Remedy

1. Replacefuseorresetbreaker.

2. Repairor replace wire fastenersat

dishwasherjunctionbox.

3.Replacetimer.

4. Replacemotor/impellerassembly.

5. Replacedoorswitch.

6. Replacelatchassembly.

7. Replaceselectorswitch.

1. Replacemotor.

2. Rotatemotorfanorimpeller.

1. Checkvoltage.

2. Rotate motor fan or impeller, or

replace.

3. Clearblockageorreplace.

4. Replacemotor/impellerassembly.

5. Cleanandclearblockage.

1. Replaceheaterelement.

2. Replacetimer.

3. Repairorreplace.

4. Replacethermostat.

1. Replacedispenser.

2. Replacetimer.

3. Repairorreplace.

4. Replacedispenser.

5. Replaceactuator.

1. Clearrestrictions.

2. Replacetimer.

3. Replacepump.

4. Makesurehoseis attached inproper

positiononsideoftub.

5. Checkforblockage,clear.

6. Replacewindings.

1. Turnwatersupplyon.

2. Replacewaterinletfillvalve.

3. Disassembleandcleanscreen.

4. Repairorreplace.

5. Replacetimer.

6. Repairorreplace.

7. Cleanfloat.

1. Replacetimer.

2. Repairorreplacetimer.

3. Repairoradjust.

4. Replace or adjust position of

thermostat.

1. Repairtoproperheight.

2. Installairgapatcountertop.

3. Reattachdrainhose.

1. Instructcustomer/user.

2. Instructcustomer/user.

3. Instruct customer/user on proper

loadingofdishes.

4. Incomingwatertemperatureof120°F

is required to properly dissolve

dishwashingdetergents.

