-2-

SAFETY INSTRUCTION

Maintenance and replacement of pick-up spring may be carried out

only when the tractor engine is stopped and the rotors have stopped

rotating.

Always keep a good distance from the rotors when the machine is

working.

Power transmission shaft with slipping clutch must always be used.

INTRODUKTION

The Fransgård rotary turner is one of the fastest and most efficient

hay-turners on the world market today.

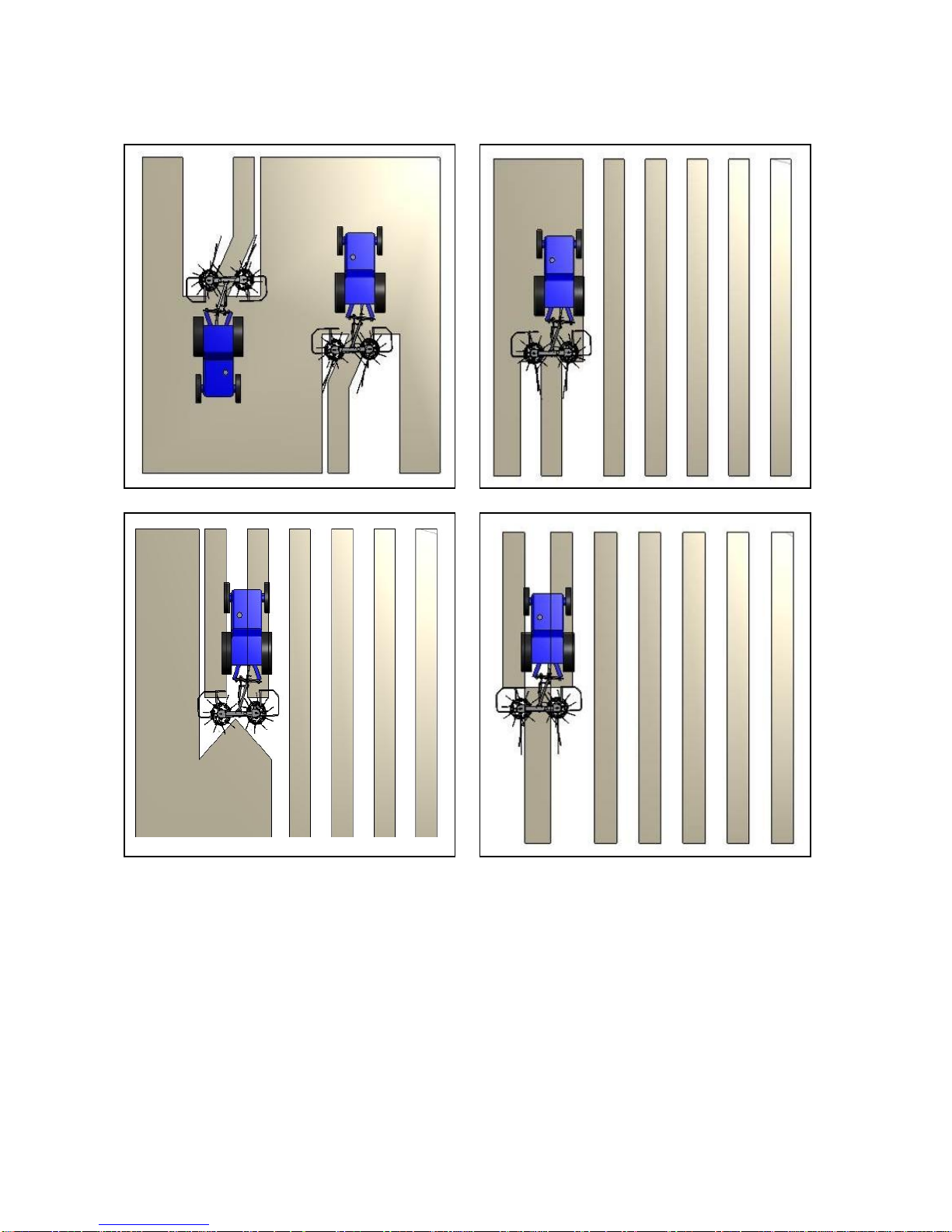

By adjusting to right wheel height and switching of the rake teeth to

turning, the material will be spread loosely and regularly over the field

to be dried quickly and efficiently.

