DGA200 Rev160525

2

CONTENTS

List of Tables

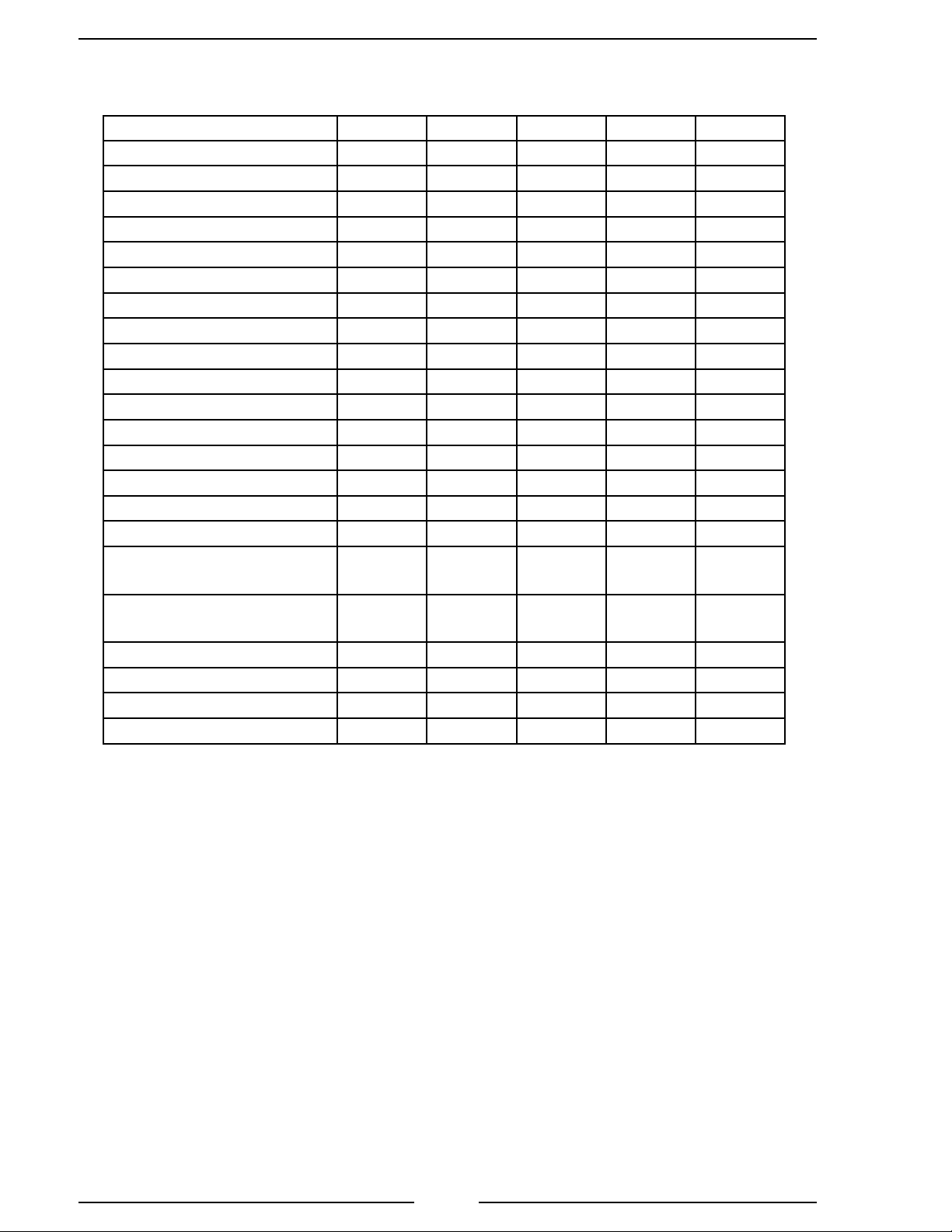

Table 1. Hardware...................................................................................................... 5

Table 2. Parts and Assemblies.................................................................................... 6

