NT 1900 B – 02/2019 _______________________________________________________________2

1GENERAL INFORMATION

1.1 BEFORE YOU START

Before installation, please read this manual, which contains all the instructions on using the product

correctly and safely.

This manual contains important instructions to ensure correct installation of the ventilation unit.

Before installing the unit, please carefully read and follow all the instructions below. The manufacturer

reserves the right to make changes to this manual and to the technical documentation without prior

notice. Please keep this manual for future use. Please consider this manual as an integral part of the

product.

Installation and maintenance must only be carried out by qualified and experienced technicians to

ensure compliance with the local standards in force and to maintain the warranty.

1.2 RECEIPT OF THE PRODUCT

Upon delivery, immediately check whether the product packaging is intact. In case of damage to the

package, inform the haulier. If the complaint is not made on time, a subsequent application will no

longer be accepted. Check that the type of product delivered corresponds to your order. If in doubt,

do not unpack the unit, and inform France AIR.

After unpacking, check the condition of the units and all components. If in doubt, consult the supplier.

Never use a damaged unit. Always store in a dry location with an ambient temperature of between +5

°C and +35 °C.

If these instructions are not followed, the France AIR warranty will be invalid.

If the ventilation unit has been exposed to temperatures of less than 0 °C during transport, leave the

unit unpacked at ambient temperature for at least 2 hours before commencing system start-up, to

allow the temperature in the unit to equalise.

In general, avoid storing the product for long periods; if this cannot be avoided, a full inspection must

be performed before start-up, paying particular attention to the turbine bearings. A maximum storage

period of 1 year is recommended.

1.3 PRODUCT DESCRIPTION

The MODULYS® Eco unit is a fan unit designed to be integrated into single-flow ventilation installations,

for air supply or extraction, and is intended for use in tertiary buildings.

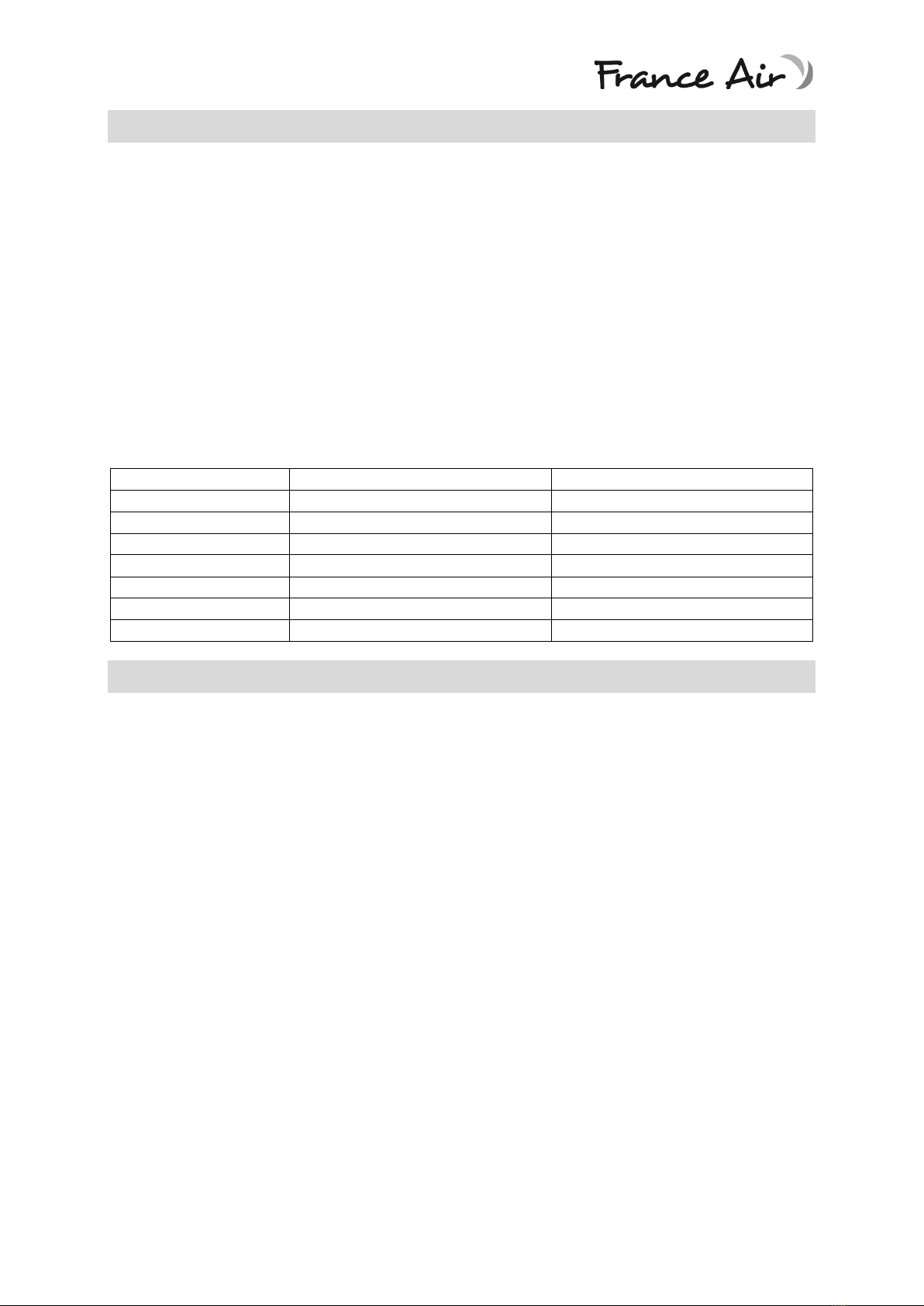

MODULYS® Eco fans are centrifugal fans with backward-curved blades (size 500) and with forward-

curved blades (size 800 and above), directly coupled to an asynchronous motor.