For raking together, the Fransgård rotary turner is ideal. After moun-

ting of swath collectors and switching of rake teeth, a light and airy

swath is laid, well suited for collection with pick-up press.

The Fransgård rotary turner is built on a sturdy sectional steel frame,

which will withstand even strong stresses when passing over uneven

ground.

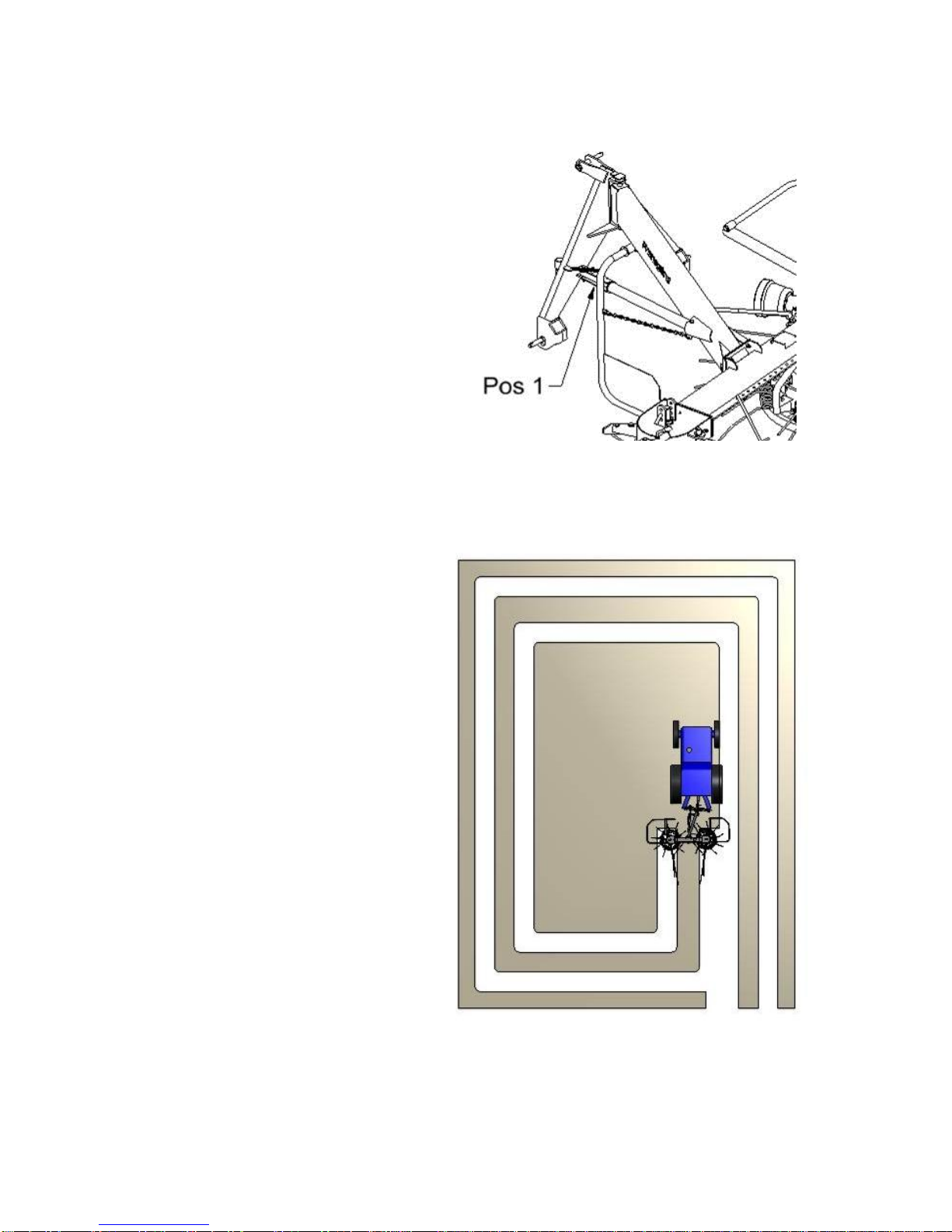

The rotary turner can be switched over quickly from transport position

to working position.

It has a closed rotor with 10 powerful pick-up springs, which are

thrown into working position by centrifugal force as soon as the engine

is started.