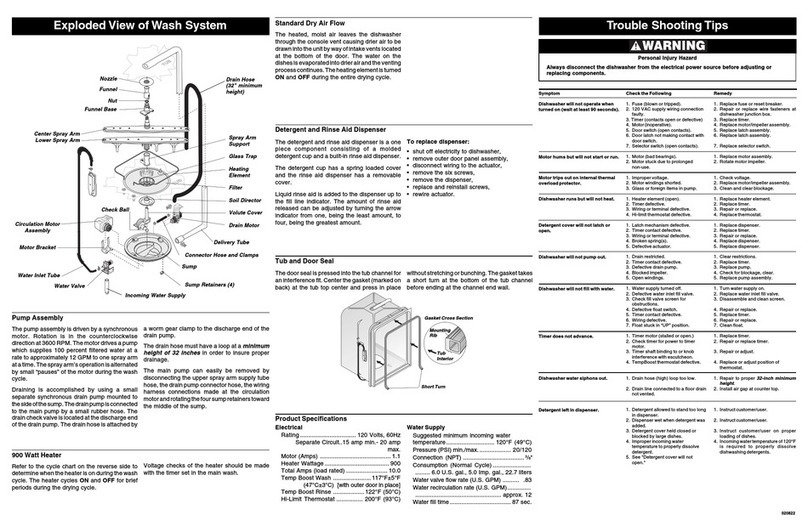

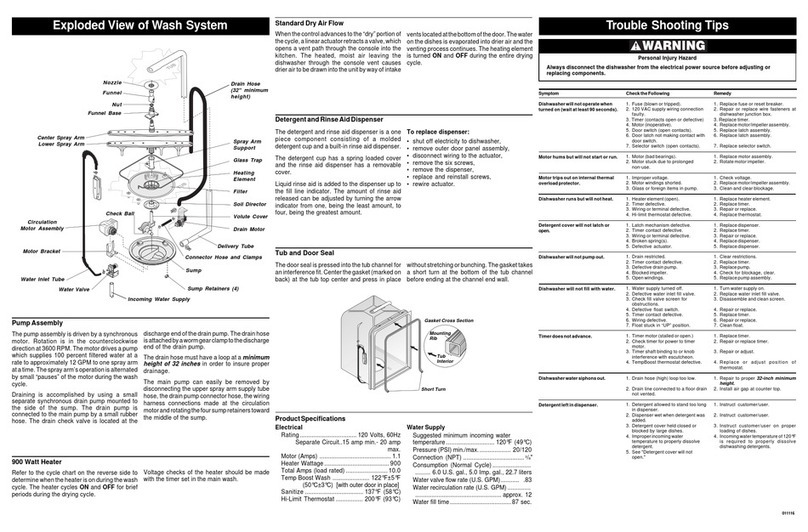

TroubleShootingTipsExplodedViewofWashSystem

Tub and Door Seal

Thedoorsealispressedintothetubchannel for

aninterferencefit.Centerthegasket(markedon

back)at the tub top centerand press in place

ProductSpecifications

Electrical

Rating .......................... 120Volts,60Hz

SeparateCircuit..15ampmin.-20ampmax.

Motor(Amps) ................................. 1.1

HeaterWattage .............................. 900

TotalAmps(loadrated) ................... 10.0

TempBoost(somemodels) .... 122°F(50°C)

HeatedWash/HeatedRinse

Hi-LimitThermostat ............. 200°F(93°C)

WaterSupply

Suggestedminimumincomingwater

temperature ...................... 120°F(49°C)

Pressure(PSI)min./max. ............... 20/120

Connection(NPT) ............................ 3/8"

Consumption(NormalCycle) .................

....... 6.0U.S.gal.,5.0 Imp.gal.,22.7 liters

Watervalveflowrate(U.S.GPM) ....... .83

Waterrecirculationrate(U.S.GPM) ..........

........................................ approx.12

Waterfilltime ............................ 87sec.

Detergent and Rinse Aid Dispenser

Thedetergentand rinseaiddispenser isaone

piece component consisting of a molded

detergentcupandabuilt-inrinseaiddispenser.

Thedetergent cuphas aspring loaded cover

andthe rinse aiddispenser has aremovable

cover.

Liquidrinseaid isaddedto thedispenserup to

thefill line indicator. The amount of rinseaid

releasedcanbe adjusted byturningthe arrow

indicatorfromone, beingthe leastamount,to

four,beingthegreatestamount.

To replace dispenser:

shutoffelectricitytodishwasher,

removeouterdoorpanelassembly,

disconnectwiringtotheactuator,

removethesixscrews,

removethedispenser,

replaceandreinstallscrews,

rewireactuator.

To replace actuator:

shutoffelectricitytodishwasher,

disconnectwiringtotheactuator,

placeaflathead screwdriverunderthe

actuatorbodyandbetweenthedispenser

housingandterminalside,twistandliftup

ontheactuatorbeingcareful nottodamage

theretainersnap-fits,

replacewithnewactuatorbypressinginto

place,

rewireactuator.

StandardDry Air Flow

Whenthecontroladvancestothedryportionof

the cycle, a linear actuator retracts a valve,

whichopens a ventpath throughtheconsole

intothekitchen.Thisventingmethodeliminates

dischargingheated moisture intothe motor

compartment.Theheated,moistairleavingthe

dishwasherthroughthe consoleventcauses

drierairtobedrawnintotheunitbywayofintake

ventslocated at the bottom of the door.The

wateronthe dishesisevaporated intodrierair

andtheventingprocesscontinues.Theheating

elementisturnedON andOFF duringthe entire

dryingcycle.

PowerDry AirFlow

ThePowerDryconfigurationisthesameasthe

Standardexceptithasacrossflowblowerlocated

intheairdischargepath.Theblowerassiststhe

heatingelementinproducingpowertodrivethe

moistairoutofthedishwasher.

Check the Following

1. Fuse(blownortripped).

2. 120VACsupplywiringconnection

faulty.

3.Timer(contactsopenordefective)

4. Motor(inoperative,check

resistances).

