Remedy

1. Replacefuseorresetbreaker.

2. Repairorreplace wire fasteners at

dishwasherjunctionbox.

3.Replacetimer.

4. Replacemotor/impellerassembly.

5. Replacedoorswitch.

6. Replacelatchassembly.

7. Replaceselectorswitch.

1. Replacemotor.

2. Rotatemotorfanorimpeller.

1. Checkvoltage.

2. Rotate motor fan or impeller, or

replace.

3. Clearblockageorreplace.

4. Replacemotor/impellerassembly.

5. Cleanandclearblockage.

1. Replaceheaterelement.

2. Replacetimer.

3. Repairorreplace.

4. Replacethermostat.

1. Replacedispenser.

2. Replacetimer.

3. Repairorreplace.

4. Replacedispenser.

5. Replaceactuator.

1. Clearrestrictions.

2. Replacetimer.

3. Replacepump.

4. Makesurehoseisattached inproper

positiononsideoftub.

5. Checkforblockage,clear.

6. Replacewindings.

1. Turnwatersupplyon.

2. Replacewaterinletfillvalve.

3. Disassembleandcleanscreen.

4. Repairorreplace.

5. Replacetimer.

6. Repairorreplace.

7. Cleanfloat.

1. Replacetimer.

2. Repairorreplacetimer.

3. Repairoradjust.

4. Replace or adjust position of

thermostat.

1. Repairtoproperheight.

2. Installairgapatcountertop.

3. Reattachdrainhose.

1. Instructcustomer/user.

2. Instructcustomer/user.

3. Instruct customer/user on proper

loadingofdishes.

4. Incomingwatertemperatureof120°F

is required to properly dissolve

dishwashingdetergents.