List of Figures

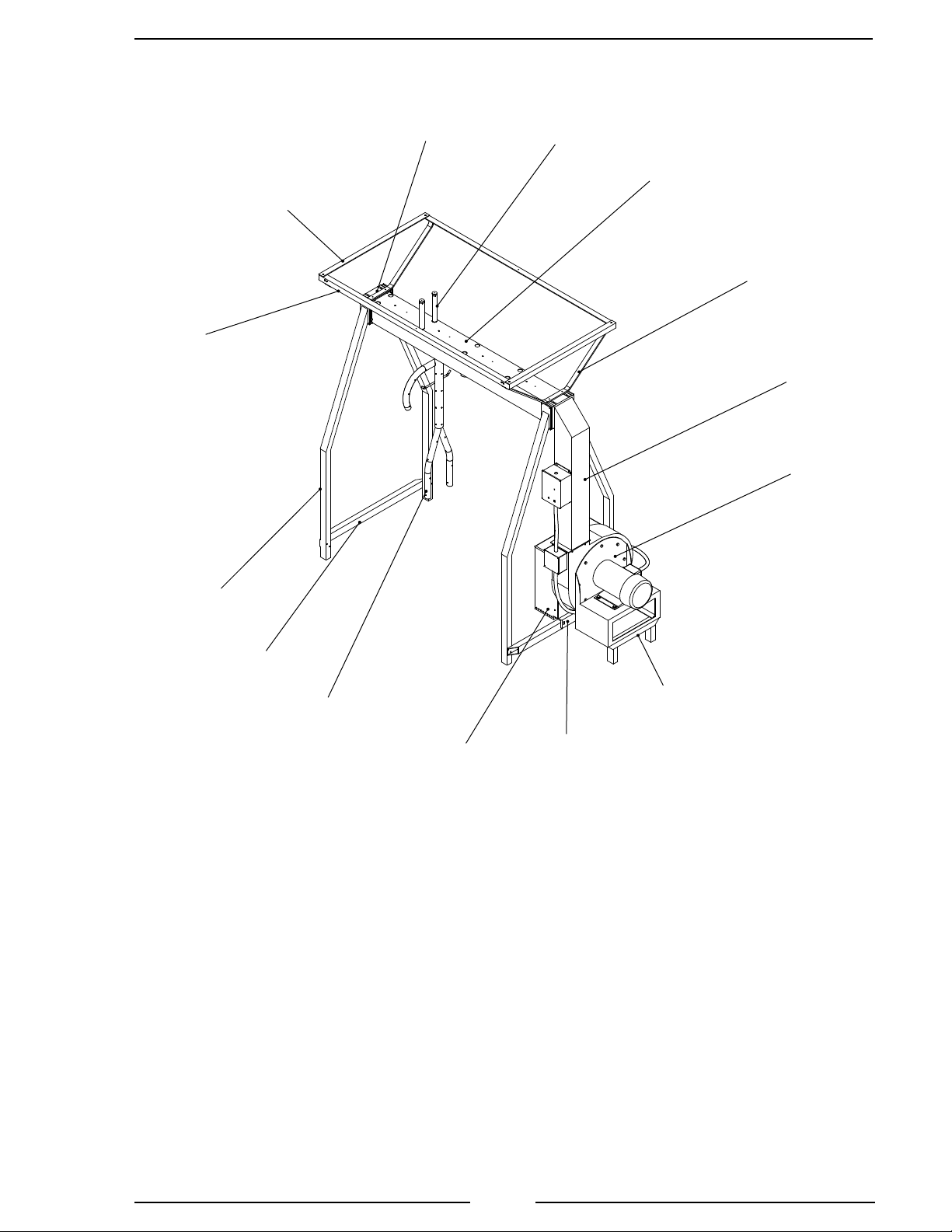

Figure 1. DryGear System Parts ................................................................................ 7