5. Doorswitch(open contacts).

6. Doorlatchnot makingcontactwith

doorswitch.

7. Selectorswitch(opencontacts).

1. Motor(badbearingsor locked

rotor).

2. Motorstuckdue toprolonged

non-use.

1. Impropervoltage.

2. Sealfacesbinding.

3. Motorshaftbinding.

4. Motorwindingsshorted.

5. Glassorforeignitems in pump.

1. Heaterelement(open).

2. Timerdefective.

3. Wiringorterminaldefective.

4. Hi-limitthermostatdefective.

1. Latchmechanismdefective.

2. Timercontactdefective.

3. Wiringorterminaldefective.

4. Brokenspring(s).

5. Defectiveactuator.

1. Drainrestricted.

2. Timercontactdefective.

3. Defectivedrainpump.

4. Airlockindrainhose.

5. Blockedimpeller.

6. Openwindings.

1. Watersupplyturned off.

2. Defectivewaterinletfillvalve.

3. Checkfillvalvescreenfor

obstructions.

4. Defectivefloatswitch.

5. Timercontactdefective.

6. Wiringdefective.

7. FloatstuckinUP position.

1. Timermotor(stalledoropen.)

2. Checktimerforpower to timer

motor.

3. Timershaftbindingto orknob

interferencewithescutcheon.

4. TempBoostthermostatdefective.

1. Drainhose(high)looptoo low.

2. Drainlineconnectedtoafloordrain

notvented.

3. Drainhosenotconnectedtoside of

tub.

1. Detergentallowedtostand toolong

indispenser.

2. Dispenserwetwhendetergentwas

added.

3. Detergentcoverheldclosedor

blockedbylargedishes.

4. Improperincomingwater

temperaturetoproperly dissolve

detergent.

5. See"Detergentcoverwillnot

open."

Always disconnect the dishwasher from the electrical power source before adjusting or

replacingcomponents.