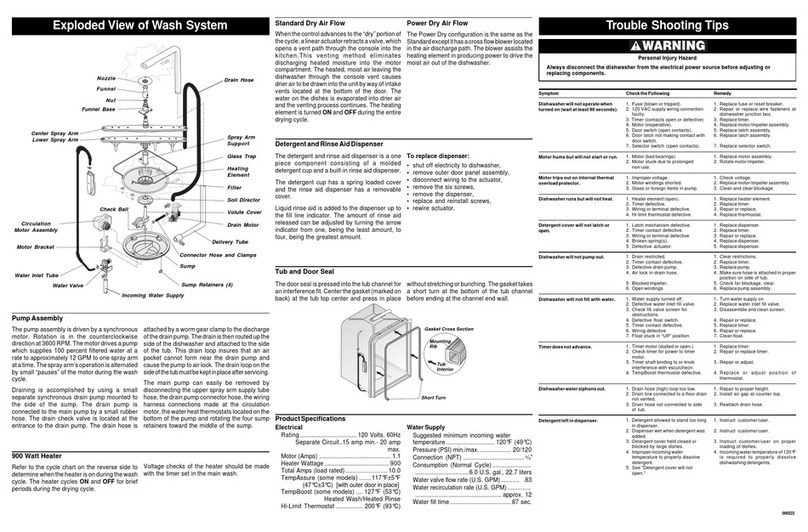

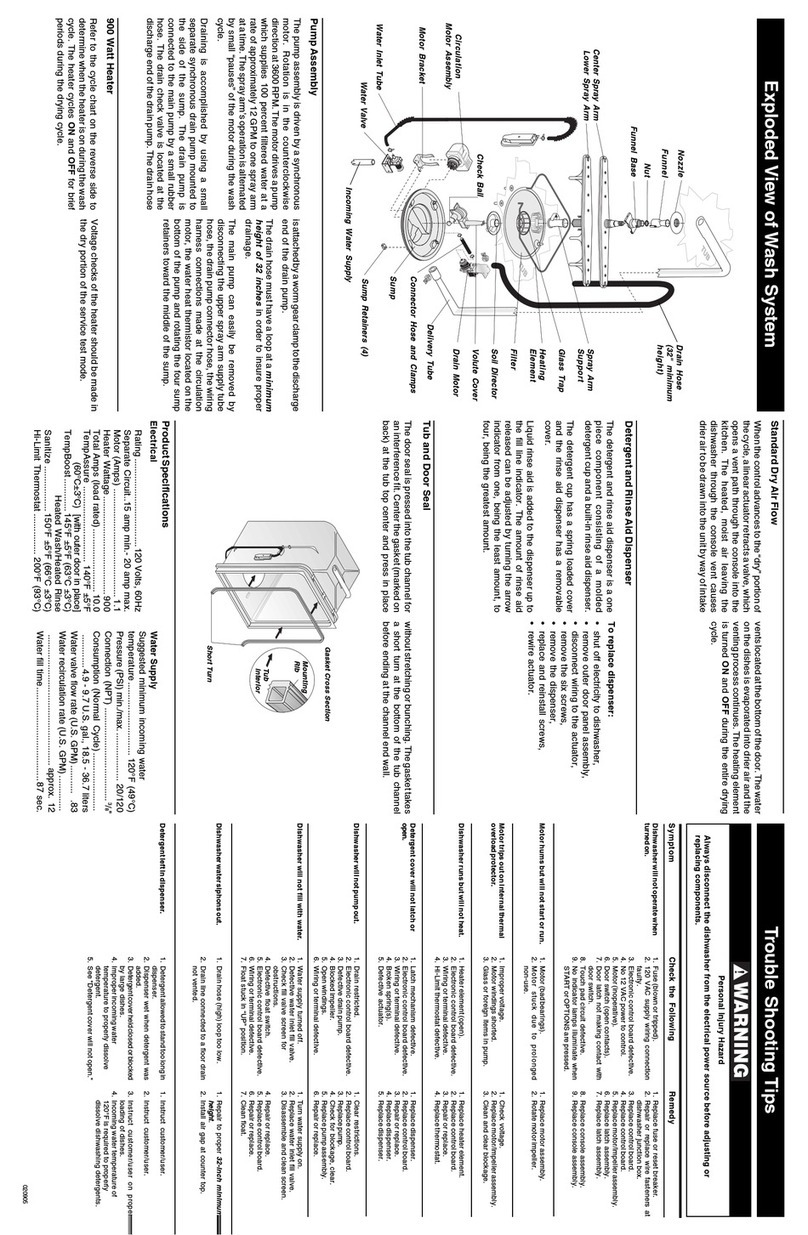

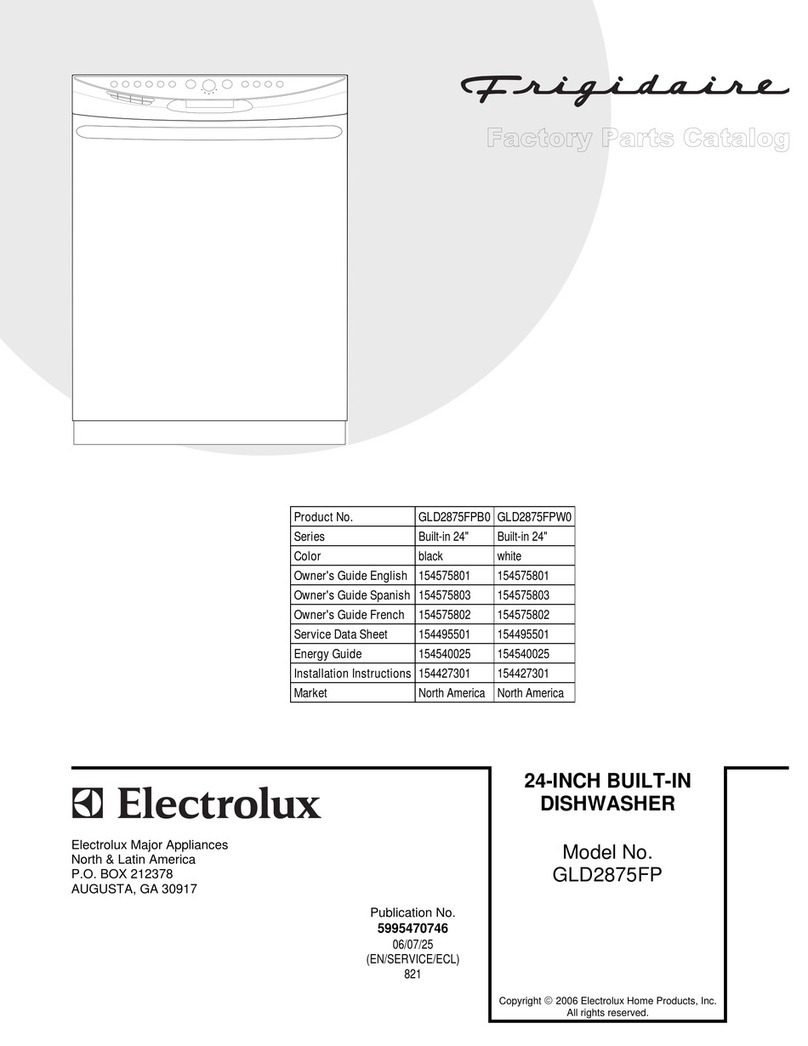

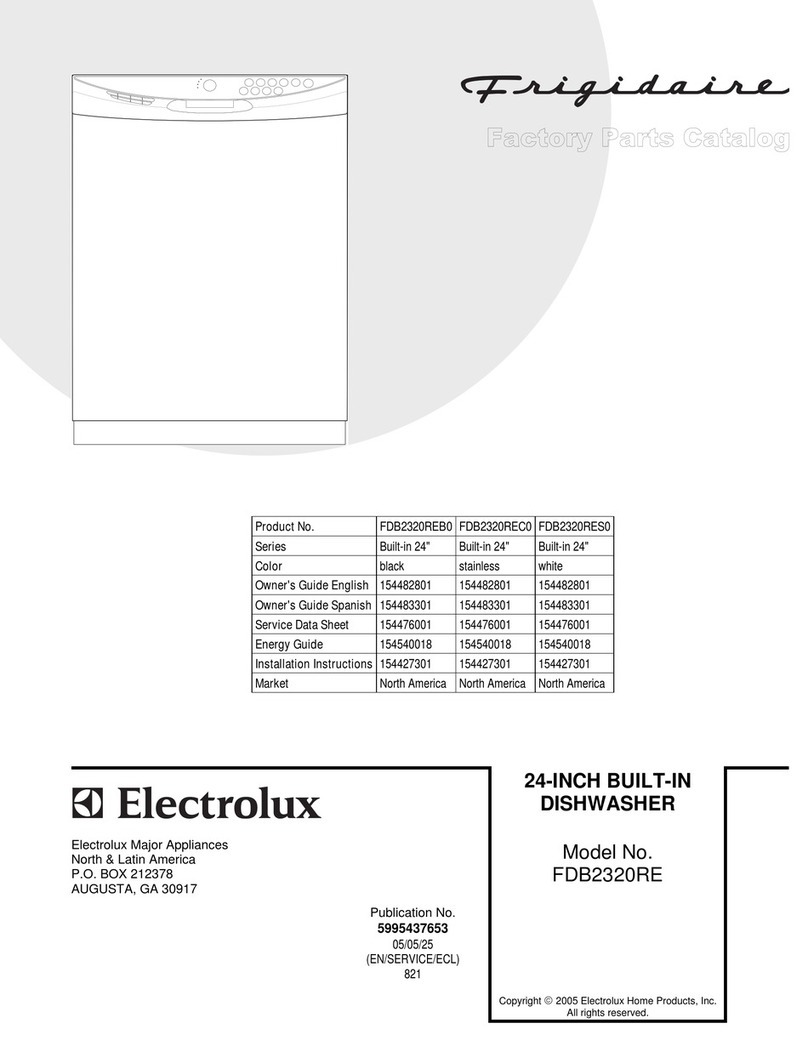

TroubleShootingTipsExplodedViewofWashSystem

Tub and Door Seal

Thedoorsealispressedintothetubchannelfor

aninterferencefit.Centerthegasket(markedon

back)at thetubtop centerandpress inplace

ProductSpecifications

Electrical

Rating .......................... 120Volts,60Hz

SeparateCircuit..15ampmin.-20ampmax.

Motor(HP) ..................................... 1

/12

Motor(Amps) ................................. 3.4

HeaterWattage .............................. 900

TotalAmps(loadrated) ................... 11.0

TempAssure(somemodels) ..... 117°F±5°F

(47°C±3°C) [with outerdoor inplace]

TempBoost(somemodels) .... 127°F(53°C)

HeatedWash/HeatedRinse

Hi-LimitThermostat ............. 200°F(93°C)

WaterSupply

Suggestedminimumincomingwater

temperature ....................... 120°F(49°C)

Pressure(PSI)min./max. ............... 20/120

Connection(NPT) ............................ 3/8"

Consumption(NormalCycle) ..................

