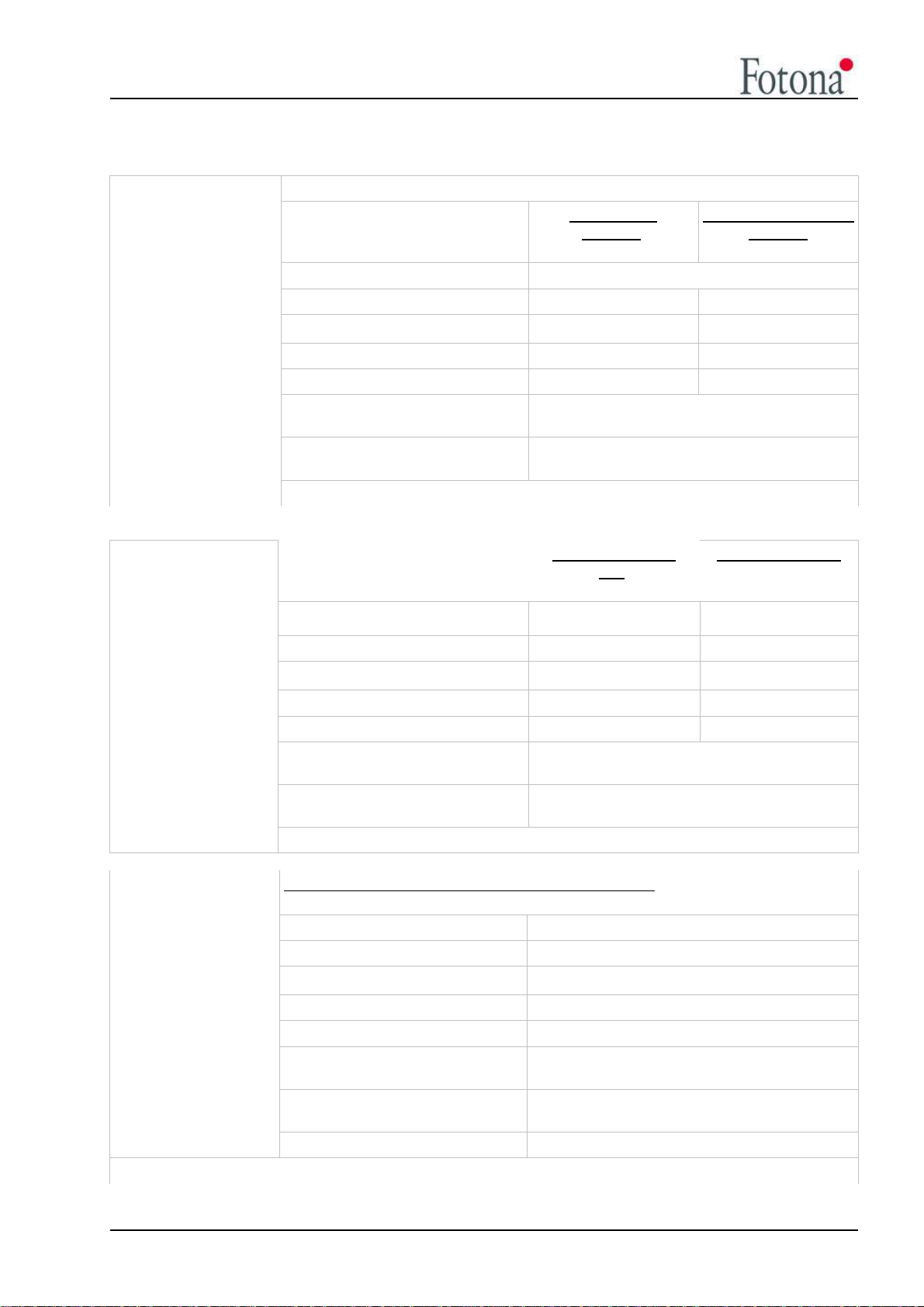

6.5.1.Nd:YAG energy meters calibration.......................................................................................................66

6.5.1.1.Checking the Q-SW energy meter calibration...............................................................................66

7.Nd Q-SW Energy meter calibration 1 (field service, preferred)..............................................................66

