of HP diaphragms can seriously impact

characteristics. However, analyses using computers

and subsequent technical experiments have

discovered that the high end will be extended and

directivity improved if driven near the center. For

the woofer being discussed now, we chose a point at

about 25 mm as the optimum performance point.

As a consequence, the network

coil for the woofer became

superfluous without loss of

smooth transition to the

tweeter.

When determining the blending detail not to miss a

single piece of the subtlest signal components in

reproduced sound, a greater amount of attention to

propagation velocity than to that of diaphragms was

paid.

D

ensity:

Young's modulus:

Propagation velocity:

Internal loss:

Modulus of flexural rigidity (√E/ρ3):

Propagation velocity X Modulus of

f

lexural rigidity:

Supported by high level strength and large internal

loss, which were attained for the first time, and by

the use of a strong magnetic circuit and rigid die-

cast aluminum frame, superior sound quality with

high transiency and linearity, which had not been

available from any speakers, became a reality.

0.64 (g/cm3)

11.02 (GPa)

4380 m/sec.

0.068

6.5

26.98 X103

- 10 -

Tangential design, 5 pcs.

Tangential design, 10 pcs.

Up-roll, UP

Up-roll, DOWN

FEM simulation of load-displacement relationship

05000 10000 15000 20000 25000

0

1

2

3

4

5

6

Displacement[mm]

Load[mN]

FEM analysis of edge-displacement relationship

05000 10000 15000 20000 25000

1.E-07

0.E+00

-1.E-07

-2.E-07

-3.E-07

-4.E-07

-5.E-07

-6.E-07

-7.E-07

-8.E-07

2nd order differential

2nd order differential

Tangential design, 5 pcs.

Tangential design, 10 pcs.

Up-roll, UP

Up-roll, DOWN

Load[mN]

Evaluation result of 2nd-differential of bi-linearity of an edge

Simulation of a rolling edge

The opposite end rises Pushed at one point

Cone

Reduction in

anti-resonance

at high

frequencies:

Added strength

and a shift to

disperse at high

frequencies

prevent any

natural high peaks

from being

generated, in

contrast to rolled edges. Chances will be remote

that peaks and dips will take place in the frequency

response, and smooth characteristics will be

achieved as with HP system diaphragms. In this

way, our philosophy of elimination of physical

distortion due to components ranging from

diaphragms to edges has been brought into

existence, allowing for natural and higher fidelity

reproduction.

Figures 10 and 11 show FEM analysis results of the

acceleration response, evidencing a high level of

responsiveness which used to be a mere gleam in

the sound engineers' eyes.

Improvement of amplitude response:

It is seen that suspension characteristics, being a soft

clipping type which works to gradually restrict

movement when the magnitude is symmetrical and

large, are ideal.

These characteristics are of particular importance to

monitor speakers, in the sense that they do not permit

listeners to perceive distortion if subjected to excessive

input power.

Improvement in rolling:

This tangential design is strong enough for the plane

dividing the rolled edges in a tangential manner not to

yield to horizontally applied stress. Rolling is unlikely

to occur to this UDR tangential edge even when a high

input power is applied, while a contact by the voice

coil with stationary structure of a speaker is

commonplace with conventional rolled edges.

Figure 9

Figure 10

Figure 11

No resonance is observed on the entire

circumference, nor is there any

axis-symmetry resonance.

Presence of an inflection point is apparent.

Rapid change starting at this inflection point develops harmonic distortion.

Input produces only a gradual change.