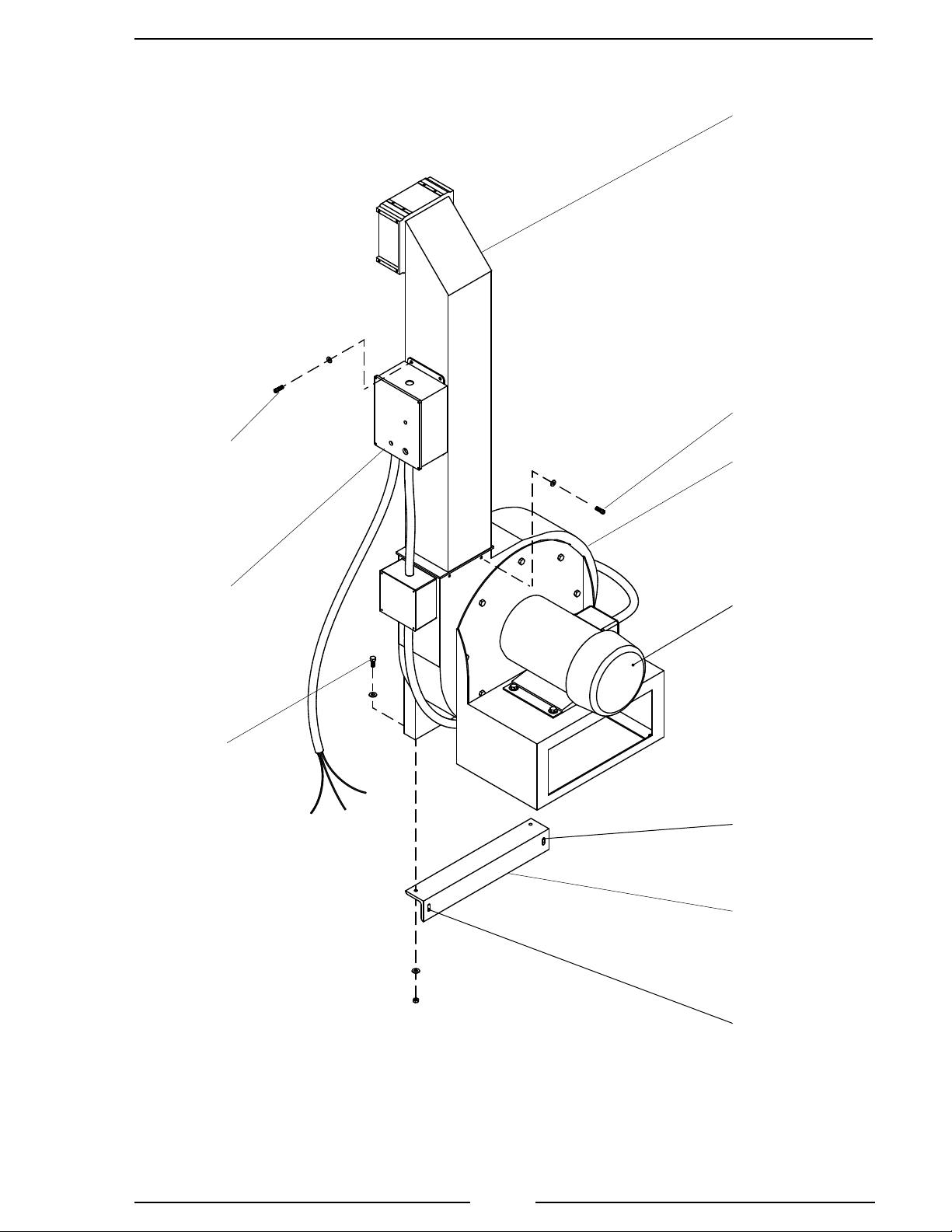

Figure 2. Blower Assembly and Transfer Tube ......................................................... 9

Figure 3. Manifold and Tent Frame Long Angles.................................................... 11

Figure 4. Leg Assemblies......................................................................................... 13

Figure 5. Blower Assembly Legs............................................................................. 15

Figure 6. Tent Frame................................................................................................ 17

Figure 7. Manifold, Tent Frame, and Mufer.......................................................... 19

Figure 8. Hanger and Glove Post............................................................................. 21

Figure 9. Tent Enclosure .......................................................................................... 23

Figure 10. Caster Kit................................................................................................ 25

Figure 11. Wiring Power.......................................................................................... 27

Figure 12. Control Box Panel .................................................................................. 29

Table of Contents

CONTENTS................................................................................................................ 2

INTRODUCTION ...................................................................................................... 3

Overview................................................................................................................ 3

Specications......................................................................................................... 4

ASSEMBLY INSTRUCTIONS.................................................................................. 5

Pre-Assembly......................................................................................................... 5

Tools Required....................................................................................................... 5

General Notes ........................................................................................................ 7

Assemble Blower Assembly and Transfer Tube.................................................... 8

Assemble Manifolds and Tent Frame Long Angles (6, 7, and 8 Station Only)... 10

Assemble Legs..................................................................................................... 12

Install Blower Assembly Legs ............................................................................. 14

Assemble Tent Frame .......................................................................................... 16

Assemble Manifold, Tent Frame, and Mufer..................................................... 18

Install Hanger and Glove Post ............................................................................ 20

Install Tent Enclosure .......................................................................................... 22

Install Optional Caster Kit ................................................................................... 24

WIRING POWER..................................................................................................... 26

OPERATION ............................................................................................................ 28