7.1.Nd Q-SW Energy meter calibration 2...................................................................................................67

7.1.1.ACC energy meter calibration...............................................................................................................67

7.1.1.1.ACC energy meter calibration test.................................................................................................67

7.1.1.2.ACC energy meter calibration........................................................................................................67

7.1.2.KTP energy meters calibration.............................................................................................................68

7.1.2.1.Checking the KTP energy meter calibration..................................................................................68

7.1.2.2.KTP energy meter calibration.........................................................................................................68

7.2.Articulated arm alignment ...........................................................................................................................69

7.2.1.Tools:....................................................................................................................................................69

7.2.2.Aiming beam alignment........................................................................................................................69

7.2.2.1.OPTION 1 (Default): ......................................................................................................................69

7.2.2.2.OPTION 2:.....................................................................................................................................71

7.2.3.Arm alignment.......................................................................................................................................71

7.2.3.1.First mirror alignment.....................................................................................................................71

7.2.3.2.Second mirror alignment................................................................................................................72

7.2.3.3.Third mirror alignment. ..................................................................................................................72

7.2.3.4.Forth mirror alignment....................................................................................................................73

7.2.3.5.Fifth mirror alignment.....................................................................................................................73

7.2.3.6.Sixth mirror alignment....................................................................................................................73

7.2.3.7.Seventh mirror alignment...............................................................................................................74