Figure 12

Figure 13

Figure 14

- 11 -

9

1

2

3

4

5

6

7

810

11

12

13

9.Cone

1.Outer yoke

2.Plate

3.Magnet

4.Magnet

5.Yoke

6.Frame

7.Voice coil

8.Cone attachment adapter

10.Damper

11.Pole cover

12.Terminals 13.Damper ring

The suspension function of dampers is to always

keep a voice coil centered. NF-1, the target for

which is perfection of every function of it, employs

a double-damper which is advantageous in view of

structure but very time consuming to produce, and

is seen mostly in expensive speaker systems. For

this particular application, considering the fact that

amplitude characteristic greatly impacts sound

quality, we developed an advanced form which can

provide longer stokes than usual, so that a vertically

symmetrical push-pull structure can be constituted

for assurance of superior hysteresis characteristic,

in order not to adversely affect amplitude response

characteristic which greatly influences sound

quality. (Reference the assembly drawing)

A high

degree of

resistance to

heat, as well

as durability

to vibration,

is attained

by the use of

a meta-based

aramid fiber

cloth.

4) Double-damper of a push-pull structure

5) Magnetic circuit

The magnetic circuit is designed to be sufficiently

powerful to be able to reproduce the deepest bass

sound for such rather small diameter speakers.

Magnets used are a large 110 mm outside diameter

strontium ferrite magnet and a 90 mm outside

diameter repulsion magnet, which form a repulsing

magnetic circuit.

The magnetic circuit created by an 8 mm thick top

plate, or 2 times that of previous equivalents, and a

long voice coil of a winding length extending to 11

mm and of a 35 mm diameter, can produce a

powerful 10.5 force factor with a 1.1T flux density.

As a result, successful reproduction of fullest bass

sound has been realized from a small speaker

system of only an 11 liter volume.

An 18 mm diameter ventilation hole is provided on

the center pole for improvement to bass sound and

heat dissipation performance.

The use of an outer yoke can keep display CRTs

completely free from an influence of magnetic

leakage.

6) Voice coil

A coil measuring 35 mm in diameter and wound of

a 0.19 diameter wire is very large for 16 cm

speakers. We believe that the use of hard duralumin

for coil bobbin material must not allow to

deteriorate the sense of fast reaction in the

reproduced sound. Better heat-resistance

characteristic and superb sound transiency are also

attained by the use of such material.

7) Die-cast aluminum frame

For speakers made of a large magnetic circuit that

can create very powerful driving force to be

firmly secured to the front baffle, conventionally

used metal or plastic frames are far from the

optional. To deal with this problem, we decided

to use die-cast aluminum frames.

Additionally, die-cast aluminum frames provide

some other key advantages such as smaller

magnetic leakage and better heat dissipation

characteristics.