Its gearbox has hardened bevel gears, with standing heavy loads.

And it has a power transmission shaft with slipping clutch.

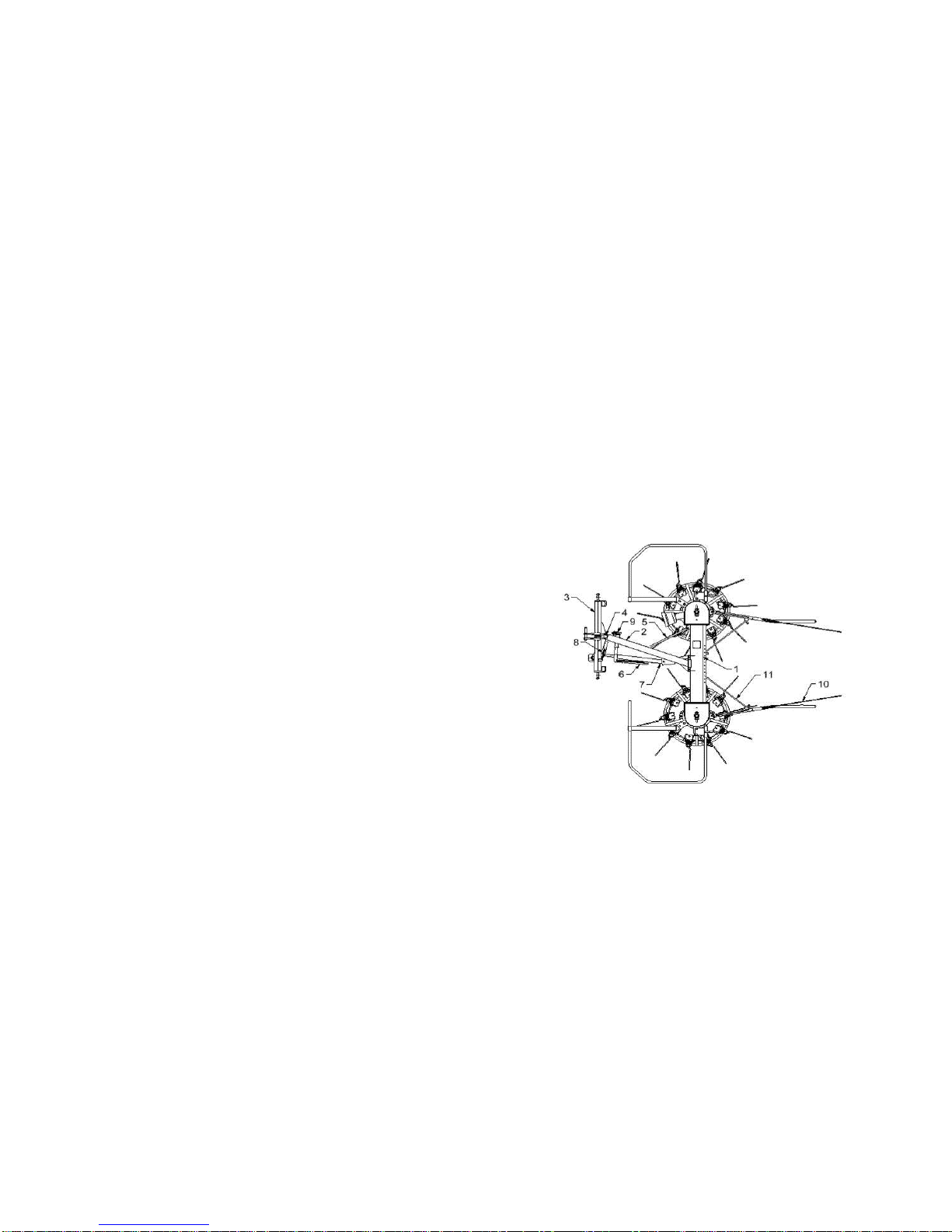

1 Main frame

2 Intermediary frame

3 Three-point suspension

4 Hinged bolt

5 Draw hook

6 Swath separator

7 Telescope tube

8 Rivet

9 Pin + spring

10 Swath collector

11 Attachment for swath collector

MOUNTING OF THE MACHINE

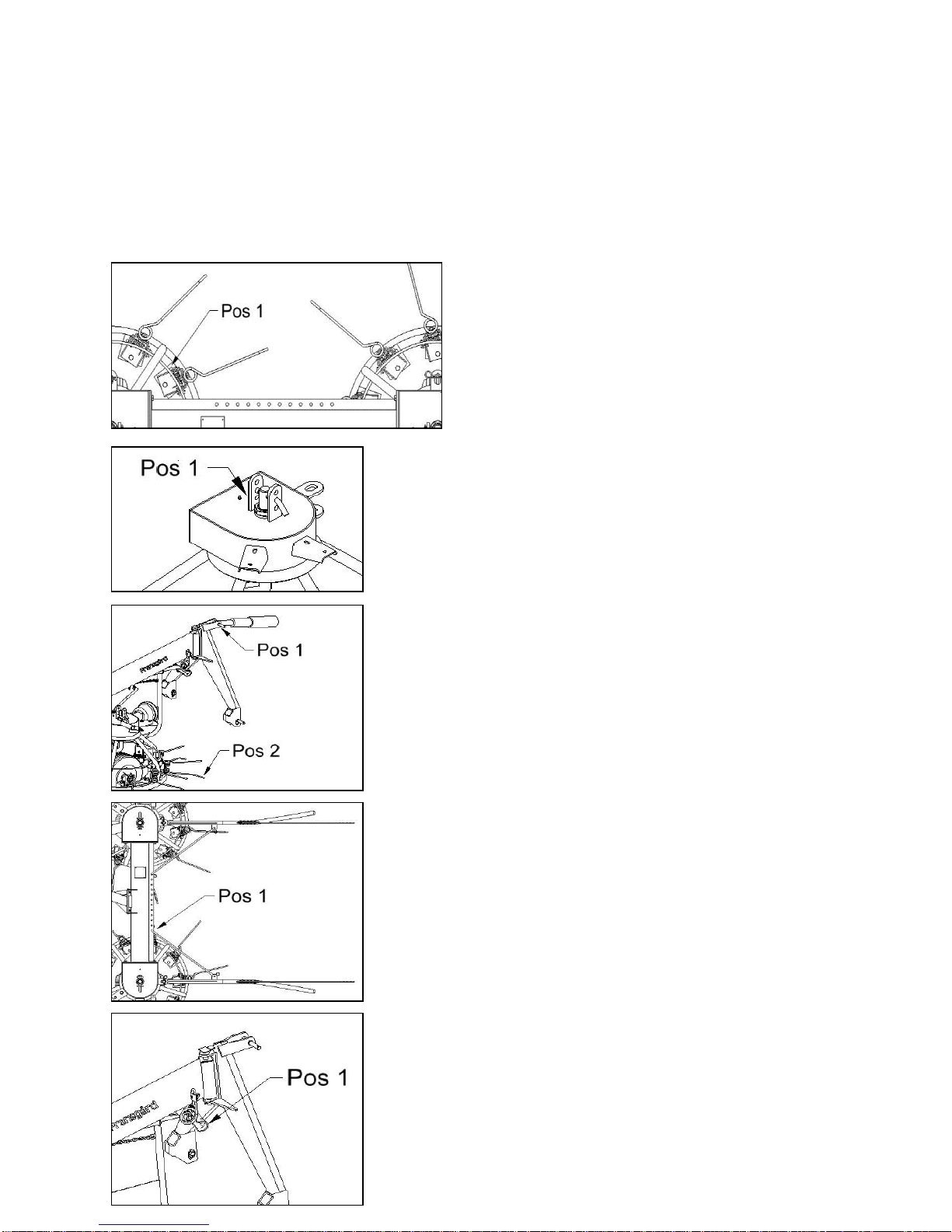

1) Intermediary frame 2is mounted on the main frame 1by means of

4 bolts and nuts. Tighten the bolts and tighten again after 2 hours

operation.

2) Three-point suspension 3is assembled and fastened to intermedi-

ary frame 2by means of hinged bolt 4. Place split pin.

3) Mount swath separator 6on intermediary frame 2. Mount spring on

swath separator and fasten with bolt.

4) Mount telescope tube 7on intermediary frame 2by means of rivets

and 2 split pins. The telescope tube is fastened to three-point suspen-

sion 3by means of rivet 8and 2 split pins.