....... 6.0U.S. gal.,5.0Imp.gal.,22.7liters

Watervalveflowrate(U.S.GPM) ........ .83

Waterrecirculationrate(U.S.GPM) ..........

........................................ approx.12

Waterfilltime ............................ 87sec.

Detergent and Rinse Aid Dispenser

Thedetergentand rinse aiddispenserisaone

piece component consisting of a molded

detergentcupandabuilt-inrinseaiddispenser.

Thedetergentcuphasaspringloadedcoverand

therinseaiddispenser has aremovablecover.

Liquidrinseaid is addedtothedispenserup to

thefill lineindicator. Theamount of rinseaid

releasedcanbeadjusted byturningthearrow

indicatorfromone, beingtheleastamount,to

four,beingthegreatestamount.

To replace dispenser:

shutoffelectricitytodishwasher,

removeouterdoorpanelassembly,

disconnectwiringtotheactuator,

removethesixscrews,

removethedispenser,

replaceandreinstallscrews,

rewireactuator.

To replace actuator:

shutoffelectricitytodishwasher,

disconnectwiringtotheactuator,

placeaflatheadscrewdriverunderthe

actuatorbodyandbetweenthedispenser

housingandterminalside,twistandliftup

ontheactuatorbeingcarefulnottodamage

theretainersnap-fits,

replacewithnewactuatorbypressinginto

place,

rewireactuator.

StandardDry Air Flow

Whenthecontroladvancestothedryportionof

thecycle,alinearactuatorretractsavalve,which

opensaventpaththroughtheconsoleinto the

kitchen.This venting method eliminates

dischargingheated moistureinto the motor

compartment.Theheated,moistairleavingthe

dishwasherthroughthe console ventcauses

drierairtobedrawnintotheunitbywayofintake

ventslocated atthe bottomofthe door.The

wateronthe dishes isevaporatedintodrierair

andtheventingprocesscontinues.Theheating

elementisturnedON andOFF duringtheentire

dryingcycle.

PowerDry AirFlow

ThePowerDryconfigurationisthesameasthe

Standardexceptithasacrossflowblowerlocated

intheairdischargepath.Theblowerassiststhe

heatingelementinproducingpowertodrivethe

moistairoutofthedishwasher.

Check the Following

1. Fuse(blownortripped).

2. 120VACsupplywiring connection

faulty.

3.Timer(contactsopenordefective)

4. Motor(inoperative,check

resistances).

5. Doorswitch(opencontacts).

6. Doorlatchnotmaking contactwith

doorswitch.