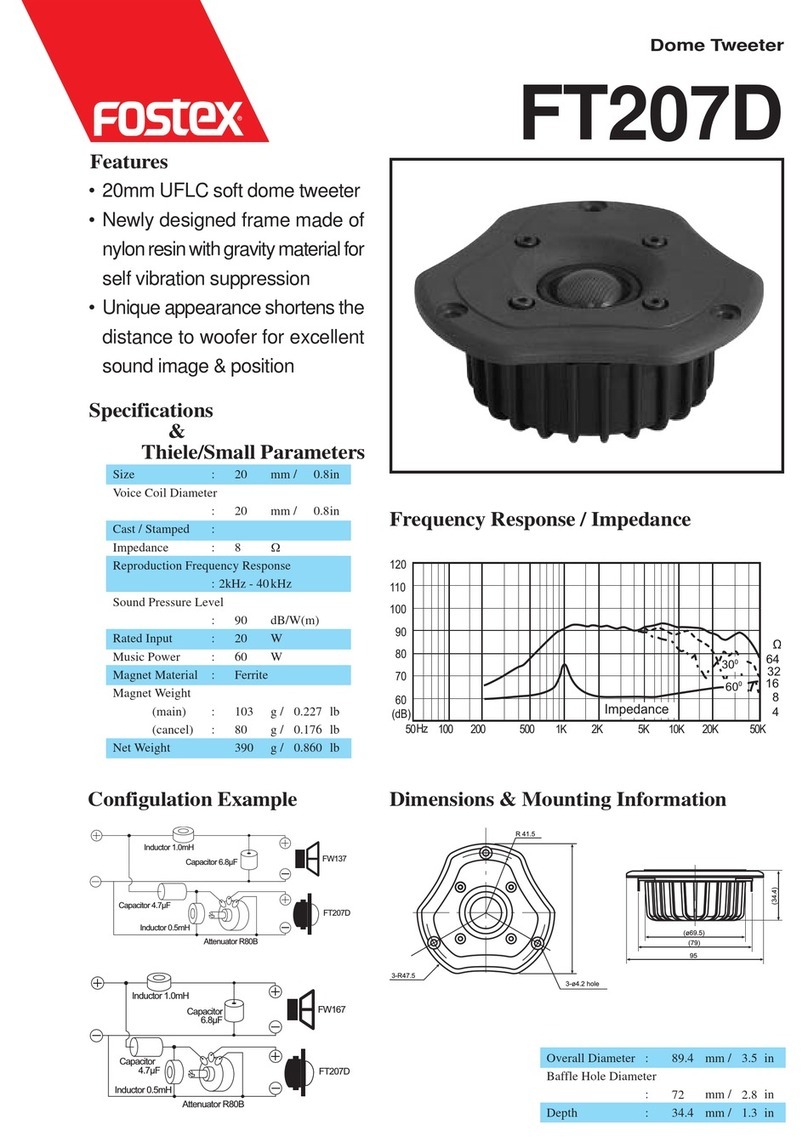

FEATURES OF THE TWEETER UNIT

FEATURES OFTHE TWEETER UNIT

The following 3 points are considered to be most

important to the high frequencies reproduction of

the next generation of monitor speakers:

Moreover, the most acceptable tweeters are those in

which input power-dependent changes in tone

quality occur to only a minimal extent. To embody

this requirement, NF-1 comprises a tweeter

employing a 20 mm diameter soft dome made of

newly developed UFLC materials and a die-cast

aluminum frame.

The feature of soft dome diaphragms is that it is

possible to use materials, the Young's modulus of

which is not excessively high while the internal loss

of which is large. This enables a good balance in

dispersed resonances occurring in the vibration

mode. Materials having a high Young's modulus,

such as aluminum and titanium, allows sound to

follow input signals very fast. However, even small

internal losses cause high peaks to develop at high

end frequencies, resulting in deterioration of

High end to extend beyond 30kHz

Deterioration of directivity to be no

greater than 6 dB at 20 kHz and 30

0

off

axis

Frequency response to be free of peaks

and dips, sound quality not to be

characterized by inherent factors and

distortion to be at the lowest possible level

a.

b.

c.

- 12 -

transiency and thus in metal-specific sound. Hard

dome tweeters, therefore, are suitable for speaker

systems where the aim is for creation of sound

characterized by such materials (metal-specific

sound).

1) UFLC material

A common previous practice when producing soft

domes is direct application or coating of damping

materials on polyester cloth to avoid adverse effects

of such materials caused by porosity or specific

inherent sound on the reproduced sound. This way

of production of soft domes, however, is subject to

variations in the amount of applied damping

materials, resulting in generation of dips in the

response due to pinholes, low output level due to

excessive application of damping materials, or

deteriorated high end reproduction due to loss of

material strength. Our new development, being the

UFLC materials, is our solution to these problems.

With it, light and highly stable diaphragms have

become available.

The UFLC materials consist of the following

component materials:

U: Polyurethane

This plastic features large internal loss, light weight

and good bonding performance.

F: Film

Prior processing is given to polyurethane resin to

roll it to an extremely thin film of a consistent 25

µm thickness.

L: Laminated

The base material and polyurethane film are pressed

while heated to bond them tightly together.

C: Cloth

The base material is large-meshed porous polyester

cloth, chosen for its lightness and strength.

The use of this UFLC material provides a 30%

weight reduction and consistent quality. The dome

shape of a newly developed special configuration

brings about ideal performance characteristics for

soft domes.

