Part No. 26984 Rev. C May 2018 - 4 - Refrigerated Milk Drawer

Interior...........................................................................................................................................................14

Empty the Drawer....................................................................................................................................14

Lift Out Plastic Guides.............................................................................................................................14

Lift Out Sloping Base Tray ......................................................................................................................14

Lift Out the Baffle Plate ...........................................................................................................................14

Cleaning Routines........................................................................................................................................15

Schedules................................................................................................................................................15

Removable Filter.....................................................................................................................................15

Condenser Radiator................................................................................................................................15

Inspection................................................................................................................................................15

Correction................................................................................................................................................15

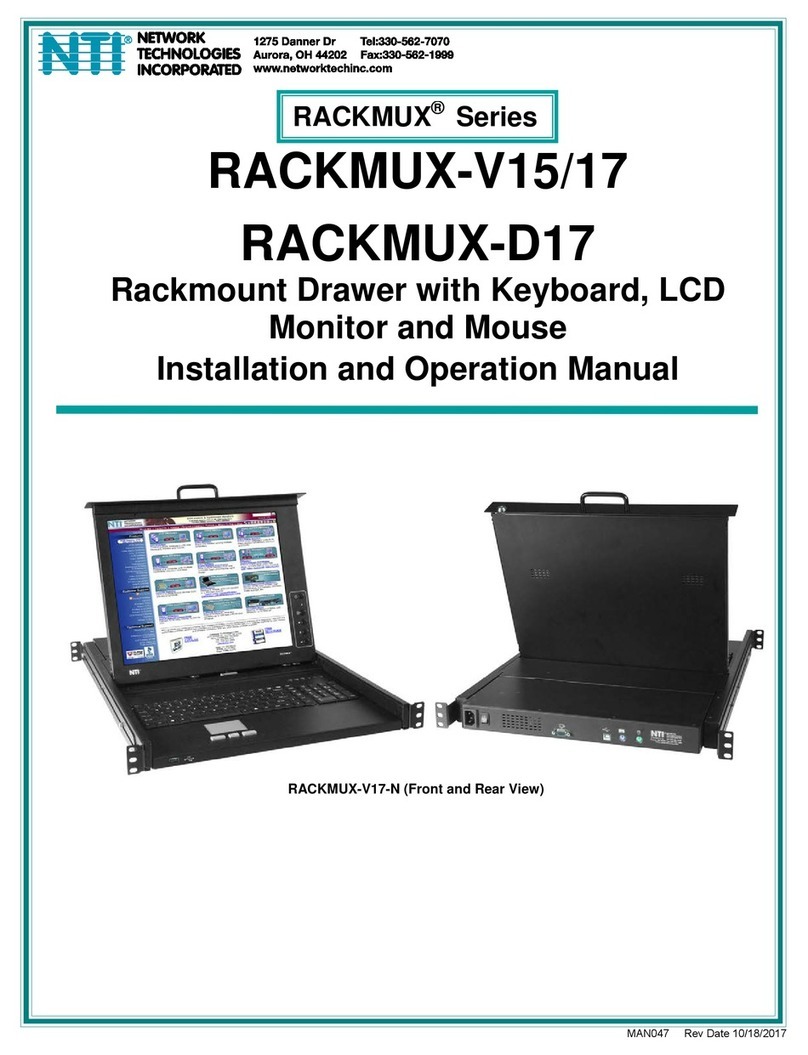

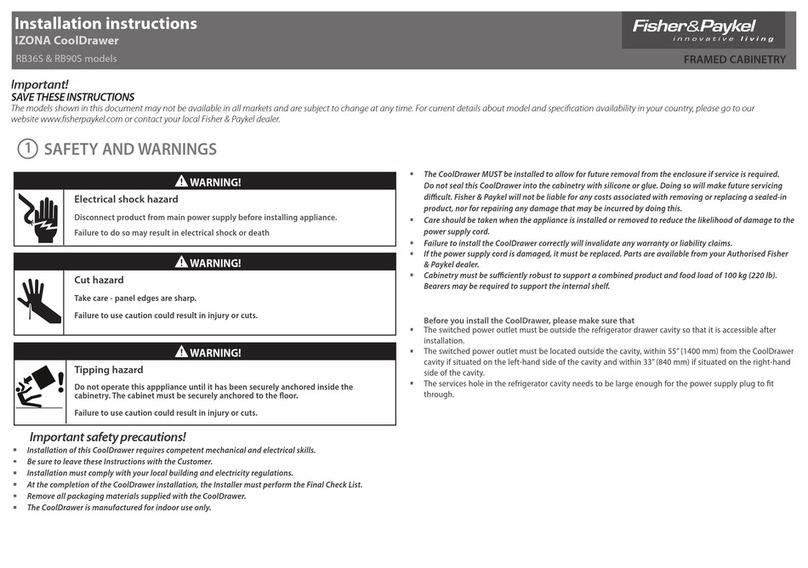

INSTALLATION...............................................................................................................16