7. Selectorswitch(opencontacts).

1. Motor(badbearingsorlocked

rotor).

2. Motorstuckdueto prolonged

non-use.

1. Impropervoltage.

2. Sealfacesbinding.

3. Motorshaftbinding.

4. Motorwindingsshorted.

5. Glassorforeignitemsinpump.

1. Heaterelement(open).

2. Timerdefective.

3. Wiringorterminaldefective.

4. Hi-limitthermostatdefective.

1. Latchmechanismdefective.

2. Timercontactdefective.

3. Wiringorterminaldefective.

4. Brokenspring(s).

5. Defectiveactuator.

1. Drainrestricted.

2. Timercontactdefective.

3. Defectivedrainpump.

4. Airlockindrainhose.

5. Blockedimpeller.

6. Openwindings.

1. Watersupplyturnedoff.

2. Defectivewaterinletfillvalve.

3. Checkfillvalvescreenfor

obstructions.

4. Defectivefloatswitch.

5. Timercontactdefective.

6. Wiringdefective.

7. FloatstuckinUPposition.

1. Timermotor(stalledoropen.)

2. Checktimerforpowerto timer

motor.

3. Timershaftbindingtoorknob

interferencewithescutcheon.

4. TempBoostthermostatdefective.

1. Drainhose(high)looptoolow.

2. Drainlineconnectedtoafloor

drainnotvented.

3. Drainhosenotconnectedtoside

oftub.

1. Detergentallowedtostand too

longindispenser.

2. Dispenserwetwhendetergentwas

added.

3. Detergentcoverheldclosedor

blockedbylargedishes.

4. Improperincomingwater

temperaturetoproperlydissolve

detergent.

5. See"Detergentcoverwillnot

open."

Always disconnect the dishwasher from the electrical power source before adjusting or

replacingcomponents.