The frequency response range widely and naturally

extends to the extreme high end of frequencies,

which had not been possible before development of

this dome design, reproducing each segment of

delivered sound signals to its highest fidelity.

2) Die-cast aluminum frame

Conventionally, tweeter frame materials for speaker

systems of this class have been plastics such as

ABS. Incapable of suppressing high frequency

vibration energy, plastic frames are usually

accompanied by undesired noise caused by

resonance, and thus poor trangency.

With the use of a 6.5 mm thick die-cast frame on

the NF-1 tweeters to assure the necessary and

sufficient strength, this problem has been solved,

and conditions become possible for utilization of

the merits and advantages of the high grade UFLC

diaphragms to the fullest extent. Consequently,

highly transient sound quality has resulted.

The athletic track-shaped and tapered frames

successfully reduce magnitudes of natural

resonance and make it possible to place the tweeter

closest to the woofer to allow for the narrowest

phase shift range.

3)Low-leakage magnetic circuit

To avoid interference with nearby magnetic devices

and displays, a canceling magnet is used in the

magnetic circuit. The canceling magnet functions

to lead outflow of the lines of magnetic force to the

gap, elevating flux density in the gap to as high as

1.2T.

FEATURES OF THE ENCLOSURE

FEATURES OFTHE ENCLOSURE

1) Driver arrangement oriented for time alignment

The most important characteristics of speaker systems

include a phase characteristic. This characteristic is of

particular importance to monitor speakers at the places

where they are used for monitoring. The prime measure

taken to address this issue was execution of positional

alignment of the woofer and tweeter to locate them as

close to each other as possible for the maximum

available monitor area.

NF-1 is designed for optimal sound when listened to at

positions between the axes of the woofer and the

tweeter, if connected in phase. In the case of opposite

phase connection, the optimal listening positions shift

beyond the tweeter position, with the optimal listening

range being narrowed.

Application conditions of NF-1 in studios are the

determining factor for connections to ensure perfect

phase characteristics. In-phase connection should be the

primary option, unless otherwise dictated by the

application environment.

Due to the fact that human ears are very sensitive to the

horizontal direction, arrangement of drivers in that

direction is undesirable in terms of phase. It should be

kept in mind that perfectly time-aligned NF-1 is

designed for use in an upright position.

- 13 -

2) Board thickness

Strength and weight are key factors for enclosures to assure optimal sound quality. Low cost enclosures

allow for undesirable resonances to be generated, and, as a consequence, listeners end up with monitoring

sounds that contain signals not present in the fed signals. NF-1, very unlike other 11 liter volume

enclosures, uses a 21 mm thick MDF material to add extraordinary rigidity to it. Our concern for rigidity

is especially apparent in the front baffle to which the woofer is mounted. It measures 33 mm thick to

ensure sufficient strength for positive fastening of drivers within the enclosure, as well as consideration to

time alignment. Rounded edges of the front baffle reduces reflection of mid-frequency sounds from the

edges.

3) Sound absorbent materials

Inclusion of sound absorbent wool in

enclosures is commonplace. This

practice, however, exhibits the following

problems:

4) Introduction of HPsound reflectors

To solve issues related to sound absorbents, we developed a new

means where an HP system reflector is employed to prevent

generation of standing waves in enclosures.

The idea is to have the sound present in enclosures to be

extinguished naturally by making it reflected diffusely, creating

conditions in which no standing waves may develop. Given below

is a comparison of sound pressure characteristics occurring in

enclosures.

Figure16 involves glass wool. Effective attenuation occurs to high

frequency sound only.

Bass sound is attenuated only minimally and abruptly, with

disturbance resulting.

Figure15

Figure16

Loss of dynamism and reduced

massiveness in bass sound occur

due to impediment to movement

of air in enclosures if a large

magnitude is applied. This

adverse effect is more obvious if

an excessive amount of absorbent

material is stuffed into enclosures

in an attempt to extend the base

reproduction range.