The product is equipped with a single filter on the intake

2SAFETY INFORMATION

The MODULYS® Eco unit is designed to convey clean air, i.e. it must not be used for extraction or supply

of smoke, gas, or dust. Similarly, it should not be used in an explosive or corrosive atmosphere.

To ensure the MODULYS® Eco provides a maximum service life, if used in a harsh environment, the

MODULYS® Eco ventilation unit should be run permanently.

The MODULYS® Eco can be used outdoors. However, you must check that the unit is installed on

drained ground or a raised support.

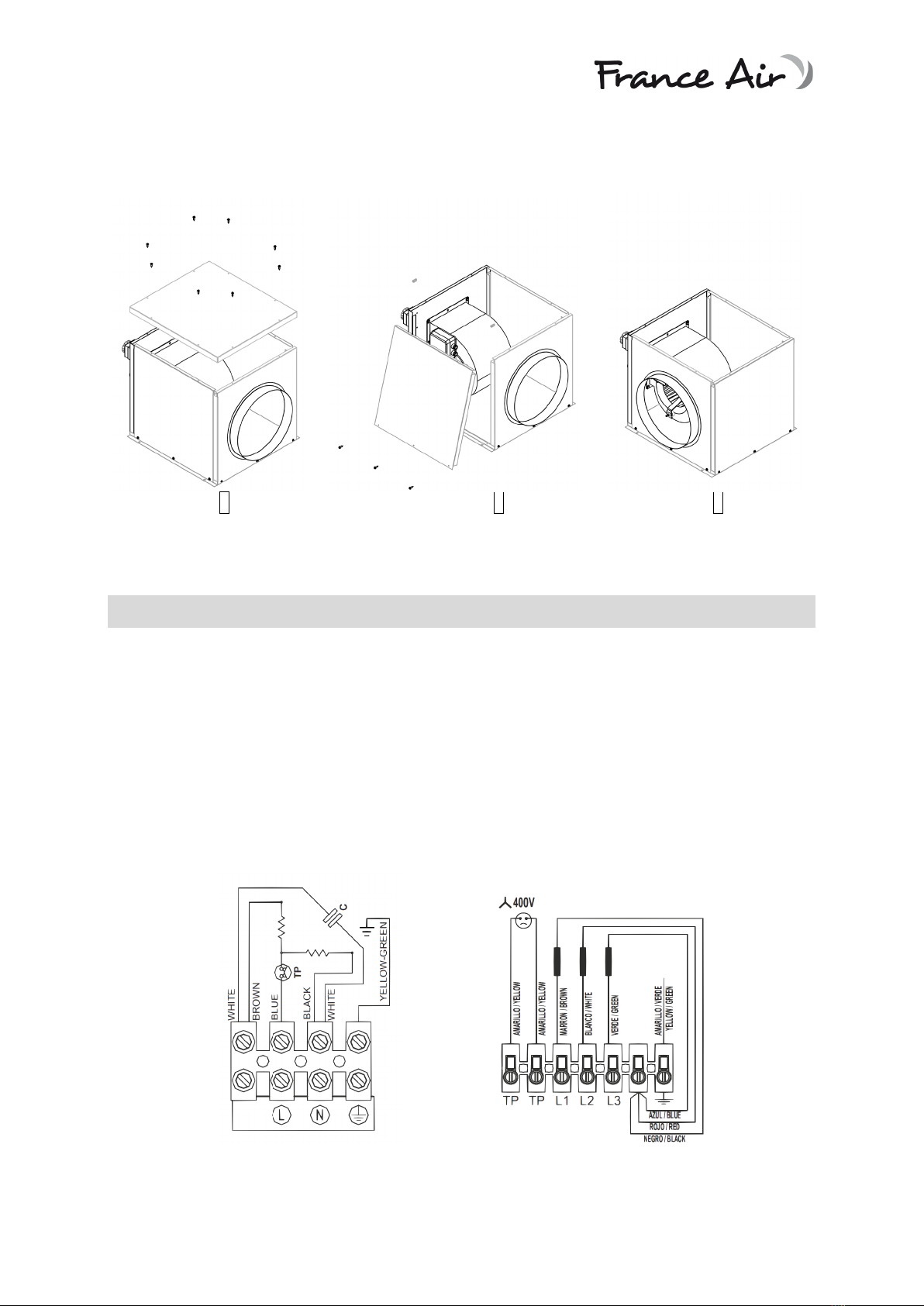

It can be installed in any position.