Personal Injury Hazard

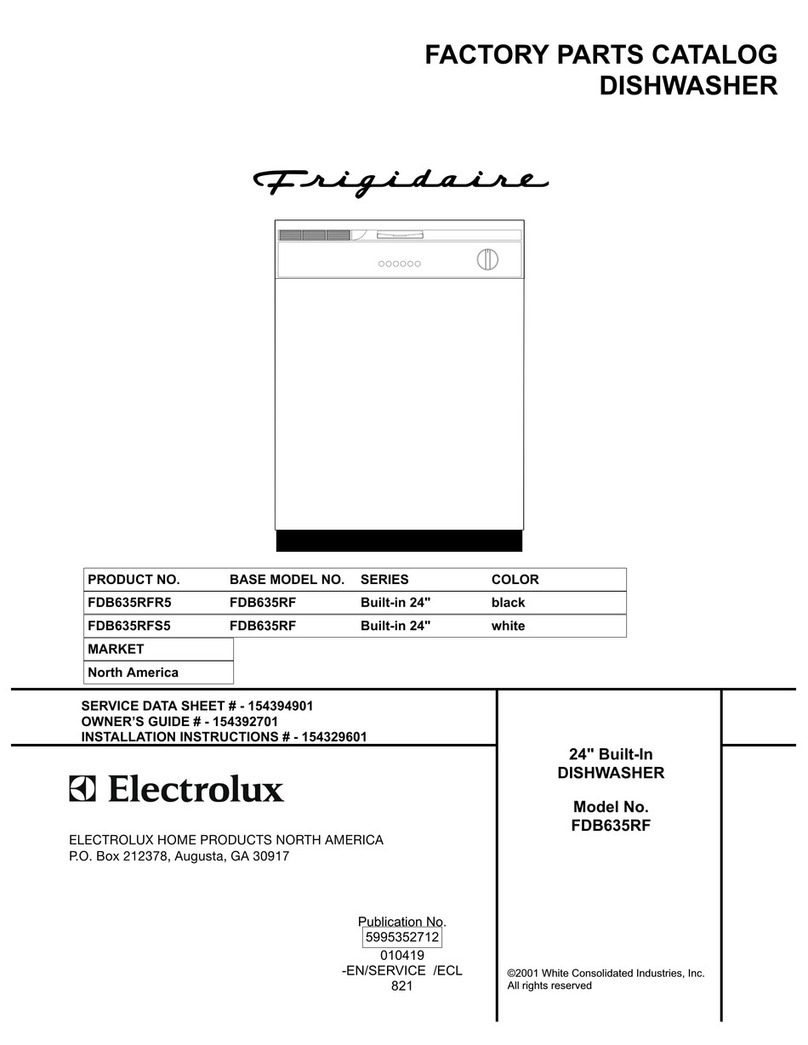

Nozzle

Funnel

Nut

FunnelBase

CenterSpray Arm

LowerSprayArm

Delivery Tube

ConnectorHose

Sump

WaterValve

WaterInletTube

Check Ball

CirculationMotor

Assembly

MotorBracket

900WattHeater

Referto the cyclechart on the reverse sideto

determinewhentheheaterisonduringthewash

cycle.The heatercycles ON and OFF forbrief

periodsduringthedryingcycle.

Voltagechecks ofthe heatershould be made

withthetimersetinthemainwash.

airlock. The drain loop on the side of thetub

mustbekept in placeafterservicing.

The main pump can easily be removed by

disconnectingtheuppersprayarmsupplytube,

thedrainpumpconnectorhose,andthewiring

harnessconnections madeat thecirculation

motorandthewaterheatthermostatslocatedon

thebottomofthepump.

Oncethepumpassemblyis removed fromthe

dishwasher,themotor/impellerassembly can

beremoved fromthe sumpby taking outthe

three (3) T-20 Torx head screws from the

aluminummotorbracketandthenthethree(3)

T-20Torxhead screwsfromthe volutecover.

Usinga large flat head screwdriver inserted

betweenthe impellerscrew andthe sumps

volute,themotor/impellerassemblycanbegently

priedoutofthesump.Use the screwdriverasa

lever.

PumpAssembly

The pump assembly is driven by a 1/12 HP,

shaded pole motor. Rotation is in the

counterclockwisedirectionat3100to3200RPM.

Themotordrives apumpwhich supplies100

percentfilteredwaterataratetoapproximately

12GPMto onesprayarm ata time. Thespray

armsoperationisalternatedbysmallpauses

ofthemotorduringthewashcycle.

Draining is accomplished by using a small

separatesynchronousdrainpumpmountedto

thesideofthesump.Thedrainpumpisconnected

tothemain pumpbya smallrubberhose. The

draincheck valveis locatedat the entrance to

thedrainpump.Thedrainhoseisattachedbya

wormgearclampto thedischargeofthe drain

pump.Thedrainisthenroutedupthesideofthe

dishwasherandattachedtothesideofthetub.

Thisdrainloopinsuresthatanairpocketcannot

formnearthedrainpumpandcausethepumpto

Symptom

Dishwasherwillnotoperatewhen

turned on (wait at least 90 seconds).

Motor hums but will not start or run.

Motor trips out on internal thermal

overload protector.

Dishwasher runs but will not heat.

Detergent cover will not latch or

open.

Dishwasherwillnotpumpout.

Dishwasher will not fill with water.

Timer does not advance.

Dishwasherwatersiphonsout.

Detergent left in dispenser.

withoutstretchingorbunching.Thegaskettakes

ashort turn atthe bottom ofthe tub channel

beforeendingatthechannelend wall.

Tub

Interior

Mounting

Rib

Gasket Cross Section

ShortTurn

IncomingWaterSupply

DrainHose

SprayArm

Support

GlassTrap

Heating

Element

Filter

Soil Director

Volute Cover

DrainMotor

991221