PersonalInjuryHazard

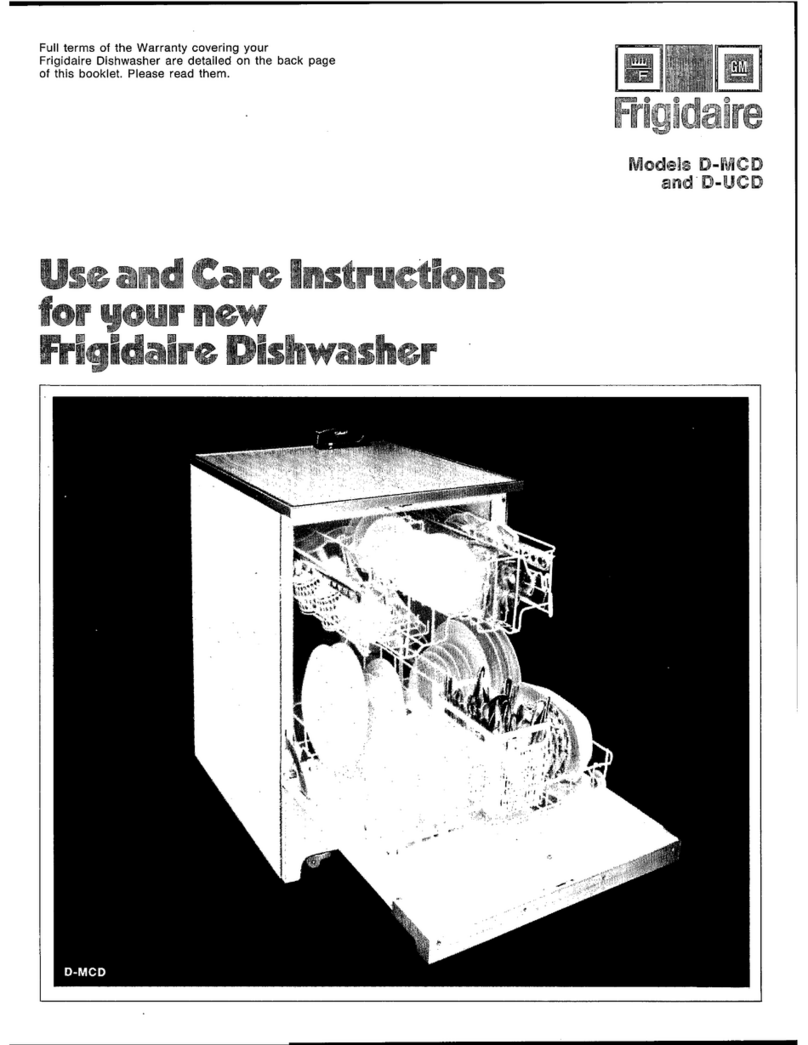

Nozzle

Funnel

Nut

FunnelBase

CenterSprayArm

LowerSprayArm

DeliveryTube

ConnectorHose

Sump

ImpellerScrew

WaterValve

WaterInletTube

Impeller

Seal

Check Ball

CirculationMotor

MotorBracket

900WattHeater

Referto thecyclechart onthe reversesideto

determinewhentheheaterisonduringthewash

cycle.The heatercyclesON and OFF forbrief

periodsduringthedryingcycle.

Voltagechecks of theheatershould bemade

withthetimersetinthemainwash.

airlock.Thedrainlooponthesideofthetubmust

bekeptin place afterservicing.

The main pump can easily be removed by

disconnectingtheuppersprayarmsupplytube,

thedrainpumpconnectorhose,andthewiring

harnessconnections madeatthe circulation

motorandthewaterheatthermostatslocatedon

thebottomofthepump.

Oncethepumpassemblyisremovedfromthe

dishwasher,themotor/impellerassemblycanbe

removedfromthesumpbytakingoutthethree

(3)T-20Torxheadscrewsfrom the aluminum

motorbracketandthenthe three(3)T-20Torx

headscrewsfromthevolutecover.Usingalarge

flathead screwdriverinserted betweenthe

impellerscrewandthesumpsvolute,themotor/

impellerassemblycanbegentlypriedoutofthe

sump.Usethescrewdriverasa lever.

PumpAssembly

The pump assembly is driven by a 1/12 HP,

shaded pole motor. Rotation is in the

counterclockwisedirectionat3100to3200RPM.

Themotordrives apumpwhichsupplies100

percentfilteredwaterataratetoapproximately

12GPMto one sprayarmata time. Thespray

armsoperationisalternatedbysmallpauses

ofthemotorduringthewashcycle.

Draining is accomplished by using a small

separatesynchronousdrainpumpmountedto

thesideofthesump.Thedrainpumpisconnected

tothemain pump byasmallrubberhose. The

draincheckvalveislocatedattheentrancetothe

drainpump. Thedrain hoseisattached bya

wormgearclamptothe discharge ofthedrain

pump.Thedrainisthenroutedupthesideofthe

dishwasherandattachedtothesideofthetub.

Thisdrainloopinsuresthatanairpocketcannot

formnearthedrainpumpandcausethepumpto

Symptom

Dishwasher will not operate when

turned on (wait at least 90

seconds).

Motor hums but will not start or

run.

Motor trips out on internal thermal

overload protector.

Dishwasher runs but will not heat.

Detergent cover will not latch or

open.

Dishwasher will not pump out.

Dishwasher will not fill with water.

Timer does not advance.

Dishwasher water siphons out.

Detergent left in dispenser.

withoutstretchingorbunching.Thegaskettakes

ashort turnat the bottomof thetub channel

beforeendingatthechannelendwall.

Tub

Interior

Mounting

Rib

Gasket Cross Section

Short Turn

IncomingWaterSupply

DrainHose

SprayArm

Support

GlassTrap

Heating

Element

Filter

Soil Director

VoluteCover

DrainMotor

961120

Macerator

Barrel Front

Barrel Rear