Absorbency of absorbent

materials is frequency-dependent.

So, they color sound reproduced

by the speakers, representing the

absorbent's characteristics.

Generally, short wavelengths, or

high frequency sounds, can be

absorbed but mid- and bass sound

cannot, causing disturbance in

attenuation characteristics.

a.

b.

without glass wool and HP reflector

- 14 -

5) Factors required of HP sound reflectors

Consistently varying third-order curved surfaces are

ideal to cause and maintain regularly diffused

reflection. For such curved surfaces to be realized,

nothing can be better than the HP structure.

Minimization of self-resonance inherent to

reflectors is also a requisite, for which a

configuration in which strength can be assured is an

important factor. The HP structure is also very well

suited in this sense.

Materials are to exhibit great strength and large

internal loss. To meet these requirements,

composite materials of carbon fibers and PBO,

compatible with those of diaphragms, are used.

6)New bass-reflex system

FEATURES OF NETWORKSAND CONNECTIONS

FEATURES OF NETWORKSAND CONNECTIONS

1) Network

The simpler the crossover networks for woofers and

tweeters, the better. An ultimate incarnation of this

formula, i.e., non-use of any network element, is a

reality with the woofer. The tweeter is connected

through a capacitor for a 6 dB/octave attenuation.

This achievement is possible simply because of

smooth roll-off of the woofer at the high end, which

no technologies other than the HP technology can

achieve.

The use of a high quality film capacitor and a 1.5

mm diameter solid wire is another factor for this

superb transition.

2) Bi-wiring

Successful achievement of our targets set for

NF-1 listed below requires use of a bi-wiring

system.

To attain dynamism and massiveness in base

response, bass-reflex enclosures are adopted.

With NF-1, acoustic conversion of extremely low

loss is achieved by the active utilization of

reverberant sound caused by the interior HP sound

reflector and exited through the bass-reflex ports.

For this, ports are located at two places between the

woofer and tweeter to allow for smooth and natural

blending of the sound exiting through said ports

with the sound coming directly from the drivers.

Figure 18 shows woofer response characteristics in

comparison with a glass wool case. It is obvious

from the figure that the sound pressure level is 2 dB

higher, assisted by utilization of sound created

behind the diaphragm.

Furthermore, bass reproduction capability at around

f

0

is 3 dB higher when an HP sound reflector is

used.

This has listeners perceive the sound to be very

rich, as if they are listening to a larger sized

speaker. As a matter of fact, the response curve

represents ideal characteristics.

Figur17shows a case where an HP reflector is located on 3

of the interior faces of the

enclosure. The use of the HP system permits time-

dependent attenuation to occur

gradually and consistently after a 10 m second period over

the entire sound spectrum.

Figure17

Figure18

20 50 100 200 500 1k 2k 5k 10k 20k

90

100

80

70

60 Hz

(dB)

Frequency responses with HP sound reflectors and glass wool

(woofer unit only)

With HPsound reflectors Withglasswool

- 15 -

a. For ideal driving of speakers, a 4-terminal structure is necessary to allow for independent connections.

b. To enable connection of a single amplifier to each speaker driver, with a wire most appropriate for each

speaker.

c. To allow to attain, by reversing the phase, characteristics most suitable for the specificlistening

environment.

Bi-wiring systems permit creation of conditions most appropriate for driving speakers, using 2 identical or different

amplifiers. If these are the case, remove the short bars present between the woofer and tweeter terminals.