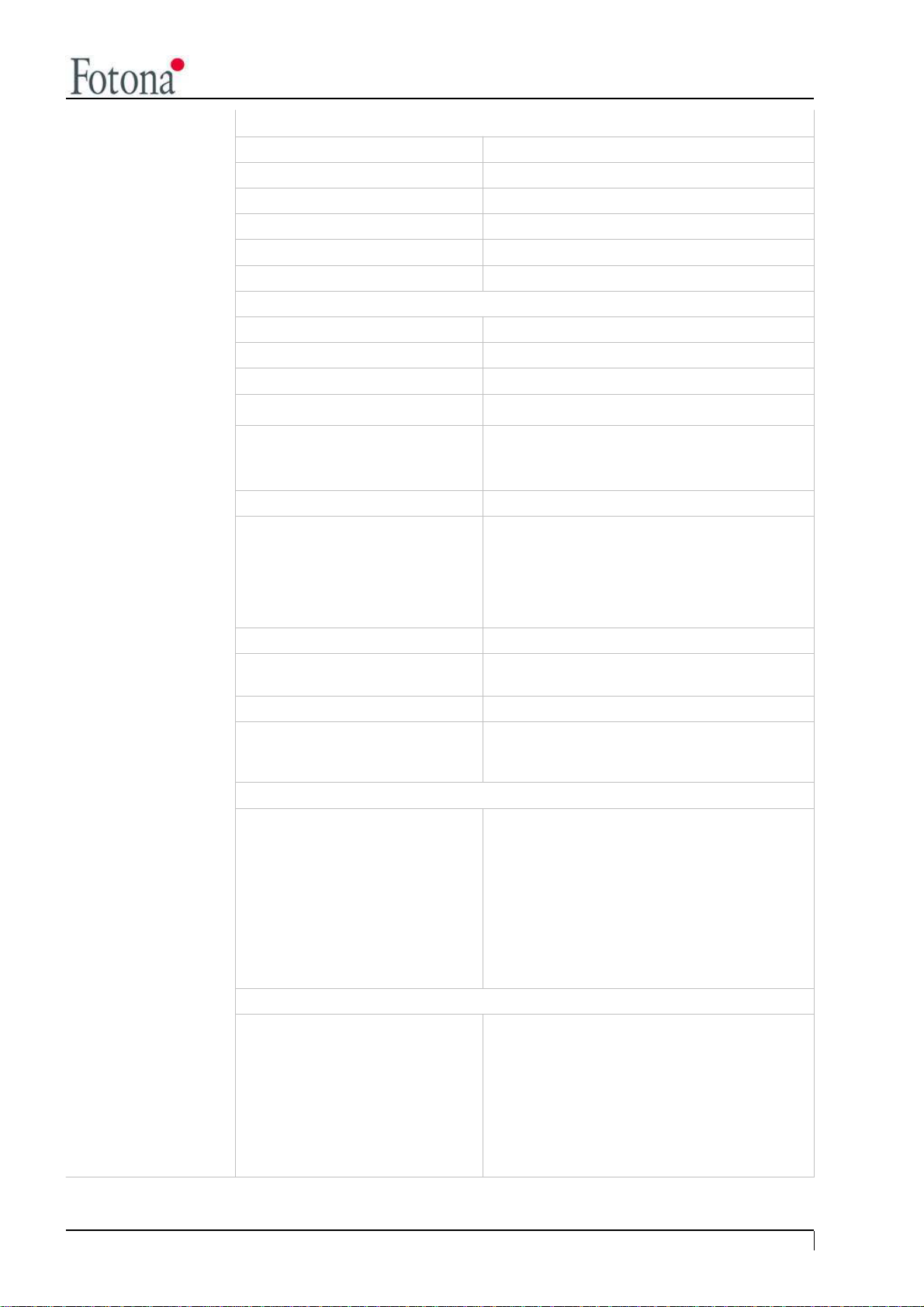

8.TROUBLESHOOTING...................................................................................................................................75

8.1.Advisory messages.....................................................................................................................................75

8.1.1.Advisory messages during power-up....................................................................................................75

8.1.2.Advisory messages during self-test......................................................................................................75

8.1.3.Advisory messages in normal operation...............................................................................................75

8.1.4.Advisory message in service mode......................................................................................................76

8.2.Error messages reported by the system.....................................................................................................76

8.2.1.System error 10 - parameters error .....................................................................................................76

8.2.2.System error 11 - Energy meter communication error.........................................................................77

8.2.3.System error 12 – Energy meter data not available timeout................................................................77

8.2.4.System error 13 - Energy meter supply voltage low.............................................................................78

8.2.5.System error 14 - Energy meter data transfer error CRC failure..........................................................78

8.2.6.System error 16 – EM1 data transfer error, wrong wavelength read....................................................78

8.2.7.System error 17 – EM2 data transfer error, wrong wavelength read....................................................78

8.2.8.System error 18 – Energy meter saturation error.................................................................................78

8.2.9.System error 19 (or five longer beeps at power-on) – Console communication (I2C) error.................78

8.2.10.System error 20 - Shutter blocked in open position............................................................................78

8.2.11.System error 21 - Shutter blocked in closed position.........................................................................79

8.2.12.System error 22 – Laser switch blocked.............................................................................................79

8.2.13.System error 23 – Laser switch blocked.............................................................................................79

8.2.14.System error 24 – Head control error.................................................................................................79

8.2.15.System error 30 - Cooling liquid flow error ........................................................................................79

8.2.16.System error 31 - Cooling liquid pump soft start circuit error.............................................................80

8.2.17.System error 32 - Cooling liquid overheated or temperature switch error..........................................80

8.2.18.System error 40 - Simmer error (simmer current not present)...........................................................80

8.2.19.System error 50 - Overshoot in energy (> +20%) of Nd:YAG laser....................................................81

8.2.20.System error 52 – Missing laser pulse................................................................................................81

8.2.21.CANNOT CALIBRATE USE LOWER SETTINGS.............................................................................81

8.2.22.System error 56 – Under energy of Nd:YAG laser.............................................................................82

8.2.23.System error 57 - Under voltage limit in calibration of Nd:YAG laser.................................................82

8.2.24.System error 58 - Energy meters mismatch >30% of Nd:YAG laser.................................................82

8.2.25.System error 59 – High Q-switch leakage..........................................................................................82

8.2.26.System error 60 - HV Power supply error (charging time > 2s)..........................................................83

8.2.27.System error 61 – PFM Module assembly error (high voltage dropped under 120V)........................83

8.2.28.System error 62 – OW1 control signal error.......................................................................................83

8.2.29. System error 67 - HV Power supply relay error ................................................................................83

8.2.30.System error 68 - HV Power supply, capacitor bank without 24VDC.................................................84

8.2.31.System error 69 - HV Power supply error in selftest...........................................................................84

8.2.32.System error 99 – Program execution error.......................................................................................84

Page 6/94 83826 SM ENG/5