Regulations...................................................................................................................................................16

Compliance with Local Requirements .....................................................................................................16

Setting Up .....................................................................................................................................................16

Unpacking ...............................................................................................................................................16

Positioning the Cabinet ...........................................................................................................................16

Support Bolt.............................................................................................................................................16

Condensate Drain ...................................................................................................................................17

Cabinet Preparation ................................................................................................................................17

Power Supply and Earthing.....................................................................................................................17

Connection Terminals .............................................................................................................................17

Isolation...................................................................................................................................................17

Mains Lead....................................................................................................................................................17

Lead Replacement..................................................................................................................................17

SERVICING .....................................................................................................................18

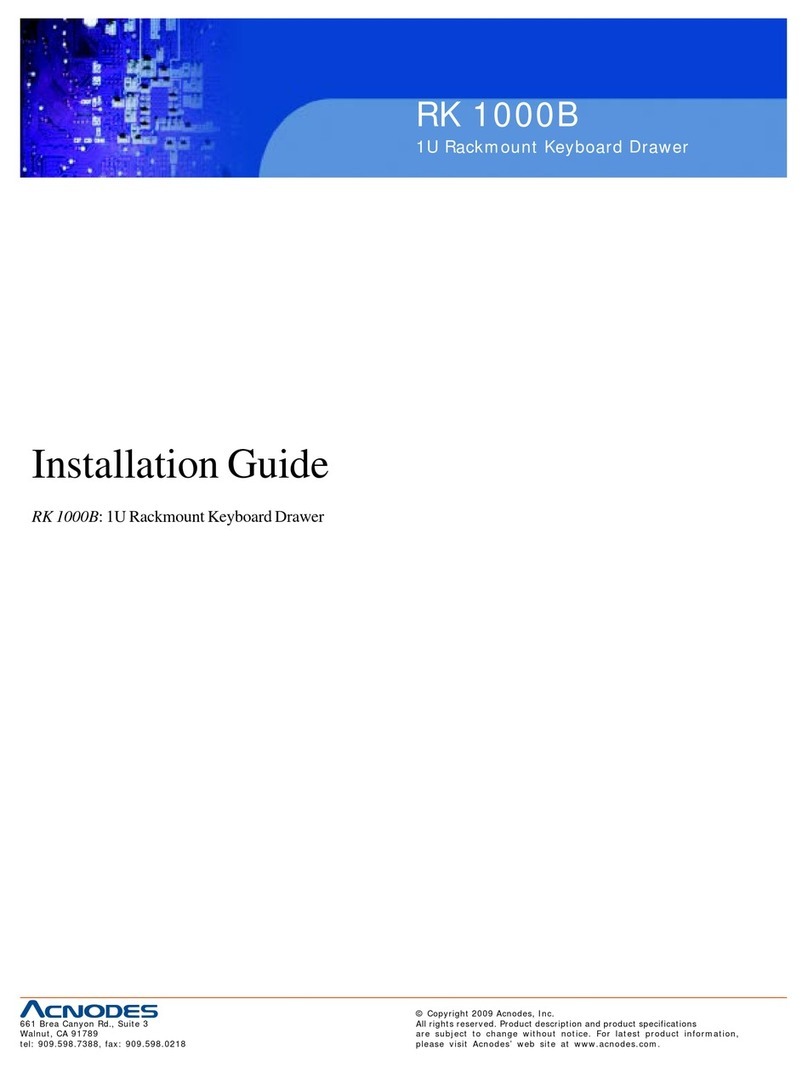

Control Gear .................................................................................................................................................18

Control Gear Location.............................................................................................................................18

Control Gear Chassis..............................................................................................................................18

Heating Element......................................................................................................................................18

Drawer Catch Adjustment .......................................................................................................................18

Refrigeration.................................................................................................................................................19

Caution....................................................................................................................................................19

Removable Filters ...................................................................................................................................19

Condenser Radiator................................................................................................................................19

Access to Refrigeration Equipment.........................................................................................................19

Support Bolt.............................................................................................................................................20

Evaporator Access..................................................................................................................................20

Evaporator Fans......................................................................................................................................20

Temperature Probes ...............................................................................................................................20