TECHNICAL SPECIFICATIONS

Impedance:

Frequency Range:

Sensitivity:

Power Hamdling (program):

Weight:

Crossover:

8 ohms

60~40k(Hz)

89dB/W(1m)

100W

9.1kg

12kHz

Frequency response (in-phase connection)

Frequency response (opposite phase connection)

40000020000100005000200010005002001005020

90

100

80

70

60

50

40

30

110

10 Hz

dB

40000020000100005000200010005002001005020

90

100

80

70

60

50

40

30

110

10 Hz

dB

40000020000100005000200010005002001005020

90

100

80

70

60

50

40

30

110

10 Hz

dB

Frequency response (directivity)

40000020000100005000200010005002001005020

80

90

70

60

50

40

30

20

100

10 Hz

dB

(274)

267

340

240

Distortion

2nd order distortion

3nd order distortion

0

0

30

0

60

0

Fostex Corporation, 3-2-35 Musasino, Akisima, Tokyo, Japan 196-0021

Tel: +81(0)42-546-4974 Fax: +81(0)42-546-9222

Other manuals for NF-1

3

Table of contents

Other Fostex Speakers manuals

Fostex

Fostex P800-E User manual

Fostex

Fostex FE163En-S User manual

Fostex

Fostex PX-6 User manual

Fostex

Fostex PM0.1 User manual

Fostex

Fostex Dome Tweeter FT207D User manual

Fostex

Fostex FE108E Sigma User manual

Fostex

Fostex FE207E User manual

Fostex

Fostex 6301B User manual

Fostex

Fostex PM-1 User manual

Fostex

Fostex FE127E User manual

Fostex

Fostex NF-1A User manual

Fostex

Fostex 6301BEAV User manual

Fostex

Fostex FE103En User manual

Fostex

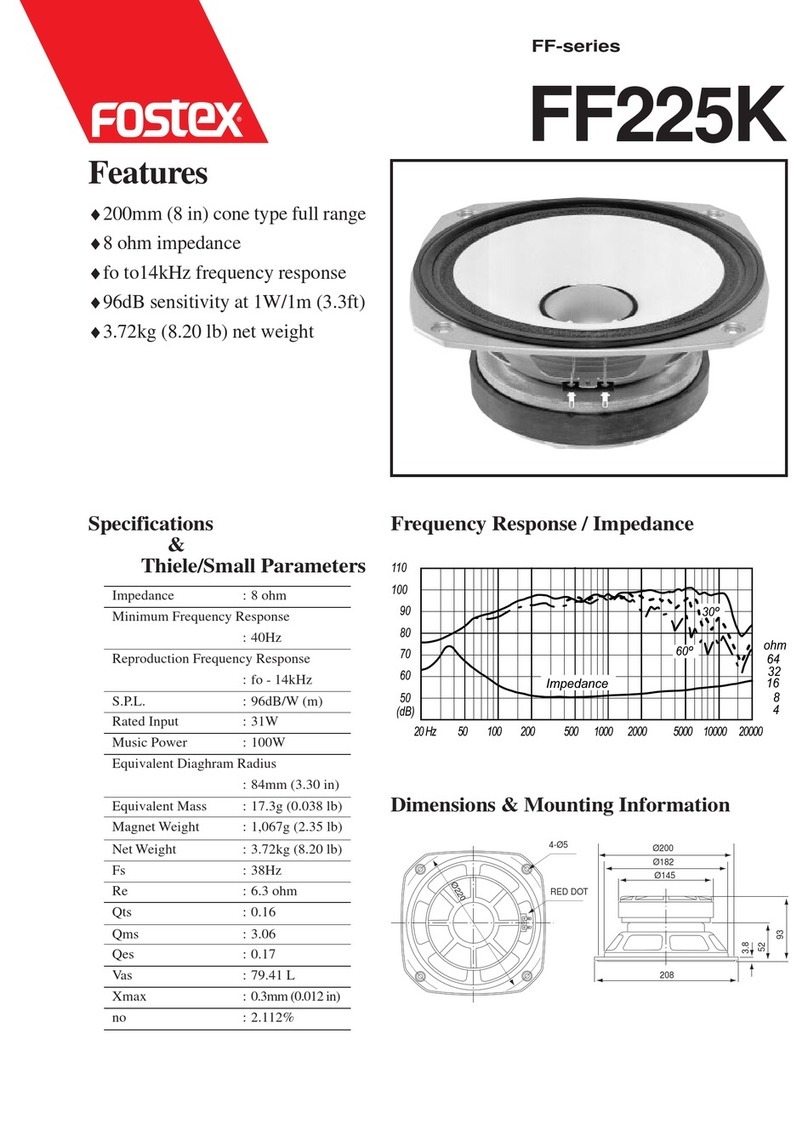

Fostex FF225K User manual

Fostex

Fostex P650-E User manual

Fostex

Fostex FE83En User manual

Fostex

Fostex PX-5HS User manual

Fostex

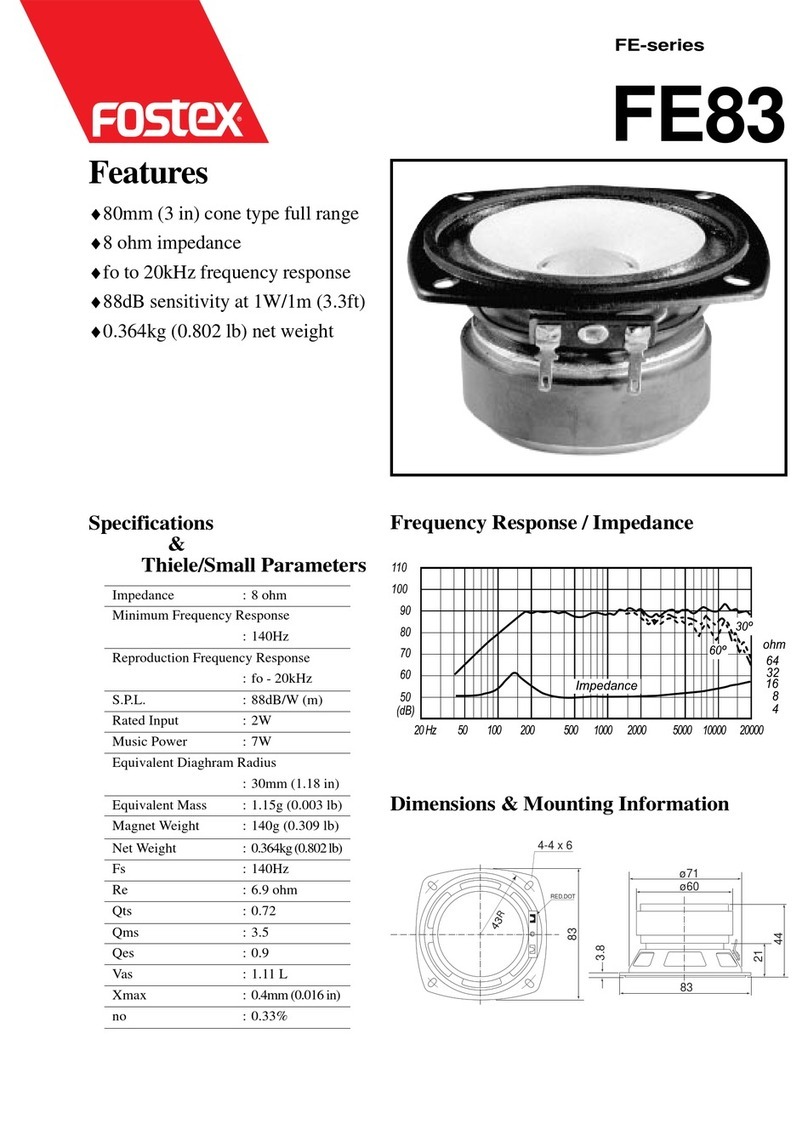

Fostex FE83 User manual

Fostex

Fostex FE206En User manual

Fostex

Fostex PX-5HS User manual